Home / Accessories and parts

Back

Reading time: 2 min

0

2050

It happens that the welding voltage may decrease due to certain factors. The reason may be high-quality wiring or a long service life.

There are options in which power outages occur. This can happen if metalworking is done in the country without outside help.

No one can guarantee that under such conditions there will be no electrical failure. You will not own additional kilowatts and will not be able to ensure uninterrupted operation of the equipment.

In such cases, a stabilizer comes to the rescue, helping the welding inverter to function. It can handle even small currents.

Don't think that you don't need a controller. Sometimes you can't do without it. If you take an inexpensive device, be sure to use a stabilizer. They can be unstable and cause voltage surges.

Sometimes they may refuse to turn on. In our article we will talk about what controllers are and in what cases they should be used.

- Total information

- How to choose a device

- Let's sum it up

general information

Surely, every home welder has had to deal with one of the most unpleasant problems - an unexpected shutdown of the welding inverter due to a lack of voltage in the household electrical network.

There are two simple solutions to this problem. You can change the diameter of the electrodes by choosing smaller rods. For example, instead of 3 mm, take electrodes with a diameter of 2 mm. This is a controversial solution, but it is effective if you need to finish the job as quickly as possible. However, you will not be able to use this solution if you are welding thick parts. After all, when using an electrode of a smaller diameter, the quality of the seams will deteriorate significantly and the welding itself will become more complicated.

But there is a second solution - the use of third-party devices. Designed to stabilize voltage. A separate voltage stabilizer for a welding inverter will help solve sagging problems once and for all. Or lack of power in the household electrical network. But this is not the most budget option. The cost of a good rectifier can be similar to the price of a welding machine. But it's worth it.

In simple words, a voltage stabilizer for a welding machine (also known as a welding arc stabilizer) is a device for stabilizing or increasing voltage. This device also protects the welding machine from power surges and failure.

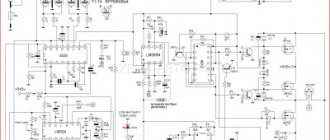

The essence of the stabilizer's operation is similar to that of a conventional transformer. Input current is supplied to the primary windings and then output from the secondary windings. If the input voltage is unstable or insufficient, the reactive coil is turned on. Its inductive reactance is adjustable. Or simply adding a few new turns in the secondary coil.

Thus, current losses are compensated and the output voltage increases. And if the output voltage is too high, then the stabilizer works on the reverse principle and occupies it. Therefore, the voltage at the output of the welding machine can be stabilized in the same way as at the input.

As you can see, a stabilizer is an effective and in some cases irreplaceable device. With its help, you don't have to worry about power surges. Once you start welding, you will be confident that you will finish it without any problems. But, despite the fact that the stabilizer is a simple device, it also needs to be chosen correctly. We will talk about how to choose a stabilizer below.

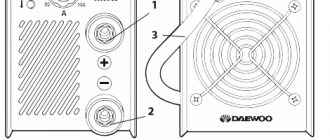

Operating principle and device

Voltage drops are especially common in densely populated areas of the city, when consumers living in nearby houses turn on all their household appliances at the same time.

As a result, the network may “sag” below a certain level (less than 180 Volts), at which it becomes very problematic to ignite an electric arc. A welding stabilizer helps save the situation.

A network stabilizer belongs to a class of electrical devices designed to protect welding equipment from significant fluctuations in network parameters. It allows you to maintain an arc discharge of the required power.

The principle of operation of some welding stabilizers is similar to the operation of an autotransformer, in which the input voltage is converted due to the inductive coupling of the primary winding with the secondary circuit.

When the input signal drops below normal, an additional reactive coil with variable inductance is activated in the secondary circuit or the required number of turns is automatically added. Such transformations of secondary circuit parameters lead to compensation of input signals, which are artificially restored to normal values.

When the parameters of the supply network are too high, when the currents in it increase significantly, the built-in regulator performs the opposite effect. It ensures the stability of the voltage supplied to the converter.

Other methods of voltage stabilization involve the use of special equipment (rectifiers or inverters) to achieve the same effect. In these devices, loss compensation is carried out electronically, due to specially constructed conversion circuits.

Stabilizer selection

When choosing a voltage stabilizer for a welding inverter, pay attention to several characteristic features.

If you have a standard 220V for a welding machine, but at the outlet you get much less voltage, then you should not buy a stabilizer for the inverter. It will not completely solve this problem. It is better to buy a stabilizer for the entire electrical network and turn it on at the input. Then this will make sense. You will be able to use not only the inverter, but also other equipment without interruption. And the resulting power is enough for the welding machine.

When choosing a stabilizer, the reactive power of your inverter is no less important. You may not even calculate this indicator. Just measure how much your inverter consumes at the input. At the same time, set the mode in which you often work. When purchasing, consider the power of your inverter welding machine. The power of the stabilizer should be approximately the same as that of the inverter. But not much more. Otherwise, you simply will not realize the full potential of the device, and you will overpay for increased power. By choosing the right stabilizer characteristics, you can save a lot of money.

Also pay attention to the speed of the stabilizer. It should be fast, without significant delays. Manufacturers produce two types of devices: electronic and electromechanical with a servo drive. Electronic stabilizers work faster and are more expensive. It is the ideal companion for a welding inverter. Electromechanical stabilizers cannot boast the same speed as electronic ones. But they are more reliable and durable. At the same time they are cheaper.

If you don’t have the finances to buy a full-fledged stabilizer, you can wind a separate step-up transformer. This is the most inexpensive and quite effective option. Even if your home is always low voltage.

Which stabilizer should I choose – electronic or electromechanical?

The preferred installation option would be the electronic version, but many consumers are frightened by its final price, which is truly inflated.

Electronic voltage stabilizer

But the use of an electromechanical version of the device will not greatly impact the consumer’s pocket. If the first electronic option is characterized by almost instantaneous response to a voltage surge, then the second option provides a certain time interval, which in some cases negatively affects the operation of inverter equipment, and indeed all devices connected to the general energy consumption network.

The electromechanical stabilizer, despite its low cost, has a number of shortcomings that will manifest themselves during the operation of the welding machine:

- Natural noise of the device.

- There are rubbing elements of the parts.

- After a certain period of operation, a built-in element.

Electromechanical stabilizer

In any case, experts believe that purchasing a stabilizer will only partially solve the issues of integrity and safety of the operation of inverter equipment and will help ensure the quality of welding work. At the same time, the general recommendation, in addition to purchasing the device, is to install transformer units to increase when supplying voltage to the house. As practice shows, most often instead of the specified 220 Volts, the network actually has 180-190 Volts, and in remote areas it does not exceed 150 Volts at all.

Features of choosing stabilizers

Welding equipment has become an integral attribute in a private home or workplace. It is difficult to name situations and cases when welding inverters are needed. Car repair, installation of a metal fence, production of metal frames and much more will definitely be needed in the home and at work. When choosing a suitable stabilizer option for a welding device, take into account the fundamental operating characteristics of the device, which are divided into the following categories:

- Transformer device.

- Rectifier.

- Inverter welding equipment.

In addition, there is a corresponding division according to class characteristics of operation:

- Semi-automatic device.

- A device that runs on diesel fuel or a gasoline equivalent.

Conclusion: conclusions and recommendations

When choosing a stabilizer, also take into account the diameter of the electrodes that you use in your work. If the diameter of the electrodes is up to 3 mm, then you will need a simple stabilization device, and for the constant use of electrodes with a diameter of more than 3 mm, you will need a powerful stabilizer that provides constant voltage support in the network.

If you cannot independently calculate how the stabilizer will suit your inverter device, we recommend contacting a specialist who will carry out a competent calculation and select the appropriate type of device that ensures high-quality operation of the unit and maintains the required voltage for the safe operation of welding equipment.

Voltage stabilizer for welding inverter

Reading time: 5 minutes

Welding voltage may drop or simply be insufficient due to old wiring or power outages. This problem is especially acute if you cook at the dacha with your own hands. Indeed, in such conditions, no one guarantees you the provision of uninterrupted electricity and a few additional kW. And in some areas the voltage is so low that even a table lamp cannot work properly. In such situations, a stabilizer for a welding inverter comes to the rescue.

Don't think of this device as an unnecessary purchase. Indeed, in some cases you simply cannot do without a stabilizer. If you use a budget machine for welding, then a stabilizer is a must. After all, low-power, inexpensive welding machines are often not able to operate stably. And during power surges they may not turn on at all. We will tell you what a stabilizer is and how to choose it in this short article.

Main settings

The technical characteristics of welding stabilizers are determined by their specific purpose, that is, by the equipment that they must maintain in working condition. According to this requirement, all welding stabilizers can be divided into the following groups:

- devices supporting semi-automatic welding operating modes;

- stabilization devices of the so-called “inverter” type;

- voltage stabilizers for welding machines in standard design.

The first of these modifications is relatively inexpensive, but has a slower response to sudden changes in voltage in the network and is noisier. Inverter welding stabilizers are much more expensive in terms of price, but they have a shorter response time and are more compact.

Conventional electromechanical stabilizers should be classified as a budget option for protective devices, the capabilities of which correspond to their cost.

About voltage stabilizers for welding

A welding stabilizer is an electrical device used to stabilize the current supply to welding equipment. Protects them from damage due to network surges.

The device operates on the principle of a transformer, where the input current is supplied to the primary windings and output from the secondary windings. When the input voltage drops, the variable inductance coil is activated, or more turns are added in the secondary winding to compensate for the loss and increase the output voltage. If the input is too high, the opposite effect occurs, and therefore the output voltage remains practically unchanged.

There are the following types of 220 V voltage stabilizers for welding:

They also highlight:

- semi-automatic;

- welding machines with a gasoline or diesel generator.

About the types of welding machines

When purchasing or renting welding equipment, there are a number of important criteria to consider. The most important of them is the type of device

.

- He can be:

- welding inverter;

- AC transformer device;

- DC transformer device;

- semi-automatic welding device.

Welding machines that use alternating current

, are the most popular. They are used for welding using consumable electrodes. Such devices are characterized by durability, high reliability and simplicity of design.

DC devices

also used for welding using consumable electrodes. The only thing in which they differ from the previous type of welding devices is the presence of a diode-type output rectifier, which ensures the formation of direct current from alternating current. But at the same time, the device loses a significant part of its power and becomes more complex in terms of design. A DC welding device is much more convenient to use due to the presence of a constant arc.

Semi-automatic welding machines

characterized by good performance, ease of use and sophisticated design. Devices of this kind are used for gas welding. If the latter is not used, then a special flux-cored wire is used.

The most convenient and modern among all welding devices are inverters

, characterized by low weight, compactness and resistance to significant voltage surges. With the help of welding inverters, welding is performed as conveniently as possible, and the quality of the result is beyond any doubt. All this is possible thanks to the use of various additional functions, for example, a stabilizing system, accelerated ignition of the working arc and protection against possible voltage surges.