New high-tech methods of processing materials are often based on the principles of natural phenomena. The waterjet technique is just one of these, repeating the process of erosion. Its essence lies in the effect of the aqueous environment on the surface of the material. Of course, this technology has been optimized for the production sector, for example by combining liquid with foreign elements. In addition, waterjet cutting of metal involves supplying a jet under strong pressure, as a result of which a high processing speed is achieved.

Features of the technological process

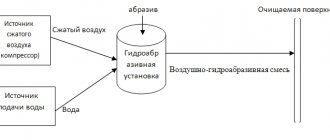

As already noted, the technology is based on the principle of natural erosion. That is, the physical impact on the material being processed occurs due to a high-speed jet mixed with hard abrasives. During the operation, the high-speed flow of solid-phase elements separates and carries away small metal particles from the processing site. The efficiency with which waterjet cutting of metal occurs depends on many parameters of the organization of this process. For example, the composition of the jet, water flow and pressure force matter. The abrasive material also deserves special attention - specialists select the fraction in accordance with the requirements for cutting characteristics.

Unlike other processing methods, this technique does not involve deforming and thermal effects. This means that waterjet cutting of metal allows you to preserve the original physical and mechanical qualities of the workpiece. But to achieve the expected result, it is necessary to use special equipment.

Advantages and disadvantages of water cutting machines

The strengths can be noted:

- Possibility of processing workpieces with thick walls with very precise cuts. That is why water cutting is used when laying high pressure pipes.

- After cutting, an exceptionally smooth edge remains. There will be no burrs, scales or burrs on the lines.

- Long work on hydraulics does not end with a curtain of dust. Remaining material is washed off with water.

- There is no need to ensure that the cutting tool is sharp, replace it or sharpen it.

- High processing speed of workpieces (including thick-walled ones).

- Water can be used to cut not only metal, but also glass, rubber, plastic and other multi-layer workpieces.

- The speed of operation depends slightly on the thickness of the materials. You can stack several parts in layers and cut them simultaneously.

But there are also disadvantages:

- The cost of a machine for cutting metal parts with water is more expensive than the cost of assembling analogues.

- Taper. It may appear during processing of refractory metal or thick-walled steel. When a taper appears, the end of the product does not come out smooth, but resembles a funnel. This defect can be removed only with the help of an additional device.

- High consumption of electricity and water.

Cutting equipment

Typically, special installations are used to perform such operations. They are based on load-bearing supports made of stainless metal. To support the workpieces, quick-change ribs are used, which also protect the supports from the impact of the working jet. In order to protect the working area from dust and noise, the machine is also equipped with a quick water control mechanism. That is, during the operation, the material being processed can be completely in an aqueous environment. As for operational capabilities, the waterjet metal cutting machine makes it possible to cope with stainless steel up to 200 mm thick. It is noteworthy that material hardness indicators for machines of this type do not matter. The fine high-speed jet with a diameter of 1 mm is capable of producing precise, high-tolerance cutting.

Operating principle and materials to be cut

Cutting metal products occurs with a water jet to which abrasive is added, after which it passes through a nozzle.

Pressure of 200-600 atmospheres allows you to cut many materials. Work can be carried out at any angle; to do this, you just need to change the angle of the nozzle. In this case, you can effectively cut:

- metals (ferrous and non-ferrous) and their alloys;

- stone products from marble and granite;

- steel (stainless steel, heat-resistant, alloy);

- armored, ordinary and composite glass;

- ceramic products (concrete, tiles, ceramics, ceramic granite);

- composite;

- rubber;

- plastic;

- cardboard.

Cutting of particularly hard raw materials is carried out with water and special sand made from minerals. Soft materials (rubber, plastic, cardboard) are cut exclusively with water without any impurities.

Assistive devices

In order to improve cutting accuracy, some machine models are also equipped with positioning devices. They are represented by inductive linear sensors, with the help of which the operator can achieve increased fixation accuracy. True, a lot also depends on the execution of the movement axes - in the best models, the combination of guides and positioning sensors is complemented by smooth operation and optimal movement speed. Also, a waterjet metal cutting installation can be equipped with an abrasive tank. During operation, it automatically replenishes the stock of this component, based on information from control sensors.

Homemade waterjet cutting installation (GAR)

Homemade waterjet cutting installation (GAR)

Message #1 Denis# » 24 Jan 2016, 02:48

Hello again everyone! This idea is probably no less crazy than a homemade laser, but they are produced, which means repetition is possible. For some time I have been haunted by CNC machines and cutting installations, because... I have a certain amount of work for them, and it’s interesting! For future parishioners, I immediately urge you not to “advise” to buy and earn money. There is no such goal, a technical forum is therefore interesting to create. God willing, we grow up and you will trade ours.

So, what I know (and I know just a little): in waterjet cutting machines (hereinafter referred to as GAR), a jet of water is used as a cutting substance, usually with the addition of abrasive. The abrasive, as I understand it, is garnet sand. The minimum operating pressure that I encountered in descriptions on the Internet is 50 MPa, these are outdated settings. Modern installations pump 500-600 MPa if I understand everything correctly. It seems like you can actually work with 100 MPa.

I personally am not a rich person, so I have to indulge in maramoying periodically. Accordingly, here too I will not consider buying ready-made branded pumps for now, but will think about how to create it myself to the maximum. Which option for increasing pressure am I considering as the main one? Animator. The idea is this: we take a regular hydraulic cylinder with a piston, say 160mm in diameter, and with a rod, say 30mm in diameter. Accordingly, the piston area GC = 20106 sq.mm, rod area = 707, respectively, the ratio will be 20106/707 = 28.44 times. Those. if we press 16 MPa on the GC piston, then the 30 mm rod will press 16 MPa x 28.44 = 455 MPa Do I understand correctly? It turns out to be quite a pressure. What we need is for a 30mm rod to press into a certain closed container filled with water, displacing this water through the valve into the transport tube. The valve must be set to open at least at a certain pressure. Next, to eliminate pulsations, we can make our GC double-sided, with two outputs leading to a hydraulic accumulator (if necessary), which, in principle, can serve as a transport bay. Well, the head itself. It is clear that this is a general scheme and the devil is in the details, but let’s first check the general concept, whether I am thinking correctly, whether I am thinking correctly, etc.

From this we will try to dance further. nikirk2, neon, T-Duke, and ALL ALL ALL. join in, just don't swear here

Homemade waterjet cutting installation (GAR)

Post #2 neon » 24 Jan 2016, 04:48

there lived Oh and Ah. I do not even know where to start. I don’t want to say that it is impossible, it is possible, but the costs will exceed all reasonable limits, especially if it is necessary to ensure an acceptable service life before replacing the main elements and seals. What does one cylinder with a liner cost? In modern versions, a ceramic cylinder costs about 140,000 rubles, and Chinese versions cost about 35,000. You can go broke with a homemade installation on the seals alone. I’m generally silent about the cylinder (manufacturing technology). We haven’t even gotten to the consumables yet (sand, nozzles, mixing tube). HPS (high pressure hoses) are difficult to obtain and they cost quite a bit.

In general, let's talk, talk and go our separate ways, this is the 99% forecast for this topic. The facts are on the Internet. Even manufacturing according to ready-made drawings will result in considerable expenses. It will be cheaper to buy a Chinese used pump and other ready-made components. At the same time, out of a large number of people who wanted to, literally only a few were able to bring the matter to the end.

I also remembered about the hydraulic accumulator, this is another finish. There are special grades of steel (expensive, protection, pre-treatment with very high pressure, etc.), usually a pipe in a pipe. Look at the wall thickness and length. How will you make such a seemingly simple component? Even without this you can get up and not get up. Sorry for the pessimism in the text, although I am an optimist squared off, I am also a realist at the same time. You can make it yourself if you have a lot of money or a spare life.

Homemade waterjet cutting installation (GAR)

Message #3 Denis# » January 24, 2016, 05:00

Well, it’s cheaper and, as I said, it’s not interesting to buy it, so we’ll skip it. About “let’s talk and go our separate ways” - it’s possible, but I don’t see anything bad in such a conversation, at least against the backdrop of many other topics.

But if you tell us about the features of cylinders, liners, and seals, it will be interesting. How did they deserve a price tag of 140 thousand, why ceramics and what characteristics are required there. Why can't you take a regular GC? It had 16 MPa and still works, why is it worse than expensive ceramics? The same goes for seals. What characteristics are required for these seals? What are they made of and how are they made? People, according to rumors, are calmly integrating their collective farm into corporate settings and working, why are we worse?

As for consumables like sand, nozzles, etc., it’s generally unclear. Either buy them for a company installation or buy them for something like this. what is the difference?

Homemade waterjet cutting installation (GAR)

Post #4 neon » 24 Jan 2016, 05:16

Manual cutting machines

Typically, this category of machines includes models that do not have CNC. In other words, control of the work process is to a certain extent transferred to the operator. The user must set the cutting angle with his own hands, and in some cases, fix the position of the functional installation. But provided that the operating rules are followed, in this case you can also count on the high accuracy with which waterjet cutting of metal will be performed. Equipment without software is equipped with the same technical components as more advanced models. Therefore, theoretically, the quality of execution should be maintained at an optimal level. Moreover, in some situations, self-tuning and cutting control allows you to achieve better processing results.

Waterjet machine - operating principle

The high-pressure pump, using a booster, pumps up pressure from 300 to 600 atmospheres. At the same time, all vibrations created by the pump are damped in a large-capacity pressure accumulator, which guarantees a pulsation-free stream of water. After this, water to generate a jet can be supplied to any arbitrary point through flexible high-pressure pipes.

Water passing through a hole in the head with a diameter of a quarter of a millimeter (the pressure increases even more) enters the mixing chamber. There it combines with abrasive (fine sand) and enters the nozzle that forms the jet. Depending on the thickness and material of the part, it can have a diameter of 0.6-1.2 mm. In the cutting head, the energy of water pressure is converted into the kinetic energy of the water jet. Water passing through a nozzle, just tenths of a millimeter in size, made of super-hard materials, is accelerated to form a thin, focused jet that serves as a cutting tool.

Soft materials such as rubber and plastic are cut with a clean stream of water. By adding sand to the jet to enhance cutting capabilities, it is possible to process materials of any hardness, such as metals, stone, glass, and composites. For hard materials, rough drilling is performed first. For some materials, preliminary centering is not necessary, since when centering the material, the first drop of water is mixed with the abrasive. Today, waterjet cutting allows you to easily cut materials up to 150 mm thick.

This method allows you to cut materials without releasing thermal energy, since it is immediately absorbed by water. In addition, complex and heavy devices for fixing the workpiece are not required. A jet of water does not have such a strong impact on the workpiece as mechanical tools (cutter, milling cutter or saw).

DIY cutting technique

Controlling the cutting process in manual mode means that the user will independently feed the workpieces and control their movement and positioning. Also, in some cases, the list of operator tasks includes regulation of the cooling system. In practice, waterjet cutting of metal with your own hands is performed using special buttons. For example, for positioning, the operator must enter several coordinate values. But even manual control is not completely free from control by the electronic system. Thus, when entering erroneous data, the technology returns the values of operating indicators to their original position.

Safety precautions

The waterjet cutting process is not particularly dangerous. The distance from the tube from which the jet comes out to the surface being treated is only 2.5 mm. This eliminates the impact of the jet on the hand. When the water pressure exceeds the permissible limit, a relief valve opens, which reduces the pressure to operating pressure. However, certain safety precautions should be observed when working on machines.

- Do not expose your body to the jet under any circumstances. Such a jet is capable of cutting metal 150 mm thick, let alone a hand. While working, keep your hands as far as possible from the cutting area. Before turning on the machine, make sure there are no foreign objects in the cutting path.

- Protect your eyes and hearing. Be sure to wear safety glasses and earplugs (or headphones).

- Do not place your hands on your desk.

The leaders in the production of waterjet cutting machines are the American companies Jet Edge, Flow, OMAX, and the Italian WaterJet Corp Inc. and Caretta Technology, Dutch Resato, Czech PTV, Swedish Waterjet Sweden, Finnish ALICO, Swiss Bystronic.

Pros and cons of technology

The advantages of cutting of this type include the clarity of the cutting line, the ability to cope with almost any metal, as well as the explosion and fire safety of the operation. Among the disadvantages of such processing are the low speed when working with thin sheet steel, the low level of wear resistance of functional elements and the high cost of consumables, that is, abrasive. Nevertheless, economically the technology justifies itself. For example, waterjet metal cutting services allow you to efficiently handle critical operations when preparing material for subsequent installation. Moreover, sandwich panels, honeycomb sheets and other cellular building materials can only be cut in this way. To increase productivity, many companies also practice batch cutting, which saves time.

What water pressure is needed to cut metal?

The water pumped by the pump should have a pressure of about 1,500–6,000 atmospheres. Coming out through a narrow nozzle at near-sonic or supersonic speeds (up to 900–1200 m/s and more), the water jet is directed into the mixing chamber, where it mixes with abrasive particles. The resulting jet comes out of a mixing tube with an internal diameter of 0.5–1.5 mm and cuts metal. To dampen the residual pressure of the jet, a layer of water 75–100 cm thick is used.

Disadvantages of technology

The disadvantages of this technology include:

- design difficulties that arise when creating high fluid pressure;

- insignificant resistance of water and abrasive nozzles - quick erasing (the service life of domestic nozzles is 50 hours, foreign ones - 500-1000 hours);

- complexity of nozzle manufacturing;

- formation of slants up to 1.5 along the height of the workpiece.

- a – at high cutting speed;

- b – at a very low cutting speed – the upper edges of the cut have a slight rounding

When the abrasive nozzle wears or the cutting speed increases, the width of the gap increases - the profile of the gap has a weakly expressed V-shape. At very low cutting speeds, the slot profile is A-shaped - turbulence causes erosion of the material. The case is considered positive if rounded top edges are required.

- a – with a distance between the nozzle and the workpiece of 2-4 mm;

- b – when the distance between the nozzle and the workpiece is more than 4 mm

How to make a hydrogen welding machine yourself?

Hydrogen welding is useful to any craftsman. The hydrogen cutter is not a cheap piece of equipment. In addition, commercially available machines are often unsuitable for soldering small parts, especially jewelry.

The way out of this situation is to make atomic-hydrogen welding yourself. All the parts necessary to create such a device can be easily purchased at any hardware store. So, let's look at how to do this at home.

Main capacity

Installation for welding with hydrogen.

The hydrogen welding machine operates as a result of the combustion of hydrogen, due to the dissociation of an aqueous alkali solution.

This process is carried out in a container for which a half-liter jar is perfect. It must be closed with a plastic cover with two holes made to remove contacts from the electrodes.

All terminals must be tightly sealed. Moment glue is suitable for these purposes.

Four-centimeter strips of stainless steel can be used as electrodes. For the best performance of a welding machine, the entire volume of liquid must be used.

To do this, the plates are drilled along the upper and lower edges and connected to each other with dielectric pins. Terminals are made on the resulting block: two negatives located at the edges, and a pole between them.

Each terminal is bent and fixed to the container with a bolt. The terminals from the power source will be attached to these bolts.

The container must be filled with a syringe with working fluid through the gas outlet fitting. The electrolyte is an 8-10% mixture of sodium hydroxide in distilled water. When the electrolyzer is operating, the temperature of the working liquid of the alkaline solution usually does not exceed 80 °C.

The second vessel acts as a hydrodispenser. In it, gases are saturated with vapors of flammable substances. Then the resulting mixture is sent to a third container filled with ordinary water. It acts as a shutter for the release of gases.

An ordinary medical needle can be used as a nozzle through which oxygen, hydrogen and flammable substances will come out.

Current source for atomic hydrogen welding

A regular 12 volt battery can be used as a power source. This option is perfect for working with metal of a fixed thickness.

Its disadvantage is the inability to control the burner flame strength, since its performance is determined by the production of hydrogen and oxygen, which depends on the current strength.

Choosing a charger for car batteries will be more preferable. To work with thin metal plates or jewelry, charging can be set to 3 volts.

Hydrogen welding can be powered with oxygen from a regular 220 V network, which allows you to use this device at home.

Exchange camera

Schematic diagram of a hydrogen welding apparatus.

To select hydrogen and oxygen supplied to the burner, another container is used - an exchange chamber.

You need to make 3 holes inside it:

- for refilling with working fluid;

- at the bottom there is a fitting for supplying working fluid to the main tank;

- fitting for supplying the gas mixture to the nozzle.

The design of the additional container must also be carefully sealed. Gases and liquids should not leak through the hydrogen seals of the hydrogen generator. This is also solved with the help of "Moment".

Making a burner

To make a burner, you can use a regular rubber hose. It is through this that hydrogen and oxygen will be transported from the exchange chamber to the nozzle. You can use a needle from a syringe or dropper as a nozzle. The latter will be a more preferable choice, since the walls of this needle are thicker.

The hose must be tightly secured to the exchange chamber fitting and the needle base. This is achieved using clamps. After completing all operations to assemble the device, you can begin testing it.

Electrolysis of the working fluid begins quickly. After just a few minutes, you can ignite the flame at the end of the nozzle. The flame is adjusted by changing the voltage on the device.

Bottom line

In many cases, the use of hydrogen welding turns out to be more convenient than other gas-flame methods. It becomes especially relevant when it comes to working at home.

The given description of how to make a hydrogen burner with your own hands will help all craftsmen who want to make such a device. This will significantly save money on purchasing a store-bought welding option.

In addition, a self-made hydrogen cutter is more promising for working with small products. Hydrogen welding is environmentally friendly, and its production does not require much labor and large costs.

The method is also similar to acetylene welding, and mastering it is not difficult.