Torch Basics

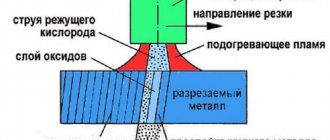

The cutting process with a gas cutter occurs by burning the metal in a stream of oxygen supplied under pressure.

The alloy must first be heated to the required operating temperature using a burning mixture of acetylene and oxygen. The only metals that can be cut using this method are various grades of carbon and non-alloy steel. Stainless steel, non-ferrous metals and alloys cannot be cut with an oxygen-acetylene cutter. To perform this type of work, in addition to the appropriate set of gas equipment, you will need the following:

- Fire extinguisher.

- Protective equipment: special glasses; thick leather gloves; sturdy work shoes with leather soles.

- Appropriate clothing – fire-resistant clothing is recommended, but if not available, well-fitting cotton clothing will do. You should not wear items made of synthetic or flammable fabrics, loose fit, or with torn or worn edges.

- Tools for measuring and marking: ruler, square and pencil made from soapstone.

- Lighter for gas cutter - designed to properly ignite the flame of the cutter. Using regular matches and lighters is very dangerous.

Preparing a place and conditions for safe and comfortable work

To ensure safe work using a cutting torch, you must follow the following rules and recommendations:

- To perform the work, choose only a place in a perfectly ventilated room or in the open air.

- You can cut away from flammable substances and materials.

- The floor in the room should be concrete or earthen.

- The surface of the earth or concrete must be cleared of any foreign objects and materials within a radius of at least 5 m, since sparks from the metal being cut scatter over several meters and can set fire to dry rags, shavings, paper, dried plants or leaves.

- The metal to be cut is placed on a suitable support so that the cutter can be used at a comfortable working height. For these purposes, it is best to use a steel table.

- Do not allow the flame to touch the concrete (especially if it is fresh) - this will cause its expansion and subsequent intense cracking with small fragments of concrete flying out of it.

- It is strictly forbidden to use flammable surfaces as workers, or on which flammable or explosive materials are spilled.

- The location of the metal cut is marked as shown in the video.

Rules to follow when cutting

When cutting, you must remember to wear personal protective equipment that protects your body and eyes from sparks. Therefore, it is a mandatory rule to use goggles and a respirator when working.

To cut the container, it is necessary to use discs with a cutting thickness of 2.5-3 mm. A thick cut will help to avoid clamping the disc when performing work, which contributes to additional safety of the work being carried out. It is not cost-effective to use discs with thin cuts, as they wear out quickly.

A drill is additionally used to make round holes. In this case, all recommendations on how to safely cut gas cylinders with a grinder are followed in the same order.

Important! Drilling into an empty vessel is strictly prohibited. If you use an angle grinder, it should be filled with water.

Preparing and setting up gas cutting equipment

In order to work safely with a gas cutter, it is important not only to correctly select the appropriate set of equipment, but also to connect and configure it correctly. First, the corresponding tubes are connected to the oxygen and acetylene cylinders. Oxygen hoses and containers are usually green, acetylene hoses are red.

Safety valves (a device that delays flashback flames) should be installed at both ends of the hoses.

The next step is to check that the acetylene supply is working properly. First, close the flow control valve - the T-shaped handle is rotated back several times. On the cylinder, in its upper part, open the valve - turn it 1 turn of the hand. They do this for safety reasons. The acetylene pressure in the cylinder should not be allowed to exceed 1 atm - in case of high pressure, this gas becomes unstable and can even spontaneously explode or ignite. To check that the acetylene pressure is adjusted correctly, do the following:

- The main valve of the container is unlocked, then the control valve is opened by turning the handle in a clockwise direction. This must be done very slowly, monitoring the readings of the pressure gauge installed at the low pressure outlet. The control valve is opened until the pressure reaches 0.34–0.54 atm.

- Then blow air from the hose - open the acetylene valve of the cutter until the sound of escaping gas appears. After this, look at the readings of the low pressure gauge. When purging, the pressure value should be stable (if not, then make sure that the regulator is installed correctly).

- The valve on the cutter is closed.

They check and adjust the oxygen supply - turn off the oxygen supply regulator (twist it down), and then adjust the pressure. To reduce the oxygen supply, twist the pressure gauge knob a few turns back. Then perform the following steps:

- The main valve on the oxygen cylinder is fully opened. It is double-seated and if it is partially opened, due to the high pressure in the cylinder (150 atm), oxygen escapes around the sealing ring of the valve stem connection.

- Slowly open the supply regulator, monitoring the readings of the pressure gauge installed at the low pressure outlet until the oxygen pressure is adjusted within the range of 1.7–2.7 atm.

- Blow out the atmosphere from a hose - open the oxygen valve on the cutter. The cutter has 2 valves for oxygen: one is closer to the hose, controls the flow into the chamber where oxygen is mixed with acetylene to heat the steel (burning the mixture), as well as for supply to the oxygen nozzle for cutting; the other is located further and supplies oxygen to a separate cutting nozzle (until this valve is opened or the special cutting lever is released, oxygen should not leave the cutter mouthpiece). First, the first valve is opened - it is turned several times, ensuring a sufficient flow of oxygen to carry out both functions. After this, open the second (front) valve slightly until the hose is cleared (3–5 s for a 7.5 m long tube).

- The front valve is closed.

What you should pay attention to?

Disassembling even an old gas cylinder requires special care from the master and consistency of all actions.

For novice craftsmen who have not yet had to deal with sawing a propane receiver, we have prepared some useful tips:

- the degree of severity of the smell of propane when rinsing the cylinder is an indicator of a high probability of fire or explosion;

- It is better to unscrew the cylinder valve away from living quarters;

- cutting a propane tank near a fire or any other source of fire is contraindicated;

- it is forbidden to stand in front of the gas outlet from the receiver, especially if there is a characteristic hissing sound;

- The markings on the cylinder should be marked in advance so as not to end up making mistakes with the calculations.

If there is a strong smell of propane, it is better to rinse the receiver again, and only then proceed to sawing off the valve.

If the smell is still pungent, it is better to postpone work for a few days and wait until it completely disappears.

Immediately after cutting, the container must be cleaned of old paint, and then thoroughly cleaned with sandpaper to create the most even surface possible.

The easiest way is to install a flap wheel on the grinder, which will facilitate the further process of surface treatment, including painting.

Ignition of the torch and heating of the metal

Before igniting the torch, you must:

- make sure that all connections (valves, pressure gauges, hoses, other fittings) are tight - any gas leak can instantly cause a fire;

- check the place of work again for the absence of flammable materials, strangers (especially children), and animals;

- make sure you are ready to work;

- Wear safety glasses and gloves.

Then the acetylene valve on the cutter is opened, allowing the oxygen in the mixing chamber to escape. A few seconds are enough for this. Then they tighten the valve until you can hear that acetylene is barely coming out. A special lighter for it is placed in front of the cutter, as shown in the video, so that its inner part touches the mouthpiece. Then press the lighter lever. When the sparks produced ignite the acetylene, a small yellow flame should form in front of the mouthpiece.

By tightening the gas supply valve, the flame length is increased to approximately 25 cm. The torch should start at the very mouthpiece of the cutter. The flame will come off or jump when too much acetylene is supplied.

Slowly open the front oxygen valve. In this case, the flame should change color from yellow to blue - at this moment, the supply of such an amount of oxygen will be provided, which is sufficient for the complete combustion of acetylene. The oxygen supply should be increased until the inner tongue of blue flame decreases and contracts towards the mouthpiece.

The oxygen valve is opened even further - the size of the torch is increased until the length of the internal flame becomes barely greater than the thickness of the steel being cut (for cold-rolled sheets with a thickness of 9.5 mm, it is enough to exceed the flame length by 1.3 mm). When you hear a "snuffing sound" or the blue flame appears feathery and unstable, there is too much oxygen being supplied. It is reduced until the entire flame stabilizes and the internal one takes the shape of a clear cone.

The very tip of the internal flame is brought to the surface of the steel being processed. It is heated until a pool of molten glowing metal forms at the point of contact. The tip of the flame must be kept motionless at a distance of approximately 10 mm from the surface of the steel as shown in the video, so that all the heat is concentrated in one area.

Cutting steel with a gas cutter

The handle of the gas cutting valve is slowly released down - a stream of oxygen is supplied, igniting the molten metal. If a violent reaction immediately begins to occur, then the steel has caught fire and you can continue to gradually increase the oxygen pressure until its stream cuts right through the material. When the reaction does not proceed, the metal is not heated enough to ignite in a stream of oxygen. It is necessary to add oxygen to the heating flame and allow it to heat the steel.

When the oxygen stream begins to cut, the cutter mouthpiece begins to slowly move along the cutting line. In this case, almost all processing products (molten slag, sparks) are blown away by a jet to the rear side of the cutting zone as shown in the video. If this flow comes back or slows down, then you need to reduce the speed of the cutter or stop it and heat the material even more (it is better to work very slowly than to try to cut too quickly). Cutting continues until the intended cut or separation of metal is completed.

Advantages and disadvantages

Cutting metal with propane has a number of advantages, among which are the following:

- Gas cutting is in demand in situations where there is a need to cut metal of considerable thickness or create products according to templates that require the production of a curved cut that cannot be made with a grinder. You also cannot do without a gas cutter even when faced with the task of cutting out a disk from thick metal or making a blind hole of 20-50 mm.

- A gas cutter is a very easy-to-use tool and is lightweight. All home craftsmen who have experience working with gasoline models are aware of the inconveniences associated with large weight, size and noise. In addition to the fact that vibration creates significant inconvenience, the operator is forced to provide serious pressure during operation. Gas models seem to be a more attractive alternative due to the absence of all the above-mentioned disadvantages.

- Using metal cutting with gas allows you to speed up the work by 2 times, which cannot be done using a device equipped with a gasoline engine.

- Among most gases, including gasoline, propane has a lower price. For this reason, it is better suited for carrying out a significant amount of work, for example, if there is a task of cutting steel into scrap metal.

- When using propane cutting, it is possible to create a narrower cut edge than when working with acetylene cutters. At the same time, the method under consideration allows you to create a cleaner cut than what can be done using gasoline torches or a grinder.

Among the disadvantages that propane cutters have, only one should be highlighted: they can only be used for a limited range of types of metals. They are suitable for cutting exclusively low and medium carbon steels, as well as ductile cast iron.

Features of use

Such tools are not suitable for cutting high-carbon steels for the reason that they have a fairly high melting point, which is almost the same as the flame temperature.

This leads to the fact that instead of the release of scale, which looks like a column of sparks, from the back side of the sheet, it mixes with the molten metal along the edges of the cut. As a result, oxygen cannot reach the thickness of the metal, which is why it fails to burn through the material. Difficulties when cutting cast iron are created by the shape of the grains, as well as the graphite between them. True, this does not apply to malleable cast iron. It is impossible to solve the problem if you have to deal with aluminum, copper and their alloys.

It is important to dwell on the following point: the category of low-carbon steels is represented by grades from 08 to 20G, medium-carbon steels - grades from 30 to 50G2. A characteristic feature of carbon steel grades is the presence of the letter U in front of their names.

Disadvantages of processing

Low carbon steel is most suitable for gas cutting, but medium and high carbon steel is not a very suitable material for cutting. Due to the high carbon content, the ignition temperature increases and the melting point decreases. And this condition complicates the cutting process.

It is difficult to cut metal using a gas mixture if it has low thermal conductivity. Therefore, these types of material are not suitable for processing.

Safety rules when gas cutting metal

Gas cutting of metal should only be performed by a qualified and experienced professional. It is important to observe all the key factors of proper processing: oxygen pressure and speed of the procedure. It is necessary to take into account the thickness of the product and the diameter of the cutter nozzle. If the rate of oxidation and metal cutting do not match each other, then the result will be poor-quality processing.

Oxygen cutting involves the use of explosive substances. If safety rules are not followed, there is a high probability of an explosion of the gas-air mixture; it is necessary to monitor the condition of the gas equipment. To protect against burns, you must use personal protective equipment.

A significant disadvantage is the possibility of metal deformation and low cutting accuracy.

Related video: Cutting metal with a cutter

Useful articles

Plasma cutting of metal - features and advantages of work

List of metal cutting companies in Rostov-on-Don

Making your own laser for cutting metal - instructions and recommendations

Cutting Features

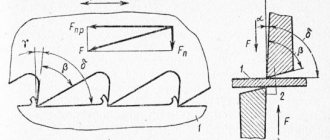

The cutter must be moved smoothly along the cutting line and monitor the angle of inclination, which deviates 5-6 degrees against the movement of the tool. When the metal thickness is more than 0.95 m, the deflection is increased by cutting through the metal to a depth of about 20 mm, and the deflection angle decreases again. We have already explained in detail how to cut with a cutter so that the cut is even in the previous section.

How much gas is consumed?

Gas consumption when cutting metal with a propane-oxygen cutter depends on the thickness of the structure and the configuration of the cut. For clarity, we present the table below:

| Workpiece size (thickness), mm | Hole time, sec | Cut size (width), mm | Consumption, per m 3 cuts | |

| propane | oxygen | |||

| 4,0 | 5—8 | 2,5 | 0,035 | 0,289 |

| 10,0 | 8—13 | 3,0 | 0,041 | 0,415 |

| 20,0 | 13—18 | 4,0 | 0,051 | 0,623 |

| 40,0 | 22—28 | 4,5 | 0,071 | 1,037 |

| 60,0 | 25—30 | 5,0 | 0,087 | 1,461 |

Gas consumption is significantly reduced when surfacing or soldering is performed.

Nuances

The main task of the performer is to maintain the speed correctly:

- normal mode - sparks fly at right angles relative to the surface of the workpiece;

- low speed - flying away from the performer and an angle of less than 85 degrees.

After the process is completed, the oxygen supply is turned off first, and the propane is turned off last.

Negative deformation

Beginning welders are concerned with the question of how to properly use a propane-oxygen cutter so that warping of the surface of the part does not occur. First you need to figure out what factors contribute to the occurrence of these defects:

- with uneven heating of the surface;

- a high cutting speed was selected;

- there was a sharp cooling of the heating area.

To eliminate the occurrence of the listed factors on the workpieces, they are first securely fixed and heated, and the speed is increased gradually. If warping does occur, then the original shape can be returned by firing or tempering, and the sheets can be straightened on rollers.

Kickback hazard

If the jet burns in an incorrect mode, a bang occurs and the flame is drawn inside the product, which leads to an explosion, as the fire spreads through the hoses and reaches containers with gases. To prevent a dangerous situation, the cutter is equipped with a non-return valve, which cuts off the flame and prevents it from spreading.

Terms of use

They are similar to safety precautions when welding, but have specific additions:

- It is not recommended to neglect protective equipment, as this leads to injury in the form of skin burns or damage to the cornea of the eyes from flying sparks, so goggles and gloves with long bells up to the elbow are required.

- The performer's clothing and shoes are made of non-flammable material.

- Gas cylinders are located no closer than five meters from the cutting site.

- The flame of the cutter is directed only in the direction opposite to the hoses.

- Cutting is carried out in rooms equipped with strong ventilation or in open areas.

If the equipment is idle for a long time, it is necessary to carry out preventive maintenance before using the cutter for its intended purpose.

How to cut a balloon safely

Since the gas cylinder is explosive, if it is cut, there is a high chance that it may explode. The sawing procedure must be done with great care and certain requirements.

Since the vessel is designed to transport liquefied gas, the remainder of its contents is a liquid called condensate. This substance has a specific odor and a high degree of flammability. Therefore, you can’t just start cutting the container with a grinder.

First you need to remove the condensate, and to do this you need to get rid of the remaining gas in the cylinder.

In this position, the remaining gas is drained from the condensate cylinder

Important! The procedure for pouring out condensate should not be carried out at home, but choose a place in advance where there will be no people. First, you need to dig a hole in the ground to the depth of one spade bayonet. After that, pour out the condensate and set it on fire, moving away to a safe distance with the cylinder. After the burning is over, the hole needs to be buried.

During long-term operation, the gas that is transported in the container eats into the walls, so even after draining the condensate, cutting it is prohibited. It must be washed with running water and detergents. But, even after such a technique, the probability of fire is very high.

To start cutting a vessel, it is necessary to build a system for constantly supplying water to it, and begin work only after the container is filled with water.

Basic design of a cutting torch

Design features of the cutter.

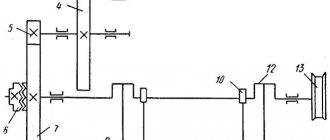

Injection or two-pipe cutter

This is the most popular model due to its design. The name “two-pipe” comes from the division of technical oxygen into two streams. This is done to functionally separate the work of oxygen.

The upper flow of oxygen flows at high speed through the nozzle of the internal mouthpiece. This is an extremely important part of the device - it is directly responsible for the metal cutting phase. This flow is regulated by a special valve, which is usually placed on the outer panel.

The second flow of oxygen goes straight to the injector. The operating procedure in the injector chamber is as follows: oxygen enters the chamber under high pressure and at high speed, as a result of which a rarefied pressure zone is formed in this space. Oxygen is injected in this case.

Nominal gas flow.

Through special side holes in the walls of the chamber, flammable gas is drawn into it - in this case it is ejected. The gases are mixed, the velocities are equalized, and as a result, a flow of a mixture of gases is formed at the exit from the chamber, the velocity of which is lower than that of the injected oxygen, but higher than that of the ejected combustible gas.

At the next stage, the formed mixture of gases enters the tip - first into its head, and then exits through the nozzle between the mouthpieces and forms the same flame in the form of a torch, which heats the metal to its combustion temperature. All gas flows are regulated by their own valves on the outside of the housing - for supplying oxygen and separately for supplying flammable gas to the injector.

Injectorless or three-pipe gas cutter

In this case, the device of the gas cutter is more complicated. Oxygen enters it through two tubes, and the third tube is rightfully occupied by flammable gas. In this welding torch, gases are mixed inside the head; there is no chamber here. This system is safer than the two-chamber model.

The fact is that there is no risk of the so-called “reverse strike”, which consists of a very unpleasant and dangerous phenomenon: the penetration of burning gases in the channels and tubes of the device in the opposite direction.

This model has a significantly higher cost. In addition to this drawback, the three-pipe cutter has one more nuance: when working with it, a very high pressure of flammable gas is required - higher than with an injection apparatus.

Examples of using cut gas cylinders

Since the metal of the vessel has a relatively large thickness, and the shape itself corresponds, barbecues are made from these cylinders. This use case is very popular, since such a product lasts a long time. The thickness of the metal will not allow the barbecue to burn out for a very long time, which contributes to maximum operation.

The shape of the cylinder allows you to get a ready-made grill with minor modifications and modifications. It is quite simple to cut the cylinder on the grill in a horizontal position.

Another option for using this vessel is a potbelly stove. With minor modifications, the cylinder can become an effective heating device in non-residential premises. The thickness of the metal will not allow it to burn during operation, and the round shape allows you to avoid many welding works. When it’s winter outside, such a stove will help to effectively heat a small area.

Stove-stove from a gas cylinder

Using a cylinder as an additional compressor receiver. It often happens that a large supply of air is needed in the compressor, which is why additional receivers are used. To do this, saw off the top of the vessel. The other part is burned out over a fire to completely get rid of odors, and again welded together. The result is a high-quality receiver that can withstand air pressure up to 15 kg. An oxygen cylinder is also used for such purposes.

Using cylinders as water containers, or homemade boilers. For such purposes, the vessels must be emptied. To increase the capacity, you can weld two cylinders together, cutting off the lower or upper parts of each. The correct choice of cut position in this case depends solely on the individual requirements for the product.

Standards and dimensions

Welding using a welding torch with gas.

All standard measurements regarding gas cutters are specified in GOST 5191-79. Naturally, the weight and size of the devices are directly related to their power. Weight, for example, comes in only two sizes: the cutters of models P1 and P2 weigh 1.0 kg, and the high-power model P3 weighs 1.3 kg and not an gram more or less.

By the way, the type of combustible gas is also related to the power and size. If powerful P3 cutters operate only on a mixture of oxygen and propane, then smaller devices such as P1 and P2 can operate with any type of gas.

Insert gas cutters:

In addition to the classic models with different powers, there is a separate category - the so-called plug-in gas cutters with a special marking RV. According to GOST, they have a very strange name: tips for a gas torch for cutting metal. In general, they differ from traditional cutters: the mixing of the combustible mixture and oxygen is carried out at the tip itself.

These devices are much lighter in weight than cutters. PB1 weighs 0.6 kg, and PB2 and PB3 only 0.7 kg each. But don't let this apparent elegance fool you. Let's not forget that these are tips for the torch, complete with which they will weigh no less than conventional cutters. What is the advantage then?

The fact is that they can be purchased in addition to an existing burner and, thus, save some money. And the compactness of the entire set, packed in a special case. And one more important detail concerns the nature of flammable gas. The fact is that acetylene is much more expensive than propane.

But for metal welding, acetylene is much more desirable: a torch with it produces a flame with a temperature 400°C higher than the same one with a mixture of oxygen and propane.

Portable models: small ship – short voyage

Cutter device.

The market now offers many portable options for autogens - this is exactly how they are positioned. They are sold as an attachment for a compact collet gas cylinder. But in essence and the principle of operation, these are burners. Most of them provide a flame temperature no higher than 1300°C.

There are, of course, portable models of the “professional” range - collet cutters that produce a higher torch temperature - up to 2000 - 2500 ° C, which is generally close in performance to a classic oxygen-propane cutter. But physics is physics: even in these models there is no main component that cuts metal - an oxygen jet that oxidizes this very metal.

Where is a portable cutting torch good? When cutting easily fusible metals or alloys such as tin, brass, bronze, copper. But even these “children’s” options are not cut, but melted. Therefore, compact attachments - cutters are used more for soldering or welding small workpieces made of non-ferrous metals. These can be parts of household devices such as a refrigerator or air conditioner. Welding, not a cutter, in a word.

In any case, be careful when choosing such models; their proposed “portability” is not always justified in the end.

How to cut a gas cylinder with a grinder

After an old propane gas cylinder has become unusable, do not rush to throw it away. In some cases, it can be used to make various products with your own hands, for which it is often cut. This process is characterized by quite a large number of features, which we will discuss in more detail later.

Equipment

The main equipment for gas cutting is a cutter. The kit includes: a nozzle for welding and melting.

Thanks to the cutter, you can control the dosage of the gas mixture and oxygen. Also, with the help of this equipment, the flammable mixture is ignited and a flame is supplied to the processing site.

The cutter consists of two blocks: cutting and heating. The first is represented by an oxygen stream outlet tube, a valve and an internal type mouthpiece.

The heating block includes valves that are designed to regulate the pressure of the gas mixture and oxygen. There is also a supply tube, an external mouthpiece, a mixing chamber and an injection cell.

Cutters are either manual or machine. The latter are stationary, so for repair work it is preferable to use manual ones.

Additionally, the following gas cutting equipment is used:

- reducer – designed to reduce pressure;

- device for changing pressure;

- steel cylinder with gas and oxygen;

- connecting hoses.

Before using the equipment, it is important to check its serviceability in order to avoid explosion of the cylinder or reducer. The cutter is pre-purged with oxygen.

Safety requirements

Gas equipment that is used in the process of cutting metals, namely an oxygen-acetylene cutter, is classified as explosive and flammable. Therefore, before using a gas cutter, you should follow all mandatory safety recommendations.

To do this, the workplace should be equipped with:

- fire extinguisher. The use of a gas cutter is accompanied by an open flame and high temperatures, so fire extinguishing equipment must be present at the post;

- protective clothing, consisting of: a cotton suit, if possible, impregnated with a fire retardant compound;

- gloves or leggings made of canvas or fairly thick leather;

- boot with leather sole;

- safety glasses with built-in light filters.

When working with a cutter, you should never wear clothing made from synthetics or other easily flammable fabrics, or that do not fit tightly to your body or have heavily worn edges. All this can lead to fire and, accordingly, danger to health and life.

Only various grades and types of unalloyed carbon steel can be cut with gas. Stainless steel, non-ferrous metals and various alloys cannot be cut with a propane cutter.

What should you pay attention to?

There are a few things to consider when cutting. The main ones can be called:

- Cutting must be carried out using special protection.

- Processing along the seams is easier, but often the markings do not match. When cutting on a round plane, you need to put a slight load on the grinder, since a small contact area leads to slipping of the nozzle.

- Many problems arise with removing rust and paint.

In general, we can say that the cutting process does not create significant problems.

How to choose a better cutter?

Operating principle of a gas cutter.

We offer a block of useful information that will help you better navigate the specifications and technical characteristics of cutters in advance:

- Nipples are made of brass and aluminum. Brass options are more durable.

- If possible, choose models with aluminum rather than plastic handles. No matter how heat-resistant the plastic is, it will “float” in any case faster than aluminum.

- The handle should be quite massive: the diameter should be at least 40 mm.

- The valves should work well. This means turning without much effort.

- Lever-controlled devices are more convenient and economical to use, they save gas.

- Valve spindles must be made of stainless steel, and not brass, which is too short-lived. There are “combined” options; they occupy a middle position in terms of durability.

- The best materials for the cutter body are metals: brass, copper, stainless steel.

- We remember that acetylene cutters are more expensive. We monitor the material from which the parts that have direct contact with the flammable gas are made before mixing in the chamber. Attention! They should not be made of copper or its alloys, where the copper content is not less than 65%.

- If the design of the device is collapsible, this is better: it is easier to clean and repair.

- Only copper! Only copper outer mouthpiece!

- The correct internal mouthpiece for an acetylene-type cutting torch should also be made of copper. But in an oxygen cutter for metal it is made of brass. These are the nuances.

- Be sure to check with the seller the status of spare parts and consumables.

Advice from experienced people: how to use

Instructions on how to use a gas cutter can be divided into general provisions and professional “minor” notes, which in fact are the most valuable practical assistants.

Table of cutting metals with a gas cutter.

First the general points:

- Only with a mask! We carry out any work with any gas cutter only in a welder’s mask or special glasses. Working with an autogen is an activity with a sea of risks; safety precautions must be carried out for real and not childishly.

- We choose clothing and gloves with fire-resistant properties. If there are none, well: at least the minimum requirement is not to wear synthetic clothes.

- There must be a fire extinguisher at the workplace with all the correct expiration dates, etc. Fire extinguishing equipment must also be placed nearby in accordance with fire safety regulations.

- Before work you need to stock up:

- a ruler, a special pencil, a square and a tape measure;

- a special lighter, which is usually included with the equipment.

- When working, it is important to choose the right location. The torch flame must be located in front of the supply hoses. The hoses, in turn, should be positioned so that they do not interfere with you during the process.

- Another safety rule: gas cylinders should not be closer than 5 meters to you during operation.

- Ventilation should be excellent throughout cutting, preferably working outdoors.

- The floor in the workshop should be either concrete or earthen.

- If you haven't worked with your cutter for a long time, or are starting to use a new device, check the channels: they should be clean. In addition, always check the vacuum level in the chamber that is formed by oxygen. First, remove the propane hose - this must be done with the valves on both the cutter and the cylinder tightened. Then open the oxygen and gas valve on the cylinder at operating pressure. The injector is checked simply: put your finger on the gas nipple, if everything is correct, you will feel air being sucked into this nipple. Close the oxygen, all the valves and then connect the hose with flammable gas to the cutter: you can work.

Scheme of cutting metal with a cutter.

Stages of action during cutting, propane cutters:

- First, an oxygen cylinder: set the operating pressure.

- Then a cylinder with flammable gas: we also set the working pressure. The reference point is oxygen pressure. The propane pressure should be about ten times less. If the device is three-pipe, then the difference will be five times.

- Slowly open the oxygen and gas valve, ignite the gas and use the valves to create the pressure of the heating flame.

- The manual gas cutter is ready for work, now the actual cutting of the metal with the cutter.

- A stream of igniting oxygen begins to flow to the combustion site. If the metal is heated sufficiently, the desired reaction will begin immediately. In this case, the oxygen supply pressure can be further increased until the metal is completely cut through.

- Now the autogen can be moved in the desired direction - along the line of the planned cut. The speed of movement must be determined as you go, it will depend on how the sparks and slag flow or are blown down from the burner.

- After cutting, carefully inspect the work area for any remaining pieces of molten metal. God forbid you step on these - they will even burn through the thick soles of your boots.

- Cooling of parts is carried out either with water or naturally.

- After finishing cutting, you need to finish the work process, which is no less important than starting work.

- First we tighten the oxygen valve.

- The flame valves are closed next - the propane valve first, the oxygen valve next.

- We tighten the valves on the cylinders.

- We release the hoses from the gas: open and then alternately close the valves of the heating mixture on the device.

Sources

- https://tutmet.ru/polzovatsja-rezat-rabotat-gazovym-rezakom-nastrojka.html

- https://stanok.guru/oborudovanie/raznoe/rezka-metalla-kislorodno-propanovym-rezakom.html

- https://printeka.ru/metally/kak-pravilno-rezat-gazovym-rezakom-metall.html

- https://tutsvarka.ru/oborudovanie/gazovyj-rezak

- https://msmetall.ru/instrument/kak-rezat-relsy-rezakom.html

- https://WikiMetall.ru/oborudovanie/kak-polzovatsya-rezakom.html

Review of the best metal cutters

Keeping these parameters in mind, let's move on to specific products selected by experts based on their characteristics and reviews from carvers. Perhaps you will immediately find a model that suits your needs here.

GCE P8 – Dragon 0767578

Rating: 4.9

The list of the best cutters is topped by a professional model from the Czech brand GCE. This is an acetylene apparatus with an injector, the flame temperature of which reaches 3000º C, which promotes rapid heating of the metal. Mixing of oxygen and flammable gas is carried out in a special chamber, and the cutting jet is supplied separately. To adjust the torch, two valves are used on the sides of the cutter, and the cutting oxygen supply tap is located on top so that the welder does not confuse anything. Additionally, these elements are marked with color. The length of the cutter is 550 mm, so it is convenient for cutting large parts (machine bodies, rails, channels, etc.).

Experts singled out the model for its high-quality assembly, which is confirmed by the owners in the reviews. It also has a long service life, which is facilitated by a nozzle with a particularly thick tip. This protects the part when it comes into contact with hot metal and when working in a high-temperature environment.

Advantages

- length 550 mm suitable for cutting large parts;

- capable of penetrating a metal cross-section up to 30 cm;

- high-quality assembly;

- the head is resistant to overheating.

Flaws

- quite high cost;

- The hose connection fittings are located close to each other and make quick connection difficult.

Autogen RPK-2 up to 500 mm 0000623

Rating: 4.8

The experts gave the second step of the review to the propane cutter, which heats the metal to 1600 degrees. This allows you to avoid overheating the workpieces, avoiding deformation of thin sheets with a cross-section of 1-3 mm. But if production needs require it, the autogen is capable of cutting steel up to 500 mm thick. In reviews, welders note a stable combustion process and high efficiency. Structurally, the cutter differs from the one described above in the way it supplies cutting oxygen. There are two valves for adjusting the torch, and cutting is carried out by pressing the lever at the top. This allows you to manipulate the tool with one hand while holding the workpiece with the other.

We recommend this cutter for cutting very large structures (car bodies, carriages) in order to protect the welder as much as possible. The length of the model is 1.3 m, which allows you to be further away from the fall of the cut parts.

Advantages

- cuts metal with a thickness of up to 50 cm;

- convenient handle for feeding the cutting jet;

- deforms the metal less;

- The hose connection pipes are separated, which makes connection easier.

Flaws

- inconvenient to operate in a confined space;

- A weight of 2.5 kg makes your hands get tired faster.

NORD-S 100P (535 mm) NORD 1390010

Rating: 4.7

The top three included a valve cutter for working with propane, which has a length of 535 mm and is suitable for parts with a thickness of up to 10 cm. Two small control valves are located on the side and are color-coded, and the cutting oxygen supply valve is located at the top and has a larger shape. The cost of the cutter is less than those described above, since there is no injector, and each gas is supplied through a separate tube. The mixing itself takes place inside the nozzle. But this implementation is simpler and more reliable. The cutter's weight of 1.1 kg reduces hand fatigue during prolonged use. The unit for cutting metal is sold together with the NORD-S 2P mouthpiece, which has a narrow shape that simplifies access to niches and grooves.

In reviews, owners praise the cutter for its reliability and “indestructibility.” Due to the three-tube design, there will never be a flashback of the flame. All elements of the tool, including the handle, are made of metal, so the cutter can withstand falls and overheating well.

Advantages

- easy replacement of mouthpiece;

- light weight 1.1 kg;

- convenient length 535 mm;

- simple controls.

Flaws

- not suitable for cutting parts thicker than 10 cm;

- more convenient for right-handers;

- Immediately after purchase, the taps will be quite tight (the flame breaks off when opened abruptly), and then they are developed.

KRASS R3P-300 2117527

Rating: 4.6

The review continues with a cutter from the Russian brand KRASS, which is equipped with an injector. Oxygen is regulated by the top valves, and propane by the side valves. All fittings and threads are made of brass, and the tubes are made of stainless steel, which ensures resistance to corrosion and mechanical stress. Gas hoses can be connected through nipples with a diameter of 6 or 9 mm. The autogen weight of 1.18 kg reduces the load on your hands. Welders in the reviews like that the valves of the cutter have a high relief, which prevents slipping in the hands. There are also signs on them to make it easier for beginners to navigate.

Experts considered the autogen to be the best due to the presence of high-quality four internal mouthpieces with numbers 1-4 included in the set. This allows you to quickly re-equip a nozzle for cutting metal with a cross-section from 1 to 300 mm and obtain a torch of a certain power. There is no need to purchase anything separately for this model.

Advantages

- light weight 1.18 kg;

- easy replacement of the mouthpiece;

- comfortable valves with protruding edges do not slip in your hands;

- nipples 6/9 mm for connection.

Flaws

- If dropped from a height, the plastic handle may break.

KEDR R3P-05 1390036

Rating: 4.5

In the next place is a cutter for working with metals with a thickness of 1 to 30 cm. Its mixing of gases is carried out in the nozzle itself, which simplifies the design. The manufacturer placed the gas valve directly on the nipple at the back of the handle so that beginners do not get confused with the adjustments. Additional color coding makes orientation easier. To install a nozzle of the required diameter for cutting metal, you will need to unscrew the crimp nut. The brass and stainless steel construction withstands construction or workshop use without corrosion or dents, and maintains its rigid shape despite its size of 52 cm in length.

Carvers share in their reviews that when working for a long time, nothing sticks in their hands. This is due to a clever overlay on the brass tubes, which reduces heat transfer. There are also many raised bumps on the handle that prevent slipping in your hands. Holding such an instrument is comfortable and easy.

Advantages

- narrow nozzle;

- handle with a comfortable grip;

- simple and durable design;

- light weight 900 g.

Flaws

- installation of nozzles is more difficult than on other models;

- You cannot adjust the flame with one hand due to the fact that the gas valve is located at the back.

Svarog RZ-345 1C005-006 95653

Rating: 4.4

The Svarog brand offers an autogen for cutting metal up to 30 cm thick. The length of the model is 50 cm, and gas mixing occurs inside the nozzle, protecting against backfire. Connecting hoses here is possible through nipples with a diameter of 6 or 9 mm. The kit includes a tip for working with propane. The lever start of the cutting oxygen makes it easier to use the tool with one hand and helps save gas up to 30%. Carvers praise the product in reviews for its weight of 770 g, which does not tire the hands at all. It is very convenient to manipulate it when cutting metal.

Autogen attracted the attention of experts with its versatility, since it is capable of working with both acetylene and propane. The model also has a unique body shape, where all controls are located at the rear. This makes it extremely thin, allowing it to be inserted into tight spaces or to cut metal through mounting holes inside a structure.

Advantages

- durable metal case;

- unique design;

- quick change of mouthpieces;

- versatility in gas types.

Flaws

- The kit does not include mouthpieces for acetylene.

Avtogen-M Mayak-2-01 9/9 SV000010180

Rating: 4.3

Among metal cutters at an affordable price, the propane model “Mayak-2-01” stands out. The tool is of the injection type with two brass tubes. The total length is 58 cm. The maximum cutting thickness reaches 300 mm. In the reviews, welders are satisfied with the package, which includes 4 internal and 2 external nozzles along with the cutter. The handle is made of aluminum and is attached with two screws, and the entire body is cast from brass, so the autogen can confidently withstand operation in harsh construction conditions.

Experts noted the cutter as the best in terms of torch shape. Unlike most of its competitors, it has a nozzle for mixing gases; it is designed not as a ring within a ring, but as holes for cutting oxygen and 10 holes in a circle from which the combustible mixture is supplied. This makes the torch always even, regardless of the service life of the equipment. In competitor nozzles with holes of small and large diameters, a hole gradually forms on one side, displacing the torch to one side.

Advantages

- made entirely of metal;

- convenient connection of the hose due to the gas nipple diverting downwards;

- Corrosion resistant;

- good equipment;

- affordable price.

Flaws

- Gradually, play forms on the valves.

REDIUS R3P-02MU SV000009025

Rating: 4.2

The TOP 8 is completed by a propane cutter with an injector, which has top and side valves for adjusting the preheating flame, as well as an additional cutting oxygen valve. The nozzle is positioned at a 45º angle, making it easier to make vertical cuts from a standing position. The hose connection nipples have a stepped configuration with diameters of 6 and 9 mm, so they are suitable for different communications. The cutter is capable of cutting metal up to 30 cm thick, for which the kit includes 4 internal replaceable tips. The model weighs 1 kg, which makes it very easy to work for 6-8 hours.

If you need a long cutter for cutting large metal, but are not ready to pay 9,000 thousand rubles, like for the Autogen RPK-2 model, then pay attention to this option. It can be bought from 2200 rubles, and the length of the tool is 77 cm. Despite the budget, the product has a decent set of 4 internal mouthpieces, and the cutter body is collapsible and allows you to replace the barrel without removing the valve block and handle.

Advantages

- convenient connection of a gas hose;

- 45º nozzle angle makes standing vertical cuts easier;

- two options for fitting diameters;

- collapsible body.

Flaws

- Long brass tubes bend and dent over time.

Announcement picture:

Detailed picture: Date of creation: 05/31/2020 18:09:48 Tags: Hand tools Articles by tags: 7 best glass cutters / 8 best cable cutters / 10 best sets of taps and dies / 8 best chisels / 15 best hammers / 7 best sets with ratchet / 7 best sledgehammers / 20 best tool sets / 8 best profile cutters / 10 best calipers