Currently, jacks are devices that are used to lift a load to a certain height. Their device can be varied. Most often, this technique is used by motorists during repair work. The rolling hydraulic jack stands out among the variety of similar devices. This device is considered indispensable when carrying out repairs in large car repair shops.

Diagram of the device of a rolling jack.

Some people use it for their private home purposes. Let's consider the device of a rolling hydraulic jack.

Using a jack

Many car owners want to assemble a jack with their own hands. This greatly simplifies the processes of repair and preventative maintenance of the car, eliminating the need to visit HUNDREDS and spend money on purchasing factory lifts.

The lift itself is a device designed to lift a load to the required height. Such devices are widely used in households and industries and vary in size and performance.

The load lifting device is used for:

- Repair;

- Bypass;

- Lifting heavy objects;

- In construction;

- When disassembling a car, replacing wheels, etc.

The main distinguishing feature is the carrying capacity. Some models are designed to lift several tons, while others can lift hundreds of tons.

Hydraulic jack device

In order to calculate a hydraulic jack for its purchase or self-assembly, it is recommended to find out what the circuit, structure and design features of this device are.

The lifting device consists of three main components:

- Movable piston;

- Frame. It is made of high-strength metal and has a cylindrical shape. In addition to serving as a housing, it also serves as an oil reservoir;

- Liquid medium. Machine oil acts as a liquid medium;

- Levers;

- Valves;

- Sinker.

- Force is applied to the lever, and the use of valves allows you to increase it by several tens.

- The piston allows the piston device to move, pumping the working fluid, which is oil, into a reservoir located under the piston.

- Thanks to the valve, oil does not flow back into the housing.

- Gradually the piston moves more oil under the piston, which helps the oil rise.

- To reduce weight, the oil must return to the device body. This requires opening the valve slightly.

The same operating principle applies to all hydraulic jacks. Therefore, the diagram, drawings, and video instructions for assembling and operating these devices are approximately the same.

Advantages and disadvantages

When deciding to assemble a bottle-type lifting device, thus creating a hydraulic jack, or to purchase factory equipment, you first need to understand the strengths and weaknesses of the device.

Let's start with the advantages, which include:

- High rated power;

- Ease of use;

- High efficiency, up to 80 percent;

- The device works well when moving loads weighing up to 200 tons. So, a hydraulic jack lifts a fair amount of weight.

But this type of jacks has its drawbacks. You should know them before you start working on it.

- The device cannot lift loads from low heights.

- The wear level of the part cannot be determined.

- This type of device requires special attention and periodic maintenance. The service program includes the need to add oil, replace gaskets and seals.

- The hydraulic jack may only be transported and stored in a vertical position. Otherwise, the oil will leak and must be topped up for it to work properly. Refilling the device is not difficult, but no one wants to do it all the time.

- The operating principle of the device does not allow it to quickly perform the functions of raising and lowering.

- The rise occurs cyclically.

- This type of device is quite expensive. Breakdowns of hydraulic jacks are not uncommon, and their maintenance is quite expensive.

- Whether you choose a factory elevator or build one yourself is up to you. There are various types of hydraulic jacks available in the market. Each of them has its own characteristics that you should be aware of before purchasing a device.

Principle of operation

The rolling jack works on the hydraulic principle, which is based on Pascal's law of pressure exerted on a liquid or gas. The working fluid in this device is hydraulic oil. Forced by the pump, it enters the cylinder and lifts it along with the housing under load. Liquids are known to be almost incompressible, and therefore a hydraulic jack can hold a raised load for a very long time. Devices of this design, depending on their purpose, can lift and hold from 1 to 200 tons.

The following design features are possible:

- latch, a special safety pin that protects against accidental unauthorized lowering;

- Pre-lift pedal for faster and more accurate approach to the vehicle being lifted.

These features make the tool easier to use. But this affects its price.

Such jacks, as a rule, belong to the professional category and cost a lot of money.

Types of hydraulic jacks

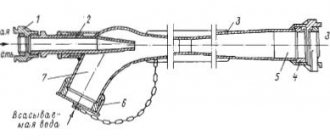

Bottle type device. The most common and at the same time the simplest type of hydraulic jack. Bottle lifts can lift up to 100 tons, have an impressive supporting surface and a compact body. They are widely used for work in auto repair shops. The bottle lift is available in two versions - single-beam and double-beam. The first of them are simple in design and are used in construction, repair of railway cars, production of bending and cutting devices. The two-link mechanism can operate in vertical and horizontal positions.

- Winding. The trolley-like device on the outside resembles a cart that moves under the lifted load. It is operated by a hand lever and adjustment is made by oil valves. Ideal for one-way lifting, suitable for use when changing wheels on a car. However, this requires a hard, level surface. It can be homemade.

- Hybrid. It combines a bottle jack and a mobile hydraulic jack, widely used in auto repair shops. Control is carried out using levers and foot pedals.

- Rhombus. Indispensable for auto repair shops. Its supporting structures are connected by loops and form a diamond shape, which influenced the name of the device. Compact, relatively lightweight, easy to transport.

- On hook. They are used where it is necessary to lift loads from a small height. The bottle diagram is used to work with it. It can be homemade.

- Assembling a homemade unit with your own hands or buying a factory-made hydraulic balloon lift is your personal decision.

The principle of operation is clear. All that remains is to figure out how to repair and upgrade the device. Consult the manufacturer's instructions to determine what type of oil to add when changing or topping up.

Types of rolling jacks

Jacks are, first of all, a mechanism that helps lift any load to a given height. There are several types of such jacking mechanisms:

- Stationary.

- Portable.

- Mobile.

In order to correctly choose the best option for a rolling jack, it is very important to know what types of such mechanisms there are.

Rolling jacks nowadays are either pneumatic or hydraulic. Let's look at them one by one and highlight which type for which cars is most advisable to purchase.

Pneumatics

So, rolling jacks are of the pneumatic type. These devices operate using compressed air, which holds the load. You can see that the basis is made up of wheels and a cart, on top of which there is a so-called accordion, where there is air. To use the device, you need to roll the jack up to the car, and then use a special lever to force the bag to lower. After the required part of the car is placed on the base with the bag, the same lever causes the bag to rise due to the movement of air in it. Together with the accordion, the load will also rise.

It is advisable to choose pneumatic rolling jacks if the weight of the car is not very large. However, keep in mind that such mechanisms will not be able to hold the car for a long time. After all, the accordion will gradually lower. Please note the lifting capacity of the pneumatic trolley. They are usually produced for loads from 3 to 5 tons. Therefore, the weight of the vehicle must be equal to or less than the specified load capacity of the device. This type is ideal for SUVs, since lifting the car to change a wheel will occur quite quickly. And powerful wheels will provide a good degree of protection against subsidence. It is very good if the trunk of an SUV is large. After all, after finishing work, the accordion deflates and becomes wide.

Hydraulics

A hydraulic-type rolling jack no longer operates using compressed air, but using liquid. Usually it is ordinary technical oil. The jack contains two vessels, where, with the help of valves that are driven by a handle, the liquid moves and creates the necessary pressure to lift the piston, and with it the car itself.

A hydraulic-type rolling jack no longer operates using compressed air, but using liquid

Hydraulic rolling jacks are considered to be the most reliable and widely used. They can hold the car in a fixed position for a long time, and the system itself is somewhat more reliable than that of a pneumatic mechanism. It is especially good if such a jack is equipped with a transmission. Then it will be much easier and more reliable for you to make the fixation.

Devices of this type are applicable to almost all cars. But not all hydraulic jacks can be carried with you. Most of them are very heavy and do not have a high degree of mobility. But they are very convenient to use in your garage and service station. They are especially convenient to use when repairing or replacing wheels on trucks. Only then should you pay special attention to the wheels so that they can withstand the expected load.

Repair and pumping

The most common failures of hydraulic lifts:

No oil;

- Excess air inside;

- Formation of rust and dirt;

- Deformed rod.

- In this case, it will be necessary to repair and bleed the hydraulic cylinder.

When used, oil will leak out of the hydraulic jack, which requires periodic refilling of the hydraulic fluid. Refueling is done using a repair kit.

- Before starting maintenance, prepare a container to drain the old oil and prepare fresh fluid for refilling.

- Using wrenches, unscrew the bolts, remove the drain valve and lifting piston.

- Clean the pistons, remove dirt, rust, check integrity.

- Partially inspect the drain valve from the outside in. The presence of defects on it indicates the need for replacement.

- Be careful not to lose the metal ball when checking the valve. If it is not tightened, the jack will not work properly.

- Drain the old oil by pumping it out. To do this, move the lever up and down until all the oil flows into the master cylinder.

- After draining the oil, clean all parts, replace seals and gaskets.

- It is best to rinse with kerosene. Pour into the jack and inflate, after removing the fixing needle. Pump out the kerosene and fill the tank with new oil.

- If an air lock has formed in the jack, remove the oil reservoir cap, open the valve and pump several times. Then open the drain valve and install the plug.

- The pumping principle and maintenance are not a problem, so any user can repair the hydraulic jack with their own hands.

At first glance, lifting a car or other load may seem like a simple task. The process of lifting a car includes appropriate approaches, as well as stocking up on specialized equipment. Experienced experts recommend giving preference to hydraulic jacks with a large load capacity and an excellent level of safety. A hydraulic jack is a simple design that can be easily made even with your own hands at home.

Nowadays, almost every car repair shop has a hydraulic jack because with the help of an old 5-ton jack, a car can be raised to a certain height for repairs. Bottle lifts are popular due to their high lifting capacity and ease of use.

Causes of breakdowns and repair of jacks

Naturally, like any equipment, a hydraulic jack requires some maintenance, which includes adding oil and visual inspection. And after a certain time, it is washed and the oil is completely changed with pumping.

Most often, hydraulic jack gaskets and seals fail, and for this reason oil begins to leak from the working tank. In addition, a malfunction may occur such as jamming of the rod during its reverse stroke.

At the first oil leak, the jack must be repaired, otherwise the rod may jam in the future. To do this, drain the oil, disassemble and replace the oil seals and seals, then fill in new fluid and bleed.

The tool rod can jam due to dirt accumulated in the liquid, which gets through the oil seal along the rod, or due to corrosion that has formed on the inner wall of the jack. In this case, in order to repair the jammed rod, the tool is disassembled and thoroughly washed. If corrosion is detected, special treatment of the walls of the lift should be carried out.

There are other reasons for equipment failure, when it occurs, it stops working fully. This is mainly due to untimely maintenance and improper operation of the tool, when the loads specified in its data sheet are exceeded. All this leads to its breakdown and, naturally, to repairs, which can sometimes be very expensive.

Common breakdowns:

- Stopping the lifting piston. Maybe due to lack of oil or clogged filter. To find out the reason for the stop, you should disassemble the mechanism, wash it and fill it with fresh fluid.

- The piston does not rise at all. Most likely, there is no fluid in the jack's reserve tank.

- The piston moves out slowly or jerkily. There is air in the working compartment of the device. In this case, you need to add oil to the lift and bleed it.

- Weak pressure on the piston. The inlet valve needs to be repaired or replaced.

Almost all causes of lift failure can be detected and repaired after disassembling it. But if the malfunction occurs due to mechanical damage to the jack body or its piston, the best option would be to write it off and purchase a new tool.

Bottle jack device

Hydraulic bottle lift

Fifty years ago, it was possible to lift a car or other load only with the help of a mechanical device, but over time, experts established the fact that the capabilities of such a device are limited. Mechanical jacks were unable to generate sufficient pressure even when using the jack optimally. As a result of these tests, a modern lifting mechanism was invented, which requires oil to operate. The working fluid helps create the necessary pressure, and the lift gradually raises the load to the required height.

It is worth noting that hydraulic lifts are used not only by gas station workers, but also at large oil refineries. These designs are indispensable in hydroelectric power plants, and over the past 10 years they have become the preferred choice of most car owners, both experienced and new. For optimal functioning of the device, both vertical and horizontal planes are suitable, which makes them popular even in the construction industry.

Today, the automotive parts and components market is characterized by a variety of hydraulic jacks. Popular device types include the following:

Jack - what is it?

Almost since the invention of cars, a jack has been part of the arsenal of necessary tools on board (just like a first aid kit or fire extinguisher). Many sections of the country's road surfaces are covered with holes and potholes (especially with the onset of spring), and the risk of puncturing tires when driving on such a surface is quite high. If this trouble does occur, then the right solution is to install a spare tire.

There may not be a tire repair shop nearby, and driving on broken tires can result in damage to the suspension and steering system. Replacing a wheel on site requires lifting the car, and this is why a rolling jack is needed. Naturally, the product may be needed for other types of repairs. The range of car jacks today is varied. How to choose the optimal model in the TTS-Auto online store? We'll figure out!

A jack is a special mechanism that allows you to lift large equipment, large loads and vehicles to the desired height. The device differs from a winch, crane and similar devices in its location. The jack is located from below, not from above - and does not require ropes, chains or other auxiliary elements.

Types, properties and characteristics of hydraulic jack

Cylinder lift and chassis lift;

- hook;

- diamond-shaped;

- hybrid.

- They are used to lift loads ranging from 2 to 100 tons, and most cylinder models operate in a vertical plane. To start the mechanism, it is necessary to prepare a supporting platform with a large plane, and the lifting height is regulated by a double-beam structure.

Rack and pinion jacks, which operate in a horizontal plane, have a wheeled trolley that must be placed under the object being lifted. By gradually moving the lever, it is necessary to increase the pressure at the output of the handle, which causes the switch to operate. In order to lower the load, you need to unscrew the lever back, but it is strictly forbidden to rush, as the machine may fall sharply.

Diamond-shaped lifts consist of four frame elements connected to each other by hinges. The process of lifting a vehicle occurs due to the fact that the angles between the frame elements change.

Hybrid lifts are so named because they combine a bottle lift and a jack lift in their design. Lifts with two lifting platforms are used in car repair shops, where they service cars of various brands, classes and modifications.

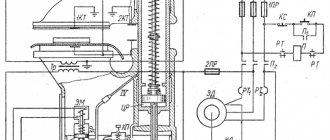

The operating principle of a hydraulic jack can be considered using the example of a popular production device. The operation of this lifting structure is based on the principle of communicating vessels, but first the elevator should be installed in a room with a hard and level surface. Then press down on the bobbin case, making sure the cylinder base and valve are closed. Before using the device, carefully read the operating instructions for the ShAZ 5t hydraulic jack.

Working principle of a hydraulic jack

Hydraulic jack design

As soon as the lift with a vehicle or other load reaches the required height, the lifting process must be stopped immediately. If the system needs to be lowered, the lift switch should be turned slowly in the opposite direction to the movement. clockwise. The main working element of the lifting structure is a special lever with which the working fluid is pumped. During pumping, the oil acts on the piston, causing the load to rise. The return of the sprayed liquid is completely excluded, since this is prevented by elements represented by the suction and drain valves.

The supporting structure of a bottle jack is a body, which is usually made of solid steel, cast iron or other metals. In addition to the load being lifted, the housing also serves as a guide for the piston rod and as a container for the sprayed liquid. The design of the jack is as follows:

How to use PD

When using a rolling jack, it is necessary to take into account safety rules. In particular, the car must stand on a flat surface so that it does not fall to the ground during lifting and hanging. If it is not possible to place the car on a flat surface, then it is necessary to put stops under the wheels (chocks, bricks or other bulky and heavy objects).

The operating procedure is very simple. Rolling jacks have rollers, with the help of which the structure must be placed under the place where the rod rests.

Most jacks have a drive handle (and some a pedal) that must be moved up and down to operate the operating mechanism. Accordingly, the body of the car begins to rise. To lower the car, the jack has a special lever or button (depending on the specific model). In this case, the working fluid returns through the open shut-off valve into the working cavity. This will cause the rod to return to its original position and the machine to lower.

That is, if a rolling jack is designed for 3 tons, then there is no need to try to lift a car weighing 3.5 or more with it. Although lifting mechanisms usually have some margin of safety, this is only designed for short-term use. Also, if the car is expected to be kept suspended for a long time, then the jack must be replaced with a permanent support .

Bottle-type hydraulic jack design: diagram

the oil that is poured into the cylinder is the working fluid;

- the working fluid puts pressure on the piston and the piston begins to rise

- The starting force is generated by a manually operated plunger pump;

- the piston is moved by moving the lever.

- This design is used in all types of hydraulic jacks. A schematic representation of a hydraulic lifting structure can be found in any reference book, one way or another related to plumbing or water supply.

Bottle lift diagram

Bottle jacks can be repaired at home yourself. The machine can be operated manually, but to do this, you must become familiar with all possible faults and troubleshooting rules. Prepare new parts in advance to replace worn parts.

Reasons why a hydraulic jack may fail

Using wrenches, remove all the bolts and bushings that are on the top of the master cylinder. After removing all retaining rings and removing the tank, ensure that the lift is not damaged. Replacement bolts should be selected to closely match the dimensions of the standard parts, and the bushings should always be round.

In the event that the upper ring comes off, it is necessary to disconnect the upper washer under the jack and carefully inspect it. Use wrenches to loosen the bolts and install the new rod. To improve fixation, it is recommended to use sealing sheets. With the lower ring removed, the lower frame is removed and the integrity of the hydraulic cylinder is checked. The piston should move smoothly, without jamming.

To unscrew the frame, turn the lift over and securely fasten it. The sealing ring is carefully checked and only then the cover is removed. We disassemble the extended extension with a Phillips screwdriver and also check the plate for damage.

Jack repair at home

Another common cause of malfunction is a broken traction arm. In this case, it is necessary to disassemble not only the short cylinder, but also the connecting device. If any damage or scratches are found on the cylinder or moving plate, these parts must be replaced. The traction device to which the lever is connected is located on the underside of the plate, and to remove it the drawbar must be released. After repair work, the bobbin case is secured to the lifting device with an elastic band on the lifting device.

To avoid premature failure of the cylinder hydraulic cylinder, it is recommended to periodically lubricate all its parts. It is strictly forbidden to accumulate debris in the socket holder, as this may cause the device to jam. Only with proper storage will the structure last a long time.

Currently, lifts are devices that are used to lift loads to a certain height. They may have different devices. Most often, this technique is used by drivers during repair work. A special feature among all the variety of this type of equipment is the hydraulic jack. This device is indispensable for repairs in large auto repair shops.

Jack design diagram.

Some people use it at home. Let's consider the design of a walking hydraulic lift.

The jack is designed to resemble a wheelchair that can easily be driven under almost any vehicle. Most often, such devices are used for repairs by large auto repair shops. Here the design is not much different from the stationary one. Jacks of this type have a hydraulic cylinder and a piston pump operating on the principle of a manual lever drive.

Device and principle of operation

The choice of a particular device directly depends on the conditions in which it will be used. This can be not only a large car service center, but also a small private garage. Many car enthusiasts have already appreciated the benefits of a convenient design. Such models can be installed anywhere, that is, even in areas adjacent to the service station. They are capable of lifting a fairly large mass to a decent height. Some models have additional attachments that significantly expand their functionality.

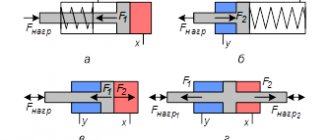

Thus, it was previously established that one of the main components of a hydraulic jack is the cylinder. The required force is obtained due to the pressure difference in the main cylinder and the actuator cylinder. It is worth paying attention to a certain design feature of such devices. The fact is that the hydraulic cylinder is not vertical, but horizontal. Of course, this does not in any way affect the principle of operation of the mechanism. There are several other design features of such devices.

Their rod does not rest directly on the car body. It rests on a lever that rests on the surface of the car. Why use such a complex mechanism when you can control the position of the cylinder with a simple vertical jack?

The answer to this question is actually quite simple. This device is easier to roll under the car than its vertical counterpart. This is due to the same design features of models of this type. If you have a car with a low chassis, you need to use this device to raise it to a certain height.

It is worthwhile to dwell in detail on the topic of a walking hydraulic lift. Thus, it is a four-wheeled stroller that can easily pass under almost any car. These wheels are rigidly fixed to the frame. The hydraulic drive is located on the frame. In a horizontal position, the piston rod is supported by a special vertical mechanism, which is attached to a lifting platform. Vehicle lifting is provided.

The mechanism for converting horizontal movement into vertical movement can be different. Most often this is a rotary gear. But this is not the only way of transformation. Much more complex mechanisms can be used here.

The entire operation of the mechanism is based on the movement of a special handle. The hydraulic jack itself slides under the car. Then the working mechanism starts. The drive creates a certain pressure in the cylinder, with which the car rises. The main work is done by the actuator and direct valve. If the pressure in the system needs to be reduced slightly, the knob can be turned. As a result, the check valve opens, releasing air from the system.

A jacked vehicle or other device is lowered. There are also alternative models of mechanisms. They have an air release check valve right next to the handle. To relieve excess pressure, just install the handle on it, having first removed it from its place. This is how a hydraulic car jack works. Its design is simple and original. It is for this reason that such mechanisms are chosen.

Jack characteristics table.

Advantages and disadvantages

There are many different positive qualities in such a system. The main advantage is that the hydraulic jack is located quite low. This makes it possible to work even with low-slung vehicles. Therefore, they are most often used in auto repair shops, where different customers may be present.

It is rational to use it in places where it constantly works. There is a tire service. Assembling such a lift under the car will take much less time than installing a standing model. It moves on wheels, making the lifting process even easier. This applies in particular to large tire currencies that employ a large number of people as well as a continuous flow of customers.

The workshop worker no longer has to bend down to cool the lift under the machine or pull it out. All these manipulations are performed using a comfortable and long handle.

The design stays back because it is mounted on wheels.

The structure remains returnable because it is built on wheels.

Of course, there are also disadvantages to such devices. The specificity of working with them is that to increase loads, only flat and equal surfaces should be used. Not in every situation you can find such a surface on the road. They are suitable for use on a flat concrete floor at a gas station or garage, but you cannot transport them in a trunk. This may be why many drivers prefer them over vertical structures that can be easily installed anywhere. Don't forget about the size of this equipment.

This can only be placed in a sufficiently capacious barrel. A small car has not been created. Lifts of this type are again created mainly for professional automotive workshops and tire assemblies. Only here you can take all the advantages.

Any person who has decided to purchase a hydraulic aerial lift should definitely consider which construction parameters are important to them. This applies to its design and technical characteristics.

Main design parameters

The main feature of the device is its carrying capacity. Most often it starts with 2 tons, but you can find models that have the ability to handle 750 kg. They are specially designed for small vehicles, namely motorcycles and ATVs. Standards for conventional vehicles are considered to be 3, 5 and 10 ton models.

For ordinary passenger cars, 2 tons is enough. You can easily store it in the garage and, if necessary, take it on a trip.

SUV fans should consider models that have a more rugged load capacity. This should start at 3 tons, of course, as long as this value does not exceed the weight of the device itself.

Not only lifting power is an important feature of such devices. Each model has its own lift range. It usually varies from minimum values of about 100 mm to maximum values, which can reach about 500 mm. You should definitely consider the design of your car. It is worth considering not only the distance from the body to the substrate, but also from the heel of the body.

The PIN, which is installed in a special slot, significantly reduces the likelihood of dangerous situations when the load is in an elevated position. Please note that security technology applies when operating such hardware. You should always consider. An additional limiter is always required. If there is a special PIN code, there will be no problem in pulling the car away from the elevator, even if the latter is damaged. Keep these recommendations in mind when operating the device.

Main characteristics

- Load capacity . Load capacity starts from 2t and above. For a simple passenger car for everyday needs, a carrying capacity of 2 tons is enough. This tool does not take up much space; it can be stored in the garage and taken with you on a trip. If you have an SUV, a load capacity of 3t or more is recommended. In any case, it is better to know the weight of the car in advance and be guided by its value in the choice.

- Maximum lift height. It is different for each model. SUV owners need to pay maximum attention to this parameter. There is no point in paying for a tool that lifts the car by 2 cm. The maximum lift height for SUVs starts at 450 mm.

- Minimum height. The parameter determines the ability to roll the device under a car. A rolling jack with a minimum height greater than the ground clearance of your car will not help you. Be sure to measure the ground clearance before choosing.

- Ease of use. Rubber pad, on the supporting support.

- Type of mechanism drive. Cardan and gear. The recommended cardan type, it has proven its reliability and is also more repairable.

Additional points

The lift lever can be long or short. The choice should always be compatible with the requirements of the individual as well as his needs. This is a very important parameter that determines the ease of working with this device model.

If someone intends to buy a lift lift of 3.5 tons or more, he should pay attention to the long handle and round handle devices. Only in this way can it be easily raised to a certain height.

The short handle is recommended for passenger cars. Universal models are available on the market. In these, the length of the handle can be adjusted depending on the type of car you need to pick up. It is best to buy such models so that then there are no problems, when working with the equipment it becomes inconvenient.

There are a huge number of such lifts on the market. Each model has its own weight. The lightest pieces weigh from 5 kg. The next group starts with a weight of 12 kg. The load capacity and weight of the device are in no way related.

For example, you need to lift a 3-ton weight to a certain height. This can be done with both a 10 kg device and a 50 kg model. Among the large number of such devices, the best lifts are Western European. It is also possible to purchase household lifts. There are also cheap Chinese models. However, they do not deserve attention because they do not comply with all safety rules and regulations.

What to look for when choosing

The choice of a particular automobile rolling jack is based on several aspects, including:

Maximum height value

- Maximum lift height . This is especially true for SUVs and crossovers. This value in this case should be from 450 mm and above.

- Minimum height . It provides the opportunity to “crawl” under the bottom of the car. This parameter must be selected based on the technical data of your car, in particular, the ground clearance height.

- Lifting speed . Some models of rolling jacks have an additional pedal that allows you to increase the lifting speed.

- Load capacity. This parameter is often the key. For most passenger cars, a jack with a lifting capacity of up to 2 tons is suitable, but owners of SUVs and crossovers are better off buying a jack capable of lifting a load of 3 tons. In any case, when choosing a particular model, ask the technical documentation how much your car weighs, and buy a jack that can lift more weight (that is, with some margin so that the mechanism does not work in critical conditions).

Minimum working height

- Ease of use . Thus, it will be more convenient for the car owner to use the jack if there is a rubber stop on the lifting platform and protection on the handle.

- Drive mechanism type . There are two types of them - cardan and gear. However, the most common and optimal is the cardan one. The handle used in it is more wear-resistant, reliable, and in case of failure, it is easier to repair.

The following additions will be useful:

Protective caps on plungers

- rotating handle for safely lowering the car;

- safety valve, whose task is to protect the mechanism from overload;

- composite coating on the drive handle, which ensures comfortable operation;

- built-in tray for storing small parts;

- polyurethane coating on metal jack rollers;

- caps on the plunger (or plungers, depending on the model), which protect the mechanism from dust, dirt, and corrosion;

- additional oilers on heavily loaded areas;

- a latch that ensures safety when performing work.

Gear and cardan transmissions in jacks

Also, when choosing, you need to pay attention to the length of the handle. If you have an SUV, then it is better to buy a rolling jack with a long handle. And for a passenger car, a short handle is more practical. A convenient option are models with a compound handle.

As for the material, it is better to choose a jack made of steel . Aluminum models cannot withstand significant loads and there is always a risk of mechanical failure, which can end very sadly. As for manufacturers, you can buy both domestic and foreign models here.

This is interesting: Vinyl stickers on cars - individuality and practical use