Manual guillotine shears for metal

Work related to cutting iron sheets is carried out in almost all enterprises and organizations related to production, equipment repair, mechanical engineering and other metalworking industries. To increase the efficiency of work, it is recommended to buy a guillotine for processing sheet metal. Depending on the volume of metal parts, their thickness, size, as well as batch volumes, various types of guillotine machines are used. One of the simplest, most affordable and quite effective devices is a manual guillotine for cutting metal.

Guillotine shears

This section “GUILLOTINE SCISSORS” discusses the type of equipment used to cut sheet metal to the required overall characteristics (size). Those. Before you start producing a particular product, you will have the task of preparing the necessary blanks (component elements) to size. To solve this problem, a wide range of equipment is used, depending on the range and type of metal you use. In particular, one of the most common and indispensable subclasses of equipment used in the procurement and metalworking industry when working with sheet metal are machines such as guillotines or, more correctly, guillotine shears. Guillotines were used in office work long before our century, and since then it has been practically impossible to cut sheet metal, whether in serial or single production, without guillotine shears.

In order to understand the level of demand and necessity of this type of equipment, we will try to indicate at least some sheet metal products used in such industries as manufacturing, construction, agricultural, municipal or service industries: various configurations of boxes, tanks, casings, panels, additional and facing elements, signs and decorative overlays; all types of metal roofing and related additional elements, any types of construction auxiliary elements made of metal (beams, profile systems, gussets, cable channels, etc.); various ventilation and drainage systems for industrial and private use; typesetting elements for the construction of more complex, composite products made from sheet metal; facade and window additional elements (ridges, slopes, wind and cornice strips, ebbs, flashings, etc.).

Unfortunately, it is not possible to list all the items and products in the creation or production of which machines such as guillotine shears are involved, but we can safely say that practically no process of procurement and metalwork production will be full-fledged, excluding from it such a necessary type of equipment for cutting metal like a guillotine.

Despite the apparent simplicity of the functionality of a guillotine-type cutting machine, its structure and design includes a complex and very metal-intensive mechanism. As a rule, despite the many modifications of guillotine shears, a machine of this type includes the following main elements: a massive and rigid frame (machine bed), gear part (machine drive), flywheel (or eccentric in the manual version), table (with the ability clearance adjustment), upper running beam, clamping mechanism, knives (top and bottom), back stop, control system.

The main characteristics of guillotine machines in terms of the parameters of the material used are the width and thickness of rolled sheets, as well as the maximum and minimum sizes of the cut workpiece. Based on the type of drive device for guillotine machines, the following main subgroups can be distinguished: manual (foot), electromechanical, electrohydraulic and pneumatic. Due to their high metal consumption, guillotines are mainly intended for stationary use at production and construction sites, with rare exceptions when small models of guillotine machines imply in their design sufficient mobility and the ability to operate in various climatic conditions.

When approaching the issue of choosing a guillotine shears machine, you need to understand that this type of equipment, despite its apparent simplicity, is a rather specific and complex device, so you need to understand that the design and specific operation of the machine must fully comply with the parameters of your products, including overall dimensions the sheet used, as well as parameters characterizing the productivity of the work, the tolerance of dimensional deviations, the quality of the surface after the work is completed, the possibility of sorting chopped metal, the presence of automatic adjustment of the knife gap, etc. Taking into account all the requirements formed when choosing the felling equipment you need, you can easily select an indispensable assistant in your office work, thereby ensuring high productivity and rhythm of work.

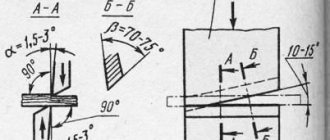

Design features of guillotine shears

A manual guillotine for rolled metal is one of the types of cutting devices. There are also foot, mechanical, electromechanical, hydraulic guillotine machines. Each of these devices has its own advantages and features of use when processing metal workpieces.

Structurally, this is a fairly simple device, which, nevertheless, effectively performs the assigned functions - namely, cutting sheet iron (steel, stainless steel, non-ferrous rolled products) into blanks of a certain shape and size. By purchasing this equipment at a low cost, you will be able to produce high-quality metal products without additional costs (workshop rent, electricity, etc.).

Lever guillotine shears consist of the following main elements:

- frame, bed with a working surface of a certain size

- upper cutter

- bottom cutter

- limiting devices

- clamping mechanism

- graduated stop

The simplest type of units at reasonable prices is guillotine shears. The mechanism is driven by the muscular strength of the hands. Externally, the design of the machine looks like a regular table on which the cutters are mounted, and the control (laying the metal workpiece on the table top, marking the cutting line and, finally, the process of cutting the sheet itself) is done manually. When deciding to buy a manual guillotine for cutting metal sheets, you should consider a number of features:

- when cutting sheet metal, it will be necessary to apply a certain mechanical force, which will increase in direct proportion to the thickness of the sheet and the length of the cutting line;

- the thickness of the workpiece will be small compared to other types of machines, but you can buy this mechanism at an affordable price;

- In addition to thin sheet steel, the guillotine bed can process workpieces made of plexiglass, plastic, and rubber

Types and features of guillotine mechanisms

Among the proposed models, we can highlight samples with mechanical and electromechanical drives. They are in demand in industrial production, where metal cut into blanks is used in the manufacture of cars, river and sea vessels, as well as in the assembly of large metal structures. Anyone can choose the right piece of equipment that is optimally suited for the stated purposes from the following incomplete list of guillotine shears (NG):

• NG 12-2000.

• NG 13-2000.

• NG 16-2000.

• NA 3214, as well as other models.

Scope of application and price

A manual lever guillotine is used both for cutting metal (there is a significant limitation on thickness) and for a number of other flat materials (plastic, rubber, plexiglass, etc.). It is advisable to buy a manual guillotine when performing small-scale work. The popularity of the product and low cost make it possible to quite often find such an installation in the personal household of a home craftsman or in the garage of a private owner. Small construction companies engaged in roofing work can also buy the unit. Often, the purchase of guillotine cutting equipment of this type is carried out in car services, repair shops, small enterprises and organizations working in the housing and communal services sector, mechanical engineering, and other industries related to metalworking.

Having purchased a product with this drive, you have an advantage, since the price of manual lever guillotine shears for cutting sheet metal is significantly lower compared to other types of machines used for processing rolled metal.

It is important to choose and buy the right type of knife and that the price is low. The quality of cutting or chopping the sheet will depend on its strength, reliability and durability. As a rule, high-strength steel alloys are used, and in some cases, knives based on chrome alloys. The most common knife sizes:

- length: from 100 mm to 3.0 m

- width: 50 – 220 mm

- thickness: 10 – 120 mm

Types of guillotine shears

There are many types of guillotine shears available. The equipment is distinguished by the type of drive, the shape of the working cutting tool, and technical parameters. The most common classification of devices is by type of drive. There are:

- Manual guillotines for cutting metal.

To increase the force, a long lever with a transmission mechanism is used. - Hydraulic equipment

. The power unit of the devices is a hydraulic system, which allows the development of force sufficient to cut thicker metal. - Pneumatic shears

. Equipment of this type is installed on profiling and other machines, as well as separately. A compressor is required to operate the shears. - Electromechanical

. An electric motor is used to drive such equipment. To increase the cutting force, gearboxes are used.

Let's consider the design of each type of guillotine shears and the scope of application of the equipment.

Manual guillotine shears

Manual guillotine shears are used in piece or small-scale production. The equipment consists of:

- From the frame on which the remaining equipment components are fixed.

- From a work table to place the workpiece, a clamping fixture can also be placed on the table.

- From a lever or foot drive to develop force and transfer it to the cutting tool.

- From movable and fixed knives for cutting metal.

Manual guillotine MOBIPROF for radius cutting

Models with long cutting lengths are made on 2 stands. The operating principle of such machines is no different from other guillotine shears. To increase the force transmitted to the knives, the design includes a transmission mechanism with a gearbox.

Manual guillotine shears are used for cutting metal from 0.35 to 4 mm; there are models for cutting rolled products with a thickness of more than 10 mm.

Based on the type of knives, straight and shaped cutting equipment is distinguished. The first is used for direct cutting of metal. Radius cutting scissors allow you to cut profiled workpieces. Due to the shape of the knives, such products are not damaged.

The main advantages of manual equipment are low price, ease of maintenance and repair. The equipment is used in workshops, workshops, directly on construction sites, that is, wherever it is suitable in terms of technology and productivity.

Hydraulic guillotine shears

Hydraulic guillotines for metal cutting are designed for serial and mass production, as well as cutting metal of considerable thickness. A hydraulic pump with an electric motor is used to drive the equipment.

Hydraulic guillotine MOBIPROF

Hydraulics allow you to develop significant forces; hydraulic shears cope with thick rolled metal and a large volume of work. Smooth movement of the knife along the entire length of the workpiece ensures high quality cutting lines. Due to the smooth action and significant force, a high-quality cutting line is obtained, without sharp protrusions and burrs.

The equipment can be equipped with:

- CNC unit for automated production.

- Laser illumination of the cutting line.

- Precise servos.

- Hydraulic or pneumatic clamping system.

- Automatic or semi-automatic feeding systems for sheet or coil metal.

Hydraulic guillotines for metal cutting are also equipped with photo sensors, automatic locking and other modern safety systems. Computer-controlled machines can work in conjunction with other equipment, allow you to set the sizes of segments, and count the number of workpieces.

Electromechanical guillotine shears

Electromechanical equipment for guillotine cutting of metals is intended for small-scale, serial and mass production. The equipment is driven by an electric motor with a gearbox.

Machines of this type can also be equipped with automated control units, as well as:

- Illuminated cutting line.

- Pressing devices of various types.

- Modern operator safety systems.

- Devices for feeding and receiving metal sheets.

- Foot pedal for turning on when manually feeding the workpiece.

The cutting force of electromechanical machines is less than that of hydraulic ones. Guillotine shears with such a drive are used for cutting metal of smaller thickness. The advantages of the equipment include high productivity and accuracy, the ability to coordinate work with other equipment.

Pneumatic guillotine shears

Pneumatically driven metal cutting equipment is used in small-, medium-scale and mass production. They produce models for installation on other machines, for example, profiling machines, as well as a separate installation.

Pneumatic guillotine MOBIPROF

Shears with pneumatic drive:

- Easily amenable to automation. On stand-alone machines you can install position sensors for knives and parts, CNC units for synchronization with other equipment and automated production.

- Develop significant effort. There are models of guillotine shears with pneumatic drive for cutting metal more than 10 mm thick.

The machines are also equipped with a remote control panel and security systems. Pneumatic equipment has high performance and can work with other machines and autonomously.