Any substance, be it a gas, liquid or solid, has a number of specific properties inherent only to it. However, these properties make it possible not only to individualize elements, but also to combine them into groups based on the principle of similarity.

Look at metals: from a layman's point of view, these are shiny elements, with high electrical and thermal conductivity, not susceptible to external physical influences, malleable and easily welded at high temperatures. Is this list sufficient? to combine metals into one group? Of course not, metals and their derivatives (alloys) are much more complex and have a whole range of chemical, physical, mechanical and technological properties. Today we will talk about only one group: the mechanical properties of metals.

Basic mechanical properties of metals

What are these properties? Mechanical means those properties of a substance that reflect its ability to withstand external actions. Nine basic mechanical properties of metals are known:

— Strength — means that the application of a static, dynamic or alternating load does not lead to a violation of the external and internal integrity of the material, or a change in its structure, shape and size.

— Hardness (often confused with strength) — characterizes the ability of one material to resist the penetration of another, harder object.

— Elasticity — means the ability to deform without violating its integrity under the influence of certain forces and to return to its original shape after being released from the load.

— Plasticity (often confused with elasticity and vice versa) is also the ability to deform without compromising its integrity, however, unlike elasticity, plasticity means that an object is able to retain its resulting shape.

— Resistance to cracks — under the influence of external forces (impacts, tensions, etc.), the material does not form cracks and maintains its external integrity.

— Viscosity or impact strength is the antonym of fragility, that is, the ability to maintain the integrity of a material under increasing physical stress.

— Wear resistance — the ability to maintain internal and external integrity during prolonged friction.

- Heat resistance - a long-term ability to resist changes in shape, size and destruction when exposed to high temperatures.

— Fatigue is the time and number of cyclic impacts that a material can withstand without breaking its integrity.

Often, when talking about certain properties, we confuse their names: we classify technological properties as physical, physical as mechanical, and vice versa. And this is not surprising, because despite the deep differences underlying this or that group of properties, mechanical properties are not only extremely closely related to other characteristics of metals, but also directly depend on them.

Hardness of base metals and alloys

The hardness value is measured on finished parts sent for assembly. Control is carried out for compliance with the drawing and technological process. Tables of hardness values have already been compiled for all basic materials, both in the initial state and after heat treatment.

Non-ferrous metals

The Brinell hardness of copper is 35 HB, the values of brass are 42-60 HB units, depending on its brand. For aluminum, the hardness is in the range of 15-20 HB, and for duralumin it is already 70 HB.

Black metals

The Rockwell hardness of cast iron SCH20 HRC 22, which corresponds to 220 HB. Steel: tool – 640-700 HB, stainless steel – 250 HB.

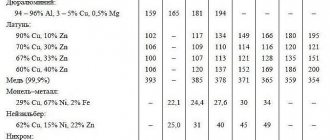

To convert from one measurement system to another, tables are used. The values in them are not true, because they are derived imperially. Not the full volume is presented in the table.

| HB | H.V. | H.R.C. | HRA | HSD |

| 228 | 240 | 20 | 60.7 | 36 |

| 260 | 275 | 24 | 62.5 | 40 |

| 280 | 295 | 29 | 65 | 44 |

| 320 | 340 | 34.5 | 67.5 | 49 |

| 360 | 380 | 39 | 70 | 54 |

| 415 | 440 | 44.5 | 73 | 61 |

| 450 | 480 | 47 | 74.5 | 64 |

| 480 | 520 | 50 | 76 | 68 |

| 500 | 540 | 52 | 77 | 73 |

| 535 | 580 | 54 | 78 | 78 |

Hardness values, even if produced by the same method, depend on the applied load. The lower the load, the higher the readings.

Physical properties of metals

The mechanical and chemical properties of metals are most interdependent with each other, because it is the chemical composition of the metal or alloy, its internal structure (features of the crystal lattice) that dictate all its other parameters. If we talk about the mechanical and physical properties of metals, they are most often confused with each other, which is due to the similarity of these definitions.

Physical properties are often inseparable from mechanical properties. For example, refractory metals are also the strongest. The main difference lies in the nature of the properties. Physical properties are those that appear at rest, mechanical properties only under external influence. The mechanical and technological properties of metals are no worse than others. For example, the mechanical property of a metal “strength” can be the result of its competent technological processing (for this purpose, “hardening” and “aging” are often used). The inverse relationship is no less important, for example, malleability is a manifestation of good impact toughness.

Drawing a conclusion, we can say that knowing some chemical, physical or technological properties, one can predict how the metal will behave under load (i.e. mechanically), and vice versa.

What are the differences between the mechanical properties of metals and alloys?

Do the mechanical properties of metals and alloys differ? Undoubtedly. After all, any metal alloy is initially created in order to obtain specific properties. Some combinations of alloying elements and the base metal in the alloy can instantly transform the alloyed element. So aluminum (not the strongest and hardest metal in the world) in combination with zinc and magnesium forms an alloy comparable in strength to steel. All this gives practically unlimited possibilities in obtaining substances that are closest to the required ones.

Special attention should be paid to the mechanical properties of deposited metals. Welded metal is considered to be metal that was used to weld two or more parts of a metal element or structure. This metal, like threads, connects the torn parts. The safety and reliability of the entire structure will depend on how the “seam” behaves under load. Based on this, it is extremely important that the properties of the deposited metal are no worse than those of the base metal.

- 1. Deformation and destruction

- 2. Mechanical properties of metals

- 3. Methods of strengthening metals and alloys

LECTURE No. 6. Mechanical properties of metals

1. Deformation and destruction

The application of load causes deformation.

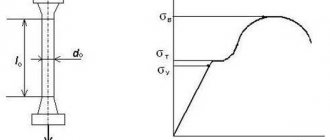

At the initial moment, loading, if it is not accompanied by phase (structural) changes, causes only elastic (reversible) deformation. Upon reaching a certain stress, the deformation (partially) becomes irreversible (plastic deformation), and the structure of the metal and, consequently, its properties change irreversibly. The dependence of deformation on stress is depicted by the so-called tensile diagram. Conditional voltage:

? = P / F0 (kgf/mm2),

where P is force;

F0

is the initial section, and the abscissa axis is the relative deformation:

? = ?l/l,

where ?l – length increment,

l

– initial length.

Tangent of the angle of inclination - straight line: tg ? = ? / ? = E – modulus of normal elasticity (in kgf/mm 2) – characterizes the rigidity of the material (resistance to elastic deformation), which is determined by the forces of interatomic interaction, depending to a first approximation on the melting temperature of the metal. Since alloying and heat treatment have very little effect on the melting point, the normal elastic modulus can be considered a structurally insensitive characteristic. All steels have E? 2?

10 4 kgf/mm 2, and for aluminum alloys

E ~

0.7? 10 4 kgf/mm 2.

Conditional stress at which the proportional relationship between ? and ?, is the elastic limit (or proportionality limit).

For technical purposes (except for elastic elements), a small deviation from the proportional dependence is not considered significant, and it is usually considered that plastic deformation occurs when the residual irreversible deformation ?pl. becomes equal to 0.2%. The conditional stress at which = 0.2% is called the yield strength

(in the diagram – ?0.2) and characterizes the resistance of the material to small plastic deformation.

The true stress reaches its maximum value at point Z

- at the final destruction of the sample.

For high-strength and low-plasticity materials ?B

> 150 kgf/mm 2, relative contraction ? (change in narrowing) at the site of rupture (destruction) is less than 40%, and is determined by ? according to the formula:

? = (Fо – Fх)Fо,

where F

0

is the cross section of the sample before failure;

Fx _

– section at the moment of maximum deformation.

Destruction

There can be two types, which can be called

“separation”

(repture) and

“destruction”

(wacture).

Separation is typical for highly plastic materials (usually high-purity metals), the deformation of which after reaching the point ? B

leads to 100% narrowing without the formation of a fracture surface. In all other cases, the narrowing reaches a certain value, after which the sample is destroyed with the formation of fracture surfaces.

Rice. 6. Types of torn samples: a – separation; b – failure with preliminary plastic deformation; c – fracture without preliminary plastic deformation.

The destruction process is preceded by: elastic deformation and plastic deformation.

2. Mechanical properties of metals

Mechanical properties

metals are determined by the following characteristics: elastic limit ?T, yield strength ?E, tensile strength relative elongation ?, relative contraction ? and elastic modulus E, impact strength, endurance limit, wear resistance.

Hardness,

determined by the simplest non-destructive methods, depends mainly on the carbon content and heat treatment conditions of the steel.

For a rough estimate of strength, you can use the following relationship: ?B = HB/3.

During operation, all metal parts of machines are exposed to various external loads, which can be applied smoothly, gradually (statically) or instantly (dynamically). By acting on parts, external loads change their shape, i.e. they deform. The property of materials made of metal and alloys to return to their original shape after the cessation of external forces is called elasticity,

and deformation that disappears after the load is removed is called

elastic.

If great forces are applied to a metal part and after the cessation of their action it does not take its original shape, but remains deformed, then such deformation is called

plastic.

The ability of metal materials and parts to deform under the influence of external loads without collapsing, and to maintain a changed shape after the force ceases, is called

plasticity.

Metal materials that are not capable of plastic deformation are called

brittle.

An important property of materials and parts made of metals, along with elasticity and plasticity, is strength.

Depending on the operating conditions, metal parts or tools must have certain mechanical properties - strength, elasticity, ductility.

During long-term operation, metal parts of machines are subjected to repeated, variable loads.

(tension – compression).

At stresses less than the yield strength or elastic limit, they can suddenly fail. This phenomenon is called metal fatigue.

The endurance (fatigue) limit is the maximum stress that materials and metal parts can withstand without breaking, under a sufficiently large number of repeatedly alternating loads (cycles).

For steel samples, this characteristic is set at 10 million cycles, for non-ferrous metals - at 100 million cycles. Is the limit of endurance indicated by a Greek letter? –1 and measured in Pa.

During operation, many machine parts heat up to high temperatures, reaching 1000 °C or more. For such parts, an important characteristic is heat resistance

– the ability of materials made of metals and alloys to maintain the required strength at high temperatures.

In metals and alloys that operate for a long time under load at high temperatures, the phenomenon of creep is observed,

i.e., continuous plastic deformation under the influence of a constant load (the metal “creeps”).

3. Methods of strengthening metals and alloys

Surface hardening of metals and alloys is widely used in many industries, in particular in modern mechanical engineering. It makes it possible to obtain high hardness and wear resistance of the surface layer while maintaining a sufficiently viscous core, and helps to increase durability and fatigue strength. Some surface hardening methods are highly productive. In some cases, they are used with great efficiency instead of conventional heat treatment methods. There are a large number of parts for which the properties of the surface metal layer have different requirements than the properties of the internal layers. For example, gear teeth experience strong friction during operation, so they must have great hardness, but have low hardness and good toughness so that the teeth are not destroyed by shocks and impacts. Therefore, gear teeth must be hard on the surface and tough at the core.

The most common method of hardening the surface layer of metals and alloys is surface hardening,

in which only part of the surface layer of parts acquires high hardness. The rest is not hardened and retains the structure and properties that were before hardening. Currently, surface hardening with induction heating using high-frequency currents is most widespread. This high-performance progressive heat treatment method improves the mechanical properties of steel, including yield strength, fatigue and hardness, eliminates the possibility of decarburization, and reduces the risk of oxidation of the surface of products and their deformation.

Parts of complex shape, band saws, cutting tools (mills, drills), levers, axles are subjected to pulse surface hardening. To do this, the hardened part of the part is heated to a temperature exceeding the temperature of the usual heating of this material for hardening, and then cooled at high speed due to heat removal into the rest of the part without the use of cooling media. As a result of pulse hardening, a hardened “white” layer is obtained, which is stable when tempered up to a temperature of 450 °C, has a fine-grained structure, high hardness and wear resistance.

Table of contents