Main goals

A water valve is usually used simultaneously with surface pumps when organizing individual water supply systems.

Purpose of shut-off valves:

- Stabilizes blood pressure. In houses, cold and hot water supply passes through different pipes and due to the difference in pressure, cold water may not be squeezed out into the mixer. This prevents normal temperature regulation. The non-return valve stabilizes high pressure, allowing you to adjust the temperature.

- Protects the pipeline from pressure drops and hydraulic shocks, and the water supply itself from unforeseen situations and subsequent repairs.

- Does not allow reverse circulation of water.

The last function is especially relevant for sewage systems. A non-return check valve blocks the backflow of wastewater, preventing it from exiting the toilet or sink.

Where is it recommended to use check valves?

These elements are required to be used in the water supply system. In addition, they are indispensable in sewer lines, heating devices, pipes near water meters, in pipe branches in water heating devices, and plumbing units. Shut-off valves in the heating system eliminate the supply of reverse flow, which is important during the operation of water heating devices.

Installation location

Sewer and water systems are not the only places where installing a valve is a necessity. Other areas are:

- Autonomous heating system circuit. The rooms where heating radiators or heated floors are located differ radically in hydraulic and pressure indicators, and therefore require the installation of automatic shut-off valves. The device fits in front of the boiler and allows you to balance the technical indicators.

- Water heater inlet. A check valve installed in front of the boiler prevents the hot water mass from moving back into the cold water pipeline.

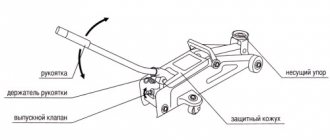

- Submersible pumps. If the water supply system is connected to a well or borehole, it is important to install a submersible pump. Its main task is to lift water masses from depth and transport them under pressure to the house. When there is a power outage, the pumped water naturally flows into the pressure tank. To avoid this, a shut-off valve must be installed in front of the pump.

- In front of the water flow control meter. All metering devices, in particular the household water meter, are especially sensitive to disturbances and changes in water supply. Water hammer has a negative effect on the device, up to its failure. Also, the locking device prevents the turbine from turning in the opposite direction.

The safety valve does not allow reverse circulation of water in any of the cases described above.

How fittings work

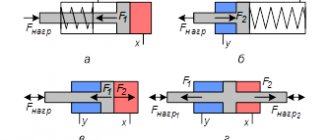

Let's figure out how the check valve works. There is nothing complicated about it. While there is no flow inside the device, the shut-off element seals the pipe. As soon as the valve opens and water begins to move inside the housing, the pressure of the liquid turns the mechanism and moves the lock. As long as the pressure is high enough, the locking element is held in the open position.

During normal operation of the fittings, water under pressure flows in a given direction. It is indicated on the device body with an arrow. When the pressure drops to minimum values or the flow changes direction and tries to flow back, the mechanism is triggered and the lock is lowered into the housing opening. It completely blocks the movement of fluid. Thus, the fittings prevent the flow from moving in the opposite direction and maintain normal pressure inside the system.

Instagram neptunrussia

Instagram satsyk.kostya

Description of devices

The check valve looks pretty simple. Inside the structure there are the following main elements:

- a small spring that functions as a delay mechanism for the bolt mechanism;

- shutter with seal - can be made of durable plastic or steel;

- a metal body (usually dismountable for ease of maintenance), consisting of two threaded parts.

Today there are a large number of locking mechanisms. Taking into account the design, the device can be supplemented with the following auxiliary elements:

- stem;

- pin on hinges;

- ball bearings;

- springs;

- elastomers;

- disc levers.

To choose the right locking element, you need to take into account the design of the system and the main purpose of the installation.

What does this valve consist of?

In addition to the body, the valve contains a small spring, a shutter, and a seal. Depending on the material from which the element is made, the modification of the device, manufacturers supplement check valves with springs, levers, bearings, and other auxiliary elements.

Principle of operation

The work is based on the elementary laws of hydrodynamics and physics. When liquid stops entering the pipeline, the spring completely closes the valve . When pressure and pressure appear on the valve, the spring weakens, allowing water to pass through. After turning off the pump and reducing the pressure, the shutter mechanism is reactivated. The resistance of the spring increases under the influence of direct pressure. This prevents the valve from opening.

The safety structure in the sewer system has a different operating principle. The valve itself structurally consists of a round plate with a seal, a spring lever and a housing. When water enters the sink, the lever opens. When the pressure drops, the shut-off mechanism closes and prevents sewer water from flowing back.

Advantages and disadvantages

Installing a check valve will allow you to effectively solve the following problems:

- stabilize the operation of the water supply system;

- minimize the risk of air entering the system;

- reduce energy costs if such a device is equipped with a hot water supply system heated by electrical appliances;

- ensure water supply for some time, even when the pump is turned off.

In addition, such devices have the following advantages:

- low weight and length;

- high degree of tightness and reliability;

- ease of installation.

The disadvantages include the fact that the device requires regular maintenance.

Installation methods

To determine which valve to choose, you also need to pay attention to the installation method. It is necessary to determine whether it is suitable for a particular heating or plumbing system:

- Wafer devices are mounted between flanges. They are small in size and inexpensive.

- Flange locking mechanisms. Mounted using special disc-shaped fasteners. As a rule, they are made spherical. Due to their reliability, they can be used even for large cross-section pipes. Made from high strength steel.

- Welded structures are made of steel. They have an absolutely tight connection. Disadvantages include the impossibility of repair and the difficulty of installation and dismantling. Most often used in the energy sector.

- The coupling locks are secured with threads and are therefore easy to install. They are mainly made as disk ones. They are usually installed for water supply systems of private houses.

The tightness of the housing elements in all models is ensured using seals that are located at the connection areas.

Installation technology

Before installing a check valve on water, you need to determine the location of the insert, as well as the technology, which differs for different systems.

Types of fittings

There are several types of check valves available on the market. The principle of their operation is the same, the difference is in the design. Let's briefly describe each type.

Spring

It is considered the most compact variety. It can be disc or double-leaf. In the first case, a metal plate-disc serves as a lock. The spring presses it tightly to the saddle. In this position, the path for liquid is closed. The water flow presses the spring and lifts the disk. When the pressure is reduced, the valve closes. This is the simplest scheme that works well in water supply systems where water hammer is not possible.

If there is a possibility of water hammer, double-leaf structures are installed. They are the same as disk ones, but the locking element, opening the hole for liquid, folds in half. This softens the effects of water hammer. There are models of butterfly valves with special shock absorbers. They are installed in complex hydraulic systems.

The main advantages of spring devices are compactness and low weight. Wafer-type models are especially compact and do not require special flanges for attachment to the pipeline. Spring systems are very easy to operate and install; they can be installed on horizontal, inclined and vertical lines. A significant drawback is that they need to be completely removed for repairs.

Instagram akvatepblg

Instagram teploplas_krd

- Water supply and sewerage

How not to flood your neighbors: 8 tips for renovating your bathroom

Turning

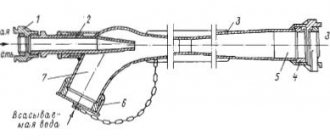

The lock in this design is a spool petal. It is mounted on a rotating axis, which is located above the passage hole. The flow tilts back the valve and opens its passage through the pipeline. If there is insufficient pressure, the petal falls and blocks the hole. If the diameter of the part is large, then the impact of the spool on the seat can be very strong. This contributes to rapid wear of the fittings and can provoke water hammer.

For this reason, larger models are available in a non-impact version. They are equipped with an additional mechanism that gently puts the spool in place. For small devices such devices are not needed.

The main advantage of rotary systems is low sensitivity to the level of contamination of the liquid supplied through them with good tightness. In addition, they can work in large pipeline sizes. True, in this case only unstressed models are used.

Instagram altor_union_minsk

Instagram kupitruby

Lifting

In this design, the passage hole is blocked by a lifting spool disc. A water flow moving under a certain pressure lifts it. When the pressure decreases, the shutter moves down, snaps into place and closes the hole.

The axis where the disc is attached is positioned so that normal operation of the valve is only possible in an exactly vertical position. Therefore, it cannot be installed even on inclined, much less horizontal pipelines. This is an important feature of the lifting structure.

Its main advantage is the ability to repair without dismantling. Cleaning and repair work is carried out through a special hatch with a removable cover. A significant disadvantage of lifting devices is their sensitivity to the level of contamination of the liquid passing through them.

Instagram krasarmaprom

Instagram ayvaz_kazakhstan

Ball

A metal ball is used as a locking element. Sometimes it is covered with a layer of rubber for a better fit to the seat. The ball is spring-loaded, so until liquid is supplied, it blocks the passage hole. The flow puts pressure on the spring and moves it along with the ball. When pressure is reduced or flow is redirected, a spring-loaded ball blocks the passage of fluid.

This is a very simple and reliable design. Can work in horizontal, inclined or vertical pipes. It is universal and can be used for various engineering systems. Some models are equipped with a cover so that they can be cleaned and repaired without dismantling.

Instagram abra_armatura

Instagram abra_armatura

Connection type

Connection of shut-off valves can be:

- coupling - the product has an internal thread and is simply screwed onto the thread on the pipeline;

- fitting - the valve has a pipe with an external thread, it is attached to the pipe using a union nut;

- flanged - on both sides of the valve there are plates with holes for bolts, which are attached to the mating flanges of the pipeline;

- welded – the reinforcement is welded. This type of connection is required where the tightness and reliability of other types of connections are insufficient (in toxic, aggressive, radioactive working environments);

- pin-type - the presence of connecting pipes with threads and a collar on the pipeline and fittings. The end of the pipeline, which has a flange, is pressed against the end of the valve using a union nut. The most obvious example is connecting a hose to a fire hydrant.