Landscaping of the homestead territory begins immediately after a house and outbuildings are erected on the suburban area. And here you need to decide how to cover the paths and areas - what material is best to use for this. There are actually many options offered by the modern building materials market, and there is plenty to choose from. In this article we will talk about sandstone paths: what are the characteristics of this material, the pros and cons, laying technology.

Sandstone garden path Source vosledoma.com

What is sandstone, its features

Firstly, it is a natural stone from the category of clastic sedimentary rocks. This material got its name because it consists of quartz grains 0.05 mm in size (that is, sand), which are interconnected by a natural mineral substance like cement. Monolithic and layered sandstone is found in nature. The best option for paths and platforms is the second. That is, the process of turning it into plates is simple and inexpensive.

At the same time, manufacturers do not try to give sandstone, as a finished product, any special evenness. That is, tiles cannot be cut from it. More often, chipped plates of different thicknesses (10-60 mm) with uneven edges, with chips and cracks on the surface go on sale. But landscape designers use this stone for finishing paths and areas very often, because it has:

- a unique structure that absorbs very little moisture, water absorption is 0.6-1.6%;

- natural color;

- a certain degree of surface roughness of the plates, which is important in rainy weather;

- aesthetically attractive appearance .

Crushed sandstone of different colors Source 2gis.ru

As for appearance, sandstone on the market is presented in different colors, which nature gave it. Usually these are light brown plates, but in the market you can find white, blue, red, green, burgundy and ash stone. Finishing material from one manufacturer is presented on the market in one color shade. It is rare to find multi-colored stones in one batch. The photo below shows a traditional sandstone stone for paths in terracotta red color.

Sandstone plates of terracotta-red color Source donstroitorg.ru

And other characteristics of this stone for information:

- density varies between 2250-2670 kg/m³, it depends on what cementing substance is in the rock: siliceous, carbonate or clayey;

- porosity 0.7%;

- fire resistance - up to +1700C, this indicator does not matter for garden paths, but this stone is used for finishing both indoors and outdoors for facades.

See also: Catalog of companies that specialize in landscape design of sites.

There is nothing better than what nature created

Paths made from layers of rock stone are never the same, they are always unique and create a unique design for your site.

The sandstone in question has a number of advantages. The main advantages are unobtrusive beauty, natural color; structure that does not absorb water; some roughness that does not allow slipping when walking on it, even after rain. If we take into account only these indicators, it competes well with any artificially created finishing materials.

Having fundamentally chosen sandstone as a paving stone of natural origin for paving your paths, all that remains is to specify your correct choice in accordance with your taste and preferences: by color, size, texture and degree of processing of the stone, and the numerous offers of stone companies.

We will talk about horizontal laying of stone on the ground to mark your paths and the ability to move around the site in any weather on clean, durable, beautifully laid tiles. Agree, it’s nice to walk, even barefoot, along well-groomed, lovingly laid out paths without getting your feet dirty. On these living stones, compressed by nature and time from sand, which has turned into the most valuable material with the strongest energy, you will not get tired of walking, walking, running in the morning and always rejoicing at your choice.

How to lay sandstone on garden paths

The technology for laying sandstone on paths is not much different from the same process if you use paving slabs or any other stone. To do this, first of all, they carry out planning, that is, they determine where the path will be laid, what its dimensions and configuration are.

After which these parameters are transferred to the ground. Usually, the boundaries of the alley are formed using chalk dust or using twine and pegs driven into the ground. Here it is very important to transfer the dimensions correctly, especially with regard to the width of the path.

Marking a garden path with twine and digging a trench Source nasha-besedka.ru

After that, turf and soil are removed within the marked boundaries to a depth of 30 cm. The bottom of the dug trench is leveled and compacted. Then they cover it with geotextile so that this non-woven material covers not only the bottom of the trench, but also its walls. And now about the nuances of paving sandstone paths.

If the path will be subject to significant loads

Typically, such paths lead from the entrance gate to the house, and they are used for the passage of cars. That is, the loads are actually large. What to do in this case:

- river sand is poured onto the laid geotextile with a thickness of 10 cm , which must be leveled and compacted;

- crushed stone is laid on top in the same layer with leveling;

- Next, they install a metal mesh , which will serve as a reinforcing frame;

- concrete mortar 60 mm thick on top of the laid materials

In this condition, the prepared path should stand for at least two days. After which you can proceed to laying sandstone.

A steel mesh is laid on a prepared bed of sand and crushed stone and concrete is poured. Source stoprsp.ru

If the paths are subject to light loads

This is a simpler and less expensive option for forming a cushion for tiles:

- dig a trench with a depth of 15-20 cm;

- cover it with geotextiles , or don’t do it at all;

- pour sand 5 cm thick;

- crushed stone – 5 cm.

If geotextiles are not used, then a black waterproofing membrane is laid between the sand and crushed stone layer.

Geotextiles are placed down the trench Source in.pinterest.com

To lay the stone on the ground you will need

The ideal building material for installation is natural sandstone. It can be of various shades.

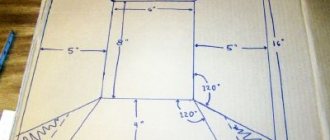

- A site plan, a proprietary one or one drawn up by you yourself, for which you need to measure your property, house, buildings, places to which the paths will lead.

- A tape measure for marking paths and other areas of your choice for lining the ground near your home and throughout your property.

- Pegs for marking the boundaries of the site in nature.

- A cord or rope for tying pegs around the perimeter of the facing areas in order to visually see the boundaries and size of the paths, walk along them, determine whether it will be cramped for you, and make adjustments.

- River sand and cement in bags for making mortar on which sandstone or a universal cement-sand mixture in sacks will be laid.

- A container for stirring the solution or a concrete mixer, depending on the volume of installation work.

- Shovel, trowel, spatula for laying mortar in place of laying sandstone, leveling the mortar, filling the gaps between layers of stone.

- A rubber mallet for shrinking natural stone into the mortar and leveling the path to the height of the sandstone protrusion above the ground surface.

- Hand gloves.

Useful tips

First of all, it should be noted that natural stone must be purchased according to thickness, depending on what path it will be used for. Because the thicker the tile, the more expensive it is. And if it’s just a garden path, then there’s no point in buying a thick, more expensive option. Thick cladding elements are purchased for car passages and areas where the car will be parked.

Sandstone itself is a fairly dense and durable material, but it can be easily cut with a grinder and a cutting disc. Some craftsmen simply split it with a hammer. After all, smooth edges are not necessary to cover paths.

As mentioned above, you need to be very careful when filling the gaps between the stone tiles. It is important here that precipitation in the form of water does not penetrate under the cladding. During the frost heave season, frozen water will simply tear the stone covering of the paths or the stones themselves.

It is recommended to water the path with water after finishing work. This will allow the cement mortar to dry evenly and gain its original strength. Some designers cover paths finished with sandstone with colorless varnish. In this way, the effect of “wet stone” is created, and this is a kind of highlight in the structure of landscape design.

Sandstone path - “wet stone” effect Source vesta-teplij-pol.ru

Sometimes landscape designers offer the option of growing grass between laid stone tiles. This is rarely done, because such a garden path does not have the required strength. Usually, for this purpose, a pillow is not laid with all the materials used to form it. Sandstone is simply laid on the ground. At the same time, they try not to use flagstone. Take thick stones with a flat or convex plane, which are mounted with a gap of 5 cm. Soil is poured between the stone elements.

If a path made of pure concrete is used in a suburban area, and it has lost its appearance and strength during long-term use, there is no need to dismantle it. After all, concrete is an excellent solid foundation. The concrete path is simply covered with sand screenings, on which sandstone tiles are laid. In order for the lining to adhere well to the sand, the finished alley is watered generously with water.

A properly designed project determines the success of the work

The procedure for laying flagstone on a sandy base.

To arrange paths on your summer cottage, you can invite specialists from a construction company who will develop a design project and complete all the necessary work in a short time. But this can be very expensive. It is much more profitable, and much more fun, to arrange your site yourself. This work is not that difficult and, with one or two assistants, you can handle it quite well.

You need to start with making a project or at least a clear construction sketch. To do this, draw a plan of your site with a schematic drawing of all existing buildings, trees, bushes, flower beds and other elements. Make several photocopies and distribute them to your family members so that anyone can draw their own version of the path layout. Then, putting all your thoughts together, create your own, the most compromise and convenient option.

Now, using the drawing, you can correctly calculate the area of all road surfaces and determine the required amount of material to purchase.

Video description

About laying a backlit path in the following video:

- Contrast. Often the combination of two different colors looks much more impressive. The combination of a gray facade with paths made of reddish, cherry or opal-yellow stone looks advantageous; For yellow walls, gray or gray-green flagstone is suitable.

- A combination of two shades of stone. A primary color is selected that echoes the color of the house, and an additional color, in contrast, in a ratio of 4 to 1.

- Laying technique. To prevent the paths from looking sloppy, it is necessary to maintain the same thickness of the seams. To do this, you have to periodically remove excessively protruding edges on the slabs. Material consumption increases, and this must be taken into account when purchasing. Laying is carried out with alternating large and small stones, which allows you to get a path with a uniform pattern.

Large flagstone terrace Source pinterest.ch

Laying sandstone limestone with your own hands. Sandstone mortar

Laying sandstone limestone with your own hands

Unfortunately, the now very popular facing sandstone masonry often collapses. It has long been noted that the root cause of this behavior is the sandstone itself. In most cases, sandstone will fall away without mortar. Caused by

Sandstone natural stone

This is because this type of stone absorbs moisture very poorly. Approximately ten to twenty percent of the total volume. And some types of sandstone absorb less, about five to ten percent. The remaining moisture is absorbed into the mounting surfaces. Let's add here the temperature regime, as well as weather conditions, which in our latitudes can quickly change to the exact opposite. Natural sandstone is capricious about such a set of surprises. So how to lay sandstone correctly and what is the composition of the mixture? For this, craftsmen select a solution that would not only be absorbed into the sandstone limestone, but would also be able to hold the stone firmly, without destruction. Let's consider this issue in more detail.

Flagstone: 6 benefits of use

The numerous advantages of this natural stone have turned it into a sought-after material for country construction and the design of a personal plot. He is considered attractive for the following reasons:

- Strength. The stone can withstand significant loads and resists abrasion and winter and summer temperatures well.

- Aesthetic qualities. A variety of shades and textures allows flagstone to fit into any landscape and style.

- Environmental friendliness. Using the stone has no side effects.

- Attractive price. The material looks advantageous compared to other natural finishing stones (marble, granite).

- Easy to install. Flagstone paths are laid in a standard way, and they do not require border edging.

Natural stone is a godsend for any style Source pinterest.pt

Performance characteristics. Flagstone is an ideal option - thanks to its rough surface, it does not slip during rain, and does not lose its decorative appeal over time.

Low operating load

Ordinary paths carry little load, since they involve only people moving along them. Therefore, it will only be enough to carry out the following preparatory measures:

- a 150 mm layer of soil is removed;

- river sand is covered with a layer of 50 mm and compacted;

- then a black polyethylene film or a special membrane, usually used in the manufacture of a reservoir, is laid;

- a 60 mm layer of crushed stone is poured on top and thoroughly compacted.

All the advantages of plastic

You think for a long time, weigh all the pros and cons, but still can’t decide whether to give your preference to this building material or not. Maybe you haven’t taken into account all the positive features of torn stone? So we will remind you of them:

- Excellent grip on the sole of the shoe. Even if it rains on the plastushka, it will not be slippery.

- Completely safe during operation.

- No heavy metals.

- It fits easily.

- Looks great.

- Environmentally friendly.

- Resistant to temperature changes.

- Retains its original appearance for many years.

- And the price of a piece of plastic is low.

Of course, this is not all the positive aspects; you can only feel them if your yard is decorated with such tiles.

Features of paving paths with different materials

Basically, the technology of paving with paving slabs, paving stones and wood cuts is similar. But in the process of laying this or that material, there are some nuances, the observance of which depends on obtaining a good result.

Features of paving with paving slabs

Paving slabs are laid on the prepared base in a direction away from you - during the process you should not step on the base. Each tile is tapped with a rubber hammer to secure the element. After finishing the masonry, the seams are sealed with grout and the tiles are watered. After 2-3 days, you need to water the path again.

Work is carried out in dry, clear weather, otherwise the result may deteriorate.

Features of laying paving stones

The paving stones are installed from the curb to the center, the elements must fit tightly to each other. After laying out each subsequent row, it is necessary to check the horizontal position, because even small deviations will subsequently cause the entire masonry to shift.

When laying granite paving stones, it is better to take elements one by one from different packages so that possible differences in shades are not noticeable.

You can see the step-by-step process of laying paving stones in our video:

dizlandshafta

Helpful6Not Helpful

PS

I received an answer from the company “Ceresit” to my question:

“What kind of mixture can sandstone be glued to on a façade?”

“Ceresit” response to the request.

I found confirmation that I am not alone in my conclusions about sandstone:

Sandstone flies off the wall.

(you can read the full text on the forum )

– A metal brush would not clean the clay. A hard clothes brush gave poor results.

Source

Range of products

The country's enterprises produce more than 100 types of products made of stone using modern technology.

The range of stone products offered will satisfy consumer needs:

- paving stone;

- landscape stone;

- facing stone;

- curb stone;

- corner elements;

- sawn flagstone end;

- tumbled flagstone;

- granite flagstone;

- flagstone dolomite.

| Types of stone | Description and cost |

| Sawn flagstone | Description: Natural facade stone used for finishing the external walls of buildings and fireplaces. The stone is environmentally friendly and is widely used in finishing work inside buildings. Price: Selling price 700 rub. for 1 sq. meter. |

| Flagstone is gilded | Description: Contains quartzites, mined in the Southern Urals. Easily processed by splitting with the possibility of forming slabs of various thicknesses. A special feature of the stone is its ability to change color when sunlight hits the surface of the mineral. Used for interior and exterior decoration of buildings. Price: Selling price 240 rub. for 1 sq. meter. |

| Flagstone lemezite | Description: A very beautiful stone, colors from light red to burgundy. It belongs to limestone, is environmentally friendly and is recommended for interior decoration of buildings. Slabs with a thickness of 15 to 30 mm are used for finishing the facades of buildings, and slabs with a thickness of 30-50 mm are used in the manufacture of landscape compositions. It has low hygroscopicity and strength. Price: Selling price 120 rub. for 1 sq. meter. |

| Galvanized flagstone | Description: Natural stone that has been processed to give the appearance of old stone. It is used for laying walls, and is also used to pave sidewalk paths; it has increased strength. Price: Selling price 480 rub. for 1 sq. meter. |

| Stone sawn into tiles | Description: Very convenient for laying. Used in difficult areas when finishing buildings. Widely used for finishing fireplaces, stairs, landings, paths. Price: Selling price 750 rub. for 1 sq. meter. |

| Lemesite paving stones | Description: Refers to luxury goods. It has a beautiful appearance, hardness and strength. During operation, it retains its original color and texture. Price: Sales price 1100 rub. for 1 sq. meter. |