| Additional professional education program | Welder (professional standard) | Number of hours | Cost of education |

| Gas welding (surfacing) (D) of simple parts of non-critical structures (A/02.2) | 182 | 10,000 rub. | |

| Manual arc welding (surfacing, cutting) with a consumable coated electrode (CD) of simple parts of non-critical structures (A/03.2) | 182 | 14,000 rub. | |

| Manual arc surfacing with a non-consumable electrode in a protective gas (RAD) of simple parts of non-critical structures (A/04.2) | 72 | 8,000 rub. | |

| Partially mechanized surfacing by melting of simple parts of non-critical structures (A/05.2) | 170 | 8,000 rub. | |

| Manual oxygen cutting machine (A/01.2) | 76 | 10,000 rub. | |

| Manual plasma cutter (A/02.2) | 76 | 8,000 rub. | |

| Electric and gas welder with a fire certificate (according to ETKS, on request) | 182 | 6000 rub. | |

| Annual certification | 6 | 3,000 rub. |

8 (499) 178-80-11

The profession of “welder” has been popular and relevant at all times. Despite this, we are talking about a specialty with an increased level of danger - it must meet additional labor protection requirements.

Courses

Training to become a welder is carried out in groups in specialized classes with demonstration models of technological equipment .

To obtain a welder's education, it is necessary to master a curriculum that provides practical skills and theoretical knowledge in handling welding.

To train as a welder with subsequent employment, internships are required in construction and industrial enterprises, factories for the production of metal structures.

The curriculum includes the following topics:

- Basics of welding technologies. Students gain knowledge of the theoretical fundamentals of arc welding; when changing the direction of study, the plan also includes basic topics on argon welding.

- RDS - technology of work production, fundamentals of processes.

- Electric arc welding.

- Training to be a welder working with semi-automatic machines.

- Gas welding and cutting.

- Argon arc (TIG) welding – training of argon workers. Cold welding, submerged arc welding, carbon dioxide protective environment and other media.

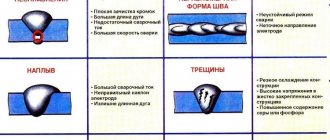

- Studying defects and producing quality control.

- Basics of safety during welding work.

The essence of the welding process

The correctness of a person’s actions and skills directly determines how reliable and high-quality the welded metal product will be. Therefore, the first step is to learn the basics of arc welding.

The place where the electrode is connected to the metal is called the weld pool. Before arc welding, you need to know the parameters of the bath. Standard sizes are as follows:

- 5-6 mm - depth;

- 10-32 mm - length;

- 7-15 mm - width.

These are conditional parameters; specific dimensions depend on the shape of the edges of the elements being connected, the welding mode, the speed of the electrode and other factors.

In order to clearly understand how to properly arc weld, novice craftsmen first need to thoroughly understand the processes occurring during welding:

- an electric arc occurs when the electrode comes into contact with a metal surface;

- the metal melts together with the formation of the arc;

- simultaneously with the metal, the electrode itself also melts and at the same time the melted particles move into the weld pool;

- The protective coating of the electrode is also melted. It forms a gas cloud that protects the bath from exposure to oxygen and ensures that the temperature required for melting the metal is maintained at the welding site;

- during the welding process, slag is formed, which also helps maintain the optimal temperature regime and prevents overheating of the weld pool;

- the welding seam is formed as a result of the movement of the electrode and the movement of the pool;

- After the metal has cooled, a slag crust remains on the joint, which must be carefully beaten off with a hammer.

If you have never seen an electrode holder before and the general concepts of the welding process are unfamiliar to you, then you should take arc welding lessons, which are publicly available on the Internet on many sites.

Note! Only if there are two current-conducting elements with opposite charges, an electric arc can occur. Such elements are metal and electrode. It is best for beginning craftsmen to use a standard electrode with a central element made of metal.

Training course program

The welding training program is based on the student's step-by-step and gradual acquisition of cutting and welding skills.

To train as a welder, they first take a theory course, and then practice, which takes up about 70% of the hours of the educational process..

Welding training also involves studying:

- rules and regulations of industrial safety at facilities subject to control by RosPotrebNadzor;

- providing first aid to victims;

- study of all types of devices - transformers, inverters, generators;

- electrical safety and electrical engineering course.

Normative base

The regulatory framework used in drawing up the training program and organizing the training process for welders:

- Order of the Ministry of Labor and Social Protection of the Russian Federation dated November 28, 2013 N 701n “On approval of the professional standard “Welder”;

- Resolution of the State Construction Committee of the Russian Federation dated January 8, 2003 No. 2 “On the Code of Rules “Labor Safety in Construction. Industry standard instructions on labor protection";

- SNiP 12-03-2001 “Labor safety in construction. Part 1. General requirements";

- SNiP 12-04-2002 “Labor safety in construction. Part 2. Construction production";

- SNiP 12-03-2001 “Labor safety in construction. Part 1. General requirements";

- SNiP 12-04-2002 “Labor safety in construction. Part 2. Construction production."

Description of the course. What is included in the theoretical and practical parts?

Welding training is provided in colleges and specialized courses. Having completed welding school, the student receives the necessary knowledge. The cost of training depends on the region, the prestige of the institution, and the rank received. There are also advanced training courses for welders who have already received rank and experience.

To learn to become a welder, it is not enough to obtain only theoretical knowledge; it is also necessary to consolidate it during industrial practice.

Upon completion of the training course as a gas or electric welder, exams are taken on the theoretical and practical parts of the profession. If the test is successfully passed, the student receives a standard diploma.

What do you need to work independently?

To earn extra money (or work full-time yourself), you will need:

- Helper. You can get by, but either the work will be much more difficult, or you won’t be able to work with large/heavy workpieces. As an option, you can find someone with a free schedule. There is an order - we call an assistant. No, we don’t call.

- Transport - to transport equipment, materials, finished products.

- Overalls + shoes and protective equipment (mask, mittens, respirator).

- Welding inverter. Since the most common technology for simple tasks is manual arc welding, an inverter is the easiest to buy for a beginner. In the Svargaz store you can find lightweight (up to 6-10 kg) welding inverters by following the link. Budget models, which are enough for most household tasks, cost $200-300. Instead of an inverter, you can take a transformer - larger, but also more reliable.

- A generator (it’s worth taking if you plan to cook not in your garage/workshop, but on the road, where there won’t always be an outlet). Ideally - synchronous or hybrid (they are quite powerful and can withstand a high starting load, unlike asynchronous ones). For beginners, gasoline is better: there is a larger selection, they work more stable at low power, and work better in cold weather. The price of a high-quality model starts from 20-25 thousand rubles. Diesel engines are better only because they are more economical.

Conditions of education

Institutions offer several programs to study to become a welder, each will cost a separate amount - depending on the duration . The term is taken in accordance with the level of existing education, specialty and form of study:

- education based on 9 grades;

- secondary (11 grades);

- increasing the existing rank;

- retraining - for example, training to become a gas welder or an electric welder.

Forms of training:

- individual;

- group;

- full-time

People with disabilities and people with disabilities can be trained to be welders with an extension of no more than six months.

Where can I get a welding profession?

The profession can be obtained at any technical school or college, where the specialties “Welder of electric and gas welding works” and “Operator of welding and gas plasma cutting equipment” are offered. Training takes place on the basis of 9 or 11 grades of secondary school, and the duration of the course depends on the educational institution. In schools, studies will last 3 years (for graduates of 9 classes) or 2 years (for 11 classes), and in technical schools and colleges - 4 and 3 years, respectively. The ranking of the best educational institutions of secondary specialized education by specialty includes:

- College of Architecture, Design and Reengineering No. 26 (Moscow);

- Petrovsky College (St. Petersburg);

- College of Water Resources (St. Petersburg);

- Nizhny Novgorod Industrial and Technological College (Nizhny Novgorod);

- Yekaterinburg Industrial and Technological College named after. V. M. Kurochkina (Ekaterinburg).

During the training process, students study theory, technology and work conditions. Before starting practical classes, they train for a long time on computer simulators, mastering the skills of working with a welding machine. From the third year of study, future specialists can be sent to various enterprises, where they practice the acquired knowledge.

Those wishing to become a gas-electric welder should take into account that access to gas equipment can only be obtained from 18 years of age. Therefore, gas-electric welders need to obtain a specialty directly in production or undergo an additional training course. Professional development will also require passing advanced training courses, the results of which are assigned the appropriate rank (from 1 to 6), and career advancement is often not possible without obtaining a higher education.

Admission to one of the following universities will allow you to obtain the profession of “Welding Engineer”:

- Moscow Aviation Institute (national research university);

- Peter the Great St. Petersburg Polytechnic University;

- Omsk State Technical University;

- Moscow State Technical University named after N.E. Bauman;

- Far Eastern Federal University.

Image sources: besplatka.ua, 74.ru, mirkosmosa.ru, gazeta.naftan.by

National Mineral Resources University "Mining"

Saint Petersburg

[22.03.01] Materials science and materials technology

| Type | Form | Price |

| Bachelor's degree | Full-time | 260 000,00 ₽ |

Moscow State Technical University named after N.E. Bauman

Moscow

[22.03.01] Materials science and materials technology

| Type | Form | Price |

| Bachelor's degree | Full-time | 257 572,00 ₽ |

Komsomolsk-on-Amur State Technical University

Komsomolsk-on-Amur

[22.03.01] Materials science and materials technology

| Type | Form | Price |

| Bachelor's degree | Full-time | 227 100,00 ₽ |

Russian Chemical-Technological University named after D.I. Mendeleev

Moscow

[22.03.01] Materials science and materials technology

| Type | Form | Price |

| Bachelor's degree | Full-time | 217 400,00 ₽ |

National Research Nuclear University MEPhI

Moscow

[22.03.01] Materials science and materials technology

| Type | Form | Price |

| Bachelor's degree | Full-time | 217 368,00 ₽ |

National Research Technological University "MISiS"

Moscow

[22.03.01] Materials science and materials technology

| Type | Form | Price |

| Bachelor's degree | Full-time | 210 000,00 ₽ |

Moscow Aviation Institute (national research university)

Moscow

[22.03.01] Materials science and materials technology

| Type | Form | Price |

| Bachelor's degree | Full-time | 203 630,00 ₽ |

National Research University "MIET"

Zelenograd

[22.03.01] Materials science and materials technology

| Type | Form | Price |

| Bachelor's degree | Full-time | 195 000,00 ₽ |

Moscow Polytechnic University

Moscow

[22.03.01] Materials science and materials technology

| Type | Form | Price |

| Bachelor's degree | Full-time | 184 800,00 ₽ |

National Research Tomsk Polytechnic University

Tomsk

Directions

Training of masters in the field of welding is carried out with the obligatory development of professional knowledge among students in the areas of:

- planning and management of technological processes;

- organization of welding work in industrial enterprises;

- development of equipment and technological equipment and others.

The objects of future activities when training a welding specialist are:

- technical processes for the manufacture, installation and maintenance of welded structures and products;

- development and reading of technological maps and processes;

- rules for working with specialized equipment and materials.

Responsibility for failure to complete training

Part 1 of Article 9.1 of the Code of Administrative Offenses of the Russian Federation provides for the imposition of a fine for violation of industrial safety requirements or the conditions of licenses for carrying out activities in the field of industrial safety of hazardous production facilities, which fully applies to welding work, in the amount of:

- for employees from 2000 to 3000 rubles;

- for officials from 20,000 to 30,000 rubles or disqualification for a period of 6 to 12 months;

- for legal entities from 200,000 to 300,000 rubles or administrative suspension of activities for up to 90 days.

Accelerated courses for welders 1-6 categories

Accelerated courses are also in demand, allowing one to study to become a welder using a “short” program and presupposing that the student has a certain rank, qualifications and knowledge.

Welders are assigned a certain rank, indicating how much knowledge the worker has in a certain area:

- Master in welding plastic products. His responsibilities include installation and disassembly of structures, performing preparatory work, and welding plastic elements.

- Master of thermite welding, proficient in reading blueprints, arc and plasma technologies.

- Master of RDS.

- Master of arc and plasma welding.

- Specialist in connecting complex elements and assemblies - vacuum structures.

- A general master who knows all welding methods at a high level.

A 6th category specialist can work in any industry, including the gas and oil industries.

Disadvantages of being a welder

Very often, heavy physical activity negatively affects the health of the welder. Often a specialist has to work in uncomfortable positions in dangerous areas under adverse weather conditions. Over the years, respiratory problems and vision problems may occur. Negative working conditions also include the need to constantly use protective clothing and a mask. Although they provide protection from the harmful effects of welding , it is inconvenient to work in it.

Before applying for high positions and decent wages, a specialist will have to go a long way, honing his skills and abilities for years. Most aspiring welders find jobs at utility companies, which, according to statistics, have the lowest wages in the profession. On average, such an employee can count on a salary of about 20 thousand rubles.

Prospects and opportunities after training

Specialists of each of the categories described above are in demand in the labor market, receive high salaries, and are valued by enterprise management . They are not left without work - organizations and manufacturing companies are in constant competition for highly qualified craftsmen, offering them the best conditions.

Employee salaries depend on the specifics of the company. The higher the level of complexity of the work, the higher the payment. Obtaining a narrow specialization and advanced training significantly increases the value of an employee.

The next level of training is admission to a technical university and obtaining a specialty as an engineer.

Nikolay Samusev, electric and gas welder, 15 years of work experience: “In the labor market, the most valuable are craftsmen who know several methods of performing welding work. They perform the duties of several specialists at once in an organization or enterprise and receive high wages for this.”

Salary and career

There is a shortage of technical specialists in Russia, so the salary of a first-class welder can exceed the income of a middle manager. Young specialists receive about 20,000 rubles, the salary of experienced high-level workers (the sixth highest category, assigned to highly qualified specialists) averages from 30,000 to 45,000 rubles monthly. But, as with other professions, the amount of a welder’s salary depends on the place of work, experience, hard work and desire to constantly improve their skills. Thus, the lowest salary for specialists is in the housing and communal services sector, and the highest in the oil and gas industry.

Typically, college graduates do not have to look for a job for a long time. Welders without experience are accepted into private service organizations and housing and communal services. With the acquisition of experience, young specialists are already entrusted with more responsible tasks and work in industry and construction sites.

What is a welding inverter and how does it work

This device was called an inverter because it converts alternating current of a 220 V network with a frequency of 50 Hz into high-frequency oscillations, and then into direct current. At the same time, the device has a high efficiency: about 85-90%, and even under fairly heavy loads the counter “winds” a little. In any case, you won’t have to pay crazy bills. The consumption will be slightly higher than without welding, but not by much.

This small box is an inverter welding machine

Yandex.RTB RA-1479455-2

Most inverter welding machines operate from a 220 V household network (there are also devices from 380 V). And this is one of their advantages. Moreover, they have practically no effect on it, i.e. do not reduce tension. Rest assured about your neighbors: they won’t even know that you are welding. The second important advantage is that they can work more or less normally at reduced voltage. Of course, you need to look at the specifications, but at 170 V, most of them still allow you to work with a 3 mm electrode. This is very important especially for rural areas, where low voltage is the norm rather than the exception.

What’s also good for beginners is that it’s easier to get and hold an arc when using inverter welding. And in general, according to many, it cooks “softer” and has a “lighter” arc. So if you want to learn how to cook, try inverter welding first.