What is NAKS

The abbreviation NAKS stands for National Welding Control Agency. This institution is engaged in the certification of both welding specialists and engineers related to welding work. Having a NAKS certificate means having access to welding hazardous production facilities and receiving a salary many times higher than an ordinary welder.

Certification of welding production specialists is not the only function of the agency. In addition, NAKS is responsible for the development and publication of methodological manuals, improvement of regulatory documents, selection of specialists for various examinations, as well as consultations during critical welding work.

Where and how to get certified by NAKS?

So, you were required to undergo NAKS certification or you want to participate in a tender where there is a condition for having NAKS certification or you work at a hazardous production facility.

Where to begin?

First, you need to accurately determine the scope of certification. To do this, you need to find out what requirements are specified in the project or what requirements are set by the Customer. To do this, in accordance with Appendix 2 of Order No. 398a of June 9, 2008, determine a group of technical devices and select a specific list of technical devices included in the group (KO, GO, OKHNVP, NGDO, SK, etc.)

Now knowing which group of technical devices needs to be certified, you need to decide what type of welding the work will be performed with. (RD - manual arc welding, RAD - manual argon arc welding, AF - automatic submerged arc welding, etc.).

And the last of the main things is to understand what metal structures require certification - diameters, thicknesses. Next, you need to look at the design documentation for welding units.

Certification is divided into 4 subsections:

- Passing certification of welding production specialists (welders, foremen, foremen, engineers, chief welders) in accordance with PB-03-273-99 and RD 03-495-02,

- Passing certification of welding equipment in accordance with RD 03-614-03,

- Passing certification of welding materials, but this is not necessary since when purchasing welding materials it is necessary to require certification from the supplier.

- Passing NAKS certification for an organization performing welding work - certification of welding technology in accordance with RD 03-615-03.

The first thing that needs to be done is to certify the staff. You have welders who need to be certified at the NAKS certification center. To do this, you need to find a certification center in your region on the website naks.ru. Go to the website of the certification center and download an application for certification of a welder - welding production specialist of level I and an application for certification of an engineer and technical worker - welding production specialist of levels II, III and IV. The welder must have at least 4 categories.

Types of certification

NAKS certification can be carried out for:

- Working personnel. An employer may oblige its employees to take NAKS exams. Employees have the right to independently undergo training and obtain a NAKS certificate in order to get a lucrative job.

- Enterprises and organizations. NACS requirements for an entire organization may increase if this company takes on a large-scale project or radically changes technology.

- Welding equipment.

As a rule, it is necessary to check the quality of equipment used in critical areas (boiler equipment, load-bearing metal structures, etc.). The technical characteristics of devices and tools are monitored, the degree of their wear is determined, and the likelihood of damage to the surfaces being welded is assessed. NAKS NGDO, as well as OCNVP, are especially carefully monitored.

Depending on the priority, NAKS certification can be:

- Primary

- Repeated

- Extraordinary.

Primary certification of welding production specialists is relevant for those who want to voluntarily confirm their professionalism and begin more complex tasks. Those welders who have not worked in their specialty for more than six months also need to undergo certification.

The repeated one is carried out 4 years after passing the previous certification. An extraordinary one is necessary only in cases where the employer doubts the professionalism of a particular employee.

Certification/training of welders and NAKS specialists is regulated by the following documents:

- PB 03-273-99 - “Rules for the certification of welders and welding production specialists.”

- RD 03-495-02 - “Technological regulations for certification of welders and welding production specialists.”

Welders/specialists are certified in independent certification centers that are part of the NAKS structure.

NAKS certification of welders/specialists is divided into 4 levels:

- The first level (I level)

is for welders. Certification gives the right to perform direct welding work. - The second level (II level)

is for welding production masters. Certification gives the right to control the entire welding process. - The third level (III level)

is for welding production technologists specializing in welding production. Certification gives the right to determine the technology of the welding process, develop and sign technological maps. - The fourth level (IV level)

is for welding engineers. Certification gives the right to sign and approve the documentation according to which welding work is carried out at the enterprise.

Cost of NAKS certification and training for welders and specialists:

| Certification | Price |

| Certification of level 1 welders | from 15,000 rubles |

| Certification of specialists of levels 2 and 3 | from 18,000 rubles |

The exact cost is formed on the basis of the Questionnaire and depends on the level of certification, the number of specialists and the necessary parameters of welding production.

Send us an application for certification, and our managers will calculate the cost of the services you need.

Our company offers its assistance in training and further certification of welders and welding production specialists at NAKS for levels I, II, III.

Level I.

For certification of level 1 welders, the following main parameters are taken into account:

1. Welding/surfacing method:

For metal materials

- RD (111) - Manual arc welding with coated electrodes.

- RDN (111) - Manual arc surfacing with coated electrodes.

- RAD (141) - Manual argon arc welding with a non-consumable electrode.

- RADN (141) — Manual argon arc surfacing.

- MP (135) — Mechanized welding with a consumable electrode in active gases and mixtures.

- MPN (135) - Mechanized surfacing with a consumable electrode in an environment of active gases and mixtures.

- MADP (131) - Mechanized argon arc welding with a consumable electrode.

- MADPN (131) — Mechanized argon-arc surfacing with a consumable electrode.

- MPG (136) — Mechanized welding with flux-cored wire in active gases and mixtures.

- MPGN (136) — Mechanized surfacing with flux-cored wire in active gases and mixtures.

- MPI (137) — Mechanized welding with flux-cored wire in inert gases and mixtures.

- MPIN (137) — Mechanized surfacing with flux-cored wire in inert gases and mixtures.

- MPS (114) — Mechanized welding with self-shielding flux-cored wire.

- MPSN (114) — Mechanized surfacing with self-shielding flux-cored wire.

- MLSN (114) — Mechanized surfacing with self-protecting flux-cored tape.

- MSOD (113) — Mechanized open arc welding with alloy wire.

- MF (121) — Mechanized submerged arc welding.

- MDS (781) — Mechanized arc welding of studs (rods).

- MKS (782) — Mechanized contact welding of studs (rods).

- AF (12) - Automatic submerged arc welding.

- AFPN (12) — Automatic surfacing with submerged arc wire electrode.

- AFLN (12) — Automatic surfacing with a submerged strip electrode.

- AFDS (782) - Automatic submerged arc welding of studs (rods).

- AAD (141) - Automatic argon arc welding with non-consumable electrode.

- AADN (141) — Automatic argon arc surfacing with a non-consumable electrode.

- AADP (131) — Automatic argon arc welding with a consumable electrode.

- AADPN (131) — Automatic argon arc surfacing with a consumable electrode.

- APG (135) - Automatic welding with consumable electrode in active gases and mixtures.

- APGN (135) - Automatic surfacing with a consumable electrode in active gases and mixtures.

- APPG (136) - Automatic welding with flux-cored wire in active gases and mixtures.

- APPGN (136) — Automatic surfacing with flux-cored wire in active gases and mixtures.

- API (137) - Automatic welding with flux-cored wire in inert gases and mixtures.

- APIN (137) — Automatic surfacing with flux-cored wire in inert gases and mixtures.

- APS (114) - Automatic welding with self-shielding flux-cored wire.

- APSN (114) — Automatic surfacing with self-shielding flux-cored wire.

- ALSN (114) — Automatic surfacing with self-protecting powder strip.

- P (15) — Plasma welding.

- PPN (15) - Plasma surfacing with solid wire.

- PNP (15) - Plasma powder surfacing.

- ESH (72) – Electroslag welding.

- G (3) - Gas welding.

- GN (3) - Gas surfacing.

- KTS (21) - Contact spot welding.

- KSS (25) - Resistance butt welding.

- KSO (24) - Flash butt welding.

For polymer materials

- NI - Welding with a heated tool.

- ZN - Welding with embedded heaters.

- NG - Welding with heated gas.

- E - Extrusion welding.

- T - Thermite welding - types of welds.

2. OTU group (hazardous technical devices):

PTO - Lifting and transport equipment

- Load-lifting cranes.

- Cranes - pipe layers.

- Cranes are manipulators.

- Elevators.

- Tali.

- Winches.

- Load-handling devices.

- Lifts (towers).

- Escalators.

- Ropeways, their units, mechanisms and parts.

- Chains for lifting and transport equipment.

- Construction lifts.

- Passenger conveyors.

- Metal structures for lifting and transport equipment.

KO - Boiler equipment

- Steam boilers with a steam pressure of more than 0.07 MPa and hot water boilers with a water temperature above 115°C.

- Steam and hot water pipelines with a working steam pressure of more than 0.07 MPa and a water temperature of more than 115°C.

- Vessels operating under pressure above 0.07 MPa.

- Fittings and safety devices.

- Metal structures for boiler equipment.

GO - Gas equipment

- Pipelines of internal gas supply systems.

- External gas pipelines of low, medium and high pressure. 2.1. Steel. 2.2. Made from non-metallic materials.

- Gas equipment for boilers, process lines and units.

- Gas burner devices.

- Capacitive and instantaneous water heaters.

- Apparatuses and ovens.

- Fittings made of metal materials and safety devices.

NGDO – Oil and gas production equipment

- Field and main oil product pipelines, pipelines of oil pumping stations (OPS), providing transportation of oil and oil products during construction, reconstruction and major repairs.

- Field and main oil product pipelines, pipelines of oil pumping stations (OPS), providing transportation of oil and oil products during routine repairs during operation.

- Field and main gas pipelines and condensate pipelines; pipelines for transporting commercial products, pulsed, fuel and starting gas within: integrated gas treatment plants (CGTUs), compressor stations (CS), booster compressor stations (BCS), underground gas storage stations (UGS), gas distribution stations (GDS), gas flow measurement units (UZRG) and gas reduction points (PRG).

- Pipelines within the gas treatment facility, compressor station; NPS; SPHG; DKS; GRS; UZRG; PRG, etc., with the exception of pipelines providing transport of gas, oil and petroleum products.

- Tanks for storing oil and petroleum products, gas tanks for gas storage facilities during construction and repair.

- Offshore pipelines, offshore facilities (pipelines on platforms, as well as welded bases of offshore platforms) during construction, reconstruction and repair.

- Unique objects of the oil and gas industry during construction and repair (operating parameters of the objects are not provided for by the current regulatory documentation).

- Shut-off valves during production and repair in factory conditions.

- Pipeline parts during production and repair in the factory.

- Pumps, compressors and other equipment during manufacturing and repair in factory conditions).

- Oil and gas pipelines during production and repair in factory conditions.

- Oil and gas field, drilling and oil refining equipment.

- Pipelines of automated gas filling compressor stations (CNG filling stations).

MO - Metallurgical equipment

- Blast furnace, coke and steelmaking equipment.

- Technological equipment and pipelines for ferrous and non-ferrous metallurgy.

- Technical devices for the production of ferrous and non-ferrous metals and alloys based on them.

- Machines for casting steel and non-ferrous metals.

- Pipe rolling units.

- Crimping, billet, section rolling and sheet rolling mills.

OKhNVP - Equipment for chemical, petrochemical, oil refining and fire and explosion hazardous industries

- Equipment for chemical, petrochemical, and oil refining industries operating under pressure up to 16 MPa.

- Equipment for chemical, petrochemical, and oil refining industries operating under pressure of more than 16 MPa.

- Equipment for chemical, petrochemical, and oil refining industries operating under vacuum.

- Tanks for storing explosive and fire hazardous and toxic substances.

- Isothermal storage facilities.

- Cryogenic equipment.

- Equipment for ammonia refrigeration units.

- Ovens.

- Compressor and pumping equipment.

- Centrifuges, separators.

- Tanks, containers (barrels), cylinders for explosive and fire hazardous and toxic substances.

- Waste heat boilers.

- Energy technology boilers.

- Boilers HERE.

- Pipeline fittings and safety devices.

- Process pipelines and pipeline parts.

GDO – Mining equipment

- Technical devices for mining and mineral processing industries and underground facilities (including equipment for mine installations and mine elevators).

OTOG - Equipment for the transportation of dangerous goods

- Specialized containers and packaging used for the production and transportation of dangerous goods and construction materials.

- Tanks.

- Crew part.

SK - Building structures

- Metal building structures.

- Reinforcement, reinforcing and embedded products of reinforced concrete structures.

- Metal pipelines.

- Structures and pipelines made of polymeric materials.

KSM - Steel bridge structures

- Metal structures of spans, supports and pylons of steel bridges when manufactured in a factory.

- Metal structures of spans, supports and pylons of steel bridges during assembly, welding and repair in installation conditions.

3. Groups of basic materials with which the welder works

- M01 - Carbon and low-alloy structural steels of the pearlitic class with a yield strength of up to 360 MPa;

- M02 - Low-alloy heat-resistant chrome-molybdenum and chrome-molybdenum-vanadium steels of the pearlitic class;

- M03 - Low-alloy structural steels of the pearlitic class with a yield strength of over 360 MPa;

- M04 - High-alloy (high-chromium) steels of martensitic, martensitic-ferritic and ferritic classes with chromium content from 10% to 30%;

- M05 - Martensitic alloy steels with chromium content from 4% to 10%;

- M06 – Cast iron;

- M07 - Reinforcing steels for reinforced concrete structures;

- M11 - High-alloy steels of austenitic-ferritic and austenitic classes;

- M21 - Pure aluminum and aluminum-manganese alloys;

- M22 - Non-heat-strengthening aluminum-magnesium alloys;

- M23 - Heat-strengthening aluminum alloys;

- M31 – Copper;

- M32 - Copper-zinc alloys;

- M33 - Copper-nickel alloys;

- M34 – Bronze;

- M41 - Titanium and titanium alloys;

- M51 - Nickel and nickel alloys;

- M61 - Polyethylene (PE);

- M62 - Cross-linked polyethylene (PE-X);

- M63 - Polyvinyl chloride (PVC);

- M64 - Polypropylene (PP).

Levels II and III.

To certify specialists of levels 1 and 2, the following main parameters are taken into account:

- OTU groups (hazardous technical devices).

Certification of welders and NAKS specialists can be carried out in any region of the Russian Federation, regardless of where the specialist plans to work.

Certificates of welders and welding production specialists give the right to perform only those welding works for which he is certified.

Information about the documents received based on the results of certification of welders/specialists is entered into the open register of NAKS.

Validity period of documents for welders and NAKS specialists:

- 2 years – for level 1 welders;

- 3 years – for level 2 craftsmen and level 3 technologists;

- 5 years – for level 4 engineers.

Upon expiration of the certificate, it is extended; the welder/specialist undergoes periodic certification. You can submit documents for extension no later than 1 month. before the end of their term. Periodic certification can be completed no more than twice. Next, you must again undergo primary certification.

Employee levels for certification

Testing of knowledge, skills and abilities of working personnel is carried out at four levels.

- Welder NAKS. A NAKS electric and gas welder who has successfully passed the exam and received a certificate may be allowed to work in critical areas. His responsibilities include welding of any metals and alloys in all spatial positions, as well as planing, welding, and cutting of material. It is necessary to have extensive experience in applying sutures of any kind and be able to make rational decisions in emergency situations.

- Master welder. The requirements for such a specialist are slightly higher. It is understood that his competence will include not only NAKS welding. The employee must be able to supervise the work of other welders and give them recommendations orally or in writing.

- Technologist. His direct responsibilities include control over production processes at the enterprise.

- Engineer. Responsible for the rules governing the welding process and the documentation approving them.

Types of certification

The certification carried out by the National Agency has several classifications, which depend on the presence of previously passed certification, as well as on the assigned level based on the results of such certification.

By type, depending on the previous certification, all activities are divided into the following:

- primary _ This type is carried out in cases where a welder or welding specialist has not previously undergone the entire range of measures for a certain type of work;

- periodic _ This type is used in cases where it is necessary to renew a previously received certificate due to the expiration of its validity period;

- additional . Certification of this type is carried out if it is necessary for a welder or welding production specialist to obtain qualifications in a new set of technologies, equipment or materials. Carrying out additional certification does not involve issuing an independent certificate: a special insert is issued for an existing document;

- extraordinary _ This type of certification activities is carried out in the event that a welder or welding production specialist has been removed from work due to significant deficiencies in work, or new confirmation of previously assigned qualifications is required (for example, when the essential conditions for the use of certain technologies change).

If we talk about the levels that are assigned based on the results of certification activities, then the following division takes place:

- first level . A person who has received this level can work as a certified welder or welding complex operator. The data is entered into the new NAKS certificate (except in cases of additional certification);

- second level . A person whose certificate contains such an indication is a certified welding master. An employee at this level may be assigned responsibilities for responsible supervision and control of the full range of welding work;

- third level . An employee who has received this level is a certified welding production technologist. Persons who have this certification level are assigned responsibilities for management and technical control over the performance of all welding-type work, as well as for working with engineering and engineering documentation, including the development and subsequent approval in specialized departments of technological maps; for carrying out approval certification activities in relation to welders who must receive permission to work (accompanied by the preparation of approval sheets); to carry out work to certify the equipment and technologies used;

- fourth level . An employee who has been assigned this level based on the qualification requirements of NAKS is a certified engineer and can be appointed to the positions of department heads and their deputies.

What documents will be needed

Before receiving a NAKS certificate, you need to complete a package of documents. We bring to your attention a complete list of required papers:

- Documents confirming education.

- Medical certificate indicating the absence of diseases incompatible with welding production.

- A certificate indicating the length of work experience.

- A certificate confirming the existing rank.

- 2 photographs measuring 3 by 4 cm.

If you are applying for a higher rank and have completed the necessary courses, then you should add a certificate of completion of the training courses to the listed documentation.

Please note: for each of the 4 levels of certification you must have a different length of experience and rank. Check this information in advance with the department where the certification is carried out. In addition, please note that certification of NAKS welders is carried out separately for each type of welding.

Required documents

It is possible to pass each type of certification activities of the National Welding Control Agency only if the applicant for certification provides a complete package of documents, which includes:

- application for certification . Its formation and direction can be carried out both personally by the applicant for certification, and by the organization in which such a person works;

- a copy of the passport of a citizen of the Russian Federation or other document identifying the person being certified;

- a document confirming the level of education of the applicant for undergoing certification activities (if the applicant does not have a welding education, you will need to provide documents on completion of retraining). Foreign citizens will be required to provide documents confirming that they received specialized welding education on the territory of the Russian Federation under accredited educational programs;

- a copy of the work book or an extract from the employment order or other documents that confirm the fact of official employment for the person included in the application for certification from the organization;

- consent in accordance with which personal data will be processed;

- photograph of the established sample for issuing a certificate.

When filling out an application for inclusion in the certified group, it is necessary to indicate the group of technical devices (using a special letter code) that exist at hazardous production facilities for which it is planned to open a certificate or insert for a welder or welding production specialist (for example, KO - boiler equipment, NGDO - oil and gas production equipment, etc.).

If the certification of a welder or specialist is additional or periodic, the package of documents is expanded to include a certified copy of the existing certificate.

All copies included in this package of documents are certified either by the employer (in the case of certification from an organization) or by a notary.

Algorithm of actions

To pass the NAKS certificate and begin welding critical structures, you need to consistently follow the following steps:

- Collect a package of documents. NAKS in Russia is represented by many branches in the form of educational and certification centers. It won’t be difficult for you to come to the nearest one and take samples of the necessary papers.

- Apply. This can be done in any city, since the documents are drawn up according to a single template. The professionalism requirements for applicants are also the same in all branches.

- Wait for the application to be reviewed.

- Find out the date on which the exam will be scheduled.

- Prepare for certification.

- Pass the exam.

- Get a certificate.

- After 2 weeks, find your name in the general register of welders. Everyone who receives a certificate is transferred to the category of highly professional specialists.

Exam

To obtain a certificate, you need to pass three exams: general, special and practical. If one of them was passed with an unsatisfactory result, you will have to retake it. This can be done no later than 6 months, and no earlier than a month after an unsuccessful attempt. Please note that before this you will have to undergo NAKS training again and pay the full cost of the exam. How much does it cost to take the exam? This figure depends on the specific training center and the level for which you are applying. The average cost of a certificate in the Russian Federation ranges from 25 to 150 thousand rubles.

If all three tests were successful for you, then you will soon become the owner of the coveted “crusts”. First level specialists must undergo re-certification once every 2 years, second and third level specialists – once every 3 years, fourth level – once every 5 years.

The procedure for certification and its cost

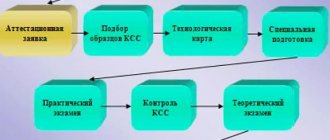

NAKS certification (except for cases of assignment of the fourth level) is carried out in the following stages:

- sending the application and package of documents to a certified certification center . You can send documents on a territorial basis or by making a choice in accordance with concluded agreements on a price basis. In addition, when sending documents, the timing of events and issuance of documents should also be taken into account;

- coordination of the timing of certification and its location (on the basis of a certification center or point or with representatives of the center visiting the workplaces of the groups being certified);

- the arrival of an employee of the certification center at the site or the persons being certified at the location of the center or point;

- completing training in accordance with the program for a specific form of admission;

- passing practical, theoretical and special exams (the latter is taken if necessary);

- obtaining a NAKS certificate in case of successful passing of all necessary exams.

Certification for the fourth level takes place exclusively on the basis of certification centers due to the need for the presence at all examination events of at least three teachers who also have a fourth level in the NAKS system.

The cost of certification varies depending on the certification center or point, level, group of materials, its frequency or primacy, as well as the number of groups undergoing training simultaneously with certification. The range per person, depending on all the listed parameters, varies from five to one hundred thousand rubles per person, however, the specific amount should be found out in each case separately.

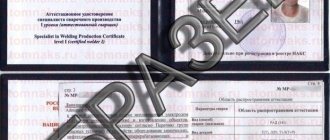

Welder's certificate

All certification activities are completed by receiving a certificate created according to the NAKS qualification requirements system. This document, which gives the right to perform certain types of work, contains the following information:

- information about the person to whom the certificate was issued (with his photograph);

- information about the certified certification center or point where the certification took place;

- date of issue of the document and its validity period;

- groups of equipment and materials covered by this document.

If you lose it, you will have to undergo certification again with a change in its validity period.

Validity

Depending on the assigned qualification level, the validity period of the issued certificate varies:

- For welders and welding production specialists assigned the first and second levels, the validity period of the certificate cannot exceed two years . Extension of such a certificate is possible for no more than one year; in some cases, for specialists with the second level, extension is permissible for one and a half years twice. The number of such extensions cannot exceed two;

- A welding specialist assigned the third level can use his certificate for three years . Extension is possible twice for up to two years;

- If a welding specialist is assigned the fourth level, then the validity of the certificate cannot exceed five years . An extension is permissible for a period of three to five years, depending on the specialist’s field of work; the number of such extensions cannot be more than two.

Sample NAKS welder certificate

If the certificate has expired and renewal options have been exhausted, a new certification is carried out and a new certificate is issued.

What you need to know to pass the exam successfully

How to pass the exam the first time? What knowledge is needed to avoid retakes? How can I get my certificate as quickly as possible? These questions once worried every NAKS welder. The best option is to carry out NAKS certification on the basis of specialized training centers. In this case, you will be provided with all the necessary knowledge, and you will not have to waste time searching for the necessary information on your own. Also, the training program in such institutions takes into account the industrial specialization of applicants, as well as the level of their professional training.

The curriculum usually includes:

- Study of all kinds of welding devices and materials used in welding. In this case, the specialization of the course participant is taken into account.

- Familiarization with safety regulations, requirements for work equipment and tools.

- Training in welding technology.

- Description of the requirements for welded joints and finished parts, as well as quality control procedures.

In addition, the programs cover such important aspects as fire safety during work, as well as methods for eliminating defects when they occur. With this knowledge, a specialist can guarantee high quality work under any conditions, and if emergency situations arise, he will be able to quickly begin to eliminate them.