Not every welder is allowed to assemble critical structures. And only those who have passed the NAKS certification. What is NAKS - the decoding is as follows: national agency for welding control. It is this organization that monitors the qualifications of workers involved in welding work. These are not only welders, but also engineers and technologists. By the way, each employee has his own level, but more on that below. So, a welder (who has received a NAKS certificate) is considered the most highly qualified, and therefore can perform work in the most critical areas.

The agency is not only involved in licensing welders; it is responsible for a fairly large number of functions.

- Development of regulatory documentation.

- Methodical manuals.

- Consultations on correctly carried out welding activities.

- Development of technical policy at enterprises.

- Formation of expert commissions.

- But the main thing is certification.

Levels of certified workers

There are four levels at which certification is carried out.

- Level No. 1 is a NAKS welder. That is, the go-ahead is given for welding of critical structures.

- Level No. 2 is a master welder. This specialist can monitor the welding process and give instructions on correctly carried out operations. Directions may be oral or written.

- Level No. 3 is a technologist. Basically, technologists control all welding processes at enterprises.

- Level No. 4 – engineers. These are the managers of welding services who approve the documentation regulating welding processes.

It should be noted that welding equipment and tools are certified by NASK. That is, the agency also controls the quality of the equipment used, which confirms the ability to weld critical structures.

Welders undergo three types of certification:

- Primary.

- Repeatedly when the time comes to complete the NAKS courses.

- Extraordinary. This can happen if a higher organization has doubts about the welder’s qualifications.

The purpose of the NASK certification has two points: to check the readiness of the company that is engaged in welding, and to confirm the qualifications of the company’s employees authorized to carry out complex welding work.

Rank and qualification requirements for candidates

There are four levels of professional training:

- welder;

- master welder;

- welding technologist;

- welding engineer;

To obtain each rank, you must meet a number of requirements given in the table below, as well as have a certain work experience (individually for each assessment level).

| Level | Minimum general education | Vocational training in welding production |

| I | Secondary or incomplete secondary | Training in vocational schools, at special courses according to programs approved in the prescribed manner. |

| II | Secondary, secondary technical; higher technical | Training in advanced training centers according to programs approved in the prescribed manner, as well as independently. |

| III | Higher technical; secondary technical in welding production | Training in advanced training centers. The necessary knowledge can also be obtained independently by persons with higher and secondary technical education. |

| IV | Higher specialized in welding production | Training at advanced training centers or independently. |

Depending on the type of passage, certification is divided into:

- primary (for those without ID);

- additional (for those whose professional activity there was a break of more than six months, or for advanced training);

- periodic (for those whose document expires);

- extraordinary (for employees suspended from work due to violations of welding technology).

How to get a NAKS certificate

Licensing of workers is carried out in special training centers, which are in the NAKS register. In order to pass the exam, the welder provides a package of documents, which, in addition to the application, includes: a medical certificate, an extract from employment confirming work experience, documents on education and special training, photographs, safety knowledge testing protocols.

There are 2 exams: theory and practice. If one of the exams is not passed, the welder can retake the test after a month. The practical exam is carried out first; if it is not passed, then the welder is no longer allowed to take theoretical knowledge. As for the certification of engineering staff, their knowledge is mainly tested to verify standards and requirements in narrow areas and narrow specializations. Often the commission’s questions affect not one type of welding, but several. Therefore, it is recommended that engineers know all types of welding, their requirements and technical standards for the welding process.

Attention! If a welder or engineer has not worked in his specialty for six months, then he must pass the NAKS exams.

Before the exam, it is recommended to study the documentation regarding welding processes and standards that were developed on the sidelines of NASK. Training in welding courses covers all positions that will be present on the exam cards. Therefore, it is very important to attend such courses. The following courses are required to study:

- safety precautions when carrying out welding work;

- methods of control of welding seams;

- welding equipment and consumables;

- welding and soldering – technological processes;

- ways to eliminate the resulting defects.

In principle, a welder can study all these sections independently, without attending advanced training courses. It’s just that a certificate will not be issued indicating that the employee has completed these courses. The main thing is to pass the certification of the commission.

Certificate

A NAKS welder receives a certificate after successfully passing the exams. NAKS certificate - what is it? This is confirmation that the employee can work at facilities that are controlled by Rostechnadzor.

The certificate is issued to all specialists (all levels). At the same time, a NAKS welder undergoes re-certification after two years, a foreman and technologist after three, and an engineer after five years. In this case, it is necessary to take into account that the certificate will indicate what types of welding work this employee is approved for.

For example, o indicates that the NAKS welder is approved only for welding operations using the manual arc welding method. RAD – manual argon arc welding with non-consumable electrodes. G – gas. MP – mechanized. KTS – resistance spot welding. AF – automatic method under flux. The list is large for each item. Often several marks are placed that provide access to several types of welding. The received certificate is permission to carry out welding of critical structures.

What is required to obtain a qualification certificate?

The main condition for obtaining is the successful passing of the exam. For admission to it you need the following package of documents:

for level I:

- completed application for certification;

- photo 3x4 (2 pcs.);

- copy of diploma;

- copy of the passport;

- a copy of the employment record or an extract from the place of work;

- electric welder certificate.

for levels II and III:

- completed application for certification;

- photo 3x4 (2 pcs.);

- copy of diploma;

- copy of the passport;

- a copy of the employment record or an extract from the place of work;

- current industrial safety protocol.

If a candidate is taking the exam under the direction of a company, all submitted documents must be certified by a seal.

Certification of enterprises and organizations

Companies that engage in welding processes must also undergo NAKS certification. Its goal is to confirm that the company has all the capabilities (technical, technological and organizational) to implement certified technology, and that control is carried out correctly within production. Of course, the presence of specialists confirmed by NACS is a prerequisite.

In this case, the enterprise must have technological documentation that describes the welding process technology used at the facility. In essence, this is a technological instruction on how to competently carry out welding operations. It is usually developed by specialists with higher education. The duration of the NAKS certification will depend on how well the documentation was developed. Inadequacies will only increase scrutiny, which may ultimately lead to refusal to issue a certificate.

Therefore, it is recommended that company specialists prepare well. What will need to be provided to the NAKS commission for this.

- Technological map of the welding process.

- Instructions.

- Agreement that the welding control laboratory conducts periodic inspections.

- Quality certificates for welding equipment and consumables.

- List of equipment that has already passed NAKS certification.

- NAKS certificates confirming the qualifications of the company’s employees.

In the process of checking a company for compliance with NAKS standards, welded joints are usually examined. Both destructive and non-destructive methods are used here. Welding equipment is also checked. If all standards are met, a certificate is issued. It is signed by the members of the commission indicating their name and position. The certificate is valid for 4 years.

As for testing equipment, it is certified according to technical characteristics, which must correspond to the indicators in the accompanying documents (passport). A deviation to the lower side gives the commission the right not to accept it as possibly used during welding operations. The same goes for consumables. If they are produced in serial batches, then the certificate is issued for three years, if in small-scale batches, then for one year. The completeness of the technological equipment must be checked.

During testing, all systems are checked: electrical, pneumatic, hydraulic, mechanical. Typically, the test takes place in the form of welding the joint of two metals. Based on this, the assessment is given.

Why is NAKS needed?

Let's figure out why they require NAKS? To perform welding work at hazardous production facilities, only specialized organizations with certified welding technology, certified welding specialists, certified welding equipment and use certified welding materials can perform work; the presence of all these requirements theoretically guarantees the performance of high-quality welding work. Currently, the independent body that controls specialized organizations is NAKS - the National Welding Control Agency.

But for now all these are words, there is no basis yet for performing the welding production certification procedure. What are the grounds for certification of NAKS prescribed in regulatory documents?

- Order No. 398a dated June 9, 2008 on the approval and implementation of the regulations on the certification system for welding production at facilities controlled by the Federal Service for Environmental, Technological and Nuclear Supervision.

- Order No. 102 of March 14, 2014 “On approval of Federal norms and rules in the field of industrial safety “Requirements for welding work at hazardous production facilities.”

- Order of Rostechnadzor dated March 14, 2014 No. 102 (as amended on March 15, 2017) “On approval of Federal norms and regulations in the field of industrial safety “Requirements for welding work at hazardous production facilities.”

- Order of Rostekhnadzor dated March 15, 2017 No. 83 “On amendments to the Federal norms and rules in the field of industrial safety “Requirements for welding work at hazardous production facilities”, approved by order of the Federal Service for Environmental, Technological and Nuclear Supervision dated March 14, 2014 city No. 102."

- Also in the regulatory documentation there are requirements:

- GOST R 52630-2012 “Steel vessels and apparatus”, clause 6.8.1,

- RD 153-34.1-003-01 “Welding, heat treatment and control of boiler tube systems and pipelines during installation and repair of power equipment (RTM-1s)” clause 5.1.1., clause 5.1.6.,

- Order of March 25, 2014 N 116 On approval of Federal norms and rules in the field of industrial safety “Industrial safety rules for hazardous production facilities that use equipment operating under excess pressure” (as amended on December 12, 2022) clause 97. , paragraph 131., paragraph 135.

- Also, the requirements for NAKS certification can be initially specified in the contract or project documentation.

additional information

An enterprise always has a group of workers who are not subject to certification by NAKS. This list includes:

- specialists working under a fixed-term contract valid for up to 2 years;

- part-time workers;

- welder NAKS (master, technologist, engineer), who is taking advanced training courses;

- an employee who has passed the competition and has been working in a position for less than one year;

- young specialist.

Not all business managers understand that NAKS certification is an admission. If the employee does not have it, then he cannot be allowed to carry out welding work or control it. This is illegal. When conducting certification, inspection organizations must present their own permit, that is, permission to conduct inspections and exams.

Who should be certified

All welders involved in welding structures, vessels, and equipment under the control department of Gosgortekhnadzor must have the first level. The second level is necessary for foremen and foremen who give direct instructions to welders.

The third level is required for managers responsible for performing welding processes. These may be representatives of the technical bureau, heads of departments, laboratories.

The fourth level is needed by heads and deputy managers who sign technical documents on welding.

Certification of welders NAKS: price

The cost of our services for certification of welders/specialists is from 15,000/20,000 rubles. and depends on the welding parameters and the number of people.

If you are interested in our offer, contact us! From our specialists you can get complete information on passing the certification of welders/welding production specialists, as well as qualified advice on any issue that arises.

Benefits of studying with us

We work with partner training centers

We are a partner of the examination center for certification of non-destructive testing specialists

We organize training in more than 250 programs

Inclusion of specialists in LDCs

We organize distance learning 24/7

Material and technical base

With our support:

320

specialists received certificates for non-destructive testing

10250

specialists received advanced training certificates

1850

specialists received certificates in working specialties

3013

specialists were certified in labor protection and fire safety standards

Procedure

The procedure for certification of welding equipment is carried out in the following sequence:

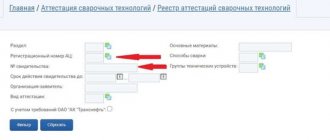

1. An application for inspection of welding equipment (WE) is submitted to the certification center. The addresses of the centers can be found on the official website of NAKS. 2. Along with the application, attach a copy of the product passport (if it is in a foreign language, then a translation is required), a warranty card, and a certificate from the manufacturer. 3. The equipment is brought to the certification center.

If the declared equipment is provided by a foreign company, documents confirming import into the country will be required. All copies of documents are certified by the head of the enterprise.

Depending on the amount of RM, types of certification of welding equipment are distinguished. This may be a check of one device, two or all available in production, as indicated in the application.

Certification of the certification body is carried out by establishing the accuracy of documents, compliance with the declared characteristics, and practical tests. The procedure is carried out in the following sequence:

1. An examination of the passport, certificate and other documents of the welding machine is carried out. 2. Certification of the CO includes the following tests: real characteristics of power, current, voltage, and load duration are assessed. 3. Welding connections are made and their strength is checked using destructive and non-destructive testing. 4. The test results are recorded in the protocol and a score is assigned to them. 5. An examination of the results is carried out. 6. A NAKS certificate is issued (if the equipment has passed the test).

The validity period of the welding equipment certification certificate (CO) is 3 years. The cost of certification of welding equipment depends on the number of devices provided for testing. Work with uncertified welding units will entail fines, the seams may be found to be of inadequate quality and everything will have to be redone, so it is better to immediately buy an inverter, semi-automatic device or TIG machine with a NAKS certificate.