It is not possible to create a steel grade with an ideal structure, so manufacturers strive to develop alloys with optimal characteristics intended for specific purposes. For example, you can compare knives made of soft steel, which is easier to sharpen, and knives made of hard material, which is resistant to mechanical stress, but is difficult to sharpen. This analysis allows you to select the necessary tool depending on the task assigned to the cutting tool.

Sheet of steel 40X13.

Characteristics

The complexity of the chemical composition affects the speed of the steel manufacturing process, which leads to an increase in the cost of the product.

Sometimes the quality of a knife depends not on a specific brand, but on the quality of heat treatment. 40x13 steel is just that case. It is one of the most popular brands and has fairly stable characteristics.

The name “medical steel” is firmly attached to 40x13 steel.

Medical scalpels have always been made from it, so the 40x13 brand has always been considered the best. This opinion was cemented due to the fact that it is stainless steel, and the excellent cutting of the scalpel was achieved due to a very thin blade and razor sharpening.

Advantages

Main advantages:

- High heat resistance.

- Corrosion resistance.

- Absolutely does not rust.

Does not corrode even in sea water. This property is used by manufacturers of diver knives. But the instruments still need good care. If the blade is kept in constant dampness, it will slowly become rusty.

Flaws

Steel 40x13 for knives has not only advantages, but also disadvantages. The cutting edge is relatively soft, can be sharpened well, but quickly becomes dull. For this reason, it is not recommended for tourists or hunters to purchase knives made of 40x13 steel, since it will have to be sharpened often.

A definite disadvantage is that the knives are very flexible; they are not recommended for cutting hard surfaces.

And one more quality that does not speak in favor of 40x13 is instability to aggressive environments and high temperatures. Therefore, use in welding is strictly prohibited.

40X13 does not corrode.

Processing methods

The steel in question is subjected to two main types of processing: thermal and mechanical. Heat treatment of 40x13 steel is used to give it the appropriate technological properties. Mechanical - to create the required shape, solve the assigned technical problems.

Experts classify such metal into the category of materials that require a certain specific approach during heat treatment. It is this type of processing that gives the required properties.

Steel 40x13 in a hardening oven

The main types of heat treatment are:

- sequential hardening;

- slow release after heating;

- hot and cold plastic deformation;

- annealing.

After hardening, the following components are formed in the structure:

- carbides;

- martensites;

- some remains of so-called austenites.

The first two processing methods make it possible to give steel good corrosion resistance and excellent mechanical properties. This is possible due to the fact that it has good plastic deformation. Hardening of such steel occurs by gradual heating to a temperature of more than 950 °C, but not more than 1100 °C. Consistent heating is necessary because this grade of steel is highly sensitive to cracks. To avoid negative consequences, a metal part (especially one with a thickness of more than 100 millimeters) must be heated for more than 10 minutes.

To avoid the appearance of cracks, including in the depths of the metal, the sample is subjected to so-called tempering. That is, a gradual decrease in temperature and keeping the sample at temperatures up to 300 °C. In this case, the steel acquires its maximum strength characteristics. If the temperature regime is not maintained and the process occurs at 450 °C, the steel will lose its impact strength characteristics. It acquires the best corrosion properties and good ductility if the following parameters are observed. Sequential heating to a temperature of 700 °C, subsequent holding for 20 minutes, cooling in a container with oil.

The so-called annealing is used as a softening heat treatment. The part is heated to a temperature of 800 °C. Next, slow cooling is carried out in the furnace itself to a temperature of about 500 °C.

Temperature of quenching and tempering of steel 40x13

As an alternative to the standard type of heating, heating with high frequency currents is used to carry out heat treatment. This method is especially used when it is necessary to harden the surface layer of a part. These are parts that are included in mechanisms with friction and rolling units, and in elements of pipeline fittings. Typically, such hardening is applied only to parts whose thickness exceeds 15 millimeters. With its help, it is possible to achieve a hardness indicator after hardening equal to 36.5 HRC units.

The above reasoning proves that the steel grade 40x13 is quite critical to the rules for observing the conditions of temperature treatment.

It is subjected to the following types of mechanical processing:

- drilling holes;

- sharpening;

- milling;

- forging.

Carrying out these operations is associated with certain difficulties:

- Hardening of the surface layer (this is due to additional heating of the workpiece at the time of cutting or drilling).

- Problems with the removal of metalworking waste (the resulting metal shavings form a long, narrow, twisted strip). This causes certain inconveniences during long-term processing. This problem is solved by installing special devices on metal-cutting tools. They produce periodic chip breakage.

- Increased wear of the cutting edge. This is due to an increase in the temperature of the part at the point of contact with the edge of the cutting tool. In this case, the presence of crystalline compounds (carbides and martensites) in this grade creates the effect of the presence of abrasive elements in it, which leads to rapid wear of the cutting edge.

In addition, difficulties arise when sharpening cutting tools made from this steel. At the moment of sharpening, the temperature of the sharpened edge increases and a so-called metallic influx is formed. This leads to uneven hardening of the edge of the sharpened surface.

Forging, as a mechanical processing, is carried out only when the part is heated to a temperature of 1250 °C. During the forging process, the temperature can be reduced to at least 850 °C.

After this operation (hot deformation), only slow cooling followed by low-temperature annealing is allowed.

Unfortunately, welding is not included in the available list of mechanical processing. The fact is that this grade of metal belongs to the category of difficult-to-weld materials. Therefore, this processing method is not used to connect structures made from this material.

Application area

The application of the alloy is quite wide. Currently, it is used to make kitchen knives at low cost. Housewives like them because they are easy to care for and, if you follow basic rules, they hardly rust. The knife blades are sharp and easy to sharpen. You can cut any food: fish, meat, fruits, vegetables. The tools are completely safe to use.

In addition, the following are made from 40x13:

- medical scalpels;

- measuring devices;

- bearings;

- springs;

- manicure tools;

- compressor parts and many other household items.

Alloy knives are used by fishermen, divers, tourists, divers and simple cooks. Some people prefer to have souvenir blades that have a beautiful appearance.

Parts made of steel 40Х13.

Scope of application of steel 40x13

Steel grade 40x13 is widely used for the manufacture of inexpensive domestic kitchen knives.

Products made from this steel are perfect for use on the farm, as they do not rust under any circumstances, are easy to sharpen and are convenient both to use and to maintain. A knife with such steel can easily cut all types of gastronomic products, meat, fish, vegetables and fruits. This blade is not only sharp enough, but also completely safe for use for food purposes. In addition, 40x13 steel is used for the production of medical scalpels and other instruments. Measuring devices, springs, bearings, compressor elements and other items that are used in the household are made from it.

The only disadvantage of products made from such steel is such a factor as instability to aggressive environments and high temperatures. Therefore, this type of steel must not be used for welding.

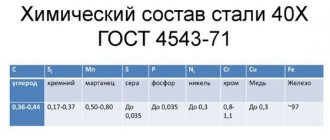

Chemical composition of steel

- the amount of carbon (C) in the alloy is from 0.36 to 0.45 percent;

- the other component is silicon (Si) . In percentage terms, its amount does not exceed 0.8. The same amount of manganese (Mn) ;

- chromium (Cr) gives corrosion resistance . 12 to 14 percent is an excellent figure;

- not without impurities in the form of sulfur (S) - up to 0.025%, and phosphorus (P) - up to 0.030%;

Technological properties

Steel gains its resistance to corrosion after undergoing a complex technological process, which consists of special hardening. During this action, complete dissolution of the carbide is noted, resulting in anti-corrosion protection. The decrease in corrosion resistance is associated with a low chromium content in the carbide or a decrease in the melting point to 6000C. If the technological process is carried out correctly, this phenomenon should not occur.

Steel melting is carried out in open furnaces or induction furnaces.

The temperature ranges from 850 to 11000C. This value is sufficient for complete deformation. To avoid the formation of cracks, the technological process includes heating and cooling modes, carried out alternately.

Molten steel 40Х13.

Heat treatment

Due to the high chromium content, 40x13 steel must be heated at a high temperature, and it must be heated very precisely.

Proper hardening gives high hardness (58HRC), but at the expense of ductility. It is believed that the hardness of 40x13 should be in the range from 53 to 56 HRC. Values exceeding this threshold are either greatly overestimated, or the hardening technology was violated. This action makes the steel too brittle.

What characteristics does steel 40x13 have?

Steel grade 40x13 has the following characteristics:

- Has powerful heat resistance.

- Resistance to various corrosions.

- It is considered an absolutely non-rusting material.

Steel acquires its anti-corrosion properties thanks to a complex technological process that involves special hardening. As a result of this procedure the carbide is completely dissolved , which provides anti-corrosion protection for the material. One of the reasons for the decrease in resistance to corrosion is the reduced chromium content in the carbide or a decrease in the melting point of steel to 600 degrees. But, if the technological process is provided correctly, then this should not happen.

Steel is melted in special open furnaces. Induction furnaces can also be used for this. The process of melting steel is carried out at temperatures from 850 to 1100 degrees , which ensures its complete deformation. To prevent cracks from forming, the technological procedure provides for special heating and cooling modes, which are carried out alternately.

Components after hardening

After the steel has undergone the hardening procedure, its components are the following elements:

- carbide particles;

- martensites;

- residual austenites.

After reaching a temperature limit of 1050 degrees and above, a decrease in the hardness of the material is observed. This indicates an increase in the amount of austenite in the steel composition. When the melting temperature decreases to 450-550 degrees, secondary hardness of the material is observed, which occurs as a result of the release of fine carbide from the steel composition.

Reviews

The popularity of products made from 40x13 steel is confirmed by numerous reviews from tool users. Such properties as sharpness and ease of sharpening are especially noted. Many also like the ease of maintenance and anti-corrosion properties.

A lot of feedback comes from medical workers, in particular from surgeons. It’s not for nothing that the material is called medical steel.

Thrifty housewives note that this is quite suitable steel for household purposes, subject to normal heat treatment. Some have been using knives for about 20 years, and even take them on hikes. The tool has never failed. Particularly pleasing is the easy sharpening with any available tools.

Manicurists and hairdressers like tools made from medical steel. They also note the durability of 40x13 steel products. Nippers and other cutting tools are needed to give nails a certain shape and neatness. A manicurist with ten years of experience admires its durability: the tool remains sharp for a long time and does not deform when sharpened.

Manicure tool made of steel 40X13.

We must not miss the point that any, even the most durable thing, requires that it be treated carefully and comply with the minimum requirements. Knife blades, for example, do not like to be stored in damp conditions. Do not leave the surface dirty. If you neglect these rules, rust appears on the blades. It can be removed when sharpening, but durability will suffer.

The material for knives must have certain properties. Be soft enough to sharpen, hard enough to not become dull when cutting. Do not rust, withstand temperature changes, safe enough for the food industry. The required qualities are achieved by composition and processing. A popular alloy for the production of knives is stainless steel 40X13 . It is used in everyday life, industry, fishermen, and hunters. This steel differs from others in its low cost and ease of maintenance. The quality of the material depends on the country of origin and the purity of the alloy.

Characteristics of steel

Steel - martensitic class, intended for parts operating at temperatures up to 450 degrees , as well as in corrosive environments. Belongs to group X13 . The absence of nickel reduces the formation of carbides, which contributes to the stability of mechanical properties. The quantitative composition of additional alloying elements is the same throughout the group. This allows you to have a number of mechanical and chemical properties as a result of the use of heat treatment technology:

- Corrosion resistance.

- Heat resistance.

- Heat resistance.

- Wear resistance.

Corrosion resistance is ensured by the content of martensite , carbides and retained austenite in the hardened state of the microstructure. It is characterized by increased resistance to vibration and alternating loads that occur in products operating at temperatures above 300 degrees Celsius .

For a material of this class, obtaining a combination of strength and hardness is not easy. The higher the hardness, the more brittle the parts become, and under impact loads they will be prone to cracking.

Heat treatment is used depending on the operating conditions of the product. For shafts and axles operating under conditions of mechanical and corrosive wear in a humid environment, normalization with exposure and high tempering is used. For products subject to shock loads during operation, stepwise hardening with high tempering is used, the number of cycles depends on the required surface hardness.

Surface hardness index for a knife is 40-60 HRC . Operating range 52-58 HRC . Steel 40X13 is difficult to harden . But you can achieve 57 HRC . The delivery condition ensures the hardness of the rolled products up to 229 HB .

It is well subjected to hot deformation - forging under slow heating and cooling conditions. Cold deformation is limited.

The alloy is produced in hot-rolled form. There are sheets, shapes, long products, calibrated rods, strips, tapes, and wires.

Composition and properties

The composition of steel grade 40x13, in addition to the main components, includes the following chemical elements: chromium (14%), carbon (does not exceed 0.45%), the remaining elements silicon and others account for no more than 0.8%, which corresponds to GOST 5582-75.

Download GOST 5582-75

Chemical composition of steel

The main chemical elements included in the composition are: iron, carbon, silicon, manganese, chromium, sulfur and phosphorus. The percentage of carbon content in this steel (depending on the release) varies in the range of 0.36-0.45%. This steel is classified as medium carbon.

Chemical composition of steel 40x13

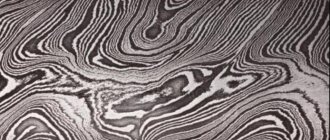

The chemical microstructure in the quenched state includes martensites, carbides and residual austenite content. It is these elements that provide good corrosion resistance. Higher performance is inherent only in stainless steel grade 30x13.

Mechanical properties

The mechanical properties of 40x13 steel are determined by its composition and processing method. After special softening treatment and subsequent tempering at a temperature of about 740 degrees, it is possible to increase the tensile strength and reach a value of 560 MPa. This treatment makes it possible to achieve a relative elongation of more than 15%, which is very important for further machining. If it is hot-rolled steel with subsequent forging and calibration, then its hardness reaches 229 HB. After the hardening procedure, the Rockwell hardness exceeds 55 HRC units. The density of this steel grade is 7.68 g/cm3.

Mechanical properties of steel 40x13

After successive hardening and gradual low tempering, this grade of steel acquires good anti-corrosion properties. The only limitation in this area is long-term use in a coastal atmosphere or in salty sea water.

Based on the given physical properties, grade 40x13 can be classified as a tool steel.

Steel analogues and scope

4X13 is the old name. There are foreign analogues that differ in the purity of the alloy, the absence or presence of impurities.

Foreign analogues from different suppliers: American AISI420, Japanese SUS420J2, French X40Cr14, English 420S45, Italian X40Cr14, Spanish F.3404, Chinese 4C13, Polish 4h23, Czech 17024. All analogs have similar characteristics.

Application area:

- Measuring tool.

- Cutting tool.

- Household items.

- Medical instruments.

- Shafts.

- Springs.

- Bearings.

- Measuring devices for forging production.

- Details of compressor units.

- Cutting knives of devices for hot stamping.

Disadvantages of use

The disadvantages of parts made from 40X13 include:

- Instability to aggressive environments.

- Poor weldability of parts.

- To achieve the required hardness, it is necessary to use multi-stage hardening and tempering.

- Do not use on hard surfaces.

- It is not recommended to store in damp conditions; the part is subject to pitting corrosion.

The appearance of corrosion points due to improper storage will be removed by repeated sharpening, which is considered one of the disadvantages and advantages of steel.

Application

Previously, this material was used to make Soviet and inexpensive kitchen knives . Unfortunately, due to their low cost, they were of relatively poor quality (due to the factories that manufactured the knives, not the steel), but they were excellent for ordinary household and kitchen purposes. With such a knife you could easily cut chicken and other meat dishes, but the most important advantage was safety for health. There is simply no risk of contracting any chemical disease using 40x13 steel.

A separate area of application is aircraft modeling. In aircraft manufacturing, it is impossible for the material from which important components are made to be highly electrified and subject to various types of corrosion, because human lives are at stake. The designers would not use low-quality steel, so this fact will be another plus. But the most common method of use is the manufacture of various components. High strength and the ability to be used in mechanisms subject to wear make the material the main component .

It is worth noting that medical scalpels are made precisely from the above alloy, which confirms the information about safety for the human body. This steel is also used to produce various technical devices: bearings, springs, elements for measuring systems, compressor parts and many things necessary in everyday life.

One of the main disadvantages is the fact that it is absolutely forbidden to use this steel for welding . With a sharp change in temperature, it loses many of its properties, begins to rust, and the crystal lattice is destroyed.

How to make a knife from steel 40X13

The technology for making a knife from steel 40X13 is the same as for other grades of steel. If you are making your first blade, then you need 40X13 steel to master the technological process .

The workpiece must be forged, preferably to a given configuration . The forging process strengthens the structure, which will have a good effect on the properties of the cutting part.

A template of the future blade is applied to the forging and cut along the contour. Cutting is carried out only in the tempered state of the workpiece, with simultaneous cooling. Avoid overheating when cutting.

The edges and planes are pre-processed and sharpened to the required dimensions, and holes are drilled in the handle to install fastening pins. Heat treatment (hardening, tempering) is carried out to impart hardness and ductility.

The workpiece is polished with mandatory cooling. Overheating will weaken the steel and reduce its strength. Polished to a shine.

The manufactured wooden handle is mounted on pins. It is glued with epoxy glue, sanded until smooth so that it fits well in the hand, and treated with oil. The oil protects against moisture and gives the wooden handle a beautiful look. Final grinding of the cutting edge of the blade. A convenient and practical knife is ready.

Basic qualities of the alloy

Main characteristics of steel 40 x 13:

- One of the first and very important parameters is the high heat resistance of the material.

- The second parameter, which also plays a very important role, is resistance to various types of corrosion. This significantly increases the service life of all products made from this brand.

- Steel 40 x 13 is a composition that almost never rusts.

Such a product largely owes its high anti-corrosion qualities to a complex and lengthy production process, which necessarily includes a stage such as hardening of the material. The result of this procedure was the complete dissolution of a substance such as carbide. This is what gives high protection against corrosion.

It may be that resistance to this defect may be reduced. This most often occurs if the amount of carbide in the chromium is too small or if the melting temperature of the steel is reduced to 600 degrees. However, with the right process, this usually does not happen.

Steel 40 x 13 is melted in special open furnaces. To carry out this procedure, you can use induction-type ovens. The metal smelting process itself occurs at temperatures from 850 to 1100 degrees Celsius. In order to avoid cracks during strong heating, the technological operation occurs in stages, alternating heating and cooling of the material.

Conclusion

Safe and widely used steel suitable for common kitchen knives . You can’t do without them in your household - they are easy to care for, easy to sharpen, and have stainless properties. Cutting any food is not difficult at all. Sufficient hardness of the knife body, sharp edge, and not too wide knife will allow you to thinly slice any product.

Widely used in everyday life - a knife on the kitchen table, a scalpel in the hands of a surgeon, measuring devices, springs, shafts, household products, and industry.

| ✅ Manufacturer | Knight |

| ✅ Total length | 202 mm |

| ✅ Blade length | 102 mm |

| ✅ Handle material | Bakelite |

The tourist folding knife looks decent and is of appropriate quality, despite the low price. The wide blade with a 2.1 mm spine has high slopes and a thin tip, which allows for smooth, precise cuts. The bakelite handle fits comfortably in the hand thanks to the classic grooves. And the metal guard and pommel reliably protect the bakelite part of the handle from damage.

Gudgeon

| ✅ Manufacturer | Knight |

| ✅ Total length | 220 mm |

| ✅ Blade length | 114 mm |

| ✅ Handle material | Tree |

This multi-purpose tool will come in handy when camping and for performing most household tasks. The blade here is fixed, made of the considered steel 40x13, therefore it has all its pros and cons. The handles are wooden, with an easily recognizable texture. The guard is metal and serves to protect the hand from slipping and the main part of the handle from damage. “Gudgeon” is supplied complete with a textile case made of cordura.

Mosquito

| ✅ Manufacturer | Knight |

| ✅ Total length | 120 mm |

| ✅ Blade length | 60 mm |

| ✅ Handle material | Tree |

The 40x13 butcher knife is hardened to 54-56 HRC and has a good ratio of hardness and elasticity. “Mosquito”, like other thrust knives, is intended for self-defense, but is not a bladed weapon. Its compactness and lightness (70 g) are convenient for everyday wear. The shape of the handle and the large finger cutout provide a secure, firm grip.

Midshipman

| ✅ Manufacturer | Pirate |

| ✅ Total length | 220 mm |

| ✅ Blade length | 100 mm |

| ✅ Handle material | Tree |

“Michman” is not just a folding tool, but more of a multifunctional tool. The main element is a full-fledged blade with a hardness of 55 HRC, which opens using a nail hook. There is also a corkscrew, bottle opener and can opener. All elements are made of steel 40x13. The folding mechanism has a built-in Back lock - simple, but strong and reliable. The handles are made of wood; the pommel has a narrow hole for a lanyard.

Flint

| ✅ Manufacturer | Pirate |

| ✅ Total length | 200 mm |

| ✅ Blade length | 83 mm |

| ✅ Handle material | Ebony |

An automatic folding device is useful on a hike, at home or in urban environments. The versatility is largely ensured by the successful shape of the blade, high slopes, and a razor-sharp blade. The Plunge-lock lock provides reliable fixation in the open and closed state. The handles are made of black (ebony) wood, firmly secured with metal rivets.

Rimbaud

| ✅ Manufacturer | Pirate |

| ✅ Total length | 395 mm |

| ✅ Blade length | 250 mm |

| ✅ Handle material | Cord wrapping |

A true survival tool. The butt is not smooth, but has deep teeth, which allows the tool to be used as a file. The guard performs the task of a Phillips and flathead screwdriver. The handle is wrapped with synthetic thread for a rigid grip on the hand, and on the pommel there is a special metal element with a hole for a lanyard.

The pommel unscrews, and a compass and a plastic container are hidden inside the handle. The container contains a good emergency supply: adhesive plaster, matches, fishing line and hook. “Rimbaud” is supplied complete with a leather case.

Target

| ✅ Manufacturer | Nozhemir |

| ✅ Total length | 240 mm |

| ✅ Blade length | 142 mm |

| ✅ Handle material | Stainless steel |

A set of 3 throwing knives, as expected, made of 40x13 steel. For throwing you need a reliable tool that is not afraid of shock loads, with an optimal ratio of hardness and flexibility. This is exactly what Michel knives are thanks to the correct processing of the alloy. Each blade is decorated with original engraving. Deep valleys and a properly aligned center of gravity help maintain the flight path. The set comes in a folding cordura case with 3 compartments.

Atacama-2

| ✅ Manufacturer | KNOX |

| ✅ Total length | 370 mm |

| ✅ Blade length | 230 mm |

| ✅ Handle material | Nut |

A serious survival tool used as a knife, ax or machete. The shape of the blade actually resembles the famous edged weapon – the machete. It is convenient to rest your hand on the butt, which is as much as 5 mm thick, when performing heavy cutting work. For safety, there is a reliable long guard and finger grooves on the butt. The non-slip surface of the wooden handle also prevents your hand from slipping. Supplied complete with a nylon case.

Frenchman

| ✅ Manufacturer | Viking Nordway |

| ✅ Total length | 230 mm |

| ✅ Blade length | 100 mm |

| ✅ Handle material | Wood, steel |

This lightweight, elegant folding knife is useful for daily carry or for use in natural conditions. The narrow blade lends itself well to sharpening to a razor sharpness and is not afraid of mechanical stress. The bevel on the butt and the finely pointed point ensure a correct, controlled cut. The wooden handle has shallow grooves for a comfortable grip, a recognizable original texture, and does not get cold on the hand. A nail hook is provided for opening.

Novgorod

| ✅ Manufacturer | Knight |

| ✅ Total length | 269 mm |

| ✅ Blade length | 140 mm |

| ✅ Handle material | Metal, plywood |

A working knife is useful for any cutting work in nature: while hiking, hunting or fishing. The fixed blade is hardened to 56 HRC, has optimal impact strength, and can be sharpened with standard abrasives. The name of the model and manufacturer's brand is engraved in the area of the canvas. There is also patterned engraving on the metal guard. A nylon case is provided for storage and transportation.

Sources used:

- https://vashnozh.ru/stal/40×13

- https://plusiminusi.ru/stal-40×13-dlya-nozhej-plyusy-i-minusy/

- https://muzhskie-hobby.ru/luchshie-nozhi-iz-stali-40h13/