Scope of use of such systems

Today it is used as a component of the boom mechanism of a tower or other crane, devices and devices for performing rigging work. They can also be used separately to carefully move and safely lift various loads on small ships and other objects. Among other areas of application, we note:

- tensioning high-voltage power lines, communication lines, load-bearing cables of various designs;

- maintaining constant pressure on the supports when lowering and lifting massive objects;

- moving massive objects, including pulling out cars that are stuck or run off the road;

- active recreation (mountain climbing, extreme tourism).

List of links

- NPAOP 0.00-1.01-07. Rules for the proper and safe operation of vanity taps // Ref. By order of the State Committee of Ukraine for industrial security, protection of goods and agricultural products, 06/18/2007 No. 132.

- Stroy-Tekhnika.ru: Construction machines and equipment, reference book. – https://stroy-technics.ru.

- Oksanich L.V. A training manual for slingers on the safe performance of work with lifting machines // Consulting project “EAM”. – https://eam.su/category/materialy/obshhetexnicheskie-svedeniya/uchebnoe-posobie-dlya-stropalshhikov-po-bezopasnomu-proizvodstvu-rabot-gruzopodyomnymi-mashinami.

Design features of modern pulley hoists

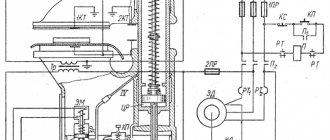

The main area of application of such systems remains jib mechanisms of tower, bridge, and truck cranes. With the help of pulleys you can significantly increase force or, conversely, speed. The first is used in cranes, and the second in lifts. Structurally, they include the following elements:

- movable and fixed blocks;

- bypass drums;

- bypass blocks.

The traditional layout of pulley blocks remains vertical, and the location of the drum is determined by the presence of bypass blocks. If the latter are absent, then the drum is at the top and vice versa. At the same time, the number of blocks (for the power type) determines the degree of growth of the total force, and the number of similar elements with a fixed axis is 1 less than with a movable one.

Specifics of multiplicity increase in pulley hoists of various types

Increasing the multiplicity in power systems allows you to reduce the load on each individual rope, which allows you to achieve several effects at once:

- possibility of using ropes of smaller diameter;

- possibility of reducing the diameter of blocks and drum;

- possibility of reducing the weight and transmission ratio of the drive gearbox.

At the same time, in this case, a larger rope capacity of the drum will be needed, since a gain in strength automatically leads to a “loss” in distance.

In high-speed pulleys, the labor force, which is developed by a pneumatic or hydraulic cylinder, is applied directly to the movable cage, and the load is simultaneously suspended from the free edge of the lifting chain, rope or rope. Here, the greater the gain in speed, the higher the lifting of the load.

Features of power pulleys

The key characteristic of such systems remains the maximum load that can be developed. In general, it depends on the following factors:

- lifting capacity of the crane where the pulleys are installed;

- multiplicity of the device (total number of rope branches holding the load);

- The efficiency of the block, which is determined by the losses to overcome the friction force, as well as those that depend on the rigidity of the chain or rope.

Several pulleys can be simultaneously installed on the mechanism for lifting and moving cargo, which allows you to evenly distribute the load and reduce the thickness of the rope or rope. At the same time, single pulleys are the simplest technically (they have one end fixed and the other on the drum). At the same time, the latter have a very limited deflection angle due to the risk of the lifting rope coming off the block. At the same time, the presence of an additional unit complicates and increases the cost of the entire system, but provides several advantages:

- the ability to increase the speed of block rotation;

- reduced rope wear;

- more symmetrical load arrangement.

The following pulley systems are most widely used in practice:

- double triple with the presence in the layout of two bypass and three working blocks;

- double triple, having a leveling beam, which will allow the use of lifting equipment in difficult conditions.

Injuries when working with a winch.

The most common injuries include the following:

– blows to the legs and arms with a loose cable during a sharp jerk (usually when running uphill and illiterate assistance from the wheels (“in the axle box”), in addition, with such jerks it is easy to break the cable and the winch gearbox).

Most often it ends in bruises, although more dangerous cases are known - open fractures.

– shocks from the cable when it breaks. By the way, it doesn’t matter whether the cable is steel or synthetic... except that the nature of the injuries may be different... Most often, fractures of the bones of the hand and deep abrasions.

- hands drawn into the drum . When the actions of the rope puller and the winch operator are not coordinated or when a hand is caught on the rope and hook. At best, bruises on the hands and fingers, at worst, severed fingers and severe broken arms.

– Injuries caused by a bark protector sliding up – bruises, scratches. On trees that bend slightly under load, the sling, tearing off the bark, can shoot up sharply. Therefore: It is not recommended to hold on to a tree trunk, and in general it is better to stand at a distance! Do not stand on the cable or the bark protector! Of course, sometimes such actions are necessary, but be sure to be aware of the risk that you are exposing yourself and especially others.

– injuries from fallen branches and tree trunks. During lying down, variable, abrupt loads may occur, causing the trunk to sway and large branches and the trunk itself to fall! There have been cases of serious vehicle damage, but serious injuries are also possible! Again, the conclusion suggests itself: stand as far as possible from the trees to which the winch is attached.

Features of choosing a chain hoist

Ideally, such a system should be designed individually for each lifting mechanism. The following factors are taken into account:

- total load capacity of the mechanism;

- the number of bypass blocks that influence the final losses due to constant friction (depending on the type of support bearings and lubrication method);

- diameters of individual pulley elements;

- angles of permissible possible deviation from the plane of bypass drums;

- material for the manufacture of lifting rope;

- the nature and type of supports, lubrication methods to reduce axle friction;

- speed of movement of moving blocks.

In practice, standard solutions are usually used, which saves time on production, design of such systems, and their certification. Additionally, they are much cheaper for the end buyer.

Refilling chain hoists

In practice, it may be necessary to change the distance between the main cargo blocks and the location of the latter. This procedure is called reeving and it allows you to change the speed or height of lifting the load. In cargo cranes, it can be used to correct the broken straightness of the lift, which increases the overall safety of work and predictability of behavior.

There are four types of reserve:

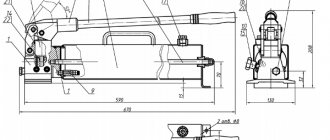

- Single-use, which is used on boom lifting mechanisms equipped with a boom. In this case, the hook is suspended on one thread of the rope and passed through all the blocks, followed by winding onto a rigidly fixed drum.

- Double, which is used on various cranes with beam and luffing jib. In the 1st case, the end of the rope is attached to the root, and the 2nd is driven through bypass drums, hook and boom blocks, and the top of the tower with supply to the winch. In the 2nd case, fixedly rigidly fixed blocks are placed directly on the boom head, and the rope is attached directly to the cargo winch.

- Quadruple, which is usually used on cranes and mechanisms with high lifting capacity. It is based on single or double refilling, but it is sold separately for each of the existing blocks.

- A variable based on the desire to change the working load capacity of the mechanism. To do this, movable clips are mounted in movable blocks, which are held by the rope or chain itself. The change in the multiplicity of the reeving carried out as a result occurs due to the lowering of the suspension onto a special support, which occurs when the rope is reeled in.

You can purchase pulley hoists, as well as blocks for them, by leaving a request by calling toll-free 8 (800) 550-93-95 or email

Crane bypass and equalizer block

Home / Lifting equipment / Manufacturing of crane blocks to order. CJSC ZSM Mayak, Kaluga.

Lifting mechanisms are used in hundreds of different industries. Not a single metallurgical production or enterprise can do without rail cranes. Cranes, winches, and other lifting mechanisms are designed to lift and move various voluminous and massive objects. Port and railway cranes are capable of lifting tens of tons, multi-meter tower cranes lift loads to the height of fifty-story buildings. All of these lifting devices use one of the unique properties of the wheel that makes it all possible. They all use a wheel with a groove around its circumference, which is included in the prefabricated structure that makes up the crane block, or pulley block.

The grooved wheel can be used with rope, chain or metal cable, depending on the purpose of the structure. The wheel spins, thus eliminating the effect of friction. The entire load is transferred to the roller or ball bearings on which the wheel is mounted. Crane blocks, as a rule, are made up of several wheels, one, two or even three wheels located in the same plane (pairs of wheels, or 3-5, depending on the expected load).

Crane block – part of the lifting mechanism

The crane block is an indispensable part of the lifting mechanism and works on a simple principle. The cable (rope) is fixed at a high point with one edge. The other end of the cable is firmly held by the drum, which is capable of rotating in the forward and reverse directions. Near the top point that holds the cable, there is a first auxiliary roller. A crane block (wheel with groove) is hung between this roller and the upper cable attachment point. Next, when the cable is wound onto a rotating cylinder, the crane block is raised or lowered. Depending on the composition of the rollers in the crane block, the lifting force increases from 1.8 times to 3 times. A larger ratio, as a rule, is not used; friction significantly reduces the efficiency of the pulley system.

Thus, using just one roller, an increase in lifting effort is obtained by 1.8 times. But the entire system must be designed to support the entire load that is being lifted or moved. Adding parallel rollers to the crane block allows you to reduce the load on the bearings without increasing the diameter of the rollers. Also, parallel addition of rollers is necessary to increase the load-carrying capacity of the system. In this case, the diameter of the cables or ropes used remains the same, but they are added in parallel. Powerful cranes can work with two or even four parallel cables and even 4.

The block with the roller also performs the function of guiding and stabilizing the movable and stationary cable. Throughout the entire length of the pulling rope, the lifting mechanism uses blocks that perform different functions.

Crane bypass block

The bypass block is divided into movable and fixed. The moving block lowers and rises (moves) along with the load. Used in hook hangers and moving pulley blocks. A fixed block (bypass) is rigidly fixed to a support and is used to direct the movement of a cable, rope or chain.

When developing and constructing crane blocks, it is calculated that the profile of the stream allows for the largest area of contact with the cable or rope. For the manufacture of crane blocks and pulley blocks, cast iron, steel or aluminum alloys (for low loads) are used. Blocks are mainly made by casting into molds, but they can also be made from rolled steel. In some cases, blocks are made by welding. After the crane block is received, it is mechanically brought to precise dimensions, then subjected to additional heat treatment to reduce internal stresses in the metal.

Bearings are installed (usually pressed) into the finished, processed block. Depending on the purpose of the future design, ball or roller bearings are used. The finished block undergoes laboratory testing, since it is one of the critical parts of the lifting mechanisms.

Main standard sizes of crane bypass blocks:

| Name | D, mm | Rope diameter, mm |

| 336-100-14 | 336 | 11-14 |

| 406-100-14 | 406 | 11-14 |

| 500-100-14 | 500 | 11-14 |

| 406-140-19 | 406 | 14-18 |

| 500-140-19 | 500 | 14-18 |

| 610-140-19 | 610 | 14-18 |

Crane equalizer block

Crane equalizing block - designed to equalize stresses and divergence of loads that arise in pulley systems using two or more working cables (ropes). During normal operation of the lifting system, there is no rotation in the block, but when the load in the chain hoist branches changes, the block rotates, thus compensating for the imbalance.

Double pulley blocks are widely used in the lifting mechanisms of many cranes - overhead, cantilever, gantry and others, where constant pressure on the drum supports during lifting or lowering of the load is important to ensure uniform loading of the bridge metal structure under both rails.

Main standard sizes of crane equalizer blocks, in mm:

| D1 | D2 | d | R | B | h |

| 230 | 90 | 9-14 | 7,5 | 20 | 20 |

| 260 | 110 | 9-15 | 8 | 25 | 25 |

| 320 | 160 | 17-19 | 9,5 | 27 | 34 |

| 400 | 140 | 17-19 | 9,5 | 40 | 34 |

| 500 | 160 | 18-23 | 9,5 | 45 | 35 |

| 600 | 180 | 18-24 | 12 | 55 | 35 |

HOW TO MAKE AN ORDER?

If you have any questions or want to know prices, please contact the sales department by phone:

+7 (multichannel)

or by email:

Professional staff will provide you with additional information and help you complete your application.

By submitting an application I give my consent to the processing of my personal data

apply for an order

Submit an application to order products

Any questions?

Contact us by phone

Is it more convenient to contact by email?

Write to us at