A hydraulic pump is a device that converts the mechanical energy of an engine into oil energy, with the help of which fluid can move vertically, horizontally, or in a circle, depending on the type of operation of the device.

The operation of the high pressure hydraulic pump is based on the piston-piston principle, and is quite simple and stable. The liquid can be taken from any source or reservoir.

Areas of application of the high pressure pump.

Due to their durability and high performance, hydraulic pumps are used in a large number of industries:

• Cleaning from dirt using a powerful jet of water supplied at high pressure

• For street cleaning

• Submersible and engineering pumps

• To clean pipes from contamination

• For extinguishing fires.

But in reality, most examples of the use of such a device are seen in car washes, where they are used to quickly and efficiently clean a car from various types of contaminants in order to wash off the detergent.

You can select the necessary accessories for high-pressure pumps, including sprayers, pressure regulators, and other devices with which you can configure the device as you need.

The high pressure hydraulic pump converts mechanical energy into hydraulic energy. Regardless of the device model, the principle of pushing out liquid is the same. They are divided into several types:

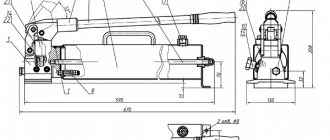

Design and diagram of a manual hydraulic pump

Diagram of a hydraulic hand pump

The manual hydraulic pump consists of two main parts, the pumping unit (1) and the hydraulic tank (2). They are connected to each other by a pin (3). You need to fill the liquid through the hole, having first unscrewed the plug that closes it (4). The handle (6) with the lever (7) drives the plunger (8) of the first and second stages, made as one part. The pumping unit has a two-stage structure. Stage number one, with reduced pressure and higher productivity, serves to accelerate the movement of the hydraulic cylinder plunger. Stage number two, at high pressure and lower capacity, serves to obtain the operating force of the actuator. Overload protection is provided by a safety valve (9). Pressure is released and hydraulic fluid is extracted from the cylinder cavity into the tank using a screw (10).

NSh 50 – areas of application of the pump

This automatic pump is successfully used in the construction of road, agricultural and machine tools. It is often used in hydraulic systems operating at a pressure of 155 kgf/cm2. This model is currently produced by several manufacturers.

The products of each of them have many similarities in design and performance, but differ in size.

Pump specifications include:

- Working volume – 49 cm3;

- The rated speed is 3 thousand rpm;

- Rotation performance 1200 rpm. – 56 l./min.;

- The nominal outlet pressure value is 16 MPa;

- The maximum outlet pressure indicator is 21 MPa;

- Weight – 8 kg;

- Efficiency indicator – 0.95.

A hydraulic pump station equipped with such a unit will last a long time, regardless of the conditions and type of liquid.

Working principle of a manual hydraulic pump

Before starting to work with any pump, be sure to inspect the tool and if cracks and chips are found on the surface, do not use it. It is important to check whether the high pressure hose is tightly connected to the hand pump.

Work algorithm:

- We connect the pump to the hydraulic system with a quick-release coupling;

- Turn the valve all the way clockwise.

- Using progressive movements, pump the pump handle up and down. As a result, oil is pumped into the system from the pump. At the same time, pressure builds up in the system, and the piston of the hydraulic tool moves, into which we pump oil.

- In a situation where the working piston of the system into which oil is poured reaches its final position, increased pressure will be created in the system, as a result it will be impossible to pump oil. Then it is necessary to stop the pump to avoid failure of the device.

- In order to lower the pressure in the system, you need to slowly turn the valve all the way counterclockwise. As a result, oil from the system will flow back into the pump. This occurs due to the return of the piston to its original position.

- After finishing pumping oil, you should inspect the hydraulic system for oil leaks, and you should also inspect the pump. If leaks are found, they should be corrected immediately.

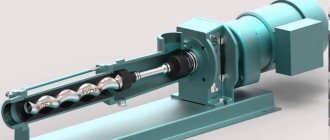

Hydraulic motor

Like a cylinder, a hydraulic motor is a drive, only a rotary drive.

The principle of operation of a hydraulic motor is exactly the opposite of the operation of a hydraulic pump. The pump pumps fluid and the hydraulic motor is powered by this fluid. As we wrote earlier, a hydraulic pump converts mechanical energy into pressure energy and kinetic energy of the fluid. The hydraulic motor converts hydraulic energy into mechanical energy.

With hydraulic drive, pumps and motors work together. The pumps are mechanically driven and force fluid into hydraulic motors.

The motors are driven by fluid from the pump and this movement in turn rotates the mechanical parts.

Malfunctions and their elimination

- The manual hydraulic pump does not supply pressure. The main reasons for this behavior may be the lack of hydraulic fluid in the tank or the drain valve is not closed. In any case, it is worth checking these versions; if the tap is still closed and there is liquid, then perhaps the reason is that the suction or discharge valve is clogged. Then you will have to disassemble and wash the hydraulic pump valves.

- Oil (hydraulic fluid) is leaking in the gap located between the body and the plunger. In this case, it is highly likely that the O-rings are worn out or damaged. It is recommended to replace them immediately to prevent failure.

- Does not produce the performance specified in the data sheet. Most likely the filter element of the manual hydraulic pump is clogged. It is recommended to thoroughly rinse the filter element.

- Does not develop the pressure specified in the technical data sheet. The safety valve is not adjusted correctly. You need to set the safety valve to the pressure indicated in the data sheet.

Where are hydraulic pumps used?

Hydraulic pumps are distinguished by their solid performance and durability, which allows them to be used in equipment from various fields of industry. The high pressure they create allows this type of equipment to be used in the design of excavators, bulldozers and other machines operating in the service of utility companies for:

- cleaning sidewalks and road surfaces;

- ensuring the operation of engineering and submersible pumps;

- cleaning pipes from dirt;

- extinguishing fires.

A pressure pump can often be seen in car washes. It helps to quickly clean the car body of dirt and wash away detergent. For this purpose, the hydraulic pumping station can be equipped with nozzles that allow it to be adjusted to the required operating mode.

How to choose the right hydraulic manual pump?

Choice

Three main selection factors:

1. The hydraulic pump tank must be larger than the hydraulic cylinder capacity.

2. Manual hydraulic pumps come in two types: single-acting and double-acting, pay attention to this parameter.

3. The pressure level should match what you need for work. Select a hydraulic pump with a pressure equal to or greater than the maximum pressure of the hydraulic cylinder.

NSh 10 – description of a popular model

The unit of this model is successfully used in the automotive industry, in the manufacture of tractors and other types of heavy agricultural equipment. It is often included in the design of domestic loaders and excavators created on the basis of tractors of the 1.4 tf class.

Among the main technical characteristics of the pump, the following should be highlighted:

- Working capacity – 10 cm3;

- Rotation speed – 3600 rpm;

- Maximum productivity – 11.5 l./min.;

- The nominal outlet pressure is 16 MPa;

- The maximum permissible pressure is 21 MPa;

- Weight – 2 kg;

- Efficiency indicator – 0.95.

Due to its high reliability and excellent build quality, this pneumohydraulic pump has proven itself well in industry. It rarely needs repairs and does not require regular maintenance.

Is it worth making a manual hydraulic pump yourself?

At the moment, hand-made pumps are almost never found. Despite this, you can make a hydraulic pump with your own hands. We will need a steel tank. The body will be made from it. To control the pressure in the tank you need a valve. It needs to be secured at the top with a washer. A lever is installed to control the closing valve. A cast iron pipe may be suitable. Use a pressure gauge to monitor pressure. In the end, you will end up with a device that will not withstand pressure of more than 4 atmospheres. With all this, a homemade hydraulic pump will take up a lot of space and be inconvenient to carry. The disadvantage of homemade hand pumps is their low efficiency; quite a lot of force will be required to activate the pump. Also, homemade devices are very unreliable. And if you take into account all the disadvantages, then spending resources on creating a homemade manual hydraulic pump is very ineffective. That is why they are not common.

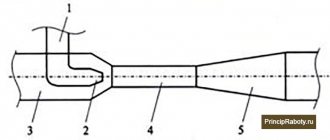

Hydraulic pump device

Pressure pumps consist of the same set of internal parts. The difference between them lies only in the materials and sizes of components. The design of the device includes:

- shaft;

- connecting rod;

- sealing system;

- piston;

- piston skirt;

- hinge;

- cylinder block;

- thorn;

- case cover;

- window;

- disk;

- spring.

Depending on the modification, the electro-hydraulic pump can be equipped with adjusting mechanisms. They allow you to set the speed of water pumping for more efficient operation of equipment in certain conditions.

Manual hydraulic pumps NRG

NRG hydraulic pumps are very reliable devices and are very common here in Russia as they are produced here. The NRG line of pumps contains devices with distributors. The letter “P” is usually placed at the end of the designation of such instruments. This letter means that the tool can work with double-acting hydraulic devices. Let's consider several models of NRG manual hydraulic pumps:

NRG pumps

- Model nrg-7020R. Creates a maximum pressure of 700 bar. And it has a nominal tank volume of 2 liters. The kit includes a hydraulic distributor that allows you to work with both single- and double-acting devices.

- Model nrg-7007. Also creates a pressure of 700 bar. The nominal tank volume is 0.7 liters. The advantages of this model are the presence of a safety valve, minimal force on the handle, and two stages of oil supply. This tool is designed for single-acting hydraulic tools with a spring return rod.

- Model nrg-67016R. The nominal tank volume is 14 liters. Handle force 55 kg. Pressure maximum 4 MPa. Capacity is 115 cubic cm. Such a device weighs as much as 30 kg and is quite large. Suitable for a small car service.

Technical characteristics of the model NSh 32

Most excavators are equipped with these pumps. Moreover, more than half of the excavators created on the basis of MTZ and YuTZ tractors have a pump mounted on the front circuit. This guarantees improved performance of the machine with bucket and bulldozer. Older chain tractors were equipped with NSh 32 pumps to ensure the operation of the bulldozer cylinders and supports.

For tractors created on the basis of MTZ, pumping equipment is responsible for the operation of the bucket, grab and boom.

Pump specifications include:

- Working volume – 31.7 cm3;

- The rated speed is 3 thousand rpm;

- Performance indicator at 1200 rpm. – 36 l./min.;

- Nominal outlet pressure – 16 MPa;

- The maximum outlet pressure is 21 MPa;

- Pump weight – 5 kg;

- Efficiency indicator – 0.95.

The unit of this model is characterized by high reliability and long service life. Thanks to this, it is actively purchased by foreign manufacturers of agricultural machinery.

Summary, pros and cons of hydraulic hand pumps.

Pros:

- Easy to use;

- Do not require any additional energy source;

- High maintainability;

- Have high mobility;

Minuses:

- Low performance;

- Muscular strength of the operator is needed, therefore, additional load on the operator;

Bottom line, it is reasonable to use a manual hydraulic pump in small workshops and mobile services, where there is no need to pump in large volumes of oil and build up significant pressure. In general, hand pumps are very convenient, and most importantly, they are mobile since they do not depend on any energy sources.

NP 90 pumps - purpose and characteristics

This unit belongs to axial piston pumps with an adjustment function. It is used when operating large hydraulic drives that include a motor. Units of this modification are widely used in the creation of combines, road compactors and concrete mixer trucks.

NP 90 pumps are easy to operate and small in size. They are durable, do not require special care and are not afraid of extreme conditions. Among the technical characteristics of the pumps, the following should be highlighted:

- The maximum working volume is 89;

- Charge pump capacity – 18.06;

- The nominal outlet pressure indicator is 26.5 MPa;

- The maximum outlet pressure value is 35.8 MPa;

- The maximum speed is 2590 rpm;

- Empty weight – 78 kg.

This model is in wide demand due to its excellent configuration and high build quality. It is well balanced, does not require frequent repairs and is much cheaper than its imported counterparts.

Valve symbols – 2

2) FLOW DISTRIBUTION VALVE

Check valve

A check valve opens to allow oil to flow in one direction and closes to prevent oil from flowing in the opposite direction.

Spool valve

The control spool valve symbol uses a complex closed system that has a separate rectangle for each position.

Four-hole valve

Typically a four-hole valve will have two compartments if the valve has two positions, or three compartments if the valve has a center position.

Lever control symbols

Lever control symbols represent a lever, pedal, mechanical controls or pilot line located on the edge of the compartment.

Line (stream) symbols

Working, pilot and drain lines

A hydraulic hose, pipe, or other conduit that moves oil between components of a hydraulic system is indicated by a single line.

The working line (suction, discharge and return) is indicated by a solid line.

The pilot line is indicated by a dotted line with long dashes

The drainage line is indicated by a dotted line with short dashes

Connection/Transition Lines

To show that two intersecting lines are not connected, we use a short loop on one of the lines at the intersection.

The connection between two intersecting lines should be indicated by a dot at the junction.

Miscellaneous

Tank

A rectangle with a long side horizontally is a symbol of a tank. The open top symbol indicates a vented tank. The closed top symbol indicates a sealed tank.

Battery

The accumulator is oval in shape and may have additional parts to indicate spring pressure or gas charge.

Oil cooler

The oil cooler is shown as a square, rotated 45° and has connections at the corners.

Filter/Strainer

Dotted line inside a rotated square