Purpose and principle of operation of the winch

The winch is used in many branches of human activity.

This is a special mechanism designed to lift a load vertically or move it horizontally by transmitting force from the drum drive to a flexible traction element, for example, a cable or chain.

Depending on the type of winch, it can be used to perform the following tasks:

- Move the car. Here the mechanism is most often used to pull a vehicle to some static object, in cases where the car is not able to move independently, for example, “sat down” in the sand. Using a winch, the vehicle can pull itself up or pull up other vehicles. In general, a winch installed on any vehicle, especially one designed for off-road driving, including a snowmobile and ATV, is used to free stuck equipment.

- Lifting a load is the most obvious way to use the mechanism. So winches are the basis of lifting systems of various cranes, including truck and tower ones. Car enthusiasts and craftsmen also buy special hand winches for garages as an alternative to hoists. By the way, the hoists themselves, as well as the crane beams, which are found in almost every large workshop, are also built on the basis of a winch mechanism.

- On the water, winches are used as part of the anchoring and mooring devices of both small boats and huge ships.

It should immediately be noted that despite the similar principle of operation, each type of winch is designed to perform a very specific, limited job.

The simplest version is installed on a well to lower and raise a bucket of water.

This is interesting: Power regulator on a triac and thyristor - we outline it

Types of winches

Today, the most common are lever and drum hand winches.

Lever winch

This type is most often used by car owners. And this is no coincidence, because a manual lever-type mechanical winch has undeniable advantages - size and the ability to operate even in the absence of a rigid attachment to the support.

The kit with a manual lever winch often comes with other useful accessories:

- extension cable;

- block that increases traction force;

- bark protection sling;

- cable arrester and protective gloves.

The standard design consists of a metal frame with a built-in mechanism and a lever. Another important element of this device is the ratchet - a kind of wheel on which thrust teeth are located. A steel pin rests against each of these teeth, which prevents the wheel from twisting in the opposite direction, thereby ensuring optimal cable tension

In this case, the winch frame takes on the entire load, so it is very important that it is made of high-quality and thick metal

Drum winch

The manual drum winch consists of:

- drums (there are models with one, two and even three drums);

- gearbox (gear or worm);

- lever;

- a band brake, which allows emergency stoppage of work in case of unforeseen situations, which has a positive effect on operational safety.

The principle of operation is as follows: the gear train, followed by the shaft with the drive gear, is driven using a lever. A friction clutch is installed at the end of the gear, and at the end of the drum there is an annular groove, the dimensions of which correspond to the dimensions of the clutch. Due to this, the rope attached to the drum is wound and lifts the load along with it.

You should be aware of the disadvantages of a drum manual winch:

- limited rope length;

- the small circumference of the inside of the drum. When using a steel cable, it forms a strong bend, so it fails very quickly;

- weak cable laying mechanism.

Types of winches and their applications, operating principle and application of the winch

Lifting equipment is one of the most necessary assistants in work. So, for lifting loads, a winch is considered one of the most convenient devices. A winch is a device for moving loads using a moving flexible element - a rope, chain or cable. The use of a winch was known back in the days of slave-owning Egypt and even then made it possible to significantly speed up the lifting and movement of goods. At that time, they were driven by muscle or horse-drawn power. The development of technology and production made it possible to use a mechanical drive, which greatly facilitated the work with the winch.

Currently, there are two main types of winches in use: manual winches and electric winches.

Manual winches are a universal and cheap solution for lifting loads on construction sites, warehouses, small industries, and are also excellent for auxiliary and installation and dismantling work. The scope of application of hand winches is very wide, since their operation does not require a source of electricity.

Hand winches include lever winches, drum winches and mounting and traction mechanisms. The operating principle of a manual lever winch is based on pulling the rope through the body using clamps that alternately clamp the rope and advance it in the appropriate direction. In a manually driven drum winch, the lifting and lowering of loads is done by manually rotating one or two handles mounted on the drive shaft. To speed up the lifting of light loads, two-speed winches are made. The mounting and traction mechanisms are unique in their own way and are less similar to other hand winches. The principle of their operation is based on pulling the rope through the winch mechanism, which allows the use of ropes of unlimited length.

Electric winches are lifting equipment intended for lifting and transport operations during construction, installation and other works, drilling rigs, for completing various construction lifting devices, mast lifts, cranes, as well as for moving railway cars and tanks.

Traction winches are designed for lifting and transport operations for installation, construction and other works, as well as for completing construction lifting devices. These traction winches are attached to any surface convenient for you, for example: floors, walls, ceilings, using fastening on a horizontal or vertical platform.

Shunting winches are intended for moving railway cars at rail warehouses, and are used at loading and unloading areas, which allows replacing a diesel locomotive. These winches are classified as single-drum and double-drum, and according to the type of energy consumed - electric and pneumatic.

Auxiliary winches and drilling winches are designed for transporting loads and tools from receiving bridges to drilling sites, lifting loads, making up and unscrewing casing pipes.

Scraper winches are designed for delivering rock mass separated from massifs during underground mining. They are also used in open-pit mines and are used as a means of mechanizing the storage of lump and bulk materials. The winch is driven by turning on or off the working and idle drums using a hand brake. The mine winch is intended for the movement of equipment and cargo, installation and loading and unloading work in mine conditions.

The advantages of using winches are low physical effort during use, simplicity of design and control, compact size and reliability, and large traction forces. With the help of a winch you can significantly facilitate the work associated with lifting and moving loads, this will save time and money.

Application of hand winch

Most often a hand winch is needed for a car . This is considered domestic use. It is customary to put lever models in cars. Their compactness and ability to work without fastening are convenient.

In contrast to models with electric drives, there is lightness and resource saving of the engine from which the winches take energy. In addition, manual installations are several times cheaper than electric ones.

Household winches are called small-sized, since compact models are sufficient for household needs.

They are used not only in cars, but also on private construction sites, in garage work, and when stringing wires. Other types of installations are highly specialized. So:

- Scraper winches are used by miners to move cradles of rock.

- Shunters help move railway cars. This need arises in unloading areas and in the enterprise.

- Traction winches are also industrial, but are aimed at various loads moved in enterprises, warehouses, and construction sites.

- Mounting models are used for assembling and dismantling various equipment. Class winches help move and hold its parts suspended.

Hand winches are made from strong alloys. Their combination with the design of the devices allows the mechanisms to be used in any conditions, be it hot, cold, indoors or outdoors.

For open-air work and trouble-free storage of winches, they are coated with anti-corrosion compounds that prevent rust.

The best manual lever winches

The design of a manual lever device is very simple - a steel frame with a mechanism inside. Traction is carried out by a lever attached to the body

Which manual lever winch to choose, and how to determine reliability? First of all, you need to pay attention to the thickness of the frame. Many people do not recommend buying units with frame thickness less than 3 mm

The category presents the best winches that have a reliable frame size.

Bison "Professional"

Cable hand winches Zubr “Professional” are considered the most reliable, affordable mechanisms. The robust metal frame provides a reliable load capacity of up to 4 tons. The main hook is made of special carbon steel that is resistant to breakage. The frame can withstand high loads and is resistant to destruction. A special switch increases safety when winding/unwinding the cable. Double solid forged ratchet provides reliable traction with maximum lifting capacity. The reinforced pawl ensures safety and trouble-free operation. Fastening points made of hardened steel increase product quality, efficiency, and durability. Warranty 6 months, cable length – 3 m, nominal weight 6.73 kg.

Advantages

- Reliability due to hardened steel;

- Light weight, small dimensions;

- Bag included;

- Traction load 4 t;

- Acceptable price.

Flaws

Short cable.

Many users note that the model features a comfortable anatomically shaped handle that provides a comfortable grip. One of the advantages is its compact dimensions and ease of use.

Sparta

Manual winch for lifting cargo Sparta with a single ratchet wheel is suitable for lifting and moving cargo in a vertical, horizontal, inclined plane. It is often used during installation and unloading work at construction sites, where speed is not needed and loads are moved over short distances. To hold loads, the model is equipped with a ratchet brake. A strong 5mm diameter steel sling ensures reliable movement, lifting and holding. Two standard hardened steel hooks securely secure the weight, increasing safety when moving. Traction mechanism with a lifting capacity of 600 kg. Maximum traction load with a block is 1.5 tons. Steel cable length is 1.5 m. Warranty – 3 months, weight – 1.8 kg.

Advantages

- Lightweight model;

- Little weight;

- Strength;

- Budget price.

Flaws

Low load capacity.

The model will be a good choice for carrying out work with small loads. It is worth purchasing for those who do not want to pay more for unnecessary traction characteristics.

Mirax

The Mirax lever cable mechanism will become a universal assistant when work takes you on the road. To operate the hand tool, no power supply is needed at all. Easily copes with moving loads on horizontal and inclined planes. The mechanical device is small in size and does not take up much space in the trunk. Two hardened carbon steel hooks, double ratchet mechanism. The ergonomic plastic handle on the handle makes it easy to grip. A reinforced frame and high-quality components will ensure a long service life. Steel sling with a diameter of 4 mm, length - 1.8 meters. Weight 2.3 kg. Traction force 1.5 t.

Advantages

- Lightweight but durable frame;

- Good traction force;

- Endurance;

- Copes with inclines up to 15 degrees.

Flaws

- No brake;

- Short cable.

Many consumers note that the work will require an additional towing strap, since often the length of 1.8 m is not enough to engage the winch hook with the fulcrum.

Assembly and traction winches

A special class of hand winches. Externally, mounting-traction models are similar to lever models, but they do not have a drum. Instead, there are special compressions that move the cable. This approach made it possible to increase performance characteristics. The mechanism is activated by a lever.

Advantages:

- work without reference to the length of the cable and moving objects over long distances;

- compact form factor;

- simple controls;

- 100% autonomy.

Installation-traction manual winches require careful handling. Do not allow contamination of the cable and mechanisms.

Types of winches

During installation, construction or repair work, various equipment is used to lift loads. But very often you have to not just lift the load vertically, but move it horizontally. In such cases, winches come to the rescue - mechanical devices for vertical and horizontal movement of loads. Using this device, you can pull out a car stuck in the mud, pull up a machine, moor a ship, or, for example, move heavy concrete blocks.

Winches are manual and electric. Each type of winch has its own advantages and disadvantages.

A manual lever-type winch is used in everyday life and when performing simple installation work. It has small dimensions and functions without rigid attachment to the surface. Thanks to its small size, the manual lever winch is easy to install in hard-to-reach places.

A manual drum-type winch operates on the principle of winding a cable onto a drum. It consists of a housing, a gear drum, two bearings and a handle. The device is used to perform simple work, allows you to lift loads to the height of a person and provides double traction force.

A manual winch of the worm type has an “Archimedes screw” (worm) in its design. Its advantage is its miniature size, variety of mounting methods and reliability.

The mounting and traction mechanism is one of the types of winches. It works on the principle of a lever and includes “cams” in its design. The cable is pulled in the desired direction and passes through the cams, moving the load. The advantage is that any length of cable can be used.

The small-sized electric winch is lightweight (up to 40 kg), easy to transport and operates on a 220 V network. Depending on the design, it can be installed permanently on a beam or on a moving carriage. The lifting capacity of small-sized winches is limited to one and a half tons.

The small-sized planetary winch has a planetary type gearbox (drive wheel and driven wheels). With small dimensions and weight, it provides sufficient power to lift cars.

An assembly winch, powered by electricity, is an industrial equipment used in construction and installation work. The weight of such devices is from 250 kg.

The traction winch performs lifting and transport functions. The high power of this equipment is designed to provide high tractive effort. For example, they can be used to move trolleys for construction cranes.

A reliable and powerful electric winch ensures high speed of moving the load, and its use does not require physical strength.

Design features

The most popular today are drum models and mechanical lever-type manual winches. Although these tools have a similar purpose, however, the principle of their operation is somewhat different.

Drum type equipment

In terms of its external qualities, this type of tool is reminiscent of automobile winches with which special vehicles are equipped. Their design includes a gearbox and a drum. The first is usually a worm or gear type. The drum in this device is designed for winding tape or steel cable around it.

Worm-worm mechanism variations have an undeniable advantage, namely that their gearboxes have a much simpler system for locking the device at the right moment. Thanks to this, the safety of using this equipment significantly increases. This tool is also distinguished by its high reliability and variety of fastening tactics. Although it also has certain disadvantages:

- The large size of the equipment makes it more comfortable to use in a room like a garage.

- Relatively light weight that this type of equipment can pull.

- Complex operating mechanism.

- The need for ongoing maintenance.

- A kind of “conflict” with dirt.

From the above it follows that this type of winches is not the best option for use on mobile devices.

As for gear devices, their design also includes a gearbox and a drum, however, unlike worm devices, they are easier to manufacture and therefore somewhat cheaper. The cable is attached to them using a ratchet, which has good reliability.

The gearbox is characterized by ease of maintenance. A rather important point is the quality of the metal used in the manufacture of gears, therefore, when choosing such equipment, it is not recommended to give preference to cheaper, untested analogues. It is better to choose a well-known manufacturer.

The main disadvantages include the following:

- A method of laying a cable, which often gets into the cavities of the gearbox gears and ceases to perform its functions.

- Small internal diameter of the drum, which causes strong bending of the steel cable. As a result, the latter deteriorates quite quickly.

- Due to the dimensions of the device, the size of the drum is limited, and this, in turn, limits the range of action of the mechanism.

From the above, we can conclude that the process of using drum-type winches in field conditions may not always be comfortable. It is better to use this mechanism in the garage.

Lever type equipment

Winches of this type are most often used in mobile devices. It is these that drivers usually purchase in order to be able, if necessary, to rescue the car from a trap.

The standard structure of the device includes a frame made of metal, inside which there is a mechanism activated by pressing a lever located on the equipment body. Due to the fact that greater force can be applied to the lever, the device is effective in cases where drum winches would not cope. The traction force of such a mechanism can reach several tons. Moreover, this figure can be further increased by strengthening the standard lever. Some manufacturers immediately include a special amplifier in the equipment package or manufacture this element using the telescopic method.

The main components of the device include a ratchet that secures the cable in a taut state. It is a kind of wheel on which persistent teeth are located. A locking pin rests against them in turn, preventing the wheel from spinning in the opposite direction. This ensures tension in the cable.

In this case, the main load is placed on the equipment frame, as a result of which the latter must be made of durable metal of the appropriate caliber. Otherwise, the device will become deformed. Experts recommend abandoning the option of a winch with a frame whose metal thickness will be less than three millimeters.

The mechanism has small dimensions, so its operation is possible even in very inconvenient places and conditions. And also the lever type of mechanism does not require mandatory fastening of the case

However, when purchasing this modification, you should pay attention to the size of the winding drum, since the smaller it is, the greater the effort required during the work process. You should not opt for a product with a diameter of this element less than 45 millimeters

Operational Capabilities

Those who prefer a high-quality hydraulic winch and carry out the installation correctly can count on very rich functionality. The mechanism is directly controlled through levers – as a rule, there are two of them. The main advantage of branded models is the support of several traction modes. For example, in the basic order, the unit performs free unwinding and locking, and the remaining several modes differ in different tension transmissions. A modern hydraulic traction winch supports several speeds, which can also be controlled via a remote control.

Manual winches

Manually driven winches are used mainly as auxiliary equipment when vertical, horizontal or inclined movement of loads is carried out during installation and loading and unloading operations. They can be single drum or lever (no drum).

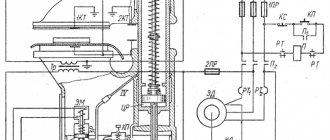

| Fig.1 Manual drum winch |

In the drum winch body (Fig. 1), consisting of two sidewalls connected by coupling bolts, shafts are mounted on which a smooth cargo drum, a transmission mechanism (gears) and a load-resistant automatic brake are located. Raising and lowering the load is done by manually rotating one or two handles mounted on the drive shaft. To quickly lift light loads, hand winches are made with two speeds. The lifting speed is changed by moving the gear block along the axis of the drive shaft.

An automatic load-bearing brake, consisting of a ratchet stop and a disc brake, provides braking of the drum when lowering the load and stops it instantly if the worker releases the winch drive handle. Since the load brake is located on the second shaft, gear shifting is possible with a raised load.

Winches are available in floor and wall versions.

| Fig.2 Manual lever winch |

The scope of use of manual lever winches (Fig. 2) is the movement of loads during installation and dismantling work, in warehouses, for towing cars, etc. These mechanisms are characterized by high reliability and ease of operation, the ability to work in any spatial position, small dimensions and weight, complete autonomy and versatility. They can function in any conditions and do not require any preparatory work.

The principle of operation of the winch is based on pulling the rope through the traction mechanism using special clamps that alternately clamp the rope and thus advance it in the appropriate direction.

Prices for hand winches

The price of a manual winch is determined by its type, length and diameter of the cable, and production. Thus, it is possible to buy a Chinese-assembled lever installation for 1200-2000 rubles.

Domestic samples will cost 3 times more. But there is no “demolition” for Russian winches. European models also boast about this. However, they are even more expensive than domestic ones.

In this situation, many people prefer more powerful electric winches. The price is the same for many, but there are more opportunities.

For those who do not understand winch drives, the offers of drum models with a worm drive may seem advantageous. The catch, as stated in the article, lies in their unreliability.

However, for domestic needs such installations are acceptable and even advantageous. A worm drive is unlikely to handle industrial loads.

Multi-speed gear models and some lever options are ideal here. However, in factory conditions, electric winches are more often used. We will devote a separate article to them.

Hello, our dear friend! Since you are here now, then probably not the most pleasant thing happened to you when the car got stuck, and no attempts to get it out on your own were successful. This is a familiar situation for many motorists. The way out of it is considered to be a manual winch, which easily fits into the trunk of a car and allows you to free your four-wheeled horse from the tenacious paws of a ditch or our wonderful road, consisting of mud and asphalt residues.

Using a hand winch

Basically, hand winches are manufactured in the following types:

- drums;

- lever;

- installation and traction.

Manual units are used on construction sites, warehouses, automobile and home workshops, and country houses. The first type is used for lifting, lowering, and moving small-sized cargo with limited weight. The source of movement is the rotation of the drum manually. The body of the product must be rigidly fixed to the selected surface.

Mounting and traction units are structurally different from drum and lever devices. They can use ropes or slings of any length. The principle of operation is to pull the rope through the mechanism in a given direction. One option for such a device is the so-called worm winch. It uses a gear drive with reversible force. The main disadvantage of such systems is the increased coefficient of friction created between the gear and the worm screw. This circumstance leads to rapid wear of the entire mechanism.

All manually driven structures are used as auxiliary (additional) lifting equipment. Especially in cases where there is limited free space.

Drive unit

The hand winch mechanism is most often equipped with a gear or worm drive.

The main element of a gear drive is the gear wheel. The teeth engage nearby gears, which have corresponding recesses, and the mechanism rotates. A mutually simple number of teeth on mating elements allows the load to be evenly distributed and their abrasion to be reduced.

A worm drive uses a threaded screw called a worm instead of teeth. It also interacts with the gear wheel. This design ensures smoother operation of the mechanism and an effective increase in torque. But the friction in it is higher, and therefore the main elements wear out faster.

How to choose an electric winch?

Paying attention to the load capacity, some owners forget about other characteristics of this useful device, which leads to mistakes when purchasing equipment. Let us describe the main parameters affecting operation:

- Type of installation - in the garage, a mobile electric suspended winch with a trolley drive is more useful. You can mount these mechanisms on a wall or horizontal plane. Choosing a car electric winch requires a special approach taking into account the vehicle model.

- Power - the traction force is affected by the mass of the load, the friction factor (resistance to movement), the lift factor (the car is pulled up or forward).

- Power type – 220 or 380 V or battery.

- Control type – equipped with an electric winch with a wired or remote control.

- Rope length.

- Rope diameter.

- Weight and dimensions of the model.

Rating of electric winches

A properly selected electric winch can help out the car owner in difficult situations, help at a construction site or in the garage. There is a wide variety of interesting models on the market, so viewing the ratings will not be a bad idea before purchasing a useful device for your home. We offer a small TOP of electric winches of different types:

- Electric winch COMEUP SEAL GEN2 9.5S

– runs on 12 V, pulling force 4300 kg, hermetic design, aluminum case, synthetic cable.

Winch MASTER WINCH MW X8288

– unit power 6.8 hp, cable 32 m, traction force 3760 kg, power supply 12 V.

Octopus 9000

affordable automotive electric winch - motor power 1.5 kW, traction force 4000 kg, remote control with a cable 4.5 m long.

Sturm eh72201

– power 540 W, lifting height 12 m, load capacity 400 kg, a good option for workshops.

DENZEL TF-250 52011

– electric lifting winch for construction sites with a lifting capacity of 250 kg, 540 W motor, 220 V power supply, lifting height 12 m, speed 10 m/min.

Let's start choosing

Of course, models such as LR-15, MTM 1.6 t or devices produced by Zubr are an excellent choice for the motorist. However, do not rush to conclusions or search for relevant advertisements on Avito.

Believe me, Moscow and St. Petersburg offer a fairly large assortment of used and brand new winches. Have I repeatedly scoured various markets in search of the perfect device for all occasions? And you know what I realized? And the fact is that cases are different, and a universal winch is a purely individual concept.

In other words, you should choose the “helper” for yourself. What is needed for this? From personal experience I will say that you should pay attention to several basic parameters.

- Design. A car winch must be of high quality, reliable and strong. Questionable build quality, rusty bolts or any extraneous play should cause only one reaction - a quick escape from such a store. You don’t want to buy a winch that won’t pull the car out and even injure you, do you? The answer is obvious.

- Belt or cable. The motorist must decide for himself what to use. From the point of view of reliability and practicality, a cable is, of course, better. But it is more difficult to install. The belt is less durable. Although let's be honest, you won't pull your car out of the mud every day, will you? Or will you? Where do you live and what do road services do in your region? Well, it's all a joke. Go ahead.

As you can see, lever units can become the optimal solution that will save you from dirt, roadsides and other unpleasant surprises on the road. I can only wish you good luck on your journey and find yourself as rarely as possible “captured” by our excellent communications between populated areas or beyond.

Have you ever found yourself in such situations, have you had to use a winch, and how rational do you think such a purchase is? Be sure to share your opinion in the comments. We will be very interested in communicating with you and answering your questions.

Of course, don't forget to subscribe and tell your friends about us! Motorists, like a big and strong family, must stick together.

( 12 ratings, average: 4.42 out of 5)

The lever winch is a manual type mechanism. Having a limited load capacity, they are nevertheless simple and compact, and therefore are used for small lifting and subsequent horizontal movement of cars, heavy machine equipment, pallets with a variety of construction materials and other operations.

How to make a hand winch with your own hands: 5 simple and proven methods

A winch is an indispensable thing in the household. It can also provide an undeniable service to car enthusiasts.

Winch functions for cars

Manufacturers install a winch on vehicles that often drive off-road. The fact is that when a car slips or cannot drive up a slope, it is this device that helps to get out of the “trap”.

By installing a winch on a passenger car, you can safely drive on any road surface, including washed-out roads and potholes.

However, it is used not only to pull a car out of a hole or tow it, but also to transport goods. Therefore, manufacturers produce a wide variety of these devices.

What types of winches are there?

Conventionally, they are classified according to:

- designs;

- connection method;

- technical features.

In addition, they are divided into removable, which are installed if necessary, and non-removable (installed on the front of the vehicle).

The winch can be of several types:

- Manual – the advantages include compact size. Most often they are of the drum type, when the cable is tensioned on a reel and rotation occurs using a handle. The disadvantages include the fact that it can work with cargo whose weight does not exceed 1 thousand kg.

- Mechanical - comes into action with the help of a motor, since there is no independent driving unit. The design is quite bulky and is not popular among car enthusiasts.

- Electric is the most convenient option. The drum moves using an electric motor. Power comes from the car battery. Loading capacity reaches up to 4 thousand kg.

- Hydraulic – has a rather complex design. It operates silently and has great power, but is unreliable because it can fail at any time.

There is no need to purchase the device. Making a manual winch with your own hands is quite simple. First of all, you need to decide on the type and parameters of the device.

The device is equipped with a so-called “anchor”, which clings to a hard surface and helps to pull out the vehicle. A do-it-yourself anchor winch can be made from almost any scrap metal

It doesn’t matter what the “anchor” looks like, the main thing is that it clings well and does not deform under high loads

While using the device, it is prohibited to stand within the radius of the cable.

Do-it-yourself winch from the starter

A homemade winch from a starter is made from materials that are always available in the garage. The basis, of course, is the starter, and the device itself runs on battery power.

It is desirable that the gearbox for the winch be planetary. You can find it on old Zhiguli models.

For manufacturing you will need: cables, cable, gears, drum, starter, gearbox, sheet of metal.

- Secure the drum seats with bolts and a welding machine.

- Assemble the drum with gearbox.

- The starter is assembled to the gearbox using adapters.

- Equip the input shaft with a gear. It is necessary to ensure that the size of the teeth matches the design. If the shaft connects freely to the gear, then the manufacturing process is proceeding correctly.

- Place the gear onto the cylinder. After the structure is securely fastened, the electrical wiring is connected.

If dirt or dust gets into the device during assembly, everything should be cleaned and only then primed and painted.

What are they needed for

A winch is a valuable acquisition for any motorist. After all, it is she who will come to the rescue in the most seemingly hopeless situation.

I will share my experience from my own life. I went to visit my parents one day. Although they live not far away, getting to them is a real challenge. They have to find out in advance whether it has recently rained near their village. If so, then the trip was canceled and postponed to another date, when the “road,” let’s call it that, dried out. I left when my father gave the green light. Everything would be fine, but the rain caught me right on the road. I think, but I’ll push and have time to get through. But it was not there. Having almost reached my parents, in front of me there was something reminiscent of a road in its outline. Only it consisted of a solid dirty puddle. The devil pulled me to risk driving through. He took a risk on his own. While my parents’ neighbors were waiting for a tow truck in the form of a tractor, more than an hour passed. The car is dirty, the mood is spoiled.

Having already reached his father, he asked, why don’t you buy yourself a winch? Every second of us has it. Thank you, dad, for your timely advice.

I watched a video about them, went shopping, talked to smart people. And then I had the idea to share with you information about these life-saving devices. They can really be useful in emergency situations. I advise everyone to buy it so as not to get into trouble like I did.

Essentially, all types of hand winches can be divided into two categories:

- lever;

- drum

And it’s better to talk about them separately.

Types of automobile winches

Depending on the drive design, winches for SUVs are:

- Manual.

- Electrical.

- Mechanical.

- Hydraulic.

Each of these types has its own advantages and disadvantages, so the choice is ambiguous. You need to focus on the most common situations that can happen to the car. Of course, a lot also depends on its design.

You also need to take into account the total weight of the vehicle, moreover, fully equipped, in order to purchase a winch powerful enough for this load. If it turns out to be weak, it will simply be useless in an extreme situation, since it will not be able to move the car. The traction force of the winch should be 2.5 times the weight of the car, then it will easily cope with the task without the need to unload things.

Stayer Maxpull 4310-4

Since choosing a winch for an SUV is not so easy, we will consider all these types in more detail, and then we will present the best models that have proven themselves well in practice.

Manual mechanisms

These are the simplest and cheapest devices. They are activated manually, to do this you have to rotate the handle or move the lever. By design, they are lever, drum and worm.

Manual winches for off-road vehicles are not suitable for everyone, since the thrust they develop is usually small. They can be used on light cars weighing up to 1-2 tons, and jeeps are much heavier. But there are also quite powerful designs, with a thrust of 4-5 tons.

Electrical devices

Electric winches for SUVs are much better and are the most popular. Such devices are powered from the on-board electrical network - from the battery. They are very easy to use and are launched with the press of a button. Their cost is quite reasonable, and installation and connection does not cause problems.

Such car winches develop quite a lot of force and some models can pull out a car weighing up to 6 tons. But you need to have a very good and capacious battery, since it is not always possible to start a car stuck in the mud to recharge.

Mechanical devices

Unlike manual options, mechanical winches for SUVs are driven not manually, but by a motor, using a special shaft that is connected if necessary.

The choice of such a winch may be limited by the design of the machine - not all have the ability to connect an additional shaft. One of the advantages is quite a lot of power, which is enough to pull the car out of any trouble. But for this you need to start the engine, which is not always possible, and this is the main disadvantage of this design.

Hydraulic devices

In devices of this type, a drum with a cable is driven by a hydraulic system. They are usually connected to the power steering. The force developed is quite sufficient and they work silently and smoothly, but they have many disadvantages:

- The cost is higher than other options due to the complexity of the design.

- The engine must be running.

- When turning the steering wheel, they may behave unstably, as the pressure from the hydraulic booster changes.

Finding a hydraulic winch for your SUV can be difficult as you need to consider connectivity options. Meanwhile, hydraulic winches do not have any special advantages over other designs.

Hydraulic winch Runva 10000 LBS

What to pay attention to

But design is not everything; there are several points that must be taken into account when purchasing.

- Cable or belt. The car enthusiast himself must decide what to prefer. The cable is more practical and durable, but requires careful installation. The belt lasts less, but the winch is not used often.

- Rope size. The longer it is, the more convenient it is to use. But on sale you can rarely find a winch with a cable longer than 5 meters.

- Rope diameter. The thicker the better is not always the case. Six millimeters is enough to pull out a passenger car, but it will fit on a drum of more than 8 mm.

- Traction force. Sellers often say that it is quite enough if this figure is 500 kg. In practice, this is not the case and reviews from owners confirm this. It all depends on how firmly the car is “settled” and the angle at which the force is applied. Therefore, the traction force of the winch must be at least 1000 kg.

Additional items

Various types of cables are used as equipment. The steel version is durable and has high strength, but if broken, it poses a great danger to people nearby. Specialized cable arresters are used to prevent such situations; in the absence of such a device, any material can be used.

Kevlar cable has less strength, but it is not capable of causing harm to others when it breaks. Among the advantages, it is worth noting convenient operation at low temperatures, since synthetics are not subject to freezing, as well as moisture resistance and lack of stretching even with repeated use.

Types of cables

There are mainly two types of cables used - metal and synthetic. The option of twisting steel threads may seem preferable, but, oddly enough, it has significant drawbacks. Firstly, you should not place special hopes on metal in terms of strength. Over time, some of its threads break, and at some point it is necessary to replace it. Secondly, a hydraulic winch with a metal cable is unsafe. Those same broken threads can injure the skin of your hands and damage your clothing, and if you miss the moment of critical wear, then a complete rupture of the cable during the pulling process can lead to tragic consequences. Synthetic is also not perfect, but it is less dangerous, less dynamic and lasts longer with proper care. Such a cable should be protected from sunlight, and after use in contact with sand, the fibers should be thoroughly washed.