Welding rectifier Blueweld Combi 4.135 Turbo

The main structural unit of the welding machine is the power source . The characteristics of this element serve as the basis for the classification of welding installations. The following main types are distinguished:

- transformers;

- rectifiers;

- inverters;

- generator sets running on diesel or gasoline fuel.

Here we will dwell in detail on the features of rectifiers.

*

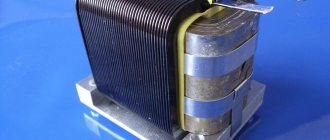

The device, what it consists of

Welding rectifier Telwin LINEAR 410 S

The welding rectifier consists of the following components and blocks:

- power transformer. In design and principle of operation, it is similar to a transformer for alternating current welding;

- rectifier unit on semiconductor devices. To convert alternating current into direct current, semiconductor elements are used: uncontrolled valves - silicon diodes;

- controlled valves - thyristors;

It is advisable to use a three-phase rectifier , i.e., equipped with a three-phase transformer. In this case, the ripple of the rectified voltage will be significantly lower, which increases the efficiency of the welding device and improves the quality of the weld.

Types of devices

There are simply a huge number of varieties of the equipment in question on sale, all of them have their own specific advantages and disadvantages. The classification of industrial welding rectifiers is as follows:

- single-phase;

- two-phase;

- three-phase.

A rectifier for three-phase manual arc welding consists of 6-12 diodes, which are often connected in parallel. Two-phase ones are characterized by parallel and series connection of bridges.

Controlled and uncontrolled rectifiers

In addition, classification can be carried out according to the following criteria:

- Output current. With an increase in this indicator, the thickness of the processed metal increases significantly. If the device produces a small current, then it will be possible to process thin elements. Also, too high a current allows the use of a welding machine for cutting metal.

- Adjustment accuracy. As previously noted, the rectifier can be used to set a wide variety of current parameters. The higher the adjustment accuracy, the more optimal working conditions the master can provide for himself.

- Number of outputs for connection. Sophisticated welding equipment can be used to connect multiple electrode holders simultaneously. A similar model may be needed when several welders are simultaneously working nearby. However, due to the complexity of the design, it becomes larger and more expensive.

- Cooling efficiency. Inexpensive models are intended for domestic use, as they can be used for a short period of time. This is due to the fact that the design does not have an effective cooling system. Professional equipment can be used for welding over a long period.

- Design dimensions. As a rule, welding work is carried out on site. Delivery of all equipment may be difficult if it is heavy and large in size. There are compact models on sale that are easy to transport.

In general, we can say that choosing a welding rectifier is a rather difficult task. When choosing, the conditions under which the work will be carried out are taken into account.

Three-phase models are very popular. This is due to the fact that they can be used to work with metal of a wide variety of thicknesses. A single-point rectifier is most suitable for domestic use, since it is used when using only one electrode holder. There are also models on sale that allow you to connect several electrode holders simultaneously.

Universal modern welding rectifiers are produced by a fairly large number of different manufacturers. Brands largely determine the build quality, service life and cost of equipment.

An inverter rectifier is suitable for domestic use. Such models can be characterized as follows:

- The transformer is responsible for reducing the voltage.

- A rectifying unit is installed, which is responsible for supplying constant voltage.

- Next, it is converted to high-frequency alternating electricity.

Welding rectifier

Such equipment requires the use of alternating current. However, due to a significant increase in the frequency of the supplied current, it is possible to use an inverter rectifier to obtain high-quality connecting seams. Due to the significant simplification of the design, the inverters are relatively small in size and are also easy to operate.

Principle of operation

One of the elements of the rectifier device is a step-down transformer with three windings and a control unit. The most common rectification circuits are single-phase and three-phase bridge, with a full-wave rectifier. The three-phase bridge circuit ensures uniform loading of all phases of the power network and greater arc stability with fewer valves.

When using this circuit, at a certain point in time, two elements connected in series with the load conduct current; in one period exactly six pulsations of electric current occur. Thus, the arc is powered by a direct, rectified current flowing through the secondary winding circuit.

Design and principle of operation

Rice.

1. Design of a welding rectifier The very concept of a welding rectifier was introduced in clause 150 of GOST 2601-84. The design of such a device includes several blocks for implementing various functions, namely:

- Transformer – used to convert alternating voltage and current. In a welding rectifier, these are step-down transformers designed to reduce the 230 V network voltage and proportionally increase the secondary circuit current.

- Rectifier - made of semiconductor elements, usually assembled into a bridge circuit. Switching diodes or thyristors are often used as elements.

- Protection unit – protects equipment from overloads, emergency situations or welder errors.

- Control panel – is a module for adjusting, connecting and monitoring operating parameters.

Rice. 2. Welding rectifier control panel

- Cooling radiator - during the welding process, enormous heating occurs of the current-carrying parts of the secondary winding of the transformer and semiconductor elements. To prevent overheating of the welding device, cooling radiators are installed, in some particularly powerful models with forced ventilation.

- Starting device - designed to start the welding installation, in some situations it can shut down in the event of short circuits and other problems.

- Welding cables with electrode holders are used to supply voltage to the welding site, secure the electrodes, and provide good electrical contact.

The operating principle of a welding rectifier is based on the conversion of electrical energy, both in magnitude and type of current. To do this, the mains voltage, after turning on the starting device, is supplied to the primary winding of the step-down transformer. An electric current will begin to flow in the primary winding, which generates an EMF of mutual induction with the secondary winding. Where its own emf is induced, causing the potential difference at the secondary terminals.

Rice. 3. Operating principle of the welding rectifier

The voltage from the secondary winding will be supplied to the rectifier. A positive half-wave voltage will be passed through one pair of bridge diodes to the load. And the negative half-wave will be passed by another pair of diodes to the electrode and the workpiece. In this condition, the voltage at terminals ‟+‟ and ‟–‟ is present in the idle state without load.

As soon as a load in the form of an electrode and a workpiece for welding is applied to the ‟+‟ and ‟–‟ terminals, a working current begins to flow in the rectifier circuit. Capacitor C is used to smooth the voltage at the output of the rectifier. In addition to capacitance, the circuit may use an inductor to prevent sudden increases in current. Some models of welding rectifier may use a regulator for the operating current.

Purpose

The welding rectifier is a device designed for steel and metal structures; an energy source for the welding arc, using semiconductor elements that converts the alternating current of the network into a direct welding current that does not change its direction and magnitude.

Welding rectifier Brima VDM 1203 (380 V). Photo Welding Technologies

Maintenance and repair

Welding rectifiers require both daily and periodic maintenance. This is the key to trouble-free operation of the equipment. Shift inspection includes the following procedures:

- Insulation inspection.

- Checking the fastening of terminals and grounding.

- Removing dust and dirt from the internal parts of the case.

All detected defects must be corrected immediately.

Symptoms of the malfunction are frequent operation of temperature sensors and increased noise during operation. The reasons may be the following:

- Short circuit of the primary winding of the transformer.

- Failure of the cooling system fan;

- Violation of the insulation of the core sheets.

Operation of faulty equipment is prohibited.

What type of welding are they used for?

Most welding technologies are produced using this equipment. These include MMA (manual arc welding with a coated electrode), MIG (fusion gas welding), TIG (non-consumable electrode argon arc welding). The use of rectifiers makes it possible to weld not only ferrous metals, but also stainless, heat-resistant and heat-resistant high-alloy steels, cast irons, non-ferrous metals, aluminum and titanium alloys.

What electrodes are used

Welding can be done with any type of electrode:

- DC welding electrodes (for example: UONII-13/55 or UONI-13/55);

- universal electrodes (for example: ANO-4, MR-3 or OZS-12);

- special electrodes.

Features of use

The first thing you need to pay attention to if you want to use a rectifier at home is the voltage of your electrical network. It is unlikely that it exceeds 220V, and often the figure is even less. Of course, there are devices on sale that can operate on 220V voltage, but they are rare. Most rectifiers require 380V to operate fully. Such an electrical network is also called an industrial three-phase network. To solve this problem, you need to use a generator that produces 380V.

This is the main drawback of the rectifier. This is a powerful device that gives you a lot of possibilities, and at the same time it is not very expensive. But for it to work, you will have to buy an expensive generator and tinker with the connection every time. It is for this reason that many beginners prefer to buy a low-power inverter and plug it into an outlet, instead of struggling with a transformer or rectifier.

Also keep in mind that for stable operation it is not enough to simply connect the rectifier to 380V and start working. The rectifier (like the transformer) is very demanding on the electrical network itself. It should not only be stable, but also have a power reserve. This is necessary to ignite the arc and ensure its stable combustion.

Also keep in mind that it is not so easy to ignite an arc with a rectifier, even if everything is fine with the voltage in the network. The important thing here is to have the skill or just practice a lot. The rectifier is not equipped with additional functionality such as arc force or hot start. So you will have to light the arc based on your experience and skills.

Differences and advantages of DC welding

Arc welding of steels

Welding with direct current has a number of advantages compared to a similar process with alternating current:

- The welding arc burns stably; the improvement of this indicator is influenced by the absence of zero instantaneous welding current values;

- the depth of penetration has been increased ;

- metal is splashed significantly and losses are reduced;

- the strength of the weld is much higher;

- the number of seam defects is reduced.

Advantages and disadvantages

Modern welding machines are distinguished by good functionality and high power in a modest size. The most compact models are inverter. Experts place them in a separate group. The transformer in such devices occupies no more than a fifth of the total volume.

The main difference between other rectifiers and transformers is that they can generate direct current, while this function is not available for transformers. It is this feature that is the foundation of a large list of advantages of devices with rectifiers:

- the electrode heats up much faster when direct current is applied to it instead of alternating current;

- Unproductive electricity consumption is significantly reduced and, accordingly, the efficiency value increases;

- the arc is characterized by combustion stability;

- uniform melting of consumables is accompanied by a minimum amount of melt splashes. This reduces the likelihood of injury among welders;

- arc stability makes it possible to better control the seam. It turns out to be as smooth and durable as possible;

- The functionality of a welding machine with a rectifier is richer than that of an analogue with a transformer;

- consumption of filler material is reduced. The savings become more noticeable the larger the amount of work performed.

In addition to the advantages, rectifiers also have disadvantages:

- it was not possible to completely eliminate power loss;

- devices with rectifiers perform worse than transformer ones in the event of a drop in network voltage;

- very sensitive to short circuits in the power supply network. They fail at the slightest short circuit in the wiring;

- Most models are not recommended for use in conditions of increased dust or humidity.

Where is the equipment used?

The advantages of DC welding over AC welding allow its use when making critical connections. It is used when welding the following metals:

- heat-resistant, high-alloy, low-carbon, corrosion-resistant steels;

- titanium;

- cast iron;

- alloys based on copper and nickel and much more.

DC welding is widely used in all areas of industry, in large enterprises, construction sites, small workshops, among home craftsmen in country houses and garages.

Advantages and characteristics over transformer devices

Unlike transformers, rectifiers provide much more powerful energy indicators , have a wider range of control limits, they are much simpler and more reliable to use , have less weight and dimensions, are more economical in manufacturing, and, what is undoubtedly pleasant, they are almost silent . Since the current flows continuously, the depth of metal penetration increases, welding proceeds stably, and the strength and quality of the seam increase.

Welding rectifier SiMZ VD-306 ST. Photo 220Volt

Safety instructions for use

Many types of welding diodes cannot work fully if there is excessive dust. Therefore, they need to be blown out before use. One of the most convenient means for this is using a household hair dryer. With its help, you can not only eliminate dust, but also remove moisture, which affects the electrical characteristics of the equipment. This purge must be carried out at least once a quarter.

Diode bridge for a welding machine Source prosvarku.info

If the welding machine has not been used for a year, it must be warmed up before use. To do this, the device is given the opportunity to work a little in all available modes. The time during which this preparation is carried out must be at least two hours.

During operation, the welding machine consumes a large amount of energy. It is important to ensure that it does not overheat. If its temperature exceeds the permissible level, you need to take a break from work.

It is necessary to check the presence of insulation on all conductive parts. If it is broken, it must be restored. The terminal connections must be secure. During operation, the welding machine must be grounded. If it overheats, one of the following may be the cause:

- There is a short circuit in the transformer winding.

- The cooling fan is not working at full speed.

- The core insulation is broken.

- Due to a malfunction in the secondary circuit of the transformer, the operating voltage is reduced.

If any malfunctions are found, they must be corrected before you start using the welding machine.

Repair of a welding rectifier Source kedrweld.ru

Classification by type: multi-post, single-post and others

There are several types of welding rectifiers.

Welding station is a welder’s workplace. Rectifiers have designs that can serve both one post and several at the same time. If everything is clear with one post, then how a group of posts functions without influencing each other needs to be explained.

Welding 4-station rectifier VDM-6303S. Photo VseInstruments.ru

Independence in operation is determined by the constant open circuit voltage of each post . This is ensured by a rigid current-voltage characteristic. With a falling characteristic, a short circuit at a single station would reduce the voltage at other posts and stop welding. Each post has an additional variable resistance to regulate the current.

A multi-station welding rectifier is used in industrial settings . Single-station welders are used by non-professional welders.

Welding rectifier ETA VD-306 B 3x380. Photo VseInstruments.ru

The main property for classifying welding rectifiers is the difference in the characteristics of the output rectified voltage from the welding current. Depending on this characteristic ( flat, steep or universal ), the applicability of the rectifier to one or another welding technology is determined.

Steeply falling characteristic - for manual arc welding with coated piece electrodes, argon arc welding with tungsten electrodes, mechanized submerged arc welding on machines with regulation of the electrode wire feed depending on the arc voltage.

Rectifiers with a flat-sloping characteristic are used for mechanized welding with a consumable electrode in a shielding gas environment or submerged arc, at a constant wire feed speed, independent of the arc voltage. The manufacturer obtains these characteristics by adjusting the transformer, adjusting the inductive reactance of the inductor, or using semiconductor devices. First of all, it is important to know what kind of work the welding rectifier is suitable for and its parameters.

- Transformer. Moving coils are located inside the power transformer. Primary adjustment is made by switching the windings from a star to a delta circuit. Fine adjustment occurs by changing the distance between the windings.

- Transistor. A semiconductor operates on the switch principle. The transistor is configured for a certain current value. In this case, the regulation of the strong current occurs at the expense of the weaker one. This control method expands the range of applied welding currents.

- With saturation throttle adjustment. Typically, the inductor (inductive reactance) is located between the transformer and the rectifier unit. The power transformer produces constant voltage. The use of inductive reactance allows you to change the parameters and the rectifier will already operate on a falling current-voltage characteristic.

- Thyristor. Here the voltage and current are controlled using an electronic circuit. The circuit has a trimming element through which the voltage and current supplied to the electrode at the welding site are adjusted.

- Inverter welding rectifiers. The welding current is adjusted according to a completely different principle. Electronic devices are capable of autonomously regulating high-frequency welding current and avoiding increasing current by reducing voltage.

Inverter rectifier Battleship VD-201I. Photo Welding Technologies

Welding rectifiers are divided into household ones , with a power not exceeding 200 A, semi-professional (power up to 300 A) and professional (over 300 A). Models differ in power, size and amount of energy absorbed.

Welding inverter rectifier Foxweld VD-306I, maximum current – 315 A. Photo VseInstruments.ru

Basic technical data of rectifiers: supply voltage and no-load voltage, maximum operating power, power consumption, type of welding current, electrode diameter, weight and dimensions. Different types of rectifiers are designed for different jobs - for example, VD2-313 is used for two-station arc welding of steel objects, and VDU-506 is a universal rectifier, capable of completing automatic welding machines and powder welding.

Different types of rectifiers are designed for different jobs - for example, VD2-313 is designed for two-station arc welding of steel objects, and VDU-506 is a universal rectifier, capable of completing automatic welding machines and powder welding.

Application of rectifiers

A rectifier for a welding machine is a device that consists of several blocks for converting and rectifying the incoming voltage. During operation, the device also increases the current intensity, thereby ensuring the most favorable conditions. The purpose of the welding rectifier is to generate direct current with a high A value.

When considering the use of a welding rectifier, you should pay attention to the following points:

- The device allows you to carry out welding work using electrodes coated with various substances. Due to the use of coated electrodes, the arc becomes more stable, which provides favorable conditions for obtaining a high-quality seam.

- There are devices on sale that can be used for welding metals up to 50 mm thick. Adjusting the current indicators also allows you to work with metal with a wall thickness of about 1 mm. This point determines that welding rectifiers significantly expand the scope of application of welding machines.

- The welding device can be used to melt the edge of the metal being processed or the rod of the electrode used.

- Many models can be used to handle filler wire. In addition, they are practically irreplaceable when using non-consumable electrodes, for example, the coating of which is made of tungsten.

- When using a welding rectifier, it is possible to connect elements made of stainless steel, cast iron, low-carbon steel or other alloys.

- In addition to welding work, using the device in question, you can cut metals. To do this, a significant increase in the current strength is carried out; the arc burns through the metal.

Compared with previously used transformers, rectifiers can significantly reduce the consumption of electrodes. Today they are quite often built into welding machines, but you can also purchase a plug-in version.

Appearance of the welding rectifier

The device is quite simple to use and is suitable for a wide variety of work situations. The features of use include the following points:

- The device usually has two terminals.

- One terminal is intended for connection to the workpiece, and the second is connected to the holder.

- Depending on the specific pole, the polarity is determined, as well as the most suitable operating modes.

Metal welding occurs when an arc is formed between the surface being treated and the electrode used. The process is relatively simple, but even when using a welding straightener, some difficulties may arise during the work, and only with certain knowledge, skills and experience can the welder obtain a high-quality seam.

Adjusting the welding current

The welding current in the rectifier is adjusted using electromechanical or electrical methods. Electromechanical adjustment of welding current involves performing this operation before the rectifier unit . In this case, the rectifying valves are supplied with alternating current, which already has the parameters required for welding. Electrical adjustment is possible on rectifiers equipped with thyristors, and consists of changing the angle of their adjustment.

Main types of welding rectifiers

Welding current converters differ in two respects: the type of design and the method of adjusting the power parameters of the connection.

Main types of rectifiers:

- adjustment is carried out through changes in the operation of the transformer;

- models with throttle. An induction coil is used, eliminating sudden voltage changes;

- thyristor. Thyristors are used as regulators that change voltage.

- transistor. The equipment circuit includes semiconductors that smooth out the amplitude of current pulses;

- inverter The device is equipped with a frequency boost converter and a current regulator.

The main differences between welding machines depending on the power indicators and the features of their adjustment:

- Models for electric arc welding, connected to a three-phase network. Characterized by large sizes. The operation of the converter is associated with significant losses of electricity. The capabilities of the device are limited by the power of the transformer and the parameters of additional resistance.

- Automatic and semi-automatic machines. The output current depends on the power of the magnetic field, which in turn is controlled by a rheostat. It allows you to change the number of turns of the secondary winding (using the principle of current-voltage regulation). In addition, an oscilloscope is installed to monitor pulse adjustment. Initially, the current is rectified, after which it is converted into high-frequency alternating current.

- Three-phase choke-type rectifiers are installed in argon arc welding. Their design provides an additional core with a winding. Its role is to accumulate charge supplied to the rectifier capacitor.

How to connect a ballast, ballast rheostat

Ballast rheostat (ballast) is a circuit device with a welding rectifier, with the help of which the welder adjusts the current. The regulation principle is based on the action of Ohm's law, known in electrical engineering. The higher the resistance that the ballast represents, the lower the current.

Ballast rheostat Ballast rheostat Brima RB-302. Photo VseInstruments.ru

Typically, a ballast is a spring, the efficiency of which depends on the optimally selected length of the spring, the diameter of the coils and wire, as well as the material from which it is made. A regulator contact is connected to the spring, moving it in the direction of winding changes its resistance, and therefore the current strength. The regulator contact is connected to the wire of the welding machine holder. The other end is connected to the power supply.

What is a welding rectifier

The device is a converter unit with the ability to adjust current (amperage) and voltage (voltage). At the output of the welding rectifier there are wires with terminals - positive and negative. One of them is connected to the electrode, and the other is in contact with the workpiece. As a result of closing the circuit, an electric arc is formed. Its high temperature allows it to melt metals and weld them.

Depending on their purpose, rectifiers differ in their level of complexity and functionality. However, the basic operating diagram remains standard. It is based on a converter - a transformer that modulates the voltage required for a specific situation. In addition, the circuit contains a certain number of semiconductors that cut off the negative part of the AC sine wave, allowing only the positive charge to pass through.

With your own hands

Practice has shown that some people successfully cope with the independent production of welding rectifiers. The main thing is to develop a workable scheme . The main initial parameters will be the diameters of the electrodes with which the rectifier is designed to work. So, for example, if it is 3 mm, then the welding current must be provided at about 150 A, if it is 4 mm. – 200 A.

The diagram must indicate the parameters of the following elements:

- Transformer. It is advisable to select a circuit from ready-made devices. However, this condition is not easy to fulfill; you have to learn how to make a transformer yourself. Calculating its elements (core cross-section, number of turns on the windings and wire sizes) is not that complicated. Assembly and installation experience is quickly gained after one or two unsuccessful rewinds.

- Rectifier block. Voltage is supplied after the secondary winding of the transformer. The following elements are used for operation: diodes;

- capacitor;

- throttle.

The diodes are assembled using a bridge circuit. After it, the current is not alternating, but pulsating. This current is not suitable for welding, so there is a capacitor . It smoothes out pulsations . Finally, direct current is obtained using a choke. The inductor works as a filter , which passes the direct component of the current, and delays the variable.

Welding rectifier BLUE WELD KING TIG 200

Diodes operating at such high currents generate a lot of heat. Therefore, they are necessarily included in the assembly complete with cooling radiators. It is important to consider forced airflow of the welding machine from a fan.

The capacitors for the welding unit are designed for the maximum ripple voltage. For the rectifier unit, they differ from those used in radio engineering, which do not work with pulsed currents.

Important! Pay close attention to the characteristics.

To make a choke, you need a core made of transformer iron and an insulated copper busbar (you can use a core twisted from tinned copper wires with insulation). The cores can be used from old radio equipment. The choke core and winding are assembled with a gap . After testing the device, the gap and number of turns in the winding can be adjusted.

- Welding rectifier base. The textolite plate has excellent insulating properties. It is not advisable to place devices on it close to each other. During operation, a large amount of heat is generated, so it is necessary to have a sufficiently large ventilated space.

There are many options for making a welding rectifier with your own hands. They will differ in design due to the way they are regulated. The contractor will develop his own design in relation to the specifics of the work performed.

Purpose of the rectifier

Welding is the joining of two metal parts by closing an arc between the surface to be joined and the end of the consumable electrode of a welding rectifier.

Two cables are connected to the output terminals of the device: the first is fixed on the metal part to be welded, and a holder or torch is placed at the end of the second.

Welding rectifier.

The polarity, as well as the mode of implementation of the welding operation, is determined by the specific pole of attachment to the metal parts of the structure being welded.

The welding straightener has a fairly simple design. It consists of several blocks that provide the welder with a stable workflow. As a result, at the output you can obtain a direct current of such strength that is necessary for welding parts made of steel and non-ferrous metals.

On a note! Such equipment also allows the welder to perform reverse polarity welding on thin-gauge, stainless steel, alloy and high-carbon steel structures that are overly sensitive to overheating.

Rectifiers are more advanced units for working with metal structures compared to conventional transformers, since they have a number of advantages:

- ensure constant arc burning, which extends the operating time of the device;

- during their operation, the amount of splashes of molten filler and base metal is minimized;

- allow you to achieve a smooth surface of the seam with a microscopic scaly pattern;

- increase the weldability of non-ferrous and alloyed metals, which significantly improves the quality of the joints made;

- provide the welder with the opportunity to save consumables when performing welding work, which reduces the cost of the finished product.

Brands, models

Welding rectifier BRIMA MIGSTAR-160

Popular models of welding rectifiers include:

- welding rectifier brand Telwin model LINEAR 410 /S. Parameters: 15000 W, 350 A.

- welding rectifier for argon arc welding brand Blue Weld KING model TIG 200 AC/DC-HF/Lift 832200.

- welding rectifier brand Blueweld model Combi 4.135 Turbo.

- welding rectifier brand BRIMA model MIGSTAR-160 .

A complete list of brands and models of equipment for DC welding is presented on the official websites of suppliers.