Many people ask the question: how to bend a sheet of metal evenly? And it is not surprising, because when carrying out construction work it may be necessary to perform a similar procedure.

Small diameter pipes are bent using a vice. Very often during construction processes there is a need to bend pipes of quite large diameter. For such work, special machines are needed that bend metal sheets and pipes. The bendable component is not deformed.

How to bend a sheet of metal evenly? Stages:

Tip: when bending parts, its thickness, ductility are taken into account and the radius of curvature is determined.

Metal bending technology

Bending sheet metal involves performing certain actions that cause the material to take the desired shape. The process of bending metal is performed without the help of welding or other connections that reduce the durability and strength of the material.

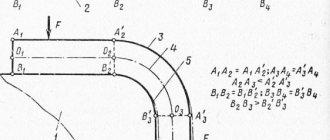

When folded, the outer layers of the product are stretched, and the inner layers are compressed. The technology is to bend one part relative to the other at the required angle.

During bending, the metal sheet undergoes deformation. Its value depends on the thickness of the product, ductility, bending angle and bending speed. The process itself is performed on equipment, due to which no damage is caused. If a part is bent incorrectly, various defects may occur on its surface, as a result of which the metal receives various damage along the bending line, which can lead to its breakage.

The bending stress must be greater than its stiffness limit. Plastic deformation may occur as a result of bending. Moreover, after the bending operation, the finished structure will retain the shape that was given to it.

Advantages of the process of smooth bending of metal sheets:

- High process productivity.

- As a result of bending, you can obtain a workpiece without a seam.

- The finished structure is highly resistant to corrosion.

- No rust will form at the bend.

- The design is solid.

- High strength.

- Special equipment is quite expensive.

- Manual bending is quite labor-intensive.

Unlike structures made by bending metal, welded structures have a weld that is susceptible to rust and corrosion.

Product bending is done manually or using special devices. Manual bending is a complex and time-consuming procedure that is performed using pliers and a hammer. If you need to evenly bend a sheet of metal of small thickness, use a mallet.

Bending of sheet metal is carried out using rollers, roller machines or a press. To shape the material into a cylinder, hydraulic, manual or electrically conductive rollers are used. Pipes are produced using a similar method.

Sheet metal bending is used for home construction purposes to produce gutters, metal frames, profiles, pipes and other structures. When bending the material with your own hands, you can make pipes of different diameters. Using machines, zinc-coated products are bent. To do this, you should make a machine, preferably using a template.

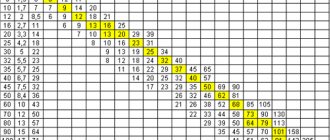

When bending any product, its parameters should be determined. The length of the structure is calculated taking into account the radius. For workpieces that are bent at right angles, without the formation of roundings, the allowance should be 0.6 mm of the total thickness of the sheet.

You can bend the following metals with your own hands:

The bending radius will depend on the quality of the metal and the bending option.

How to bend a sheet of metal evenly with your own hands?

To make brackets using the bending method, the following tools and materials are used:

- vice;

- a metal sheet;

- frame;

- hammer;

- power saw for metal;

- bar.

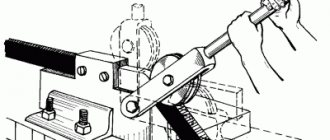

In advance, according to the scheme, the length of the workpiece strip is calculated and the bending of the metal sheet is calculated. For each bend, a reserve of 0.5 mm of thickness is made and 1 mm for bending the ends to the side. According to a pre-drawn diagram, the workpiece is cut out and the bending point is marked. In order to bend the material, use a vice with squares.

First, at the bending level, you need to clamp the workpiece in a vice. Then the first bend is made using a hammer. The workpiece is rearranged in a vice and clamped by the frame together with the block, after which a second bend is performed.

How to bend a sheet of metal evenly: making a machine with your own hands

In order to create a device that allows you to bend a metal sheet at home, you need to prepare the following materials and tools:

- corner 80 mm;

- bolts;

- metal beam I-beam 80 mm;

- loops;

- welding machine;

- clamps;

- handles;

- table.

All work begins with preparing the base of a homemade machine from a profile - an 80 mm I-beam. After this, an 80 mm corner is screwed onto the top of the I-beam with two bolts. During bending, it will secure the workpiece. Three hinges from steel doors are welded under the corner, the other halves of which are welded to the corner itself.

To perform bending, two 800 mm handles are welded to the corner, with which you can turn the machine. The sheet bender is pressed to the table using two clamps. The clamping angle is unscrewed. Then the workpiece is laid, and the corner is moved into place.

Read also: How to remove a rivet on jeans

If necessary, it can be raised without removing it. After this, the material is threaded between the I-beam and the angle. The metal sheet is carefully aligned. The bolts are tightened and by turning the workpiece is bent to the required angle.

A homemade machine is not a universal device, since it is used for bending sheets of small thickness. If there is a need to bend material with a large thickness, you should use machines made in production.

Low tides are responsible for collecting water from slopes and transporting it to drainage points, therefore they are the most important component of any drainage system. Due to the large length of drainage gutters, their purchase is a significant part of the cost of constructing the entire drainage system. The final price will be quite high, even if you choose inexpensive tin products. That is why every self-respecting home craftsman should be able to make ebbs from galvanized steel with his own hands. A well-tested technology will not only save your budget, but will also allow you to emerge victorious in a situation where roof installation requires gutters of non-standard sizes.

Bending and bending of sheet metal using various methods and devices

Bending sheet metal allows you to obtain a product of the desired shape with relatively little effort. Because welding requires more effort, both physical and financial. A sheet of metal can be bent manually or using automation, but the general principles of operation remain the same. It is the features of this process that will be discussed.

Metal bending is carried out using various methods. Welding is often used, but temperature exposure can change the shape and properties of the finished product. This reduces performance properties and manufacturing accuracy.

Since when bending metal, the outer layers of the metal stretch, and the inner ones begin to compress, it is necessary to bend part of the rolled metal relative to another by a given angle. The angle can be found using calculations.

The product is deformed to those values that are within the specified limits. They depend on the following parameters:

- Thickness of the metal sheet;

- How much is the bending angle?

- How durable is the material;

- Speed and time of the procedure.

The permissible deformation indicator will depend on them. The next step is to select the type of bending.

Types of bending of metal products

Metal bending is done manually and using automatic devices. In the first case, the process will be quite labor-intensive, requiring the use of pliers and a hammer, as a result of which this procedure will take a lot of time.

It will be much easier and better to mechanize the process with the help of machines and corresponding devices. The cylinder shape is given to the product by special rollers. With their help, chimneys, gutters, and pipe products are created.

The development of machine tool production has made it possible to achieve bending of material for the manufacture of the most complex products. And the quick replacement of the working tool allows you to reconfigure the machine device as efficiently and quickly as possible.

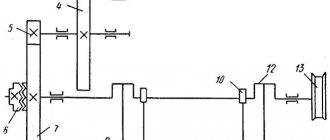

For the modern metal bending process, there are many options for the latest devices. In production, presses are usually used , which can be divided into the following types:

- Rotary, bending metal by moving between special rollers. Suitable for the production of large-sized products in small batches.

- Rotary presses bend the plates using bending beams and two plates. The stationary plate is located at the bottom, and at the top there is a rotating plate. The optimal option for processing sheet metal products with a simple relief and small dimensions.

- Standard pneumatic or hydraulic presses are used for mass or small-scale products made of stainless steel or other metal. Bending is done between the punch and the die. Due to this, even thicker products can be processed. It should be noted that hydraulic presses are used more often than pneumatic ones due to their simpler operation and cost.

Of all the types of equipment described above, the most modern is rotary. It operates automatically, and the worker does not need to calculate the optimal force value in advance.

Rotary presses are also considered automated. Here one sheet is sent to the device, which must be positioned as required by the task. Most often used in small enterprises where they work with metal parts.

Handmade

This work is usually done with hand scissors . Marks are placed in the right places along which manual bending of the metal will be carried out. The sheet is securely fixed in a vice. The first fold is made with a massive hammer. The product is moved to a new bend location, clamped with a block of wood, and bent in the desired direction.

Upon completion of the work, you must ensure that the product meets the established standards. The check is carried out using a square and, if necessary, defects are eliminated.

Sometimes you need to make a machine at home . This will make bending metal easier and increase productivity. Here you will need a corner, a metal beam, hinges with bolts, clamps, handles, a table and a welding machine. The procedure is as follows:

- The base is made of metal; an I-beam profile is suitable.

- The corner is attached to the top of the beam using bolts.

- Three hinges are welded under the corner using a welding machine.

- We bend the aluminum sheet by turning the corner.

- Two clamps ensure tight pressing of the metal.

- The corner does not have to be removed; you can raise it. Place the product between the profile and the corner. Then a metal sheet is aligned along the edge.

Check the bolts to ensure they are secure. Turn the crossbars and bend them so as to form the desired angle. This will avoid wasting time on angle calculations.

Whatever the devices, the main principles remain the same . By following them, you can obtain products that meet the standards and wishes of the customer.

Manufacturing technology of galvanized steel ebbs

Companies that manufacture galvanized steel castings use special bending equipment. Radial bending of the workpiece is obtained due to the reorientation of internal stresses in the steel during rolling of a sheet of metal between the rollers of the machine. Of course, it is irrational to buy or make such a device for a one-time job. Therefore, at home, hand tools are used to process workpieces.

For small-scale production of gutters, special sheet bending machines are used

Required tools and materials

Before you start making roof ebbs with your own hands, you should prepare everything you need. The first thing you need for work is, of course, galvanized steel. The industry produces sheet metal of various thicknesses, so the selection criterion is the shape of the future gutters. For L-shaped or rectangular products, you can use galvanizing with a thickness of 0.5–0.7 mm - this will allow you to handle its processing without much effort. Classic semicircular castings made of such material without stiffening ribs will be too flimsy, so for their manufacture it is better to take sheet metal with a thickness of 1 mm or more .

Galvanized sheet steel is the most suitable material for the manufacture of gutters

The next thing you should pay attention to is the quality of the protective coating. According to standards, the specific gravity of the zinc layer must be at least 270 g/m2. The retail network offers steel sheets with zinc coating from 60 to 270 g/m2. Be sure to clarify this point with the seller, since the difference in price will not be that big, but the durability of roofing iron may differ several times.

You can also use steel sheets with a polymer coating, but only good, high-quality material is suitable for this. Finding out its quality is not difficult at all - just bend the corner of the sheet at a right angle and look at the condition of the protective layer. If it has retained its original structure, then the coating will not crack during the molding of blanks, which means it will be perfect for the task at hand. If the polymer layer is damaged and peels off, then you should not buy such metal - water will flow into the cracks, and the steel will very quickly be destroyed by corrosion.

Tools you will need to make galvanized castings:

- rubber and wooden mallet;

- hammer;

- metal scissors;

- pliers;

- roulette;

- ruler;

- marker or simple pencil;

- a flat metal corner with a shelf width of at least 50 mm;

- a piece of steel pipe with a diameter of at least 100 mm as a template;

- wooden slats with a cross-section of at least 20x30 mm.

To make castings you will need the simplest tools

Since the brackets for attaching the gutters can also be made with your own hands, you will additionally need a structural steel bus 20–30 mm wide, at least 2.5 mm thick, and a steel strip 1 mm thick. Thin metal will be needed to make the clamps. You can attach them to the holders using rivets, or using a welding machine.

Step-by-step instructions for making ebb tides

- A strip 180–220 mm wide is cut from a sheet of galvanized steel.

Both hand and electric tools can be used to cut galvanized sheets.

Beading the edge of the gutter will make it more rigid

To clean the edge of a galvanized steel workpiece, you can use a plane made from a piece of broken hacksaw blade.

To form a flange without damaging the surface of the galvanized sheet, use a wooden mallet

To obtain a semicircular gutter, use a pipe of suitable diameter

If, after making a semicircular gutter, its edges move a little to the sides, it doesn’t matter - after installation in rigid holders, the configuration will be restored.

Semicircular ebbs for the roof water drainage system can be obtained in another way - by cutting galvanized drain pipes of suitable diameter in half.

Video: making a gutter

How to make ebb holders

Hooks for attaching gutters can be bent from a steel bar. A metal strip with a cross-section of 20x2.5 mm is suitable, since thinner metal may not cope with the snow and ice that accumulates in the drain in winter. If it was not possible to buy such a tire, then the holders can be cut from a steel sheet of suitable thickness. To do this, it should be marked by drawing the required number of strips 20–30 mm wide and 400 mm long.

The configuration and length of the hooks depends on the shape of the gutter and the method of its attachment (on the rafters, sheathing or front board).

To obtain many holders of the same type, it is necessary to build a special device. The bending of C-shaped brackets can be accelerated by welding a 50 mm ring from a Ø100 mm pipe and a vertical clamp from a Ø15 mm rod of the same length onto a metal sheet. The hook of the desired shape is obtained by clamping a steel bar in the fixture and wrapping it around the pipe. A device for making triangular or rectangular holders can be made from wooden blocks, pieces of metal corners or profile pipes.

Read also: Revolving press for brick production

When making holders with your own hands, be sure to take into account their shape and size of ebbs.

After the last strip is bent, 2-3 drillings are made on the connecting parts of the brackets for fastening to wooden roof structures. In addition, pieces of wire 3–4 mm thick or strips of steel up to 1 mm thick can be welded along the edges of the curved part of the hook. They will be needed to fix the ebb in the holder.

After the last hook is made, the products are painted. Paint will add completeness to the parts and protect the metal from rust.

Video: how to make a bracket for ebb tides with your own hands

DIY sheet metal bending technology

In the process of building a house or cottage, there is often a need to equip drains, sewers, and metal frames.

When manufacturing such products, it is necessary to give the flat workpiece the necessary spatial shape. Advice from experienced craftsmen on how to bend a sheet of metal at home will allow you to produce good quality structures that will last a long time.

Bending technology - basic information

Metal bending is performed without welding seams, which avoids corrosion in the future and produces a product of increased strength. Deformation does not require significant effort and is usually performed in a cold state.

The exception is hard materials such as duralumin or carbon steels. Sheet metal bending technology is developed according to the assigned tasks in such options as:

- radius,

- multi-angle,

- single-angle,

- U-shaped.

A special case is flexion with stretching. This technology is used in the manufacture of parts with large bending radii and small diameters. When making parts with your own hands, the process is combined with operations such as cutting or punching.

Soft types of metals and alloys, such as brass, copper, and aluminum, are well suited for home processing. The production of products by bending is carried out on rolling or rolling machines, or manually.

The last procedure is quite labor-intensive. Bending is done using pliers and a rubber hammer. If the sheet is thin, use a mallet.

How to bend at right angles

To bend a bracket from a metal sheet, you will need a set of tools and accessories, consisting of:

- vice,

- hammer,

- power saws,

- bar,

- frames

The length of the strip is made according to the scheme, with the calculation that there should be a margin of 0.5 mm for each bend, plus another millimeter for folds on both sides. The workpiece is placed in a vice with squares. Clamping it along the fold line, process it with a hammer.

After this, the future bracket is unfolded in a vice, clamped with a frame and a block, and the other side is formed. The workpiece is pulled out, the required length of the sides is measured, making bends along the bottom.

Use a triangle to check the correctness of the angle, correcting inaccuracies with a hammer. When performing both operations, the workpiece is pressed with a block and a frame. The finished staple is filed to the desired size.

:

How to make a sheet bending machine yourself

To give the metal the desired configuration, tinsmiths use a sheet bending machine. But what should a master do if he doesn’t have special equipment at hand?

In fact, the question of how to bend sheet metal at home is easily resolved. It is enough to use your own ingenuity and basic equipment to make a simple machine.

To make a bender for a metal profile, you will need:

- I-beam 80 mm,

- fasteners (bolts),

- loops,

- corner 80 mm,

- clamps,

- a pair of handles.

You will also need a welding machine and a stable table on which the finished machine is mounted.

The basis of the device is an I-beam, to which a corner is screwed with two bolts, holding the workpiece during the bending process. Three door hinges are attached under it by welding. Their second part is welded directly to the corner.

In order for the machine to easily turn while bending sheet metal, handles are attached to it on both sides. The finished machine is secured to the table with clamps. Before laying the workpiece, the corner is unscrewed or lifted. The sheet is pressed, aligned along the edge and folded, turning the machine by the handles. The homemade device is only suitable for processing workpieces of small thickness.

:

Bending a metal sheet with a hammer

In order to bend a sheet up to 1.2 mm thick at a right angle, use the simplest tools - pliers (clamps) and a rubber hammer.

The processing is carried out on a flat wooden block. The fold line is drawn using a pencil and ruler. Then the sheet is clamped with pliers so that their ends fall exactly on the marking line.

The edge is gradually bent upward, moving along the fold. Once the angle approaches 90 degrees, the sheet is placed on the block and finally leveled using a hammer.

Narrow parts, such as tin edges, are made in this way.

Tip: Use a rubber or wooden hammer to prevent dents from forming on the metal. If bending is performed with a conventional tool, you need to take a textolite plate as a gasket.

It is convenient to bend sheets up to 2 mm thick on a desktop. The metal is positioned so that the marking line falls on the edge. A steel corner is placed under the material being processed.

The sheet is clamped in a vice using two wooden blocks. Bending is done using a hammer, tapping the metal from one end to the other. At the same time, the edge of the sheet is directed downward so that it ultimately lies completely on the corner fixed along the edge of the table. This method can be used to make products of any width, including boxes or barbecues.

:

Making pipes without using a machine

Home craftsmen have invented a lot of ways to bend a metal sheet into a pipe without using a machine.

We propose to consider the simplest option using a blank of suitable size. It is made from an old pipe of suitable diameter.

A sheet of metal is laid out on the floor and a piece of the required length is cut from it. To determine the required size, the required pipe diameter is multiplied by 3.14 and added 30 mm for the seam.

A pair of tubes are welded to the blank on both sides, perpendicular to one another. The crowbar should be freely inserted into their holes.

Master's recommendation: by bending a metal sheet using a blank, it is convenient to make pipes no more than a meter in length.

To use the device, the effort of three people is required. The blank is placed on the edge of the sheet. One person stands on top, two others screw the metal onto the blank, turning the crowbar 90 degrees.

The entire length of the sheet is rolled in this way, the remaining edge is hammered. The seam is secured by welding.

:

It must be taken into account that the bend radius of sheet metal depends on its thickness and manufacturing method. Hot rolled steel is more suitable for pipes; profile products are made from cold rolled steel.

Installation of ebb tides

The fastening of galvanized ebbs is carried out in several stages, performing the work in a strict order. Only in this case can we hope that the drain will be installed at the desired angle, and individual brackets will not hang in the air. Next, we will provide instructions on which to act, but now we suggest that you familiarize yourself with the list of tools needed for the job:

- bending tool for hooks;

- mites;

- angle grinder or hacksaw;

- riveter;

- electric drill;

- screwdriver;

- hammer;

- rubber mallet;

- metal scissors;

- cord;

- roulette;

- pencil.

The main condition for high-quality operation of the drain is the straightness of the gutter and compliance with the calculated slope. It is best to use a laser level to mark the mounting locations for the mounting brackets. If you don’t have such a device at hand, then you can use a simple spirit level (hydraulic level).

Installation procedure for ebb tides

The galvanized drain is a fairly lightweight structure, so the ebbs can be attached both to the rafters and to the frontal (sometimes also called wind) board. In the first case, installation is carried out at the stage of roof construction, before laying the roofing material. For these purposes, elongated brackets are used, which are placed on the rafter legs and fixed with self-tapping screws. Fastening in this way can only be done if the pitch of the rafters does not exceed 0.6 m.

When installing flashings, it is necessary to take into account the type of fastening, slope and distance from the front board

If the distance between the rafters exceeds 0.6 m, then hooks for ebb tides can be installed on the bottom board of the sheathing.

As for installing brackets on the wind board, this method makes it possible to install a drain at the final stages of construction or as needed.

Do-it-yourself installation of galvanized ebb and flows is carried out in the following order:

- At the far edge of the ramp, select the attachment point for the first holder. It should be at such a height that the ebb is located as close as possible to the drip edge or the edge of the roof. The drip tide is installed in such a way that water flowing from the roof or dripline does not fall on the walls, but on the bottom of the gutter.

- Using self-tapping screws and a screwdriver, the bracket is attached to the board or rafter.

Flashing brackets can be attached to rafters or to a wind board

When installing the hook, not only horizontal alignment along the tensioned cord is used, but also vertical alignment

You can install the holders in one line using a cord stretched between the outer elements

If the brackets are installed at a distance of 1 m from each other, the three supports will completely accommodate a standard two-meter gutter

Since the homemade design does not provide any locking or sealing elements, the joint can be additionally protected with waterproof sealant.

The main enemy of galvanized flashings are branches from trees, which can damage the protective metal layer and accelerate corrosion. To protect the gutters, their upper part is covered with gratings or mesh. Today you can find perforated protection of any type - made of plastic, steel or brass. You can fix the mesh at the same time as installing the gutters by placing its edge under the grips of the brackets.

Video: installation of gutters

Types of bending based on the contour of the product

- V - shaped (single-angled). During the bending process, the upper part of the workpiece is bent, and the lower part, on the contrary, is stretched, creating the required radius.

- U-shaped. The essence of the impact is similar, but involves a larger number of stages. During the work, a punch is used to ensure the necessary bend.

- Multi-angle (faceted). It is necessary when creating complex contours and involves the use of both one and several elements.

- Radial. The essence and main advantage of this type of bending is the ability to produce complex contour workpieces without the use of welding. This aspect allows you to achieve not only maximum aesthetics, but also ensures the strength of the product due to the absence of seams.

Repair of galvanized steel gutters

A significant disadvantage of gutters made of galvanized steel is that if the protective layer is damaged, the corrosion process occurs as quickly as it does with ferrous metal. Since the thickness of such castings most often does not exceed 0.7 mm, through rust appears on damaged areas within a few years.

To prevent the process of metal destruction, you should periodically inspect the ebbs and make their repairs. Most often, prevention is carried out twice a year - in early spring and early autumn. Areas damaged by ice or branches should be cleaned, degreased and painted over with clear varnish for metal work. In areas of the drain that are hidden from view, any enamel for exterior use can be used for this purpose.

If it was not possible to prevent the destruction of the metal and areas with through corrosion appeared on the ebbs of galvanized steel, then they can be repaired. For this:

- The clamps of the holding brackets are bent and the defective drainage element is removed from the bracket.

- If the side wall of the gutter is rusty, then a galvanized steel patch is applied to the damaged area. To do this, cut a rectangle from a metal sheet that will overlap the undamaged metal with an overlap of 20–30 mm, and fasten it with rivets. To ensure that the appearance of the drain is not damaged, the drip tray is installed in place with the repaired side facing the wall.

- If the corrosion has touched the bottom of the gutter, the leaky area is cut out entirely. To repair the ebb, use a piece of galvanized steel of the same configuration. It should be 20 cm longer than the cut part, since when installing the patch, the part is overlapped. You should definitely pay attention to how the patch will be applied. On the side of the drainage funnel it is attached on top of the ebb, while on the other edge it should be located below - this will not allow water to flow into the gap. The repair part can be secured using aluminum rivets. It will be possible to avoid water seepage if the joints are treated with a moisture-resistant sealant.

Read also: Weight of gas cylinders empty and full

The process of making galvanized steel castings with your own hands is not difficult and is accessible even to a beginner. Since gutters will cost the same as sheet metal, the drainage system will cost much less than a finished one, even if the remaining elements (funnels, pipes, etc.) are purchased at a retail chain. But that is not all. Invaluable experience working with galvanized metal will be useful in other projects. For example, when making a functional chimney deflector, a stylish weather vane, or a beautiful canopy over the front door.

You can buy galvanized pipes freely, but the cost of such products can be quite high, so the desire to make a galvanized pipe with your own hands is dictated, first of all, by considerations of economy.

At the same time, the production of galvanized pipes does not require the use of special efforts, special expensive devices and tools and any professional knowledge, so any home craftsman who has a set of standard carpentry tools can cope with this.

Production features of the method

The advantage of this method of processing metal sheets is the ability to produce a variety of metal profiles. Our company’s specialists can perform bends not only at right angles upon customer orders. Our company's production capacity allows us to perform Z-bending of sheet metal. This requires specific equipment and extensive professional experience.

Steel bending technology consists of simultaneous impact on a metal sheet from different sides. As a result, the linear size becomes larger on one side and smaller on the other. However, along the axis the metal completely retains its physical parameters. It is important that our clients can request bending according to customer drawings - for a specific project.

In different production conditions and depending on the task set by the client, the place of pressure and the force of pressure on the rolled product may be different. In order to fully meet the client’s requirements, bending is carried out according to a previously drawn up project.

Characteristics of galvanized pipes

Pipes made of galvanized metal are used to equip chimneys; they are popular due to their light weight and, accordingly, ease of installation. Galvanized chimneys do not require the construction of a foundation, and this significantly reduces the cost of chimney equipment.

Such pipes meet fire safety standards, withstanding temperatures up to 900°, so they can even be used for smoke removal from solid fuel heating boilers and furnaces.

Galvanized pipes are also used in home construction to equip drains. Such pipes are already quite affordable in cost, but the process can be made even cheaper by using hand-made products.

What you need to make a galvanized pipe

At home, to make a galvanized pipe, you need a sheet of tin; the material does not require much effort due to its softness and ductility.

Tin plates are industrially made from thin sheet steel with a thickness of 0.1 to 0.7 mm on rolling machines, after which they are coated with an anti-corrosion protective layer of chrome, tin or zinc. Finally, the workpieces are cut to standard sizes, ranging from 512 mm to 2000 mm wide.

The strength of such products is in no way inferior to their steel counterparts, especially if the material has additional stiffening ribs, but at the same time it is very plastic and allows the installation of pipelines of complex shapes by hand. Anti-corrosion coating protects the pipe from the effects of the external environment.

The problem with such pipes is insufficient bending strength, therefore, for the manufacture of open parts, stiffeners are added to the structure to strengthen the product.

- The stores offer a wide range of such pipes of various sizes: single-circuit;

- double-circuit (made in the form of a sandwich and consisting of an internal and external pipe);

- corrugated, characterized by increased flexibility.

Note! At home, it is technically possible to make only a single-circuit pipe.

When choosing sheet thickness, the purpose of the pipe should be taken into account. For example, a galvanized pipe for smoke removal from solid fuel stoves and fireplaces must have increased resistance to high temperatures, and at the same time high anti-corrosion properties.

It is important! The higher the temperature of the working environment, the thicker the pipe walls should be.

Tools

To work, you need special tools to bend, correctly measure the bend angle and cut the pipe to the required length.

A set of tools that will be needed for work:

Note! The blades of the scissors should not be dull; the formation of a smooth edge of the product depends on this. When cutting with a blunt instrument, nicks are formed that must be removed. To avoid unnecessary work, it is important to monitor the quality of sharpening.

- a hammer with a rubber pad, a mallet (a carpentry tool made of wood in the form of a hammer);

- bending pliers;

- workbench for cutting and marking;

- a pipe for calibration measuring more than 100 mm and an angle with edges of 75 mm;

- ruler or tape measure;

- marker (sharpened steel rod).

How to bend metal at home

In order to bend metal sheets in production, additional processing of the workpiece is not necessary. For this, special equipment is used. It may vary in design and principle of operation. Metal bending is considered a separate technological process that requires certain skills and knowledge to perform.

Metal bending

Types of bending machines

Before bending an aluminum angle, a steel pipe or a metal sheet, you need to select the equipment for the work. Metal bending is performed on different types of machines:

- Manual models. This is equipment for placement in private workshops. It has small dimensions and does not require additional skills to carry out the work. Using hand tools, you can bend metal sheets and parts of small thickness.

- Mechanical models. They are a structure that is driven by energy transmitted from the flywheel. Initially, the master must unwind this element.

- Hydraulic machines. The equipment contains a hydraulic cylinder.

- Electromechanical units. Common industrial machines that operate using an electric motor. It drives other mechanisms using belts and gears.

- Pneumatic models. This is a design whose mechanisms are driven by pneumatic cylinders.

- Electromagnetic machines. Powerful electromagnets are used to operate the equipment.

On sale you can find mobile devices for bending metal sheets and parts. They are used in garages, private homes, and workshops.

Operating principle of the machines

A variety of equipment is used when bending metal parts. These can be machines for bending strips, pipes, sheets. In order to do quality work, it is important to understand how certain mechanisms work.

Manual sheet benders

Designed for bending metal sheets. They differ in the width of the working surface and the depth of the workpiece feed. Work order:

- The master presses the sheet of metal using a special beam.

- Using a bending beam, the sheet is bent to the desired angle.

- The workpiece is wrung out and pulled out of the machine.

On construction sites, in garages, workshops, it is more convenient to use manual sheet benders, but they are only suitable for bending metal sheets whose thickness does not exceed 2 mm. Manual sheet bender

Hydraulic sheet benders

This is modernized equipment that makes workers' work easier thanks to the use of hydraulic cylinders. Operating principle of the equipment:

- The fluid in the hydraulic cylinder drives the operating mechanism. It pushes the plunger, which changes the position of the cross member with the strikers.

- The sheet begins to bend under the influence of the working part of the machine.

The operation of the cylinders allows you to perform work accurately and quickly.

Electromechanical sheet benders

The operating principle of this equipment is the movement of an electric drive. On the basis of such machines, sheet metal presses are manufactured. Sheet benders equipped with an electric drive are available through and through. With their help, you can process workpieces of different lengths, heights and widths.

Metal bending and its main methods

Not many novice craftsmen know how to bend a profile or metal pipe. To do this, it is important to know the technologies for bending various workpieces.

At home, you can bend sheet metal using hand tools. Before you start bending sheet metal with your own hands, you need to accurately calculate the dimensions of the workpiece. It is important to understand that the length of the part to be processed must be greater than that of the finished product. For calculations, ready-made tables are used, which can be found in engineering reference books or on the Internet.

Bending sheet metal at home

Metal pipe bending

When replacing plumbing, it is important to know how to bend water and sewer pipes at home. For this purpose, a manual or mechanized method is used. The process of changing the shape of the pipe represents a force impact on the workpiece.

To bend the pipe without breaks or folds, a cold and hot method is used. The first option is suitable for bending pipes with a small diameter. Large-diameter pipes are initially heated to increase ductility.

Metal bending

To bend the profile, it is necessary to use the rolling method. In this case, there is not enough information on how to bend an aluminum sheet. For this purpose, profile bending machines are used. They can accommodate up to 5 rolls. To make it easier to bend high-strength workpieces, the metal can be preheated. In this case, high frequency current is used.

Equipment Maintenance and Safety

When working with industrial equipment, you must follow safety precautions:

- Before work, employees are given instructions.

- In mechanized machines, electronic control is used to start the working mechanisms. This reduces the risk of injury while working.

It is important to periodically lubricate the moving elements with machine oil to increase the service life of the sheet bender.

Machines for bending metal are used both in enterprises and in private workshops. When choosing equipment, you need to take into account the size and thickness of the workpieces being processed. The type, size and characteristics of the machine depend on this.

Subscribe to the channel, like, repost, and we will post useful information about metals for you! You can also visit our website, where you will find a lot of information about metals, alloys and their processing.