How to make an electromechanical elevator with your own hands

General elevator parameters

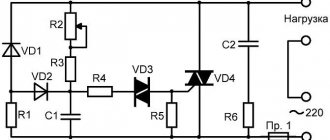

In our case, the design of a self-made elevator is a movable frame made of a 60×40 square pipe, which moves between two channels - guides. There are 8 wheels installed in pairs at the corners of the frame, with the axes of one pair (one corner of the frame) located perpendicular to each other. One wheel rests against the wall of the channel, the other against the shelf. This design ensures free movement of the elevator frame up and down, while reliably fixing it from frontal and lateral displacement (Fig. 1).

We weld the loading platform to the bottom of the frame. To ensure structural rigidity, we connect the platform and frame with stringers. When constructing an elevator, you will need to use a welding machine; here we describe in detail how to weld with electric welding.

The location of the stringers at the top or bottom is dictated by the specific conditions of the room, since each option has both pros and cons. Stringers located above the platform can complicate the installation of the cabin walls. The location of the stringers from below will require lengthening the movable frame. In this case, you will have to make a pit, otherwise the elevator car will not reach the floor.

DIY electromechanical elevator guide diagram

Installation of guides

We take no less than No. 10 channel for the guides. Its length depends on the required lifting height. As practice has shown, even channel No. 12 with a length of 7.5 meters has high flexibility and “plays” under its own weight. Therefore, during the installation process we repeatedly control the verticality, checking it in different places.

We attach the channel to the wall every 600 mm at two points. To do this, we pre-weld fastening plates to the channel, the edges of which protrude from both sides of the shelf.

How to attach the plates to the wall depends on its material. For brick or concrete - concrete anchors 200x16, for aerated concrete - plastic anchors for aerated concrete 10x120 and self-tapping screws, for wood - self-tapping screws with a hexagonal head, 4-5 mm in diameter (we do not use nails!).

Channels - guides for an electromechanical elevator with welded strips

To install the second guide, we place the assembled movable elevator frame (with wheels) between the channels, and gradually lifting it up, we position and fasten the second channel “in place.” In this way, the most accurate geometry of the structure is achieved. Tolerances will be minimal, which means that the elevator movement will be stable, without swaying.

Introduction

For a very long time the word welding was used only in the context of metal structures, but everything changed with the advent of construction blowers and the popularization of the use of polymers in construction. Then the concept of welding plastic appeared. But in addition to the tool, special add-ons are also used that increase the productivity and expand the functionality of the tool.

A hair dryer attachment for soldering plastic is a very useful device that has already received many variations and is widely used in various fields of activity. Therefore, it is important to know about the principle of use and the types available on the construction market.

Safety comes first

An elevator structure is a potentially dangerous object, so its arrangement must be approached with all responsibility.

PHOTO: If you decide to make an elevator with your own hands, then remember that all mechanisms must be regularly checked and maintained

When installing a home elevator, you must ensure that the mechanism is protected from accidental entry by children and pets and that the doors, which should not be opened during movement, operate adequately. It is imperative to provide insurance for the cabin in case of cable breakage and grounding of the cabin power supply.

Make sure that the elevator does not start moving until people have fully entered or exited it. This is the only way to avoid serious injury.

PHOTO: And be sure to work with your family, especially children, about the rules for safe use of the structure

Main characteristics of a hair dryer

- Power consumption. The main parameter that determines the range of application of the device. Typically lies in the range from 500 W to 2.5 kW.

- Air temperature at the nozzle exit. In most heat guns, the maximum heating is limited to 600-650 degrees. Professional devices for specific tasks can heat air up to 800 degrees. The parameter is directly related to the power of the heating element.

- Volume of pumped air (performance). From 200 to 700 l/min. Depends on the power of the fan motor and the characteristics of the impeller.

- Duration of continuous operation.

These parameters can change directly or inversely. For example, the same device, with a fixed power of the heating element, by adjusting the fan speed, can reduce the air volume while simultaneously increasing the temperature. Or maintain heating while increasing the flow rate. There are also characteristics such as the size and weight of the device, but they are considered secondary parameters.

These connections were made as amateurishly as possible, because this is more of an experiment, and I followed the simple path, without coming up with anything easier to implement.

Source

How to start installation?

The simplest model of elevator to the 2nd floor in a private house is electric. To create, you do not need to purchase or rent special equipment. But you shouldn’t think that everything is so simple and easy - there is a lot of manual work in this process. In addition, you will need to comply with the rules and recommendations of GOST. True, when creating such an installation with your own hands, the result is a high-quality design, even no worse than a factory installation.

You need to decide where exactly to mount the unit. Since the rails will need to be fixed to move the cabin, the walls themselves must be reliable. Sometimes they are even improved or strengthened to create safe movement. In order for a home elevator to move safely in a private home, it is worth considering several points:

- If the cable breaks, there must be a special system that allows the elevator to automatically stop.

- There should be any communication system inside in case the unit stops at an unnecessary moment or between floors.

- The voltage should not exceed 24 Volts, otherwise it is dangerous.

Experts advise entrusting the development of the plan to a professional who has experience in this work, and you can already implement the finished project with your own hands. Today there are not many real masters, but you have to pay for such services. But you shouldn’t save money when looking for a master. Otherwise, the structure will be unreliable and may pose a danger to residents.

Process Features

Together with them, slag-forming substances are loaded: lime and bauxite. The body is surrounded by a support ring attached to the pivot pins. With their help, the vessel is tilted and the finished steel is poured through this hole - the tap hole. Bottom blowing is carried out through through holes (tuyeres) made in the bottom of the furnace.

Historically, it has been the custom that the method used everywhere is called the Thomas or Bessemer method. In the last century, the open-hearth process became predominant. The regenerator is heated by purging furnace gases, after which it heats the cold air entering the melt.

In modern designs, the top method is more often used, in which blowing at high speed is carried out through nozzles lowered to the metal surface. In Russia, it is primarily the top blowing of furnaces that is used.

Being under a stream of air, cast iron intensively oxidizes in the contact zone. Since its concentration is much higher than other impurities, iron oxide is predominantly formed. But it dissolves in the slag. Therefore, the metal is enriched with the released oxygen.

C, Cr and Mn are oxidized, reducing the percentage in the metal structure. Oxidation is accompanied by the release of heat. Due to the presence of slags CaO and FeO before heating, phosphorus is removed at the very beginning of blowing.

The slag is merged with it and a new one is created. Steel production is accompanied by express analyzes and monitoring of current changes using control devices installed in the furnace. The phosphorus content in cast iron should not exceed 0.075%.

Preparing for elevator installation

The preparatory work required before installation consists of the following:

- First of all, the owners need to decide what type of elevator will be installed in the basement. Further nuances of preparation will depend on this.

- The installation site of the elevator shaft and engine room must be cleared of foreign elements and the load-bearing walls must be strengthened, if necessary.

- Calculate the required lifting capacity of the lift.

If you will assemble and install the elevator yourself, do not forget:

- Read the safety instructions carefully and take all necessary precautions.

- Prepare the necessary materials and equipment for assembling and installing the elevator.

The installation of each type of elevator has its own nuances. If you have difficulties at any stage, seek help from specialists.

Operating principle

The operating principle of a hair dryer is very similar to its household hair dryer. The material is heated to give it a certain shape and fix it in this position. The only difference lies in the power and object of heating, as in this case, soldering. To ensure proper soldering, the following tools are required:

The solder is always special rods made of the required material. The solder material is selected from a material similar to that of the welded object. These rods are installed in a hair dryer or in a special compartment on the nozzle, heat and weld parts, crevices, and so on. In addition, it would be a good idea to use clamps for reliability and files for quality processing.

Video on how to use a soldering gun and attachments

Rules and instructions

Oddly enough, there are many emergency and dangerous situations that have already happened more than once. Sometimes hands or feet get stuck in the cracks of the door, or the cabin falls from a height. And children's games with elevators never bring positive stories. All this is taken as a basis in the process of installation work and installations. Such a unit should not cause problems for the owner.

Many people do not agree to ready-made installations due to the need to create a non-standard cabin. But these dimensions should not be made too high. It is much easier to remake a finished structure than to create a full-fledged new elevator that will fully cope with its purpose. Of course, an elevator to the second floor in a private house is a reality, but you shouldn’t forget about safety.

Of course, every person believes that comfortable living conditions should be in any private home. Today, creating a lifting device is not so difficult, but only if all the rules are followed.

Terms of use

To improve quality and avoid mistakes, you need to follow certain rules of use. Compliance with the rules will protect you from problems with use and harm to health . These are the rules:

- During the process, you must maintain a safe distance between the nozzle and the object being processed, 25 cm or more. A shorter distance will reduce the coverage area and damage the coating.

- Before work, treat and clean the surface so that the solder lies more evenly. And after welding, remove defects; after hardening, this process can disrupt the integrity.

- A safe area from the air intake grille must always be maintained. Closing the grill can lead to critical overheating of the instrument, as well as its failure.

- During operation, the nozzle on the hair dryer for soldering plastic overheats greatly, so you can use the tool only with protective gloves that can withstand high temperatures.

What should you not forget?

Every person wonders whether it is safe to build a homemade elevator in a private house? Everyone has their own opinion, but the concern is that if such a device collapses or something fails, there may be casualties. Therefore, it is sometimes better to take and order a design from professionals. Although some people do it themselves, the design lasts for many years and does not fail.

When an elevator appears in a private house, installed with your own hands, it is worth checking it periodically. Each family member should be aware that the elevator is a complex structure and must be handled with special care. In addition, it is worth knowing that an elevator for people differs from a simple lifting elevator. The first one must be installed in compliance with all rules and regulations. The house should be as safe as possible for all its inhabitants. Care must be taken to ensure that the protection is:

- Accidentally entering a traffic block.

- Opening the door while moving.

- Protection from unauthorized movement (if people are not yet inside, but movement has begun).

You can always find information and detailed instructions in the documentation. It is designed with all the conditions and methods. When installing even a small elevator for a private home, do not forget about GOSTs and standards.

Production process

Steel is produced by smelting. The raw materials are cast iron, scrap steel or cast iron itself, pellets, fluxes and ferroalloys.

Cast iron itself, by nature, is not a sufficiently hard and brittle material, and therefore has limited use.

However, it is indispensable as a raw material for steel production. The essence of smelting is, in the case of using pig iron, to reduce the percentage of carbon in it to the required level.

Impurities not included in the final formulation are removed. The traditional composition of the charge is 55% cast iron and 45% steel scrap (scrap). There is also an ore process where ore material is added to components or a scrap process to recycle waste from engineering production.

To make it easier for impurities and carbon to be removed from the components during the smelting process, they are converted into gases and slag. First of all, when cast iron reacts with oxygen, iron is oxidized, forming iron oxide FeO.

At the same time, C, Si, Mn and P are oxidized, and oxygen is released from iron oxide to chemically active impurities. Flux is added to the charge mass to better dissolve the metal: limestone or lime, bauxite. Coal dust, liquid fuel oil, natural or coke oven gas are used as fuel.

What types of elevator cabins are there in country houses?

The most popular among homeowners today are panoramic elevators - with continuous glazing from floor to ceiling.

In second place are the originally decorated elevator cabins - with bright elements made from rare materials - for example, rare and valuable tinted stainless steel, valuable wood in an antique style, and unusual ultra-modern lighting. This approach is designed to make your guests captivated by your home.

Interestingly, such bright designs do not interfere with functionality. The elevator in the cottage is, of course, different from what we are used to seeing in apartment buildings, but it performs its functions. It works reliably and smoothly, and the owner can comfortably move between floors and not worry about safety.

However, it should be borne in mind that it will not be easy for emergency services to gain access to private territory if such an elevator gets stuck. Therefore, this security option must be provided in advance. For example, automatic movement of the elevator car to the nearest floor in case of power outages, ensuring continuous communication with the security service, because a mobile phone may not be at hand.

Oxygen-converter method of steel production

Steel production today is carried out mainly in this way. BOF production recently accounted for up to 60% of global steel production.

However, this percentage is decreasing due to the advent of electric arc furnaces (EAFs). The furnaces are purged with pure oxygen (99.5%) under high pressure.

The product of an oxygen converter furnace is steel with specified chemical properties. It enters a continuous casting machine (CCM), where the material solidifies into a bloom or slab. To obtain certain stringent parameters, the metal is recycled.

Difference between elevator and lift

The lift is also called “minilift” or cantilever. I would like to immediately note that a lift is a simplified form of an elevator that can be installed not only inside a building, but also outside.

Lifts are divided by type of use:

- construction lifts, for example, for lifting goods received in supermarkets from machines to the site for further delivery to the warehouse;

- lifting disabled people around the steps to various buildings;

- food lifts in private homes.

Of course, these are not all types, but we have identified the main range of directions.

But the elevator is a much more complex mechanism that requires preliminary preparation for installation. You won't be able to install it anywhere. Here we will have to tinker with calculations and with the project as a whole.

Elevators are divided into only two categories: freight and passenger. The difference lies in the load capacity, and freight elevators, as a rule, do not differ in beauty and comfort.

Features of the second stage

The second stage of steel production technology is called steel boiling. The main purpose is to reduce the carbon content by percentage due to oxidation. FeO + C = CO + Fe.

The oxidation reaction occurs more intensely during boiling and is accompanied by heat absorption. Therefore, it is necessary to create a constant flow of heat into the bath, as well as to equalize the temperature in the melt.

During this oxidation reaction, carbon monoxide gas CO is intensively released, which causes rapid boiling in the liquid aggregate state, for this reason the process is called boiling. To ensure that excess carbon is more intensively converted into oxide, the production of high-quality steel involves injecting pure oxygen and adding scale to the molten structure. This is why the quality of raw materials for steel production is so important. All source materials undergo scrupulous testing.

It is important at this stage to remove sulfur, which improves the quality of the final steel. The sulfur used in the components is not present in direct form, but in the form of iron sulfide FeS.

At high temperatures, the component also reacts with CaO oxide, forming calcium sulfide CaS, which dissolves in the slag without combining with iron. This allows the sulfide to be easily removed outside the bath.

Converter steel production

How different types of elevators work

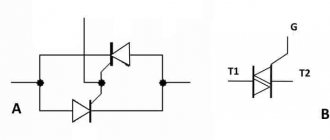

An electromechanical, or simply electric, elevator is designed on the principle of a counterweight. At one end of the cable there is a cabin, at the other there is a counterweight. A drive mechanism is installed on the top floor, which powers the entire system.

The use of a counterweight reduces the inertia of the heavy cabin to a minimum, due to which the power required is not as much as in other types of mechanisms. Electric elevators are something that all residents of high-rise buildings use every day.

Hydraulic and pneumatic elevators are the oldest systems. In the first case, a powerful engine is installed, which creates enormous pressure in the system. The hydraulic cylinder, under fluid pressure, silently lifts the elevator upward. The descent is carried out practically without the use of electricity, by releasing the fluid pressure. Hydraulics are quiet, but consume a lot of electricity.

The pneumatic elevator in the house works on the principle of a piston. There is a special air shaft above the cabin. When it is necessary for the elevator to rise, the air in this shaft is thinned with the help of fans. As a result, the air density under the cabin is much greater than above it. Thanks to this, the elevator is pushed upward.

Process Features

The steel production process occurs sequentially in three stages.

The first stage is the melting of the rock. At the stage of its implementation, a melt is formed in the bath and the metal is oxidized, simultaneously giving oxygen to silicon, phosphorus and manganese.

One of the main tasks of this stage is phosphorus removal. Its implementation requires a relatively low temperature and the presence of a sufficient amount of FeO. When the ingredients interact, phosphorus anhydride forms an unstable compound (FeO)3 + P2O5 with iron oxide.

The presence of the more stable base CaO in the slag causes the replacement of FeO. As a result, it binds phosphorus anhydrite into another compound (CaO)4 x P2O5 + 4 Fe, which is what was required to be achieved.

Pure Fe was released in the melt, and phosphorus formed slag, which is removed from the metal surface and disposed of as unnecessary. Since phosphorus anhydride transforms the composition of the slag, the process must be continuous.

Therefore, FeO must be continuously replenished by loading new batches of iron ore and scale, which introduce ferrous slag into the melt.

How to build an elevator to the cellar with your own hands?

Any owner of a country house or dacha strives to make every possible effort to ensure that life in such a room is comfortable. If your private house has several floors or there is a cellar, which is often used for storing vegetables, fruits and, most importantly, for preservation, then an elevator may well be your lifesaver.

We dare to note that you, of course, can very well use the services of experienced specialists in the field of installing a home elevator. However, you should not doubt your own abilities. you can do everything yourself. This option is much more economical (in terms of material and time costs). All you need is a certain set of quality tools that are simple and easy to use.

What it is

A construction hair dryer is a fairly simple tool that is designed for working with polymers and other flexible materials. Using it, you can solder parts together. The tools themselves are divided into several varieties according to power and specifics of work, but the main element when soldering polymers is the nozzle for a hair dryer for soldering plastic.

This part also has a number of variations in shape and functional features. The nozzles are capable of changing the degree of heating jet and influencing other factors. To carry out such work, you need to understand the features of the main types and use them correctly.

What are the requirements for an elevator at home?

A cellar elevator installed on your property must meet the following requirements:

- The structure must have a backup power supply system. This is especially true for electrically driven lifts. Hydraulic and pneumatic lifts will slowly descend to the lowest point of the shaft in the event of a power failure. Electric ones will freeze in place and will not move until power is restored.

- If the cabin is lifted using a cable, precautions must be taken in case it breaks.

- The elevator controls must be easily accessible both inside and outside the car.

- Do not forget to ground the power elements of the lifting mechanism, especially if the machine room is located in close proximity to the elevator shaft.

- Consider options for emergency de-energization of the system if necessary.

It is advisable to improve the area both around the elevator and inside it. You should not leave unnecessary elements around that may make access difficult in the event of a force majeure situation.

Design and design drawings

The design of a technical hair dryer differs little from household models used for drying hair. The main components of this unit are the housing, the heating element and the device with which the hot air is redirected to a given location.

Unlike other thermal appliances, there is no open flame in a hair dryer. This reduces the fire hazard of the device and eliminates the need to burn fuel. The device contains the following structural parts:

- Electric motor.

- A heating element.

- Fan.

How to stay safe

To ensure security, you need to apply several techniques:

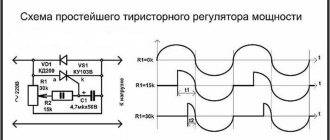

1. Mandatory use of a safety rope. This is a simple and reliable way to protect people if the main cable breaks. You can use a drum with a cable secured between ratchets from a passenger car. 2. Regular checks for the presence of lubrication in the mechanisms, the uniformity of the cables and the serviceability of all structural components. This basic elevator maintenance is a must! 3. It is also necessary to have an emergency button and grounding of the elevator electrical equipment. 4. You can install a non-latching button in the control unit. When pressed, the elevator moves. If you release the button, it stops.

Requirements for a home lift

The main criterion for an elevator is its load capacity. To make a cellar elevator with your own hands, you need to carefully study the structure of this structure and the requirements that apply to it.

Standard elevators consist of the following parts and mechanisms:

- Lifting device. Operates by manual force or electricity.

- Platform. A base used to accommodate a movable fragment.

- Cabin. Designed to accommodate a person and cargo. Can be open or closed.

- Rails. They are mounted on the wall and serve as guides for the movement of the cabin.

- Controls. These include starters, relays, fuses and other parts that regulate the operation of the structure.

A homemade elevator to the cellar must meet the following criteria:

- safety;

- sufficient load capacity;

- ease of use;

- efficiency;

- availability of an insurance system;

- aesthetics;

- durability;

- Possibility of DIY installation.

When choosing a control method, it is recommended to use a remote control with lifting, lowering and emergency stop buttons.

Installing an elevator in a private house yourself

Lift Project Installing the lift may require the help of a partner, since you will have to deal with quite heavy objects, and you will also need support for attaching them.

Construction should be carried out in the following sequence:

- In accordance with the project, apply markings to the floor, ceiling and walls. Double-check their accuracy, compare horizontals and verticals.

- Make a frame for the movement of the cargo compartment. A closed loop is made, which is rigidly attached to the supporting structures of the building. Rails are attached to the frame as guides for the rollers.

- Assemble the cabin. A channel is used for the frame and a reinforcement grid for the floor. The structure is equipped with railings and a swing door. If necessary, the walls are covered with steel mesh.

- Install the support beam onto the frame. Then attach the power mechanisms of the engine, gearbox, winch and clutch to it.

- Connect the lifting device and the cabin. Attach the cable and band brake.

- Check the quality and reliability of connections, eliminate curvature and play.

- Clean the metal from scale and rust. Treat it with anti-corrosion agent and paint.

- Supply electricity. Make channels for the cable, secure mounting boxes, remote controls and switches.

- Test the device in different operating modes, with maximum load. Check the operation of the protection when the light goes out and the operation of the emergency braking device.

Upon completion of installation, you need to go upstairs and lower the cabin to the bottom position to remove the load from the supporting structures.

Place for arranging an elevator

An important step, since the ease of use, strength and safety of the structure will depend on it. First of all, pay attention to the walls to which the lift shaft will be attached. At least one of the walls must be load-bearing and there must be no defects or damage on it.

It is strictly forbidden to attach an elevator shaft to a wall whose masonry consists of foam concrete. It is also prohibited to attach to a wall whose thickness does not exceed one layer of masonry. This is regulated by the fact that the overall design of the lift has an impressive weight, and frequent use will quickly destroy the unreliable wall, which will lead to an accident.

Installation of all elements must be carried out according to the instructions and in a strictly established order. An elevator, like any other mechanism, has several key components that must be correctly connected to each other and securely fastened.

Build an elevator to the cellar with your own hands

Where is it used?

Today, hair dryers with attachments are used both at home and in large enterprises for a variety of tasks. The tool itself is not capable of performing many functions, but with a set of attachments the tool becomes universal and is used for:

- connections and processing of joints;

- repair of cracks, irregularities, deformations;

- soldering parts made of plastic, polymer film and other materials;

- roofing works;

- installation, repair, dismantling work in the automotive sector.

In addition to these tasks, a hair dryer with nozzles is capable of performing many other tasks where soft polymer materials are used and thermal effects are required.