A do-it-yourself stationary high-pressure washer can be made on the basis of a special pump for sinks, a high-pressure hydraulic pump for special equipment (like NSh) or an air compressor. When the question arises whether to buy a factory-made pressure washer or make one yourself, there are several factors to consider. A homemade car wash using improvised means is usually cheaper than a ready-made MIA with similar parameters. Provided that components are chosen wisely and are of high quality, it surpasses factory ones in reliability and is not inferior to them in performance.

In this material we will look at how to make a high-pressure washer with your own hands and look at the three most popular design options and answer basic questions about homemade MIAs.

How to make a homemade Karcher?

There are many ways to do it.

First way. The main mechanism of the future Karcher is taken - the compressor. It can be taken from any equipment that is no longer used on the farm. The mechanism is connected to the fitting using a hose. Take a brush to which the tap is attached. The tap is necessary to regulate the power of water supply. The brush and tap are also attached using a hose. When fastening, you will need to use rubber gaskets, FUM tape, and hermetic glue. The hose, on the other hand, is fixed in a container into which more than ten liters of water can be poured. The simplest homemade Karcher compressor is ready for use. You can make a more automated method that will connect to the electrical outlet or the cigarette lighter in the car.

View gallery

Second way. Take a canister into which you can pour more than twenty liters of water. A compressor from the car is connected to the inlet brass nipple from the tire. The hose is attached to a gun (you can purchase it at any garden store). The hose length is at least six meters. Diameter 16 mm. For fastening, rubber flaps, clamps and nuts are used.

What parts are needed to assemble such a device?

Do-it-yourself dehumidifier for a compressor

First you need to buy a pump. This is the main detail of homemade units of this type. It should have fairly high performance at a pressure of 0.1-0.2 kilobar

Particular attention should be paid to the material from which it is made. It is necessary to select a model in which the head on the cylinder block is made of brass, and the pistons of the pump itself are made of high-strength steel or ceramics

The duration of operation of the created sink depends on this.

Washing power diagram.

The other main part of the unit is the electric motor. As its speed increases, the performance of the washing pump also increases. For such devices, electric motors with a power of 2-3 kW at a shaft speed of 1.5-2 thousand revolutions per minute are best suited. To ensure reliable engine starting, it can be equipped with starting capacitors.

The coupling must be soft: if the pump or electric motor jams, it will act as a fuse.

The water tank can be selected from 5 to 22 liters. It is advisable to install a filter at the outlet of this vessel. Usually this role is performed by a fine mesh. It traps unwanted particles in the water and prevents them from entering the pump.

The frame is the base on which all the elements of the sink are attached. Most often it is made from curved pipes. You can attach a stop and wheels to it, which will make it possible to move the sink. The frame has handles for carrying it around the work site.

For hoses, plastic and rubber hoses with reinforcement inside are best suited. Their thickness is selected to the average diameter. All their connections in the unit must be sealed and made of material that is not afraid of corrosion.

A pistol with a nozzle must be selected so that its trigger operates smoothly, without jerking. Tips are bought ready-made. The sink can be equipped with several nozzles that will create the desired jet shape.

Preparing material and tools

To make a mini-sink you will need the following components. The pump is one of the main components of the sink. The performance of the device must be quite high (pressure range: 100−200 bar). When choosing a pump for a mini-wash, you should also pay attention to the material it is made of. It is desirable that the cylinder head be made of brass, the pump pistons made of ceramics or durable metal. The period of operation of such a pump will undoubtedly please you.

Device

The best mini high pressure washers for washing your car

Now it would be useful to consider the structure of the sink and understand what components it consists of. The design of any high pressure washer will consist of 5 main and a lot of auxiliary elements. If we talk about the main ones, we are talking about:

- motor;

- pump;

- pump;

- fuse;

- filters.

Now let's talk about them in a little more detail. The motor is the basis of the entire structure. It is thanks to its presence that it is possible to achieve pump operation that can be called stable. The electric option will be the most common, although there are also autonomous solutions. If we talk about autonomous options, then the fuel for them will be either diesel or gasoline. If we talk about a pumping unit, then its main purpose will be pumping water from a special container or a centralized network. If we are talking about a centralized option, then the sink must be equipped with special hoses.

The pump is directly responsible for increasing the pressure. An important criterion for this part is wear resistance. Here it should be said that this parameter will depend on the material from which it is made. Most often these days it is made of plastic. This option is not of very high quality, since if you use the device for more than 20 minutes, its failure is almost guaranteed. There are brass solutions that will be more reliable. It should be said that the models on the market, as a rule, are equipped with plastic options. For this reason, a self-made model can be significantly more reliable.

The motor fuse is responsible for controlling the operation of the entire pump. As soon as the water level reaches a critical level, rotation of the engine becomes impossible. This is usually observed when liquid enters but does not come out due to the fact that the hose is blocked and the type of washer in question continues to operate. The filter is the main element of protection that protects the sink from mechanical problems due to sand or other foreign particles of considerable size getting inside through the nozzle.

Selection of parts for washing

Choosing the best compressor for the garage and whether you can do it yourself

Scheme of a homemade mini-wash.

When choosing an electric motor, you should pay attention to models that have a power supply of about 220 or 308 volts. If the high-pressure washer is used at home, it is advisable to use a single-phase 220 volt connection, as it will not entail additional costs and meets all safety requirements

To ensure optimal starting of certain motors, it is advisable to use additional capacitor units. Thus, the performance of the pump directly depends on the number of engine revolutions: the higher the frequency, the greater the performance.

But it is worth considering that working in this mode may negatively affect its resources. You should not give preference to too fast models. The maximum permissible rotation speed in this case is up to two thousand revolutions with a power of two or three kilowatts.

A high-pressure washer of a certain design allows you to provide the required pump performance when using a single-stage gearbox operating using a V-belt drive. Their gear ratio depends on the parameters of the pulleys (driven and driven). The characteristics of the distance between the axes of rotation also play an equally important role in the operation of gearboxes.

A coupling is usually used to secure the pump and motor. The most suitable option is a soft coupling that can compensate for minimal axial misalignment of the shafts and act as a safety element in case the gearbox or pump jams.

A very important structural element of any sink is the water storage tank. In order to ensure maximum pump performance, it is necessary to use a certain volume of liquid. To do this, it is possible to use a special liquid tank that can be recharged from the water supply network. It is imperative to install a filter element (this can be an ordinary fine mesh) at the outlet point from the tank, designed to clean the liquid from dirt particles and prevent blockages from entering the pump. To enhance the cleaning effect, you can add a special or regular detergent to the liquid.

Hydraulic diagram of a car wash.

A do-it-yourself car wash must have a pump performance regulator in its design. Typically, this device is connected to an automatic unloading valve, which can, in a critical situation, redirect the liquid back to the tank so that no harmful load is created on the pump.

In order to fix all the structural elements of the sink, a special frame is used. For its construction, you can use hollow curved pipes. To ensure ease of use, you can fix a pair of small support wheels in its lower part and place a stop to give the structure stability during use. One of the ends of the frame can be equipped with a special handle designed for transporting the sink around the yard or garage.

The main structural element of a homemade sink is a water container. To ensure maximum pump performance, a certain volume of liquid must be used.

One of the most important elements that make up a DIY sink is high-pressure hoses. A standard, not too thick, reinforced rubber or plastic hose can act as a sleeve. It should be taken into account that all structural connections of hoses must be made in compliance with tightness conditions, on the one hand, and not be afraid of corrosion and can be easily disassembled, on the other. To equip the fasteners, you can use fittings or threaded bushings made of hard aluminum alloys or brass. For this purpose, it is possible to install bayonet mounts.

When building a sink with your own hands, you must also select a gun equipped with a nozzle. Thanks to its shape, an imitation of the shape of the working jet is obtained. Actually, in appearance it resembles a pistol used at gas stations. To start dispensing water from the nozzle, press the handle. This is a definite advantage, as it allows you to save a large amount of water: liquid is supplied only when it is needed, when you press the gun handle. Making a shut-off valve with your own hands is quite problematic; the simplest and most reliable option would be to purchase a ready-made tip.

External car wash units

External components are mounted on a frame, which is better to make yourself or choose a suitable ready-made structure. Usually the frame is made on the basis of a profile or curved pipe. You can install wheels on the bottom so that the sink is not stationary, but mobile. Stops, handles and clamps will help you move the device.

- Hose. If you have sorted out the water intake, you need an element through which the liquid will begin to flow to the machine. Choose reinforced rubberized hoses or plastic products. Just make sure the hose is durable and has tight connections to the water intake. If necessary, you should be able to quickly repair the hose and change it.

- Connections. It is better to connect areas where elements are connected to each other and come into contact with water using fasteners made of corrosion-resistant materials. For example, bronze or brass.

- Gun and nozzle. You can take a ready-made sandblaster or another suitable gun that has a nozzle. Outwardly they resemble pistols at gas stations. The water jet should only be released when you press the button. It’s better to take a ready-made gun and not worry. My advice to you.

We do everything consistently and carefully, connecting the elements tightly together. In fact, selecting parts and creating a full-fledged sink from them is not an impossible task.

But you will still need a cutter to cut the holes, a whole set of different components. It is far from certain that they will be at hand or suitable in size, type of material, and so on. Someone makes sinks from NSh 10 (gear pump) and is happy with the result. Others twist and turn something, but in the end they go to the store and buy a foaming agent, connecting it with the purchased branded sink. Although a foam generator can be made from a compressor and auxiliary mechanisms, I would prefer a ready-made product.

In some cases, it is better to think about which sink from a leading manufacturer to take to wash your car, rather than spend several days unsuccessfully trying to assemble a sink from scrap materials.

I am not at all opposed to making useful things with my own hands. But in terms of washing there are many pitfalls. As for me, it is better to spend more money and less time on a proven Karcher factory car wash, for example, than less money and more time on a homemade device. It remains to be seen how this homemade product will work and what surprises it will reveal during operation.

The rating of factory sinks clearly demonstrates the leaders of the segment. Will you be able to achieve similar characteristics to such devices by doing the washing yourself? Hardly. Can you save money? Probably yes.

How to make a homemade Karcher for a car

How to Make a Karcher with Your Own Hands / Simple homemade products / Sekretmastera

Watch this video on YouTube

The design of the sink is extremely simple; to create it you will need a plastic container with a tight screw cap with a capacity of 4 - 20 liters (canisters for storing gasoline are very suitable), a spray gun, a set of quick-release hose connectors (3/4 threaded fitting, two connectors for the diameter of the hose , adapter coupling 3/4 - 1/2), car nipple for tubeless tires and a piece of hose 1.5 - 2.5 meters long. The tools you need are a knife with a sharp end, silicone sealant and a car pump or compressor.

Watering gun Water container

The operating principle of a mini washer. A hose with a watering gun is connected to the bottom of the water tank. A car nipple - a fungus - is built into the filler neck. Fill the container with water to 3/4 - 4/5 of the volume, screw on the lid and pump the container with air. The system creates excess pressure under the influence of which water will flow out when the trigger of the gun is pressed.

The assembly diagram for a mini sink should not cause any difficulties if executed carefully.

1. Using the sharp end of a knife, slowly and carefully form a hole in the lid of the container, slightly smaller than the fitting diameter of the nipple.

2. Insert the nipple from the inside. Tests have shown that the nipple becomes tight and does not require additional sealing.

Hole for nipple Hole for adapter Nipple inserted into cover

3. At the bottom of a flat canister without protrusions or seams, slowly and carefully make a hole for the coupling.

4. Using a wire from inside the canister, insert the coupling into the hole.

5. Apply silicone sealant to the joint and screw the fitting to the coupling. We are waiting for the sealant to harden.

Hole for the adapter Installing the mini-sink adapter Sealant applied

6. Screw on the lid. We are waiting for the sealant to harden. We connect the pump. We plug the fitting with our finger and increase the pressure in the container; if everything is done carefully, the container will hold pressure.

7. We equip the hose with connectors. We connect one end of the hose to the canister, and the other to the watering gun.

8. Fill the canister 3/4 - 4/5 with water and pump air inside. We do not pump the canister too much; it expands under pressure (becomes more round). Don't get carried away with increasing pressure. When using large-volume canisters, it will be necessary to provide clamps to prevent excessive inflation of the container.

The fitting is screwed in. The connectors are installed. The hose is connected to the container. The hose is connected to the gun. Homemade mini-wash

9. We press the trigger of the gun and water under pressure begins to flow out; if necessary, select the type of water jet; the gun in the photo has four operating modes.

Do it yourself low pressure Karcher. Make a mini sink with your own hands.

: Attach a bucket for storing the Hypermop

Show 3 more imagesThe hyper mop is long and heavy. She needs a “quiver”! A 20 liter bucket is ideal for our needs. I drilled a few holes in the bottom of the bucket to allow the water to drain, and then drilled small holes in both the bucket and the scuba holder to secure them together.

High pressure washer design

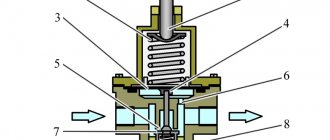

1.1 The main functional component of the sink is the pump, which is also the most complex (and expensive) structural element. Let's consider the requirements for the pump:

- High level of productivity (at least 15 liters per minute);

- Working pressure in the range of 100-200 bar (optimally 200 bar);

- Materials used to make the pump. The most acceptable is a pump that has ceramic pistons, a brass cylinder head, and the crank mechanism liners have a large support area.

The optimal pump to be installed on a high-pressure washer will be a plunger pump driven by an electric motor, the rated power of which is at least 75% of the maximum value.

1.2 The next element of the high-pressure washer, assembled by yourself, is an electric motor, the supply voltage of which is 380 (220) Volts. For a sink that is intended to be used in domestic (home) conditions, it is preferable to use a supply voltage of 220 Volts due to its low cost and less danger during operation. The use of an additional capacitor block will significantly increase the reliability of engine starting.

1.3 If the performance of the pump installed in a high-pressure washer, assembled by yourself, is lower than required, a single-stage gearbox is included in the technological scheme of the device.

1.4 The pump is connected to the engine using a “soft” coupling, which performs the following additional functions:

— compensation for axial misalignments of shafts;

— acting as a fuse when the pump (gearbox) jams.

1.5 Capacity (cylinder) for working fluid (water). The container must have a recharge system from the main water supply and a filter element at the outlet. A fine mesh is used as a filter element to prevent dirt particles from entering the pump.

1.6 The next element required for a device such as a high-pressure washer is a pump performance regulator. The purpose of this element is to redirect liquid into a container to avoid overloading the pump.

1.7 Frame. This element is the basis of the unit. It is usually made from hollow pipes bent accordingly. For ease of movement and operation, the frame is equipped with two wheels, a reliable stop and a handle.

1.8 A rather important operational element is high-pressure hoses. It is recommended to use rubber (plastic) reinforced hoses of small thickness as hoses. The main requirements for hose connections are tightness, ease of disassembly and resistance to corrosion. You can use brass and aluminum fittings and threaded bushings or bayonets.

1.9 The next element of the high-pressure washer is a gun with a nozzle. This is a rather important part of the unit, forming the working jet. Making a gun shut-off valve is a technically complex process and therefore it would be advisable to purchase a ready-made tip.

Comparison table of characteristics

To visually compare the 7 best models of high pressure washers, we use a comparison table:

| Model | power, kWt | Water consumption, l/hour | Pressure, bar | Water, t °С | Weight, kg | Average price, rub. |

| Bosch AQT 35-12 | 1.5 | 350 | up to 120 | 40 | 5.53 | 8890 |

| Champion HP6300 | 2.4 | 420 | up to 225 | 50 | 25 | 13 635 |

| Karcher K 7 Compact | 3 | 600 | up to 160 | 60 | 16.89 | 32 676 |

| Lavor Pro Vertigo 28 | 2.8 | 510 | up to 180 | 60 | 22 | 28 895 |

| Portotecnica Elite 2840 T | 5.3 | 780 | up to 190 | 50 | 44 | 55 251 |

| STIHL RE 163 Plus | 3.3 | 650 | up to 160 | 60 | 27.6 | 51 390 |

| Karcher HD 9/20-4 M | 8.4 | 900 | up to 200 | 60 | 55 | 100 490 |

Making a sink at home

Pump and electrical part

The main part of any water supply unit is the pump. For our product we will need it to be powerful enough, capable of developing a pressure of at least 150 atmospheres. When selecting a finished pump, it is necessary to take into account the materials from which the working units are made.

In this case, it is recommended to select the block head from brass or bronze alloys. This design is more durable. Its service life between repairs is quite long. A speed of 15 l/min will be sufficient for the pump.

It is advisable to select an electric motor with a voltage of 220 V. Reliable starting is ensured by an additional capacitor unit. Higher rpm will provide greater productivity.

Consumers of 2-3 kW and rotation up to 2000 rpm are considered optimal.

Rotation transmission

A do-it-yourself high-pressure washer must have the necessary safety elements in the circuit to preserve important components. This link is the coupling connecting the pump and the motor.

It is also possible to install a single-stage belt drive. Such a gearbox balances the speed and load between the engine and the pump. The gear ratio is selected based on the required output parameters for the rotation frequency.

Reservoir and performance regulator

The mini sink must be equipped with sufficient water capacity. A tank that can be additionally powered from a permanent water source is suitable: a water tap, a deep-water well, or a small water tower.

What to make a sink from

You can add car shampoo or other approved car cosmetics to the main water container. The process will be more efficient.

The pump's capacity regulator is usually combined with an auto-unloading valve, which redirects unused pressure back to the tank, reducing the load on the pump.

External elements

All units are mounted on a frame made of profile or round curved pipes. Often a pair of wheels are attached to the down pipes to help transport the unit. Stops for fixation and a handle are also installed so that the entire structure can be moved.

Exterior view of a DIY car wash

The structure must be dismountable and repairable. Therefore, it is advisable to use threaded connections where possible.

Also, in places of contact with water (fittings, valves), low-corrosion alloys should be used: brass and bronze.

Direct water supply is carried out through a gun with a nozzle installed in it. It bears a visual resemblance to the gas station gun. A stream of water is generated only after pressing the key. This method helps save prepared working fluid with consumable additives. You can simply buy a pistol at any hardware store.

Operating a DIY sink

Parts for assembling the sink

When operating, you must follow a few tips:

- periodically it is necessary to inspect the connecting units and tighten the threaded connections with a wrench;

- filters installed in the device need to be inspected before each connection so that the throughput is not reduced;

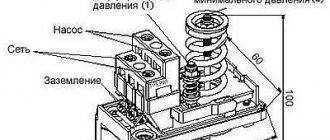

- the electrical part must be grounded to avoid accidents during operation; for this, a cable with three copper cores is used, and the plug must have a grounding terminal;

- During the washing process, you do not need to fix the jet at one point on the car body for a long time, so as not to damage the paintwork with strong pressure.

STIHL RE 90, 120 bar

Another analogue of Karcher, powered by a household city. The washer produces pressure up to 120 bar and consumes 1800 W. The device can use detergent, has a basic set of attachments and a steam generator. There is anti-twist protection, a carrying handle and wheels for moving equipment. Price - 14,000 rubles.

Pros:

- The optimal solution for the car.

- High quality, like Karcher.

- Ease of use.

- Great resource.

- Famous brand.

Minuses:

- Short cord for washing.

- Few attachments for this price.

Principle of operation

Using high pressure, a jet of foam is supplied, which not only removes all contaminants from the surface, but also disinfects it. The internal structure of the unit allows you to create foam of the desired density and evenly apply it to the machine. Foam is formed in several stages:

- A stream of water passes through a car shampoo suitable for a foam generator.

- It mixes with the air stream and foam begins to form.

- At high speed, the resulting substance is sent to a special foaming “tablet”.

- Foam of the required density is already coming out of it.

The foaming agent allows you to clean very quickly, and it also significantly saves water. A small amount of water is sufficient for the jet; high pressure will ensure the required spray speed and surface area to be treated. Thus, a foaming agent and a high-pressure car wash very quickly take a leading position in the list of necessary tools for the garage, according to car enthusiasts.

: Disassemble the mop head

This is a fun step. You start with 8 mops and end up with an amazing car wash hyper mop.

- Buy mops

- Drill out the rivets

- Remove all plastic parts

- Carefully wrap the zipper around the center across the existing blue cord

- Cut the blue cord

- Tighten the zipper slightly

- Wrap the mop around the hyper mop handle

- Tighten the zipper

- Go back to step 1 and repeat until you have no mops left

The hyper mop is almost ready!

Do-it-yourself compressor washing

The attachment to the compressor allows you to wash parts under high pressure. Let's take a closer look at it. This washing gun consists of a main element - an air blow gun. Its cost was around 200 rubles. All plumbing fittings cost around 200 rubles. For clarity, the gun is divided into two parts: the plumbing part and the gun itself. We put aside the plumbing part of the car wash to take a closer look at the second unit.

Various cheap and interesting new equipment in this Chinese store.

Gun car wash

Let's look at the gun itself. There is a Euro air entrance here. A nozzle was screwed into the back side, which blew out air. After it was unscrewed, it became clear that there was a ten thread there. The pitch of one turn is one.

Plumbing part

The plumbing part is a little more complicated. Two Christmas trees were used. The first one has an internal diameter of 1/2 inch. The second one has the same outer diameter parameters. A nozzle with an internal diameter of about 6 millimeters.

The mechanism of operation of the washing gun

Water enters through a quick release and a plastic tap. It rests against the tee and comes out through the nozzle. It is advisable to use a longer nozzle. In this case, its length is 20 millimeters. It is advisable to make it 50 millimeters long. You should not make it too narrow, as the throughput will be reduced. The air that passes through the gun increases the force with which the water hits. Adjustment occurs using a lever on the handle.

Advantages and disadvantages

The positive thing about this device is its low price. The total cost with all parts was 400 rubles. That is, within this amount you can assemble your own reliable gun for washing parts. The second positive point is ease of manufacture. It is very easy to make it with your own hands.

There is another plus. If you have a compressor that is idle, you can make such a washing gun and wash various parts. minuses. The first and most important disadvantage is that in addition to water, air is also supplied to the nozzle, which reduces its performance. In standard devices, only high-pressure water is supplied through the nozzles. But here the air reduces the impact force and the result is not the effect that we would like to have. The second disadvantage is the performance of the compressor. It will be easier for professionals to buy a Karcher than to fool around with a compressor. Although the compressor is more multifunctional. It can be used as a blower with this attack to wash parts. Its other function is a spray gun. Beginners often use a regular household compressor, which has low performance. Due to this, the power of the gun is reduced, since a household compressor has low productivity, about 200 - 300 liters per minute. This power is not enough to fully work without interruptions. Therefore, this is also a significant drawback of a device that you can make yourself.

Here, at the beginning of the video, the master showed how he washes a mini tractor using his homemade device.

The subtleties of making a mini-sink yourself

During the assembly process of a car wash, there are several important points that determine the safety of further operation and the absence of malfunctions.

The frame is the basis of the entire structure:

- it is planned to manufacture a system with optimal dimensions, for which suitable pipes are selected - round, curved;

- in addition to the wheels, it is advisable to install clamps at the bottom;

- handle - makes transportation easier.

Grounding – safety element:

- a three-core wire is selected;

- you will need a plug with a grounding terminal;

- The socket is grounded.

After preparation, several main steps are performed:

- Electrical equipment is installed on the frame, including a motor, pump, and other structural elements.

- A gun with a nozzle is attached, supplying water after pressing a special button. Such devices are used by professionals, but they can also be easily purchased in a store.

- A high-pressure hose is being installed.

After completing the assembly, connect to the water supply. A 7 m long hose is suitable for this.

How to avoid unexpected device breakdowns

When thinking about how to make a car wash with your own hands, it is advisable to ensure optimal operation, preventing the need for subsequent restoration.

Important points about using the installation:

- before starting, all connections and fastenings are checked;

- the filter element needs to be regularly cleaned to remove dirt;

- You should not often use the equipment at full power;

- Installing a battery will protect the device from power surges.

Secrets of designing a foam generator

A car wash is used to remove debris, dirt from the car body and other parts. A foam generator allows you to maximize the quality of cleaning. It's also easy to make yourself.

A small amount of tools is selected:

- roulette;

- knife;

- Bulgarian;

- wrenches;

- pliers.

When thinking about how to make a foam generator for a car wash with your own hands, it is worth choosing suitable materials and parts for assembly.

Basic moments:

- A pipe with a length of at least 50 cm is required. It is filled with polyethylene sponge for subsequent foam formation.

- A filter is installed in the form of a mesh to prevent filler from getting into other units.

- One edge of the pipe must be plugged and a tee must be installed to subsequently secure the foam concentrate tap.

- Using a fitting, connect the pipe and hose intended for foam.

- A valve is connected to the other end, providing a flow of compressed air masses.

The characteristics of the foam that will be obtained as a result of the operation of such an installation are determined by the length of the pipe used. The density of filling the surface with a washcloth requires attention. For filling car cosmetics, a container that can withstand the pressure exerted by the system is suitable.

A car wash and a foam generator are useful units that simplify the process of car care. They can easily cope with loads in home use, perfectly replacing factory tools.

The cleanliness of a car is not only an aesthetic indicator, but also protects the product from negative environmental factors. After all, stuck and dried dirt may contain aggressive elements that damage the paintwork. Also, long-term and regular contamination of the body can lead to irreversible damage to the metal, including through corrosion on individual elements.

In this case, regular visits to a car wash or home water treatments can help. But in the second case, you need to buy a washing device or make a car wash with your own hands from improvised materials. Prices in stores generally start from 5 thousand rubles. The upper threshold may not stop at 20 thousand. Therefore, we will do it ourselves.

Procedure

- Now let's proceed directly to assembling the type of sink in question. First, it would not be superfluous to check the functionality of the pumping equipment. To do this, we attach two hoses to it. The first will serve to receive water, and the second will supply it to the gun. We unscrew the special clamp and then put it on the hose. After this, you should tighten everything and check the tightness of the connections. We take a blow gun, which is also connected to the structure with a hose and secured with a clamp.

- It often happens that a blow gun comes with nozzles that are slightly unsuitable for connection to the structure. To solve this problem, you can unscrew the nozzle and screw in a carburetor jet, which will fit perfectly on the thread. Many people use a carburetor jet from a Zhiguli car. This solution is necessary to reduce the hole in the gun, which allows you to create a more powerful compact jet.

Now we need to deal with the electrical part. First you need to connect the activation/deactivation toggle switch to the wire. You can purchase such a solution at any store that sells electrical spare parts. If suddenly, for some reason, you want to make such a device mobile, then take a screwdriver battery and solder the wiring to it along with the contacts so that the solder in no way interferes with the charging connection, and the battery can be recharged if desired.

Now we fix the wires with electrical tape. Now we connect the wires themselves to the pump. At the same time, we connect the circuit using contacts.

- If you want, you can also make an extension cord with a wire of different lengths. Such a device will not be superfluous if you want to use a car wash by connecting it to the car’s battery. Now the assembly of the device parts in a housing made from a plastic bucket begins. To do this, we punch 4 holes in its wall using the drill mentioned above. We attach the pump to the wall of the bucket and tighten it with 4 screws and nuts.

- At the bottom of the bucket you can make a mount to secure the screwdriver battery. We also make fastenings for the extension cord. It will be located under the lid. Now we drill a few more holes in the container for the gasket and for connecting the hoses. Everything can be neatly placed in this plastic bucket. True, the container will need to be carried separately, but you can somehow come to terms with this drawback.

- In general, it should be said that there is nothing difficult in assembling a mini-sink with your own hands from available elements. The main thing that is required is the necessary components, basic technical knowledge in the field of electronics, the specified tools and the desire to make a mini-wash no worse than the one sold in specialized stores at an incredible price.