Organizations performing high-risk work are required to undergo periodic compliance testing, which results in the issuance of a permit or certificate giving the right to carry out the relevant activity. NAKS certification is a check of the level of training of welders, technology and compliance of the enterprise with current technical standards. In regional centers, personnel involved in welding work can improve their skills.

What does it represent?

Every welder should know how to decipher the abbreviation NAKS. This is the National Welding Control Agency , which deals with the welding certification system. First of all, this applies to enterprises whose activities are controlled by Rostechnadzor. In addition to NAKS certification of welders, the committee checks joining technologies and materials used.

NAKS - the decoding of the abbreviation is clear. In addition to the above functions, her area of responsibility includes:

- Develop and approve methodological guidelines in accordance with the latest scientific achievements.

- Provide consulting support regarding the best ways to perform work.

- Controls the activities of certification centers and provides them with information and logistical support.

- When conducting inspections of organizations and individual specialists, the composition of the certification commission is approved.

- Accounting for existing registers, which include information about persons who have undergone certification for various types of activities, as well as the final results.

Welding methods

Certification of NAKS equipment is carried out taking into account technologies that can be applied to one or another type. If you are going to take the exam, you should definitely know how to decipher each type of welding. For beginners, here is a translation of some of them:

- MP – mechanized welding using a consumable electrode, carried out in a shielding gas environment.

- RAD – manual welding with a tungsten electrode in an argon environment.

- RD - manual arc welding using a consumable electrode.

- AF – automatic welding carried out using flux.

- P – plasma welding.

- MPS – mechanized welding using flux-cored wire.

- ES – electroslag welding.

- MAWP – mechanized welding using a consumable electrode in an argon environment.

- AMA – automatic welding with a tungsten electrode in an argon environment.

- AADP – automatic welding using a consumable electrode in an argon environment.

- G – gas welding.

Who can and should pass?

If the welder’s activities are random in nature, and the places where work is performed are predominantly private objects, there is no point in preparing any documents. Obtaining a certificate is the main step on the path to professional activity.

Potential candidates must submit a medical certificate confirming their level of health and the absence of contraindications. In addition, a document on basic and vocational education, if available, is required.

All workers involved in welding work are required to undergo certification by a NAKS specialist, based on the results of which a certificate is issued. The validity period and type of approval depends on the level of certification.

There are four levels of NAKS for training specialists:

- Level 1 . Designed for ordinary employees directly involved in the welding process.

- Level 2 . Master. This level of training is necessary for junior managers who monitor the progress of work and the execution of assigned tasks. Implies deeper knowledge of welding technology. The main conditions for obtaining a certificate of this level are the requirement of work experience in the profile.

- Level 3 . Technologist. For employees involved in the preparation of technical documentation, for example, work projects, which provide instructions on the selection of the necessary welding methods.

- Level 4 . Engineer. Highest level of training. A higher specialized education is required for training. The presence of this degree of certification allows us to approve design documentation for industrial and construction projects.

All employees, starting with the foreman, undergo mandatory certification. Its presence is the main requirement when obtaining a permit to perform critical work, the list of which is approved at the legislative level.

Welders levels

According to the NAKS system, there are four levels of professional training:

. Must have a diploma and rank. Persons who have undergone professional training at courses, schools, or at their place of work are allowed for inspection. The minimum work experience in a specific type of welding varies from 6 to 12 months.

. Must have secondary technical education or higher education, undergo training in advanced training centers. With higher education, work experience is acceptable from 6 months. With an average - 9-36 months.

. Persons with higher technical education in welding. Work experience from 6 to 12 months and level II certification. If there is no such certificate, the work experience must be 18-36 months.

. Persons with higher education in welding production. It is acceptable to not have a higher education diploma in welding if you have academic degrees (doctor, candidate) in technical sciences.

Requirements for training specialists

Regardless of the level to which a candidate is applying, basic education and training in welding technology is a prerequisite.

Before certification, employees undergo a special training course, the complexity of which depends on the level of training . The program is developed in accordance with modern requirements for welding production. It includes familiarization with the latest equipment for performing work in various modes and the features of their operation, the consumables used, as well as techniques for safe and high-quality creation of permanent connections.

Kinds

Let's consider groups of technical devices of hazardous production facilities of NAKS, where welding and surfacing work should be carried out only by certified specialists:

- NAKS NGDO . This includes facilities in the oil and gas industry: Main pipelines for transporting petroleum products, industrial gas pipelines, tanks for storing petroleum products, gas tanks for gas storage facilities, as well as other oil and gas field, drilling and oil refining equipment.

- NAKS OCNVP . This group includes enterprises of the chemical, petrochemical, oil refining industries, as well as explosive objects: Tanks for storing explosive and toxic substances, oil refining equipment operating under pressure above 16 MPa, cryogenic equipment, isothermal storage facilities, waste heat boilers and boiler equipment.

- NAKS CO . Boiler equipment, including steam boilers with operating temperatures above 115 Cº, steam and hot water pipelines, fittings and safety devices, as well as various designs for boiler equipment.

In addition to the above objects, the NAKS group of technical devices includes the following equipment:

- PTO – lifting and transport;

- GO – gas;

- MO – metallurgical;

- GDO – mining;

- OTOG – for transportation of dangerous goods;

- SK – building structures;

- Steel bridge structures;

- PR – other designs.

The NAKS equipment used is certified by type of welding, ranging from manual arc joining technology to automatic submerged arc welding.

There are four types of certification:

- Primary . All workers who do not have permission to carry out welding or surfacing work pass.

- Additional . It is necessary in cases where it is necessary to add additional work to the certificate for which the employee does not have access. In addition, additional certification is carried out if new regulatory documents are approved.

- Periodic . Carried out to extend the validity period of permitting documents. The verification interval depends on the type of identity.

- Extraordinary . It is carried out in case of cancellation of a valid certificate for any reason: gross violation of technological requirements, inadequate quality of the seam. As a rule, it is appointed on the instructions of the regulatory authority.

During an extraordinary inspection, it is necessary to go through all stages of certification, from general to specialized exam.[stextbox]

In this article:

It states that they have the right to conduct preparatory courses and certification, study welding equipment for compliance with specifications, and check welded joints. Now there are accredited centers with a license that have the right to carry out inspections and issue certificates.

The need for certification arises at enterprises and industries operating under the Gosgortekhnadzor of Russia, where the following is used:

- transportation mechanisms for moving dangerous goods;

- lifting and transport devices;

- building construction;

- gas equipment;

- mining;

- boiler room;

- metallurgical;

- equipment for chemical, explosive, petrochemical production.

What is needed to obtain a qualification certificate?

On the Internet you can find many advertisements, the authors of which offer everyone who wants to receive a NAKS certificate within 1-2 days. They are placed by scammers, and a document purchased in this way will be invalid. When trying to get a job, the deception will be revealed, since the certificate will not be in the NAKS register.

Before contacting the nearest regional center, you must prepare the following documents:

- Written statement;

- Certificate of education;

- A document confirming the candidate's qualifications;

- Extract from the work book;

- Photo 3x4 – 2 pcs.;

- Occupational health and safety certificate;

- Medical certificate.

Remember that a welder with a NAKS certificate is a professional, which is confirmed by the relevant committee . All other things being equal, the employer will give preference to a certified employee. In addition, specialists are always entrusted with the most responsible work, which is reflected in the level of wages.

Order of conduct

The certification procedure is established in accordance with the current regulatory documents of NAKS, which coordinates the activities of regional centers.

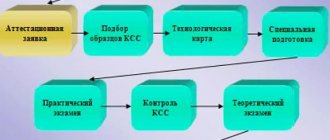

Stages of certification of welders:

- The specialist provides the nearest regional center with a package of documents, including an application, a certificate from the place of work or an extract from the work record book, documents confirming qualifications, as well as a medical certificate of the established form.

- The processing time for the application is 3 days. The candidate is notified of the committee's decision by written notice. According to current legislation, in case of refusal, the center is obliged to indicate the reason.

- The test begins with a practical exam. The candidate receives tasks whose complexity corresponds to the declared category. The connection must be made taking into account all the requirements of the relevant government standards.

- The next stage is the theoretical exam. As with testing practical skills, the complexity and number of questions depends on the declared level. For example, to obtain a first-level certificate, you need to answer 15 questions, and to certify technologists, the number of tasks in the ticket increases to 20.

In case of a negative result, the candidate has the right to try again within 3 months . Re-certification is carried out in the same center.

The period for testing a welder’s knowledge, as a rule, does not exceed 2 weeks. The cost depends on the specific regional center and geographic location. It varies between 28,000-33,000 rubles.

Procedure for certification of welding technology

The organization submits a package of documents to the certification center, which checks the application, PDD, technological maps, documents for people and equipment. AC NAKS issues a contract and an invoice for payment, then a welding technology certification program is drawn up for this enterprise. After this, a commission visit is organized to the site or production base of the company, where welders weld samples of the welded joints and the commission takes photographs. Next, the welded samples are transferred to the laboratory, where tests are carried out (mechanical and non-destructive). After which NAKS gives a conclusion on the readiness of the applicant organization to use certified welding technology.

This is what the certificate looks like And this is what the application looks like (also known as the distribution area)

Documents based on the results of the inspection

In case of successful passing of the theoretical and practical exams, the specialist receives the following documents:

- Certificate of certification of the established form, valid throughout the Russian Federation.

- A copy of the protocol indicating successful completion of the relevant certification.

- Document confirming the completion of the inspection.

The above information is entered into electronic and paper registers.

In case of loss or damage to documents, it is enough to contact the nearest regional center with an application for restoration. It should be remembered that the resulting document is not universal . He allows the welder to perform only those works, the list of which is indicated in the certificate. To obtain other permits, you must undergo additional certification.

Professional skills require periodic testing, the interval of which depends on the type of certification. For example, for the first level this period is 2 years, and for the fourth level – 5 years. During the periodic review, you can apply for advanced training.

Welding technology certification register

Data on the certification of the enterprise are entered into the public register on the NAKS website, which guarantees its authenticity. It is available at this link. It is better to check using the certificate number and the registration number of the certification center, since a search by the name of the organization does not always work correctly.