Metal sheets are the most popular rolled metal products. Construction, repairs and other areas of human activity cannot do without flat rolled steel, which is used in different ways. Products made from metal sheets surround us everywhere in everyday life: car body, roofing, building facades, ventilation systems, art products, steel pipes - all this is made from sheet steel. Therefore, you can buy sheet steel as a blank for the further manufacture of all kinds of goods or as a finished building material.

Metal sheets are selected for specific tasks based on their thickness, type of steel used and other features. They are flat, rectangular-shaped products that, due to their flexibility and ductility, can be processed into specific shapes. In many cases, special treatments are added to the composition or carried out in order to preserve and protect the metal product from external atmospheric and climatic influences, increase its resistance to impacts or improve surface properties.

Sheet steel is classified according to sheet thickness as thin sheet (from 0.35 to 3.9 mm) and thick sheet (from 4 to 160 mm).

Sheet steel by rolling type

Based on the type of rolling, products are classified into cold-rolled and hot-rolled. They can then be subjected to treatments such as heat treatment and skin tempering to increase their yield strength or zinc coating to protect against corrosion.

Cold rolled steel

The manufacturing process involves placing a metal alloy between rollers located at the top and bottom. They deform the metal into a thinner piece or sheet than its original size.

The blank for cold-rolled products is hot-rolled. Its properties are improved: the metal is washed with acid at the manufacturing plant before the final rolling is completed. The final stage of obtaining the material consists of heat treatment, known as annealing. Cold rolled steel is harder and stronger than hot rolled steel and looks more presentable. Cold rolled steel sheets and coils are commonly used where dimensional tolerances, strength and surface finish are critical.

Areas of application of cold-rolled sheet metal products: ♦ Metal furniture. ♦ Automotive components. ♦ Electronic equipment. ♦ Household appliances and components. ♦ Lighting lamps. ♦ Construction of buildings.

Hot rolled steel

Products of this type are subjected to rolling processes at temperatures above 750 degrees Celsius. Due to their unsightly appearance, they are usually used where finishing is not critical to the project. This is one of the types of steel most often used for the manufacture of parts of mechanically welded structures, for bending or profiling, assembly by welding, and even for artistic sculptures. The color variations on the steel sheets give character to the entire sculpture.

Hot rolled sheets - classification

Sheet steel or steel sheet is a rolled metal product that is used both as a finished product of metallurgy and as a raw material for the production of other types of rolled products, such as strips or strips. The sheet comes in different types and is produced by both hot and cold rolling.

Metal sheets made by hot rolling, otherwise called rolled sheets, are the most common and popular type of rolled metal in industry.

Selling rolled metal in the form of such sheets is popular because it is the most economical type of metal product. It is used in construction for the manufacture of metal structures, and in mechanical engineering, and in the manufacture of household appliances.

Special technologies for manufacturing metal sheets make it possible to produce high-quality products that are strong and durable during use.

According to standardized characteristics, five groups of sheets are distinguished, and according to the quality of surface finishing - four groups. The first group includes galvanized sheets of especially high finishing, the second group includes sheets of high finishing, the third group includes sheets of high finishing, and the fourth group includes sheets of ordinary finishing.

According to their drawing ability, the sheets are divided into sheets with deep and normal drawing ability. There are also GOSTs 19903-90 and 19904-90, which define parameters for hot-rolled and cold-rolled sheets.

According to these standards, in terms of assortment, sheets with a width of 500 millimeters or more are manufactured with a thickness of 0.5 to 160 millimeters (in sheets) and from 1.2 to 12 millimeters (in rolls).

You can view the wholesale price list of rolled metal sheets and find out the price of various types of steel sheets on the page - hot-rolled sheets.

view the retail prices of rolled metal sheets on the page - retail price list of hot-rolled steel sheets.

Classification of rolled sheets

Rolled sheets are divided by thickness:

- Thin sheet - up to 4mm;

- Thick sheet - 4-160 mm.

According to rolling accuracy:

- Increased accuracy - A;

- Normal accuracy - B.

By the nature of the edge:

- With unedged edge - BUT;

- With cut edge - O.

By flatness:

- Particularly high flatness - PO;

- High flatness - PV;

- Improved flatness - PU;

- Normal flatness - PN.

According to the assortment, rolled steel is divided into sheets and coils; according to the steel base material, the sheets are divided into thin-sheet cold-rolled and thin-sheet cold-rolled hot-dip galvanized.

Depending on the type of coating, the sheets can be:

- Cold rolled with paint and varnish coating in strips (LPC);

- Galvanized with cold-rolled hot-dip galvanized with paint and varnish coating (LKPOTS);

- Cold rolled with organosol coating (OSP);

- Cold-rolled hot-dip galvanized with organosol coating (OZPOTS);

- Cold rolled with plastisol coating (PZP);

- Cold-rolled hot-dip galvanized with plastisol coating (PZPOTs).

Thin sheets of rolled metal with an organic coating are used for the manufacture of building structures, instrument casings, and the manufacture of thermal insulation of equipment outdoors and indoors. The sheet coating can be paint, plastisol or organosol.

The coating of the sheet, including galvanized steel, can be either one-sided or double-sided.

According to their drawing ability, steel sheets are divided into:

- Complex drawing steel;

- Very deep drawn steel;

- Deep drawn steel;

- Normally drawn steel.

Classification of hot-rolled sheets GOST 19903-74

The range of hot-rolled metal in the form of sheets is regulated by GOST 19903-74. This standard applies to hot-rolled sheets with a width of 500 mm or more. Rolled metal is produced in sheets with a thickness of 0.5 to 160 mm and in rolls with a thickness of 1.2 to 12 mm.

Material of manufacture: high-quality carbon and alloy steel. The process of producing rolled metal sheets consists of several stages.

At the preparatory stage, the source material is cleaned, various surface defects are removed from it in order to obtain high-quality rolled sheets at the output.

Before rolling, the metal is heated in a special way and the temperature of this heating is controlled throughout the entire process. However, the features of the production of rolled metal sheets may vary depending on their types.

Weight per square meter of steel sheet according to GOST 19903-74 and 19904-90

Thickness S, mm Weight of 1 m² sheet, kg Thickness S, mm Weight of 1 m² sheet, kg Thickness S, mm Weight of 1 m² sheet, kg

| 0,5 | 3,925 | 6 | 47,1 | 60 | 471 |

| 0,6 | 4,71 | 7 | 54,95 | 65 | 510,25 |

| 0,7 | 5,495 | 8 | 62,8 | 70 | 549,5 |

| 0,8 | 6,28 | 9 | 70,65 | 75 | 588,75 |

| 0,9 | 7,065 | 10 | 78,5 | 80 | 628 |

| 1 | 7,85 | 12 | 94,2 | 90 | 706,5 |

| 1,2 | 9,42 | 14 | 109,9 | 100 | 785 |

| 1,4 | 10,99 | 16 | 125,6 | 110 | 863,5 |

| 1,5 | 11,775 | 18 | 141,3 | 120 | 942 |

| 1,7 | 13,345 | 20 | 157 | 130 | 1020,5 |

| 1,8 | 14,13 | 22 | 172,7 | 140 | 1099 |

| 1,9 | 14,915 | 25 | 196,25 | 150 | 1177,5 |

| 2 | 15,7 | 30 | 235,5 | 160 | 1256 |

| 2,5 | 19,625 | 35 | 274,75 | 170 | 1334,5 |

| 3 | 23,55 | 40 | 314 | 180 | 1413 |

| 3,5 | 27,475 | 45 | 353,25 | 190 | 1491,5 |

| 4 | 31,4 | 50 | 392,5 | 200 | 1570 |

| 5 | 39,25 | 55 | 431,75 |

In some cases, hot rolled metal sheets are cold rolled. Thanks to this, they become smoother and acquire better mechanical properties. Hot-rolled metal products are usually produced in the form of individual sheets or whole rolls.

Rolled thin sheet carbon steel GOST 16523-97

Technical conditions for rolled thin sheets made of carbon steel are regulated by GOST 16523-97. This standard applies to thin-sheet hot-rolled and cold-rolled carbon steel of high-quality and ordinary quality for general purposes, manufactured with a width of 500 mm or more, and a thickness of up to 3.9 mm inclusive.

According to the production method, rolled sheets are divided into:

- Hot rolled,

- Cold rolled.

By product type:

Depending on the minimum value of tensile strength, rolled products are divided into strength groups:

- Made from carbon steel of ordinary quality of strength groups - OK;

- Made from high-quality carbon steel of strength groups - K.

Hot-rolled steel is divided into groups according to the quality of surface finishing:

- Advanced finishing - III;

- Regular finish - IV.

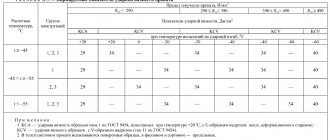

Rolled thin sheets of high strength steel GOST 17066-80

Technical conditions for high-strength thin-sheet rolled products are regulated by GOST 17066-80. This standard applies to hot-rolled and cold-rolled sheets of structural low-alloy steel with a thickness of 0.5 to 3.9 mm, a width of at least 500 mm, manufactured in coils and sheets.

Sheet steel by processing method

Galvanized sheets

Galvanized steel has a zinc coating, so it is a more durable material that is resistant to atmospheric and aggressive influences. It is widely used in construction and component manufacturing due to its characteristics of durability and stability over a long service life.

Galvanized sheets are used: ♦ In construction. ♦ Mechanical engineering, automotive industry. ♦ In the manufacture of pipes. ♦ For the production of roofing materials. ♦ In the chemical and food industries. ♦ For external decoration of balconies, walls, fences.

Hot rolled sheet - characteristics according to GOST

Hot rolling is the process of deforming a workpiece at forging temperature. The main volume of rolled steel is obtained in this way. Hot-rolled sheets can serve as rolled sheets in the production of cold-rolled sheets or be used for the manufacture of structures and products for various purposes. The thickness of hot-rolled sheets can be 0.4-160 mm.

Assortment of hot-rolled sheets according to GOST standards

These metal products are manufactured in accordance with various regulatory documents.

- Hot-rolled thick plates made of carbon steel of ordinary quality, the thickness of which is 4-160 mm, are produced in accordance with the technical conditions set out in GOST 14637-89.

- Thin hot-rolled steel (up to 3.9 mm) is produced in accordance with GOST 16523-97.

- Thick-sheet hot-rolled products with a thickness of 4-160 mm from carbon, low-alloy and alloy steels, used in the production of vessels, boilers and furnaces, are manufactured in accordance with GOST 5520-79.

- Sheets of normal and high strength, 4-60 mm thick, made of carbon steels and grades with a high manganese content, manufactured in accordance with GOST 5521-93. The products are used in shipbuilding.

- Thick-rolled steel for the manufacture of bridges of conventional and northern design from low-alloy grades is regulated by GOST 6713-91. Alloy steel products used in the construction of bridge structures must comply with GOST R 55374-2012.

Dimensions of hot-rolled sheets in accordance with GOST 19903-2015

GOST 19903-2015 regulates the range of hot-rolled sheets with a thickness of 0.4-160 mm. Metal products are produced in sheets or rolls (thickness 1.2-12.0 mm). For production, unalloyed steel of ordinary quality and low alloy is used.

Rolled sheets are produced with cut and uncut edges, in terms of rolling accuracy - increased and normal (for rolled products up to 12 mm thick), in terms of flatness - normal, improved, high, especially high. A roll may contain no more than two pieces, individually or connected by welding. The lengths of the pieces must have a ratio of at least 1:5.

The number of pieces or the ratio of their lengths may be different, but only by agreement with the customer.

Sheet sizes:

- width – 500-3800 mm;

- length – 710-12000 mm.

Methods for calculating the mass of rolled sheets

The most convenient option for determining the mass of a hot-rolled sheet is to use an online calculator, which takes into account its dimensions and the exact value of the density of a particular steel grade.

The mass of a unit of sheet metal can be calculated using a simple formula.

M = H*B*L*7.85 , where:

- M – mass, kg;

- H – thickness, mm,

- B – width, m,

- L – length, m,

- 7.85 kg/dm3 is the average density of steel, corresponding to the weight of a sheet with a thickness of 1 mm and an area of 1 m2.

The weight of hot-rolled sheet can also be found using a table that indicates the weight of 1 m2 of products of a certain thickness. The values indicated in the table are for reference.

| Thickness, mm | Weight, kg | Thickness, mm | Weight, kg | Thickness, mm | Weight, kg | Thickness, mm | Weight, kg | Thickness, mm | Weight, kg |

| 0,4 | 3,14 | 4,0 | 31,4 | 10,0 | 78,5 | 36,0 | 282,6 | 70,0 | 549,5 |

| 0,6 | 4,7 | 4,5 | 35,33 | 12,0 | 94,2 | 40,0 | 314,0 | 80,0 | 628,0 |

| 0,8 | 6,28 | 5,0 | 39,25 | 16,0 | 125,6 | 42,0 | 329,7 | 90,0 | 706,5 |

| 1,0 | 7,85 | 5,5 | 43,18 | 20,0 | 157,0 | 48,0 | 376,8 | 100,0 | 785,0 |

| 1,2 | 9,42 | 6,0 | 47,1 | 24,0 | 188,4 | 50,0 | 392,5 | 110,0 | 863,5 |

| 1,5 | 11,78 | 6,5 | 51,03 | 26,0 | 204,1 | 52,0 | 408,2 | 120,0 | 942,0 |

| 2,0 | 15,7 | 7,0 | 54,95 | 28,0 | 219,8 | 54,0 | 423,9 | 140,0 | 1099,0 |

| 2,5 | 19,63 | 7,5 | 56,24 | 30,0 | 235,5 | 56,0 | 439,6 | 150,0 | 1177,5 |

| 3,0 | 23,55 | 8,0 | 62,8 | 32,0 | 251,2 | 60,0 | 471,0 | 160,0 | 1256,0 |

Where else is sheet steel used?

Sheet metal has many different uses in interior and exterior design. It is capable of soundproofing and optimizing air, so it is excellent for ceilings and also for dividing spaces. In addition, elements such as tables, shelves, partitions, railings, drawers, containers, etc. are made from sheet steel. The small thickness of the product makes it possible to bend it, creating a variety of bent or profile products.

Thick sheets are used to create metal frames, in the construction of welded structures, and in the manufacture of various parts.