Device for correct drill sharpening angle

How to sharpen drills with the correct sharpening angle without much effort and skill?

Unfortunately, many of us do not succeed the first time. This device is very simple in design. Therefore, each of you will be able to repeat it. Many people know that the edges of bolts and nuts have the same angle as a standard drill sharpening. We will use this. We will not weld two nuts together to get the correct pattern. The design is a little different. To start, you need any nut. The larger the diameter, the larger the diameter of the drill that can be sharpened in it.

The nut has 6 faces, 2 of which we need. Take a caliper and mark 4 mm from the edge of the nut. We turn the nut the other way around and make a mark on the edge that is one and a half mm larger than the first one. We make a triangle on 2 sides. Cut with a hacksaw or grinder. The result was a nut with cuts.

We weld another one. The device is almost ready. He misses the puck, which we throw into the middle. You will also need a bolt; it screws into a small nut.

The cuts in the nut have different depths, which differ by 1.5 mm. This difference is hardly noticeable to the eye. We insert the rod, fix it, and apply a ruler. The gap between the ruler and the round timber is smaller on the left than on the right. That is, the device has a certain angle. Where the gap is smaller, the master made a mark.

Operation of the device mechanism

We take a straight, unsharpened drill and place it in the device. Where the mark is, the drill must be placed, as shown in the photo and video. We fix the drill so that it protrudes slightly from the edges. The drill will be sharpened on the working side. In the example shown, it is possible to clamp with a diameter of up to 8 mm.

When we start grinding the edge of the drill using sandpaper, there is a guide in the form of the plane of the edge of the nut, which sets the correct sharpening angle.

This is a great device for those who cannot find the right angle by eye.

The video shows how to position the tool relative to the sanding wheel. From the 6th minute you can see how the drill is processed.

Alexander Polulyakh. In addition to this video tutorial, another homemade device using bolts and nuts.

Advantages of the nozzle

The most popular function of a drill, which craftsmen do not ignore, is sharpening various tools. This most useful addition will save you from having to visit specialized services and spend money.

An attachment designed specifically for this purpose easily turns the drill into an electric sharpener. It can be represented by two subclasses:

- devices for sharpening saw blades;

- devices for sharpening drills, knife blades, planes and chisels.

The popularity of a drill with such functions is easy to explain. The success is due to the high cost of professional tool sharpening services. At the same time, installing the described attachment will not require serious preparation or extra funds from you. The sharpening itself is also simple; all instructions are included when purchasing the structure. By following the instructions, you can easily put the tip of the drill in order, increasing efficiency and comfort in work.

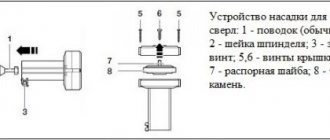

Drawing of a device for sharpening drills

If we talk about those drills that are used by craftsmen at home, their cost in stores is low. But even in this case, you should not use them as a consumable for one-time use. After all, updating the drill to the best working condition will not be difficult if the master has the skill or special tools.

There are factory-made machines that are designed for sharpening, but this is a separate expense item, so most often craftsmen create such devices with their own hands.

Most of the problems are caused by drills for metal, and wooden blanks do not quickly reduce the sharpness of the cutting edges.

To make a machine for restoring the sharpness of cutting elements, the necessary control means (template) are used to check the tool.

Typically, tools for ferrous metal, carbide bronze, steel or cast iron have an edge angle of 115-125 degrees. The length of another material, these parameters are different.

for soft bronze, red copper – 125, for brass alloys – 135;

for aluminum and soft aluminum alloys, granite, ceramics and wood – 135 degrees;

for magnesium and its alloys – 85 degrees;

for plastic, textolite and silumin - from 90 to 100 degrees.

Masters, if necessary, make templates in accordance with the above data. By the way, theoretically, a single drill can be suitable for all these metals and other materials, if you sharpen different working surfaces each time.

An elementary handicraft device that is often used, bushings attached to the base. There are many drawings on the Internet for self-production. It is necessary to take into account that the tool must be well clamped, the accuracy depends on 1 degree.

If desired, you can make a large-sized holder by using aluminum or copper tubes corresponding to the standard characteristics of drills, or drill many holes in a soft metal workpiece. It is necessary that the sharpener has a comfortable hand rest to move the device and hold the stop.

This primitive sharpening machine is easy to install on a workbench or table.

The essence of the problem: there are drills, they need to be sharpened. We will use one of the sharpening methods, close to the factory ones. Too lazy to catch with your hands. Better than the monkey method - install it and you're done. It took approximately 1 hour to manufacture the device according to the finished drawing.

Read also: Technological chain of non-ferrous metallurgy production

A little welding work according to the template. A corner was made. We put the washer on, it’s just pressed on.

Let's try the first sharpenings, if everything is assembled correctly, we will refine and refine it, make a quick adaptation.

After sharpening the drill, we carry out a test. Two casting chips are visible, which means that sharpening was carried out correctly.

The only drawback is that one chip is longer than the other, which means they missed the length of the edges. You need to make a stop that will adjust the length

Video of the channel "Anton Fomenko".

Advantages and disadvantages

When assessing the effectiveness of devices, remember that it is not intended for intensive use. Without making excessive demands and using devices for their intended purpose, there should be no complaints. The cost of the nozzles is low. Since the design is simple, you can learn how to handle them in a fairly short time, even if you have no experience at all.

The disadvantages of the device are as follows:

- The drill sharpening attachment is designed more for straightening “sagging” edges. If you use it to fully sharpen very dull products, the emery wheel will not last long.

- Most models do not have a particularly reliable fixation on the cartridge.

- The angle at which the drill is sharpened is inherent in the design of the device, and this parameter is almost impossible to change.

- When purchasing an attachment, it is not always possible to try it on the chuck of a specific drill model. In this regard, the rotating cartridge often touches the inner surface of the adapter coupling.

If you do not use a homemade bracket, with which the drill is fixed together with the nozzle during operation, using the device is not particularly convenient: at the same time you have to hold the drill with your hand, turn it on and off, and manipulate the drill with your other hand, directing the tool into the holes that is in the cover of the device.

The procedure for making devices for sharpening drills with your own hands: drawings, video

In order for the processing of materials to be high-quality and fast, it is important to take care of the necessary sharpness of the drill.

Regular replacement of the tools used requires significant financial costs, and therefore a do-it-yourself drill sharpening device would be an excellent alternative. Moreover, making it at home is not so difficult - you just need to select suitable drawings and materials.

How important is it to use sharpening equipment?

How quickly does a drill lose its sharpness? This depends on many different factors: the material being processed, the feed speed, the presence of additional cooling, and the speed of rotation. If we are talking about working with wood, then sharpening the drill is not required as often as when working with metal.

There is no point in neglecting this procedure - it is better to spend about half an hour to return the instrument to its former sharpness than to waste time in vain. After all, work productivity decreases significantly; additional efforts have to be made, increasing pressure. But in any case, the process slows down, and accordingly, you will have to spend 2 times more time on one workpiece.

Regular purchase of new drills is only relevant if we are talking about small amounts of work. Otherwise, the level of costs begins to grow exponentially - it is much easier to learn how to sharpen them correctly on a homemade machine.

Choosing a sharpening angle

How can you tell if a drill needs replacement? As a rule, the master hears an unpleasant creaking sound, and additional efforts have to be made to process the metal. Initially, the angle of the cutting edge becomes dull.

If the necessary measures are not taken in a timely manner, the service life of the tool will be reduced by an order of magnitude - the wear process will be more active.

It is important to consider that during the sharpening process on a machine, it is necessary to select the correct angle - it depends on what materials you will be working with. In this case, it is best to follow a fairly simple rule: the harder the surface being processed, the blunter the drill angle should be.

- Plastic – 30-60.

- Wood – 40-60.

- Non-ferrous metals – 40-50.

- Hardened steel – 130-140.

If desired, you can use the universal option by sharpening the drill at an angle of 90-100 degrees. But this decision is relevant only if the quality of processing can be neglected.

How to make a simple design?

At home, it is most convenient to use a sharpening machine, which is easy to make with your own hands. Moreover, this will require only a little effort and materials that are at hand. You can choose a simple drawing - the work will take a minimum of time.

The sharpening stand consists of a base that is securely fixed and a holder designed to work with drills of different sizes, which makes this device truly universal.

To make homemade sharpening equipment, you will need the following items:

- Base - for this purpose you will need to select a board whose thickness is at least 30 mm.

- Rail - attached to the base in any convenient way (you can either glue or nail this product). Fixed at an angle of about 30 degrees. The side edge should be beveled. This element is necessary to install the holder at the desired angle.

- Holder – to create it you will need a rectangular block of wood. One edge should be beveled (approximately 60-65 degrees) - it is this part that is attached to the rail. On the other hand, you need to make holes of different sizes for all types of drills used.

- Emery wheel - used for quick and high-quality sharpening. You can also purchase a diamond wheel for this purpose - although the cost is higher, its service life is much longer.

The simplest machine is ready. The design is quite compact in size, and therefore there is no need to allocate additional space for its installation - it will probably fit successfully on one of the corners of the table.

Do-it-yourself equipment with an electric motor

If desired, you can create a more advanced design, which is much more convenient to use and requires minimal time for processing. To do this, you will need to select a suitable motor, as well as take care of the choice of housing, which will make the device safe to operate.

To manufacture such a machine, you just need to select a suitable drawing, and also adhere to the chosen algorithm of actions:

- Install the motor on the chosen base, or on a table (an electric motor from an old washing machine would be an excellent solution).

- Mark the locations of future fastenings, make holes and secure the motor.

- Attach a grained wheel to the motor shaft (you can use a special attachment on the disk, which will make the sharpening process easier and faster).

- If the diameter of the shaft differs from the dimensions of the abrasive disk, it is necessary to install a sleeve.

- Connect the wires to the starter - the latter must have at least 3 open contacts.

- Install a metal box - it is necessary to protect the equipment from dust, which will increase the life of the engine.

Read also: Production of masonry mesh business plan

As additional protection, you can use a protective cover - it should cover 2/3 of the disk. In this case, even if the circle breaks during the work, the master will be safe.

Secrets of proper sharpening

To ensure high-quality sharpening of drills, it is not enough to select a suitable drawing and make a homemade machine.

It is also important to remember a few simple rules that will help you easily achieve the desired result:

- When processing the surface of a tool, it is important to ensure that the tip is always located in the center.

- It makes sense to practice first and only then start working - this will help you learn how to maintain the required angle and not put too much pressure on the product.

- Overheating is unacceptable - you can simply ruin the instrument, and therefore it is important to constantly cool it (if the surface is hot, you should not put it in water - first you need to let the product cool).

- It is recommended to start the process with a coarse abrasive, and then move on to a finer one.

And most importantly, always follow safety precautions - then there won’t be the slightest difficulty with the sharpening procedure.

The manufacturing process of the machine used for fast and high-quality sharpening is quite simple. It does not require significant costs, since materials that are probably at hand are perfect for its creation. At the same time, such a rack will allow you to save on frequent tool renewal, which is very profitable.

The quality and accuracy of drilling depends on the sharpness of the working tool. In addition, unlike a table knife, the drill must be sharpened correctly. Experienced mechanics can straighten the cutting edge on a regular sharpening machine by simply holding the drill in their hands (at least according to them). But this method requires skill and many years of experience. Even if you have a steady hand and an excellent eye, without understanding the process, you will simply ruin the instrument.

Sharpening stand

Many models are equipped with a special sharpening device. But it is inconvenient to use it for its intended purpose. For proper sharpening, it is necessary to hold the drill in weight, symmetrically process the tip on all sides and maintain the correct angle of the end. Not every master can do all the steps correctly, so a special stand for the drill was developed. It includes the following elements:

- durable metal body;

- a mounting ring, the main task of which is to connect the stand to the neck of the drill;

- top panel, which acts as a conductor during sharpening;

- grinding head;

The most important and, at the same time, difficult to use part is the grinding head. It is made in the form of a cylinder with an emery coating, secured with a nut. It is clamped in a lathe, after which it is given the desired shape using special tools. In the future, the point angle will shape the sharpening of the drill. When choosing the desired angle, they are guided by the characteristics of the material.

For example, the most suitable angle is considered:

- for aluminum - one hundred and forty degrees;

- for cast iron - one hundred and eighteen degrees;

- for low-carbon steel - one hundred and thirty degrees.

An individual sharpening angle is selected for each material. Not everyone can afford to buy or make such a part on their own; in such cases, it is possible to change the design of the drill stand.

You can use an ordinary cylindrical circle and make guide holes in the top panel. Don’t forget to give them the angle necessary for proper sharpening.

A few basic rules for sharpening (using the example of twist drills for metal):

For a better perception of the material, let’s remember the structure of the drill.

- Do not press the tip against the sandpaper for more than 2-3 seconds at a time. The metal heats up and the so-called “tempering” occurs, that is, deprivation of hardening. Accordingly, the necessary hardness of the metal is lost. The first sign is the presence of temperature discoloration on the edge.

- For drills with a diameter of up to 4 mm: each time the sandpaper plane touches the drill, the drill is held in one position: rotation around its axis is not allowed. For larger diameters, the sharpening geometry is slightly different.

- On twist drills, only the back surface of the cutting part is sharpened.

- The cutting edge should be directed towards the rotation of the sharpener (for mechanical sharpening).

- The main angle (2φ in the illustration) depends on the type of material being processed.

Which drills should I sharpen and how often?

Feather and other special wood drills cannot be repaired at home, and they do not become dull so quickly. Pobedite tips for concrete cannot be sharpened in principle. The most popular tool remains - twist drills for metal. Of course, they are also used for processing wood (plastic, rubber and even stone), but this is not relevant to the topic.

Twist drill. The cutting edge is small in size, so during operation it quickly heats up due to friction (there is no dissipation area). The main reason for dullness is overheating. When used correctly, wear does not occur as intensely. Characteristic signs of a blunt drill:

- A creaking sound is heard during operation.

- Instead of curled shavings, sawdust comes out of the hole.

- Instant heating of the tool without moving deeper.

Important: Do not use a dull drill; wear from overheating will only progress.

So, it's time to sharpen the tool. You don't want to ruin the drill and want to mechanize the process.

Selection rules and scope of application

When choosing a device such as a drill attachment designed for sharpening drills, you should consider a number of factors. This will allow you to purchase a truly convenient and effective device that will successfully cope with all tasks.

The first thing you need to pay attention to when choosing such an attachment is the compatibility of the diameter of the mounting hole in its coupling and the size of the drill chuck on which it will be installed. An important parameter is also the tool sharpening angle provided by this device. Many manufacturers of such attachments include an additional sharpening stone with the device, which allows you to sharpen drills at a different angle. To ensure that the sharpening attachment you purchase has wider functionality, it is better to opt for models with an additional sharpening stone included.

A sharpening stone is usually enough for several dozen sharpening processes. In some models, the grinding wheel can be adjusted, which increases the service life

When using attachments on a drill, remember that this is not a full-fledged sharpening machine, but a device designed to quickly correct a “lost” drill in cases where there is no access to stationary equipment. That is why you should not overload such devices, then they will serve you much longer. It is not advisable to use such attachments in production conditions, where the need for full sharpening of drills arises quite often, since under conditions of intensive use they will quickly fail. This device is indispensable in small home workshops, which are not always equipped with a traditional sanding machine.

Mini sharpening machines are at your service:

All devices are divided into two types: attachments or stops for universal tools, and independent devices of narrow specialization. Let's look at the most popular of them, from simple to complex:

Hand holder

This is just the device for those who have a steady hand and a diamond eye. In fact, it only allows you to hold the drill in a given position without fear of injuring your fingers. Angle control is visual, according to the position of the “wings” relative to any landmark. There are few advantages: instant readiness for work, compactness and price. The disadvantages are obvious: manual control of the process does not add accuracy.

Stop for electric sharpener

In fact, this element is not a special device for drills. It simply allows you to fix the tool at a certain angle. The accuracy will be higher than in the previous version. Most stops allow you to set the angle of inclination, and even have a marking scale. And yet you have to rely on firmness of hands.

Read also: Features of a metal crystal lattice

There are also more advanced stands: with replaceable elements and adjustment of not only the angle, but also the height. The devices are mounted not on the emery body, but on the workbench: which makes them more versatile.

In fact, such a stop can be adapted to any electric sharpener. An additional bonus is that with the help of such a stand you can sharpen knives, cutters, screwdrivers, chisels, etc.

Semi-professional guides for all types of drills

This is a fairly advanced tool that allows you to control sharpening characteristics with micron precision. All linear parameters are securely fixed, the values are set according to the markings. The drill is mounted in the groove, accidental displacement or rotation around its axis is excluded.

For sharpening, the possibility of both linear movement and movement of the edge along the arc path is provided (for conical sharpening of large diameter drills). Linear movement (along the axis) can be controlled by a master, or a limit stop can be installed.

From the point of view of processing quality, the device has practically no shortcomings. But for proper sharpening, the operator must know the parameters of the drill. That is, there is no automation: therefore the tool belongs to the professional category.

As a development of the line - a guide with its own sharpening unit. There is no need to install a stop on the workbench and change discs. In fact, you have a semi-automatic tabletop sharpening machine.

Important note: All listed devices are designed to work with standard electric sharpeners. Therefore, before starting to process drills, it is advisable to install a special emery disc.

Electric sharpening machines

They are specialized power tools for performing a single task: sharpening twist drills.

Even a person who is far from technology can use the machine (although why does he need sharp drills?). The operator only needs to determine the diameter of the drill and immerse it in the appropriate hole. It is convenient to work, errors are practically excluded. However, all drills are sharpened with the same comb. The price to pay for ease of use is the lack of flexibility in settings. For home use - the best choice: especially if there is an additional attachment for sharpening knives and scissors.

There are versions for masters. The drill is installed taking into account the sharpening parameters, the process can be controlled by the operator.

The sharpening angle, the method of edge processing (linear or conical), and the depth of metal removal are selected. The drill is not located in a common holder, but in an individual cartridge.

Industrial sharpening equipment for a metalworking shop

During intensive use of drilling machines, a separate post is required to restore the functionality of the tool. Professional stands for sharpening drills of any diameter save time and effort, but the cost of such equipment is too high for home use.

The information obtained will help you choose a sharpening device without extra financial costs. In addition, there are replaceable attachments for hand-held power tools (for example, a drill). But this is a topic for another article.

How to sharpen drills with the correct sharpening angle without much effort and skill? Unfortunately, many of us do not succeed the first time. This device is very simple in design. Therefore, each of you will be able to repeat it. Many people know that the edges of bolts and nuts have the same angle as a standard drill sharpening. We will use this. We will not weld two nuts together to get the correct pattern. The design is a little different.

To start, you need any nut. The larger the diameter, the larger the diameter of the drill that can be sharpened in it.

The nut has 6 faces, 2 of which we need. Take a caliper and mark 4 mm from the edge of the nut. We turn the nut the other way around and make a mark on the edge that is one and a half mm larger than the first one. We make a triangle on 2 sides. Cut with a hacksaw or grinder. The result was a nut with cuts.

We weld another one. The device is almost ready. He misses the puck, which we throw into the middle. You will also need a bolt; it screws into a small nut.

The cuts in the nut have different depths, which differ by 1.5 mm. This difference is hardly noticeable to the eye. We insert the rod, fix it, and apply a ruler. The gap between the ruler and the round timber is smaller on the left than on the right. That is, the device has a certain angle. Where the gap is smaller, the master made a mark.

Various sharpening attachments

Each drill model has its own sharpening attachment. Manufacturers advise paying attention to the neck dimensions of a suitable drill; in addition, find out the length of the turbine adapter. Without precise knowledge of these parameters, you may choose the wrong attachment. During operation, it may dangle or not be secured tightly; you will have to press it with your hands. This is especially true for economy class models.

For example, for a Sparta drill, an attachment with a diameter of forty-three millimeters, made for twist drills, is best suited. The body has about fifteen slots for various sizes in diameter. The special shape makes it possible to sharpen at an angle of one hundred and eighteen degrees. The nozzle is equipped with an additional stone.

Drill attachment for sharpening Sparta drills

In the service, the same sharpening will cost six hundred rubles and more.

Original attachments from Bosch have become extremely popular among customers. To be convinced of the high quality of the product, simply read dozens of positive reviews. Among other things, the attachment can be used for sharpening knives.