Material hardness

Brinell hardness is a characteristic that allows you to determine the hardness of a material.

Stainless steel fasteners are also equipped with special markings on the top of the fastener.

Type of steel A2 or A4 and tensile strength - 50, 70, 80, examples: A2-70, A4-80. Fasteners that have a clearly defined thread are color-coded for A2 in green and for A4 in red. The value for the yield strength is not specified.

For example, a value of 70 is the most standard and demonstrates the maximum strength of stainless steel fasteners.

Maximum fluidity for stainless steel hardware, often only a reference value.

The fluidity in this case will be 250 N/mm2 for A2-70 and about 300 N/mm2 for A4-80.

The approximate increase will be no more than 40%. In other words, this type of steel perfectly changes shape before irreparable deformation occurs.

Old domestic measurement methods according to GOST did not allow paying due attention to the maximum permissible loads on bolts, so the produced hardware was significantly lower in quality compared to modern ones.

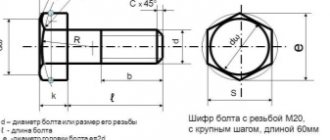

An example to calculate the load on a material as accurately as possible using strength classification:

M12 fastening with strength 8.8, size d2 = 10.7 mm and maximum section length 89.87 mm2. In this case, the maximum permissible degree of load will be: (8*8*10)*89.87;0) = 57520 Newton.

Load chart for carbon steel and stainless steel bolts.

| ST-4.6 | ST-8.8 | A2-70 | A4-80 | |||||||

| THREAD | d2, mm | Area 62, tt2 | Max. load, Newton | Working load, kg | Max. load, Newton | Working load, kg | Max. load, Newton | Working load, kg | Max. load, Newton | Working load, kg |

| M1 | 0,8 | 0,5 | 121 | 322 | 10 | 126 | 151 | |||

| M2 | 1,7 | 2,27 | 544 | 20 | 1 452 | 70 | 567 | 20 | 681 | 30 |

| M3 | 2,6 | 5,31 | 1 274 | 60 | 3 396 | 160 | 1 327 | 60 | 1 592 | 70 |

| M4 | 3,5 | 9,62 | 2 308 | 110 | 6 154 | 300 | 2 404 | 120 | 2 885 | 140 |

| M5 | 4,4 | 15,2 | 3 647 | 180 | 9 726 | 480 | 3 799 | 180 | 4 559 | 220 |

| M6 | 5,3 | 22,05 | 5 292 | 260 | 14 112 | 700 | 5 513 | 270 | 6 615 | 330 |

| M8 | 7,1 | 39,57 | 9 497 | 470 | 25 326 | 1 260 | 9 893 | 490 | 11 872 | 590 |

| M10 | 8,9 | 62,18 | 14 923 | 740 | 39 795 | 1 980 | 15 545 | 770 | 18 654 | 930 |

| M12 | 10,7 | 89,87 | 21 570 | 1 070 | 57 520 | 2 870 | 22 469 | 1 120 | 26 962 | 1 340 |

| M14 | 12,6 | 124,63 | 29 910 | 1 490 | 79 761 | 3 980 | 31 157 | 1 550 | 37 388 | 1 860 |

| M16 | 14,6 | 167,33 | 40159 | 2 000 | 107 092 | 5 350 | 41 833 | 2 090 | 50199 | 2 500 |

| M20 | 18,3 | 262,89 | 63 093 | 3 150 | 168 249 | 8 410 | 65 722 | 3 280 | 78 867 | 3 940 |

| M24 | 21,9 | 376,49 | 90 359 | 4 510 | 240 956 | 12 040 | 94 123 | 4 700 | 112 948 | 5 640 |

| M27 | 24,9 | 486,71 | 116 810 | 5 840 | 311 493 | 15 570 | 121 677 | 6 080 | 146 012 | 7 300 |

| M30 | 27,6 | 597,98 | 143 516 | 7170 | 382 708 | 19130 | 149 495 | 7 470 | 179 394 | 8 960 |

We present to your attention an updated table of maximum loads on stainless materials and high-strength connections.

To be additionally confident in the safety of the load, you can, without a twinge of conscience, divide the load in Newtons by thirty.

| Stainless steel A2-50 | |||||||

| THREAD | d2, mm | Area d2, mm2 | Yield strength, MPa | Max. load, Newton | Working load, kg | ||

| M1 | 0,8 | 0,50 | 200 | 100 | |||

| M2 | 1.7 | 2,27 | 200 | 454 | 20 | ||

| M3 | 2,6 | 5,31 | 200 | 1 061 | 50 | ||

| M4 | 3,5 | 9,62 | 200 | 1 923 | 90 | ||

| M5 | 4,4 | 15,20 | 200 | 3 040 | 150 | ||

| MB | 5,3 | 22,05 | 200 | 4 410 | 220 | ||

| M8 | 7,1 | 39,57 | 200 | 7 914 | 390 | ||

| M10 | 8,9 | 62,18 | 200 | 12 436 | 620 | ||

| M12 | 10,7 | 89,87 | 200 | 17 975 | 890 | ||

| M14 | 12,6 | 124,63 | 200 | 24 925 | 1 240 | ||

| M16 | 14,6 | 167,33 | 200 | 33 466 | 1 670 | ||

| M20 | 18,3 | 262,89 | 200 | 52 578 | 2 620 | ||

| M24 | 21,9 | 376,49 | 200 | 75 299 | 3 760 | ||

| M27 | 24,9 | 486,71 | 200 | 97 342 | 4 860 | ||

| MLO | 27,6 | 597,98 | 200 | 119 596 | 5 970 | ||

| Stainless steel A2-70 | |||||||

| THREAD | 62.mm | Area d2, mm2 | Yield strength, MPa | Max. load, Newton | Working load, kg | ||

| M1 | 0,8 | 0,50 | 250 | 126 | |||

| M2 | 1,7 | 2,27 | 250 | 567 | 20 | ||

| M3 | 2,6 | 5,31 | 250 | 1 327 | 60 | ||

| M4 | 3,5 | 9,62 | 250 | 2 404 | 120 | ||

| M5 | 4,4 | 15,20 | 250 | 3 799 | 180 | ||

| MB | 5,3 | 22,05 | 250 | 5 513 | 270 | ||

| M8 | 7,1 | 39,57 | 250 | 9 893 | 490 | ||

| M10 | 8,9 | 62,18 | 250 | 15 545 | 770 | ||

| M12 | 10,7 | 89,87 | 250 | 22 469 | 1 120 | ||

| M14 | 12,6 | 124,63 | 250 | 31 157 | 1 550 | ||

| M16 | 14,6 | 167,33 | 250 | 41 833 | 2 090 | ||

| M20 | 18,3 | 262,89 | 250 | 65 722 | 3 280 | ||

| M24 | 21,9 | 376,49 | 250 | 94 123 | 4 700 | ||

| M27 | 24,9 | 486,71 | 250 | 121 677 | 6 080 | ||

| MLO | 27,6 | 597,98 | 250 | 149 495 | 7 470 | ||

| Stainless steel A4-80 | |||||||

| THREAD | 12, mm | Area d2, mm2 | Yield strength, MPa | Max. load, Newton | Working load, kg | ||

| M 1 | 0,8 | 0,50 | 300 | 151 | |||

| M2 | 1,7 | 2,27 | 300 | 681 | 30 | ||

| M3 | 2,6 | 5,31 | 300 | 1 592 | 70 | ||

| M 4 | 3,5 | 9,62 | 300 | 2 885 | 140 | ||

| M 5 | 4,4 | 15,20 | 300 | 4 559 | 220 | ||

| MB | 5,3 | 22,05 | 300 | 6 615 | 330 | ||

| M 8 | 7,1 | 39,57 | 300 | 11 872 | 590 | ||

| M10 | 8,9 | 62,18 | 300 | 18 654 | 930 | ||

| M12 | 10,7 | 89,87 | 300 | 26 962 | 1 340 | ||

| M14 | 12,6 | 124,63 | 300 | 37 388 | 1 860 | ||

| M16 | 14,6 | 167,33 | 300 | 50199 | 2 500 | ||

| M20 | 18,3 | 262,89 | 300 | 78 867 | 3 940 | ||

| M24 | 21,9 | 376,49 | 300 | 112 948 | 5 640 | ||

| M27 | 24,9 | 486,71 | 300 | 146 012 | 7 300 | ||

| MLO | 27,6 | 597,98 | 300 | 179 394 | 8 960 | ||

Fastening to structures made of weak materials

The definition of “weak” materials includes plasterboard, porous (light) concrete, and hollow brick.

The general rule for drilling holes in the listed materials is to exclude the impact mode.

It is recommended to use nylon dowels. Their diameters should be larger than for structures made of solid concrete or brick. The diameter of the hole is 2 mm smaller than the dowel hole.

Butterfly dowels are suitable for fastening to walls made of sheet material (plasterboard, chipboard, OSB, etc.).

Types of dowels

Dowel type Driva

Perhaps the most popular fastener for plasterboard sheets. It comes with or without a drill, metal or plastic. When making a hole for its fastening, use a drill with a diameter of 8 mm. The manufacturer declares the working shear load that gypsum board can withstand using this dowel is 25 kg, while the maximum load is up to 50 kg.

The popularity of the Driva dowel is due to its fairly high reliability and relatively low price. The strength of such fastening is achieved by distributing the load over a large area, which is ensured by the shape of the dowel.

Driva drywall dowel is simple and effective

Flat dowel nail

This dowel is made of fire-resistant steel, is quite simple and easy to use, since it does not require additional drilling and, accordingly, eliminates dust. It can be hammered into the drywall with a hammer or pressed in by hand if you can do it.

The principle of operation of a dowel-nail is that when a self-tapping screw is screwed into it, the initially flat front part opens up, forming a reliable stop.

It is used for sheets up to 12.5 mm thick inclusive. Self-tapping screws are chosen with a diameter of 3.5-5mm. The working load for pulling out, declared by the manufacturer, is 15 kg, for shearing - 30 kg, the maximum shear load, obtained experimentally, is 48 kg. Among other things, the dowel-nail is reusable, that is, it can be dismantled and mounted in another place several times.

The flat dowel-nail for drywall is very convenient to install, as it does not require drilling

Universal expansion dowel Butterfly

The butterfly dowel is suitable for both drywall and concrete bases. The hole for its installation is drilled with a drill with a diameter of 8 mm, the diameter of the complete self-tapping screw is 4.5 mm.

For the butterfly dowel, we recommend using self-tapping screws without missing threads, since when screwing in, having reached the smooth neck, the self-tapping screw will begin to scroll, and the dowel will not take the desired shape as a stop.

In general, the plastic butterfly dowel works approximately the same as the others, creating a stop behind the gypsum board when screwing in the self-tapping screw. The shape of this stop is somewhat reminiscent of a butterfly, hence the name of the fastening element. The calculated working load on the dowel is 25 kg, the maximum load is 55 kg.

The Butterfly dowel for drywall is the most popular because it is equally inexpensive, convenient and effective.

Dowel Molly

The Molly dowel, or rather the Molly anchor (after all, it is an independent fastening unit that does not require an additional screw) is another popular type of fastening for drywall, made of metal. This dowel, unlike the previous ones, is available in various sizes and, accordingly, for various loads.

For example, for Molly of the minimum size marked 4/16/38 (4 is the diameter of the screw, 16 is the length of the neck and the maximum thickness of the sheet for which it can be used, 38 is the total length of the element), the working load is 25 kg, the limit for cutting is 47kg.

To make holes for Molly, choose a drill 2 times larger than the diameter of the neck (the first number in the marking), that is, for a four it will be 8 mm, for a six it will be 12, etc.

To install the Molly dowel, you need a special tool that brings the fastening element into “combat readiness”. With its help, the screw is slightly pulled towards itself, while the hooks bend. Then you can turn the screw with a screwdriver, bending the hooks until they stop. All this should be done by inserting a dowel into a hole in the drywall.

If there is no special tool, you can activate the anchor using wire cutters (side cutters) or even a regular flat-head screwdriver.

Molly dowel for drywall - a solution for professionals

Fischer plastic twist dowel

When a self-tapping screw is screwed into such a dowel, the latter twists, forming a stop behind a sheet of drywall, hence the name of the fastening element. The drilling diameter for such a dowel is 8 mm, the screw diameter is 5 mm.

When tightening a self-tapping screw, the main task is not to pinch too hard, otherwise it will begin to rotate and the fastener will need to be re-done. For this reason, when using a screwdriver for tightening, set it to the minimum speed.

The working load for tearing off a twisting dowel is 10 kg, for shearing - 25 kg, crash load - 70 kg.

Twistable plastic dowel for drywall - an interesting and effective solution, backed by Fisher reliability

What to consider when choosing a drill for a dowel

Selecting a drill to create a hole in which the dowel will be fixed should take into account:

- the material from which the wall itself is made, as well as its finishing;

- expected loads of the fastener.

You should also choose a drill depending on the diameter of the fasteners used. On the outer surface of factory-produced dowels, as a rule, there are markings that allow you to correctly select drills of the appropriate diameter for them.

Table 1. Selection of drill and screw for dowel

It is important to know not only how to choose a drill for a dowel, but also how to drill a hole correctly. If it is necessary to drill a hole in the wall for a dowel, the diameter of which is 10 mm, then first use a drill with a diameter of 8 mm and an impact drilling mode. After the hole is drilled, the tool is replaced with a drill with a diameter of 10 mm and is used without using the impact drilling mode. This approach will allow you to get a hole in the wall of the required diameter with smooth and neat edges.

If you need to drill a concrete wall, it is better to use a Pobedit drill, which can handle such a durable material without any problems. The selected cutting tool must be at least 3 mm longer than the dowel itself. If you neglect this requirement, the dowel will not completely fit into the resulting hole, in the final part of which dust and pieces of crumbled material, as a rule, accumulate. In addition, the shape of the bottom of the hole may not match the shape of the tip of the fastener.

Calculate the drilling depth with a margin relative to the dowel length

Criterias of choice

The dowel dimensions are selected based on the following factors.

Supporting material

. Dowels of the same length and diameter, made of the same material, can withstand greater loads in concrete structures than in brick ones. But this fastener is not suitable for fastening massive objects to foam concrete - it does not hold significant weight and comes out of the installation hole. In such cases, chemical anchors should be used.

Load per fastener

. The greater the design load, the more attachment points required. Before purchasing, pay attention to the maximum permissible and recommended load indicated on the packaging.

Location

. The prevailing load depends on it: along (axial, tearing) or across (for fracture and bending) the axis. In the first case, the length of the fastener matters, in the second – the diameter.

Allowable hole depth

. A large load requires a maximum dowel size.

How deep will the screw be screwed in?

. This is true for fasteners located horizontally: the closer the screw head is to the wall surface, the lower the fracture/bending load and the shorter the permissible length of the fasteners.

For light items

Light objects are attached to structures made of brick and concrete with plastic dowels with a diameter of 6 mm and a screw. The drill is selected to be of equal diameter. The length of the dowel for fastening to the wall and ceiling is 4 and 6 cm, respectively (the values given are minimum). The depth of the mounting hole is 5 mm larger.

For medium weight items

A dowel-nail, which is a fastening pair, copes with the task. One of the advantages of its use is the speed of installation (the name is “quick installation dowel”). The mounting sequence is as follows:

- a hole of the selected diameter and depth is drilled;

- dust is removed from the hole;

- a plastic part of the fastening pair is installed;

- The “nail,” despite the presence of a thread, is driven in with a hammer, which gives a gain in time during installation (compared to a screw).

The diameter of the dowel used in this case is at least 8 mm. Length – 6 and 8 cm for mounting to the wall and ceiling. The diameter of the drill is selected similarly to the considered method “for light objects.” Number of fixation points – up to 4.

For heavy objects

Massive objects (TV stands, bookshelves, furniture cabinets, equipment) are fastened with hardware with dowels, the diameter of which is at least 10 mm. The lengths for fastening to walls and ceilings are 6 and 8 cm, respectively. The number of fixation points is at least six.

Fastening medium-weight products

Objects weighing between 5–10 kg are secured with impact dowels Ø8 mm, a drill Ø8 mm, but always with a Pobedit tip. The fastener should extend into the wall cavity by 6 cm, and if the ceiling is 8 cm. To secure an object weighing up to 10 kg, 4 fasteners should be used.

Read also: Comparative characteristics of steels u7 u8 u9

Methods for securing a dowel in a large hole

What should you do if the hole drilled in the wall is larger than the dowel? Professionals recommend following the following methods of fixing a dowel in a wall:

- Using a repair cloth. It means a piece of special material that is wrapped around a dowel and then placed in a hole made in a brick, aerated concrete, or concrete wall. Before “wrapping”, the napkin must be moistened in water. Once the fastener is wrapped, it is driven into the gap. Next, you need to wait until it hardens - about two to three minutes. Then, you can insert a self-tapping screw, screw and other fastening devices.

- Use a 2-component composition. It means a special type of glue, which contains polyurethane without styrene, which is safe for the human body. The package, which resembles a syringe, contains a 2-component composition.