general information

NAKS is the National Welding Control Agency. It was created less than 10 years ago, but has already proven itself as an effective tool for monitoring welding enterprises. Certification is carried out by specialists from certified centers. Such centers are opened by private individuals, but inspections are carried out in accordance with NAKS certification standards.

Certification of welding equipment by NAKS (and in general any certification from the National Welding Control Agency) is carried out voluntarily. But there are exceptions when many complaints are filed against an enterprise and an inspection becomes mandatory.

There are currently about 300 NAKS centers operating in the country, so the test can be completed in most major cities. Specialists from NAKS centers certify not only equipment, but also workers, welding technologies, etc.

Certification of welding equipment by NAKS consists of testing devices for compliance with domestic and international quality standards. Thanks to the test, you can find out whether your equipment is suitable for performing critical work.

Types of certifications

The subject of NAKS equipment certification is the ability of the equipment being tested to carry out the types of work specified in the technological process of a particular company according to specified quality standards. Over time, welding fixtures can break down, change their characteristics, and be subject to environmental influences and wear. Therefore, there is a need to carry out certification regularly at specified intervals. Depending on the purpose and time of completion, certification is of the following types:

- Primary . It is carried out when welding equipment is put into operation at a specific production facility. It must be carried out before using welding in production processes.

- Periodic . It is carried out in order to monitor the performance and ensure the quality of the work performed by the welding tool during its use, as well as to extend the validity of the current certificate. It needs to be done once every three years.

- Additional . Mandatory in case of changes in the technological process in the case where it is necessary to confirm the possibility and quality assurance of a new type of welding work.

- Extraordinary . It is carried out in case of changes in state equipment standards, downtime for a year or more, during modernization, as well as by decision of the State Mining and Technical Supervision Service in cases of repeated episodes of creating products of unsatisfactory quality.

Why do you need a certificate?

Since the NAKS check is voluntary, then why go through it at all? Isn't it easier to just work under the same conditions as before without worrying about inspections? But the certificate will still have to be updated...

Let’s put it this way: if you are confident in the quality of your welding production, then it’s definitely worth getting certified. And if you have something to hide, then a sudden inspection from Rosgostekhnadzor will reveal your secrets in any case.

So, what does the NAKS welding equipment certification certificate provide? First of all, it confirms that you can continue to use all your welding equipment. If a mandatory government inspection comes your way, you can present your NAKS certificate and secure your enterprise.

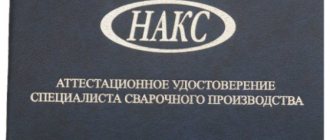

Sample of NAKS certificate

Thanks to the certificate, you can also use certified equipment to perform any special work that you have not previously performed in your production. For example, you have equipment for argon arc welding. It has been certified and can now be used for welding particularly critical structures, for example.

Another important advantage is the ability to present a NAKS certificate for welding equipment as a guarantee of quality for your work. Such a document can be shown to business partners or other enterprises with which you want to cooperate. The certificate will be a guarantee that you are doing quality work.

The only disadvantage of certification is the bureaucratic red tape and high price. Certification is not carried out free of charge, but this requires the allocation of money from the enterprise budget.

Submitting an application for certification of welding equipment

To obtain a certification certificate, an organization that manufactures, repairs or installs devices for hazardous production facilities submits an application with a set of necessary documents attached to it to the certification center.

Upon completion of the necessary certification stages, the customer company is issued a confirmation document.

To undergo certification, the customer company must provide the following documents:

- company card and bank details;

- passport of the organization that manufactured the equipment that is planned to be used;

- original certificate of conformity of the Russian Federation and two copies certified according to GOST R-7.0.97-2016;

- data on operating conditions;

- technological maps for welded joints that will be performed;

- welding equipment logbook , which contains all data on repairs, inspections and movements;

- copies of documents of certified welders of the company staff;

- certificates for the welding materials used;

- photocopies of documents of a specialist monitoring the welding process at the enterprise;

- certificate of certification of laboratory non-destructive testing;

- if there is a certificate for the type of welding equipment in the industry , then it must also be provided.

Employee certification

Certification of welding production specialists by NAKS is a mandatory procedure that must be carried out in production. It should be carried out in different situations - during changes in welding technology, during advanced training, during a short-term cessation of activity of one or more employees. But you definitely need to consider the main nuances of employee certification.

How is certification carried out?

To undergo certification, the employee must independently come to the NAKS center. The center conducts examinations, based on the results of which the person being checked is given an identification document. He assigns him the necessary degree of qualification. It can also be used to confirm a previously assigned qualification level.

For the test result to be valid, the following requirements must be met:

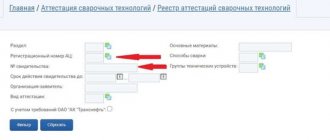

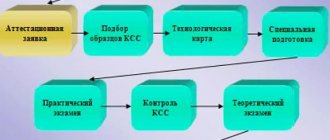

- The first step is to draw up an application; you can use a sample for this. Afterwards it must be submitted to a specialized certification center.

- The application must be accompanied by the required documents - copies of the identity card of the person being checked, diploma, documents including certificates of certification for welding-related professions, copies of the work book, employment orders. Photos taken in accordance with NAKS requirements.

- At the next stage, the time and place of the inspection is agreed upon. Certification of welding and workers under the control of NAKS are sent to training, which is based on a specialized program and an exam on knowledge of the required material.

- Passing final exams to confirm qualifications. There are usually two of them - practical and theoretical. But training must be done first.

- If all exams are passed successfully, the employee is issued a certificate of assignment of a certain level of qualification or renewal of an existing certificate.

It is worth noting! Applications can be submitted from legal entities, namely from an enterprise, as well as from an individual in situations where the welder has decided to apply for inspection independently.

If the welder’s documents are in full order, they are allowed to take the exams. There are only two of them - practical and theoretical. The second includes knowledge of the theory of welding, namely its technologies, principles of conduct and other important nuances. Practice comes first, and then theory. If a specialist cannot cope with the practice, then he is not allowed to take the theoretical exam. Retake is usually done after a month.

But for specialists of the second, third and fourth levels, only a theoretical exam is conducted. Engineers, technologists, and chief welders must know the standards of welding technologies, narrow areas, principles and other important nuances.

But in any case, you need to know what the NAKS register of certified welding materials and technologies includes, namely what stages of testing, required documents and types of certification. For the production audit process to be successful, it is necessary to adhere to established standards and follow the basic rules.

Features of certification

Certification is an important and secondary stage for large industries and enterprises. First of all, welding is certified. NAKS determines which technologies will be used in a particular production, the agency makes a conclusion and gives permission for the work being carried out. For this reason, it is very important to approach the preparation process with full responsibility.

In order for welding certification to be carried out under the supervision of NAKS, authorized employees of the enterprise collect the required documents and independently submit an application. Afterwards, a commission arrives at the production site and conducts an audit.

During the inspection, the commission takes into account compliance with the following requirements:

- sufficient amount of equipment at the plant;

- no problems with staff;

- compliance with important norms and rules - labor, fire safety and others.

It is worth noting! The commission operates in accordance with special regulatory documents. In accordance with them, it makes basic requirements for production institutions.

Certification of welding production by NAKS is a mandatory event that is carried out at every high-risk production enterprise. This is the law that all official proceedings must adhere to. A study is also carried out on the suitability of the technologies used. The commission must ensure that the equipment used can produce products that meet all qualities and standards.

What is required to obtain a certificate of certification of welding equipment?

The certificate is issued only if, during the expert assessment process, the quality of welds made using the equipment fully complies with the established requirements. To check the seams, a non-destructive testing method is used. The welding machines themselves are also examined. Experts analyze whether the mechanisms are fully complete, how well they function, and whether their work meets labor safety requirements. In addition, research is carried out on systems and equipment components. The presence of this document will allow the company to increase its reputation in the eyes of partners and customers. It will also be a confirmation of the high level of quality of work performed by its employees.

Test classification

SM certification is a complex of special, general and practical tests. Verification studies (practical and special) are carried out in appropriately accredited laboratories of the AC NAKS, adapted and equipped for such procedures.

- General tests mean carrying out checks for compliance of the MS characteristics stated in the accompanying documents with the requirements set out in the technical documentation and standards.

- Practical tests are an analysis of the technical and technological capabilities of SMs in practical conditions, i.e., when using them to carry out certain welding operations on control seams.

- Special tests are only necessary for gases, moreover, if such a condition is previously stipulated in the relevant documentation.

How to get NAKS certification? Algorithm

You can certify devices used for welding and obtain a certificate of compliance with standards at any regional NAKS laboratory center . For this purpose, an official letter is sent, certified by the signature of the manager, to which the application is attached. The application shall indicate:

- details and legal address of the organization or enterprise;

- names of individual units or groups of welding equipment, indicate technical characteristics separately for each type;

- start date of use;

- types of work subject to inspection;

- methods of surfacing or welding with a list of unsafe materials or technical devices.

The letter received in response, sent from the center, contains information about the deadlines for completing the NAKS for equipment and the provisions of the contract. As a rule, certification is carried out within 30 days after the conclusion of the contract .

The procedure for NAKS certification of welding machines, inverters and other equipment consists of several stages:

- verification of information received from the applicant;

- appointment of a commission inspecting the equipment, taking into account the specifics of the applicant enterprise’s activities;

- determination of the main points of the Program for certification;

- carrying out equipment testing in accordance with the paragraphs of the Program;

- production of welded control joints used as test samples;

- testing in laboratory conditions of the provided sample joints in accordance with the standards and technical conditions used for welding work at high-risk facilities;

- creation of a protocol on the implementation of certification;

- issuance of a Certificate of Attestation.

Subject to completion of the procedures, the applicant enterprise receives a NAKS certificate.

Types of equipment certification NAKS

The current price for certification of welding technology, as well as welding equipment (WE) in the NAKS system with the help of specialists from the Gefest Consult Group of Companies, ranges from 10,000 to 60,000 rubles and depends on the number of units of WE that needs to be certified by your enterprise. In order to begin the process of passing the CO certification, you need to call our employees at the telephone numbers indicated on this page, or write to us using the feedback form on the website.

Currently there are 4 types of CO certification:

- Primary, for import or for CRM that has not previously been certified;

- Periodic – for a CO whose previously issued NAKS Certificate has expired;

- Additional certification, carried out if new regulatory documents have been introduced or previous regulatory documents have been changed, the scope of its application has been expanded;

- Extraordinary - this is a certification carried out if, during the work performed at a given CO, defects are repeated, after the overhaul of welding equipment, its long-term downtime (more than a year) without tests, modernization or changes in design.

During certification, in addition to checking compliance with the certification standards, practical and special tests are carried out. The first type of testing involves the evaluation of welds at control joints by certified non-destructive testing. Special tests consist of checking the main technical characteristics of the RM given in the passport, testing the compliance of the RM with various safety and health requirements, regulatory documents, and checking various components of the RM.

Kinds

The presence of a huge number of methods and technologies used in welding and in the industrial sector and in construction has expanded the range of work of certification centers.

NAKS certifies:

- materials and equipment (welding inverters according to NAKS, power supplies, semi-automatic devices, transformer devices, etc.);

- methods of welding work (plasma, RDS, automatic, etc.);

- individual technical processes used in production.

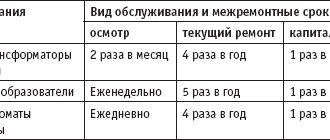

What is the validity period of the Certificate of Completion of Certification of Equipment for Welding Work? The following frequency of inspections has been adopted:

- for equipment produced in large quantities – 36 months;

- for small batches of industrial equipment, if more than 6 years have passed since the start of use - 18 months.

If, according to the documents received from the manufacturer, the service life of the equipment is more than 6 years, then it will be subject to periodic certification every 36 months until the end of the service life specified in the documentation.

What is it for?

The main task is to check the NAKS to the extent that the performance characteristics of the SM correspond to the characteristics given in the accompanying documentation, technical specifications, as well as other standards for the SM. In addition, this is confirmation of the suitability of certified products for repairs, reconstruction and other types of work at high-risk facilities.

After their successful completion, the customer receives a NAKS certificate, valid for 3 years - for mass-produced SMs and one year - for experimental samples and batches of SMs.