For any official production, there comes a time when it is necessary to confirm the qualifications of its workers and approve all welding technologies. This process is called certification, and it is necessary not only for welders, but also for the rest of the workshop employees.

Certification is carried out under the control of NAKS (national welding control agency). In this article, we will detail everything you need to know about welding technology certification and worker certification.

Application procedure:

To gain access to the NAKS EDF system, you must send the details of your company to the email address (indicate “For access to EDF” in the subject line of the message).

In response to your message, we send you a login and password to log into the system.

After receiving the password, you need to go to the website in the “AUTHORIZATION IN EDO NAKS” section.

First of all, fill in the details of your organization in the “Account” section. Please pay attention to filling out your organization’s personal information in the “Account” section. The data will automatically be used to fill out documents.

Next, you need to fill out an application electronically in the NEW PERSONAL ACCOUNT “Personnel Applications”.

After filling out and saving the application, return to the “Personnel Applications” section and send the electronic application to the Certification Center ( Krasnoyarsk: SSR-GATs

) (left-click on the name of the person being certified and in the menu that opens, select “send to AC”).

In order for a center specialist to check your Application, you must send scanned documents to an email address (lists of documents are listed below);

After verification, a completed printed version of the application will be sent to you by email. The application will need to be printed, signed, sealed and provided to us with all the documents.

The certification process can begin only after providing a complete set of documents.

All copies of documents must be certified. The certification mark includes the word “True”, the position of the person who certified the copy, his signature with a transcript, the date of certification of the copy, as well as the seal of the organization.

How is certification carried out?

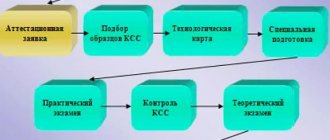

To confirm the professional level of its employees, the employer submits an application and sends them to the certification center.

The essence of certification is as follows.

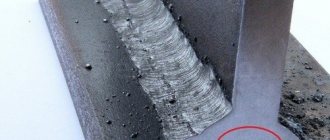

- First, a practical exam is taken. Its purpose is to show the commission the current level of quality of work. Based on how well the practical task is completed, the commission decides whether to allow the student to proceed to the next stages of verification or not.

- Then general and special exams are held. General includes questions on theoretical material. The special test is taken for the types of welding in which the certified welder works. The exam is taken for each welding technology. Based on the results, a separate certificate is issued for each type of work: plasma welding, manual arc, argon arc, contact point, electroslag, etc.

In the case of specialists, they are also tested on their knowledge of theory and given a practical task. As a result, the specialist receives permission to perform certain activities in production. This may include management, development of documentation, control and other activities. A certificate is provided for each type.

- Based on the results, protocols are drawn up and a conclusion is written.

- Employees who pass the test are issued a certificate.

Experts of all categories - from I to IV - must pass the knowledge and skills test.

List of documents required for welder certification:

1. Original application, consent to the processing of personal data (filled out by the person to whom the application is submitted) CONSENT_welder;

2. Certificate or extract from the work book confirming work experience in welding;

3. A certified copy of documents on the welder’s qualifications (category, skill level);

Documents confirming qualifications are:

- a copy of the order (instruction) issued on the basis of the conclusion of the qualification commission of the enterprise before 04/09/2018;

- a copy of the work book with a record of the assigned qualification (record, for example: Assigned 5th category);

- a copy of the document on education (issued before 2013), on qualifications (after 2013), education, professional training, issued by an organization carrying out educational activities in the Russian Federation.

- certificate of qualification obtained from a qualification assessment center.

4. A certified copy of the document on education (training);

5. A certified copy of the welder’s certification protocol (for periodic certification);

6. A copy of the document confirming the absence of medical contraindications to working as a welder;

7. Color photograph 3x4 cm, printed on MATTE PAPER (1 piece, if one welding method is declared).

REGULATIONS

RD 03-614-03 “Procedure for the use of welding equipment in the manufacture, installation, repair and reconstruction of technical devices for hazardous production facilities” Open

Order of the Gosgortekhnadzor of Russia No. 14 dated January 28, 2004. “On the introduction into force of the Procedure for the use of welding equipment in the manufacture, installation and reconstruction of technical devices for hazardous production facilities” Open

Resolution of the Gosgortekhnadzor of Russia No. 102 dated June 19, 2003. “On approval of the Procedure for the use of welding equipment in the manufacture, installation, repair and reconstruction of technical devices for hazardous production facilities” Open

List of documents required for additional certification of a welder:

1. Original application, consent to the processing of personal data (filled out by the person to whom the application is submitted) CONSENT_welder

2. Certificate or extract from the work book confirming work experience in welding;

3. A certified copy of a certificate confirming the qualifications of a welder (category);

4. A certified copy of the welder’s initial certification protocol;

5. Copy of medical certificate;

6. Original certificate with marks on the work of the welder (to be completed every 6 months).

Certification in EC "Rosttech"

With us you can confirm the qualifications of welders and specialists of levels I-IV working on lifting and transport equipment, building structures, oil and gas production equipment, steel bridge structures and other technical devices.

Types of certification that can be passed at the ROSTTECH EC:

- Primary. It is carried out for personnel who previously did not have permission to perform welding work.

- Periodic. It is carried out to renew an existing permit after its expiration date (2,3 and 5 years). Applies exclusively to those jobs for which you already have permission.

- Additional. Mandatory after a break in work for more than six months for welders and more than a year for specialists. It is also needed to expand the type of activity when obtaining new permits. Additional verification is carried out, including in case of innovations by Rostechnadzor.

- Extraordinary. Necessary if the employee was temporarily suspended for reasons: a) poor quality work; b) non-compliance with welding technology. Such a removal could occur as a result of the employer's demands or an order from Rostekhnadzor.

Based on the results of testing knowledge and skills, the following is issued:

- A certificate registered in the NAKS register. The document is valid throughout Russia.

- Certification protocol signed by the commission.

The certificate is valid for two, three or five years, depending on the confirmed category.

List of documents required for certification of welding production specialists:

1. Original application, consent to the processing of personal data (filled out by the person to whom the application is submitted) CONSENT specialist;

2. A certified copy of the education diploma;

3. A certified copy of the document on retraining for a specialty in welding production with basic technical education;

4. A certificate or extract from the work book confirming work experience in welding indicating the position;

5. A certified copy of the specialist’s certification protocol (for periodic certification);

6. Certified copies of protocols on passing exams according to the Safety Rules of Rostechnadzor (MANDATORY!!!);

7. Color photograph, 3 x 4 cm, printed on MATTE PAPER (1 pc.).

LETTERS FROM ROSTEKHNADZOR

Letter of FS ETAN No. KP-25/369 dated 04/08/08. “On the approval of recommendations for the use of PB 03-273-99, RD 03-613-03, RD 03-614-03, RD 13-615-03 and on the participation of Rostechnadzor representatives in the certification” Open

Letter of FS ETAN No. 11-11/109 dated January 21, 2005. “On the use of the list of groups of dangerous technical devices when preparing documents for certification of welding production personnel, welding materials, equipment and technologies” Open

Letter of FS ETAN No. 11-14/699 dated March 16, 2005. “On the procedure for issuing permits for certified welding materials, equipment and technologies” Open

Letter of FS ETAN No. BK - 43/3211 dated December 23, 2009. “On carrying out welding work” Open

Order of FS ETAN dated March 15, 2017 No. 83 “On amendments to the Federal norms and rules in the field of industrial safety “Requirements for welding work at hazardous production facilities”, approved by order of the Federal Service for Environmental, Technological and Nuclear Supervision dated March 14, 2014 No. 102″ Open

List of documents required to renew a welder's certificate:

1. Original application-petition, consent to the processing of personal data CONSENT_welder;

2. A certified copy of the certification protocol;

3. The original certification certificate with marks indicating that there was no break in work for more than 6 months in accordance with the scope of the certification (for a welder of external pipelines made of polymer materials, a break in work is allowed for no more than 6 months);

4. Final certificate certified by the technical control department (control laboratory) and the head of the enterprise, confirming the quality of work performed by the welder for at least the last 6 months, in accordance with the actual work performed in the field of certification distribution specified in the certificate (the documents may include test results of permissible joints);

5. A certificate or extract from the work book confirming work experience in welding indicating the category.

Welding certification NAKS. Control instructions

It often happens that in order to carry out installation, repair, production and reconstruction of technical devices at hazardous industrial facilities, the Customer hires a specialized installation organization, the range of services of which also includes welding work.

Before starting welding work, it is necessary to check the permitting documentation of the installation organization. Only after checking the permitting documentation can the installation organization receive permission to begin work. As a rule, the decision on permission to work is made by the technical supervision (construction control) of the Customer. Such a specialist must have the necessary knowledge in the field of welding production, and must also check and pay attention to the presence of the following documents in the process of checking the permitting documentation of the installation organization:

Certificate of NAKS on the readiness of the applicant organization to use certified welding technology in accordance with the requirements of RD 03-615-03

Certification of the NAKS technology confirms the fact that the installation organization has the technical and organizational capabilities, qualified personnel to conduct welding work in accordance with the certified technology, as well as control that the welded joints implemented in the conditions of a specific production using the certified technology comply with the requirements of regulatory documentation to hazardous production facilities.

Just having a welding certification certificate is not enough. It is important to pay attention to what welding method and what group of technical devices it is issued. It is also necessary to check the validity period of the certificate.

If necessary, the authenticity of the certificate can be checked on the NAKS website, where by the certificate number or the name of the organization you can find out whether the certificate is included in the NAKS register or not.

It is important to remember that an annex must be prepared for the certificate, which contains the following data about the established scope of the production certification of the technology:

- welding method

- nature of the work performed (manufacturing, installation, repair and reconstruction)

- groups and brands of basic materials

- welding materials

- diameter range

- thickness range

- seam type

- connection type

- type of connection

- cutting angle

- welding position

- presence of heating

- presence of heat treatment

- type of electrode coating

Based on this annex to the certificate, it is necessary to assess the ability of the installation organization to carry out a set of welding works provided for by the working documentation or the welding production project (WPP).

Certificate of certification of welding equipment in accordance with the requirements of RD 03-615-03

Certification of welding equipment by NAKS is carried out to check the ability of the equipment to provide specified technological characteristics for various welding methods, which determine the required quality of welded joints in the manufacture, installation, repair and reconstruction of technical devices used at hazardous production facilities.

During the verification of this certificate, first of all, it must be revealed that the serial number on the welding equipment corresponds to the number specified in the equipment certification certificate. The name and brand of the equipment must also match.

Also, in the certificate of certification of welding equipment, it is necessary to check the compliance of groups of technical devices for compliance with the facility at which welding work is carried out (GO, GDO, KO, KSM, MO, NGDO, OTOG, OKHNVP, PTO, SK). Simply put, is the presented welding machine suitable for carrying out work, for example, on the installation of boiler equipment.

The type of welding assumed and specified in the working documentation or welding work project (RD, RAD, MP, etc.) must correspond to that specified in the certification certificate.

The validity period of the certificate is also subject to mandatory control. Equipment with expired certification certificates are not allowed to perform work.

The authenticity of welding equipment certification can be checked on the NAKS website.

Welding production specialist certification certificate

Certification of welders NAKS is a set of documents, according to which a welder is allowed to work at hazardous production facilities. It is worth noting that work carried out at hazardous production facilities must be performed not only by certified welders, but also under the supervision of a level II or III welding specialist. Uncertified personnel cannot be allowed to carry out work.

Welding production specialists have the following certification levels:

Level I – welders who have the right to perform welding work using specific welding methods, both manually and by mechanized or automated methods.

Level II – specialists (craftsmen, work producers) who have the right to give instructions to welders in written or oral form, as well as to exercise guidance and technical control during the welding process.

Level III – specialists (technological engineers, laboratory employees) who provide, as well as carry out management and technical control of welding work. Level III welding production specialists have the right to develop and sign production and technological documentation for welding work (welding production projects and technological maps).

Level IV – specialists who are the managers of the enterprise’s welding service (chief welder), who provide management and technical control of welding work, and also have the right to develop and approve guidelines and regulatory documents for the performance of all types of welding work.

It often happens that checking the documents of welding production specialists is limited only by their availability. But no one pays attention to which hazardous production facility was certified by NAKS. It is important to remember that a specialist certified in gas equipment (GO) does not have the right to carry out work on the installation of oil and gas production equipment (OGPE).

The certificate of a welding production specialist must be accompanied by a certification protocol. The protocol contains information about the groups of dangerous technical devices for which the specialist is certified, as well as the name of the organization in which the specialist worked at the time of certification. The certificate will be valid even if the specialist changes his place of work several times.

In addition to the NAKS certificate, a welding production specialist must be certified according to safety rules in Rostekhnadzor for hazardous production facilities specified in the certificate.

Certified welders must have a certificate of the established form, which reflects and must verify the following data:

- type of welding (RD, RAD, MP, etc.)

- type of parts (T - pipe, L - sheet, T+L - pipe + sheet)

- types of seams (SSh - butt weld, USH - fillet weld)

- group of welded material (M01, M02, etc.)

- welding materials

- thickness of parts

- outside diameter

- welding position

- type of connection

Certified welders are allowed to perform welding work at hazardous production facilities in accordance with RD 03-495-02 and PB-03-273-99.

It is not uncommon for installation organizations, in order to save money, to have only one certified specialist or not at all. Thus, they are forced to illegally attach other people’s copies of certificates of specialists, often not working in this organization, and sometimes even forged certificates. Therefore, the authenticity of the ID must be verified on the NAKS website.

Certificate of certification of welding materials in accordance with the requirements of RD 03-615-03

When checking the quality of welding materials, it is necessary to pay attention not only to the availability of certificates, but also to the presence of a NAKS certificate of certification of welding materials.

Such certification is necessary to verify the compliance of the actual technological properties and characteristics of welding materials with the properties and characteristics specified in the accompanying documentation and the requirements of current standards, technical specifications and other regulatory documents for welding materials. Based on the certification results, the possibility of using welding materials during installation work is determined in accordance with the declared welding technology.

The certification certificate for welding materials contains the following data:

- brand of welding materials

- standard size (diameter)

- welding method (RD, RAD, MP, etc.)

- groups of basic materials (M01, M02, etc.)

- groups of technical devices (KO, GO, SK, OKHNVP, etc.)

The type or brand of welding materials must correspond to those specified in the working (design) documentation or the welding project. It is also necessary to check the validity period of the NAKS certification. Typically, the validity period is 3 years.

The authenticity of the certificate of certification of welding materials can be checked on the corresponding page of the NAKS website. The certificate must be entered in the NAKS register.