Drilling holes in the metal of critical products requires high precision. The formed channel must strictly correspond to the required diameter. It is difficult to obtain such a result with only one drill: even a slight runout leads to an error. Therefore, precision drilling is carried out in two stages: first, a drill is used, and then a countersink for metal.

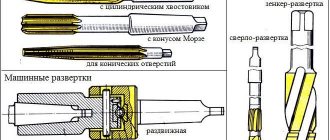

A countersink is a special tool that has several blades. With it you can make an expansion of the finished hole or a finishing groove. If the working cutting part of a drill is located at the end, then a countersink has cutters that run in a spiral along the entire body. Its operation is similar to that of a milling cutter, that is, when it rotates, it cuts off a thin layer of metal in a drilled channel.

The operation of processing metal with a countersink is called countersinking. There are different types of countersinks, some of which look similar to a metal drill, especially those that have a one-piece design.

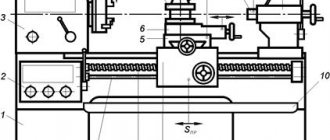

For high-quality processing of holes, you should not use a conventional hand-held electric drill - only a drilling machine or lathe!

Types of countersinks

Countersinks according to their geometric shape are divided into: cylindrical, conical, end-face. Depending on what result should be obtained, the appropriate type of tool is used:

- • for working with cylindrical parts and shapes. They have different diameters and angles of inclination. Designed to expand the hole up to 10 mm. Using a guide pin, recesses for fasteners are made;

- • for working with conical parts (sensors, valves). The surfaces being processed are usually made of cast iron and steel;

- • for processing the end plane of a part or product (booms, bosses).

Countersinks are classified according to the type of construction: solid, prefabricated, welded and with overlay carbide plates. According to the method of fastening: tail and mounted countersinks.

Classification of countersinks and their purpose

The countersink was developed for mechanical engineering and is used primarily in metalworking operations. There are different types of countersinks - they are all used in certain technological processes. The instrument is classified primarily into two main groups:

- The first group includes elements of various types and designs, the main purpose of which is the intermediate stage of processing, followed by allowance and deployment.

- The second group includes tools designed for finishing holes in metal with precision that corresponds to classes 4 and 5 (H11 - quality).

There are differences in design. There are the following types of tools in this category:

- An all-metal element, where the cutting working part and the shank are made on one metal rod.

- The prefabricated element is a mounted countersink, which is put on the guide rod. The guide can be a continuation of the shank or a special drill. The point is that you can combine elements of different diameters on one tool if the hole is complex and has several diameters.

- Welded countersink.

- A tool containing carbide cutting inserts.

There are also differences in the shape of the working area. These are the following types of tools:

- Elements with a working area in the shape of a cylinder. Their main purpose is to expand holes using the countersinking method.

- Elements with a cylindrical working area where there is a guide pin. This design is used for processing holes for fastening hardware.

- Conical countersinks are necessary if you want to form a conical recess at the beginning of the hole.

- Elements with a working area at the end of the tool make it possible to clean the end planes of bosses and bosses.

Features of conical countersinks

Conical countersinks are used for metal countersinking operations.

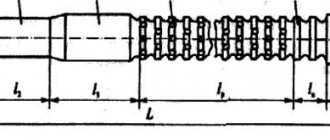

This technological process involves chamfering a hole or creating a conical depression in the metal. The most common and accessible conical shaped element is the VK8 type tool. Its diameter varies from 15 to 75 mm. The intended purpose is to create conical surfaces at the beginning of holes with a high accuracy class. In this case, the depth is insignificant, and the processing angle is average. A conical countersink has a shank, a body (base) and blades. The sharp edges that are responsible for cutting in such a tool come in 6–12 units. These edges have a straight type shape, while the base of the outer part is made flat. The angle of the working part (expressed in degrees), depending on the standard, can be 120, 90, 75 and 60 units. To maintain alignment when machining holes, some conical elements are equipped with a guide pin. According to the depth of processing, conical countersinks are divided into:

- countersinking cutters to a shallow depth - their base is cylindrical and oblong;

- cutters for countersinking to a shallow depth and countersinking sheet steel materials - they have a conical base with a narrow cylindrical skirt;

- cutters for countersinking to great depths - the base is narrow, cylindrical, with a slight angle to the shank.

Obtaining the required recess in the hole with a conical countersink suggests that during drilling you need to provide an allowance of 2–3 mm. The processing process itself is carried out through the use of a lathe, into the chuck of which it is attached. The part is placed with the hole opposite the cutter in strict adherence to the axes. The working part of the tool is fed to the workpiece manually.

When working with a countersink, materials that serve for cooling and lubrication must be supplied to the processing area. Only carbide-tipped elements do not need such a procedure!

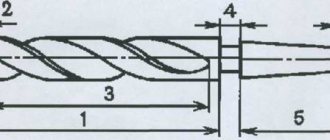

Countersinking

The work is performed on lathes (to produce holes from the end side), drilling, CNC milling and boring machines (to change the size of the hole). The selection of tools is made based on the location of the hole and material, the depth and size of the hole, and the method of fastening. The processing speed in countersinking is identical to the drilling speed. For light steel, the angle of inclination is 15-20 degrees, for medium-light alloys - 8-10 degrees. High-alloy steels and cast iron are processed at an angle of 0-5 degrees, according to GOST 12479-71.

The use of automatic equipment allows us to achieve high precision of the processed surface. When performing work, you must adhere to the following safety rules: the surface of the countersink must be well sharpened and free of burrs and cracks. When attaching the shank, you need to pay attention to the smoothness of the surface as fasteners.

This processing is similar to a drilling operation. Only in the case of countersinking does the final version come out more accurate, the surface cleanliness improves in the process, and any errors are eliminated. Next, reaming is usually performed - a type of finishing.

Countersinking is the secondary processing of ready-made holes for installing bolt heads, rivets, and screws into them.

What are these instruments like nowadays?

Countersinks of all types are made of high-alloy steel materials, as well as alloys with different cutting angles. Countersinks are divided into different types. Does this determine which specific type to use?

These instruments differ primarily in their design. Their differences depend on the conditions of use on CNC equipment and machine tools, as well as on GOST. According to their design, countersinks are divided into the following types.

— Attachment countersink. It belongs to the high-speed type of parts. It is made from high-alloy alloys. Indicated by the marking P6M5. Can be of different diameters. From 25 to 75 mm.

- Carbide. This is also a mounted countersink of various diameters. Its design contains plates made of hard alloy. It is marked VK8. There is one particular thing here - for example, the marking VK8 25 means that the countersink has hard alloy plates with a diameter of 25 millimeters. And if the marking is VK28 75, then this means that the diameter of the plate is 75 millimeters. Typically, this alloy is used when working with molds made of steel or cast iron with a high content of alloying elements.

— The same marking, BK8, is used to mark the tail mounted countersinks. This is a part that is equipped with a special conical shank.

- Whole. The most affordable, but at the same time type of countersink with the lowest productivity. Usually, if you need more precise processing and greater speed, other prefabricated options labeled BK8 are used.

How does a countersink differ from a countersink?

Often a countersink is confused with a countersink. Countersink and countersink - belong to the class of cutting tools, with 3 or more cutting edges. Both tools are used for conical and cylindrical holes. But the countersink expands the hole, at the same time grinding it and adjusting it to the specified parameters. And the countersink only polishes the hole from burrs at the finishing stage.

Current GOSTs

A countersink is a high-precision tool. All its geometric dimensions, the angles of the cutting edge in the conical element, the shape of the blade spiral, and the number of blades are strictly specified by standardization standards in GOST. Thus, the current documents on different types of countersinks are as follows:

- GOST 14953-80 describes the conditions (technical) for using elements with a conical working area. The geometric parameters, the material from which the tool is made, and the metal with which a particular element can work are indicated.

- GOST 12489-71 concerns such a tool as a one-piece cylindrical countersink.

Dear site visitors, who have information related to the topic, support the discussion in the comments!

The difference between countersinking and related operations

Countersinking is similar to reaming holes; the cutting edges of the tool remove excess material from the stenoctium, reduce roughness and increase the diameter. This is a semi-finish operation, which means it is followed by another processing step. Deployment is the final procedure. During countersinking, defects in drilling, stamping and casting are eliminated. In the process, you can slightly adjust the binding to achieve better alignment for the future connection. Accuracy can be increased to 5, and sometimes even to 4th class.

When setting the cutting mode, you need to remember that the thickness of the metal removed during countersinking is equal to half the allowance for a given hole diameter. Compared to drilling, the feed can be made 1.5-2 times larger, but the speed can remain the same. Specific cutting parameters are calculated using formulas given in the regulatory literature.

Since a countersink has greater rigidity compared to a drill, due to the increased number of sharp protrusions, the accuracy of the direction of movement increases, as well as the quality of processing, smoothness and cleanliness of the surface. For comparison, drilling gives a roughness of 20 microns and grades 11–12, countersinking gives a roughness of 2.5 microns, grades 9–11, and reaming gives a roughness of 0.25-1.25 microns and grades 6–9. Quality is the precision of manufacturing a part; as its value increases, tolerances increase and accuracy decreases. If the technological process for processing a product requires both countersinking and reaming, then they are performed in one installation and alignment of the workpiece on the machine.

This type of machining creates recesses to accommodate fasteners flush with the surface of the part. In addition to chamfering, a countersink is used to cut conical-shaped recesses. Another purpose will be to clean and process recesses before installing fasteners; this is done using flat or end countersinks, also called counterbores, which is more correct.

The most widely used on the market are conical countersinks with working angles of 90 and 120º, which create recesses to hide the heads of bolts and screws. In the metalworking industry, countersinks with a flat tip are also used, used for cleaning recesses for fasteners. Countersinks are installed in the same machines as other tools for processing holes for fasteners.

Terminology

A countersink is a multi-bladed cutting tool used for making holes in metal parts. After processing, conical/cylindrical type recesses are obtained, you can create a reference plane near the holes, and chamfer the center hole.

Countersinking of holes is the secondary preparation of finished holes for placing hardware heads - bolts, screws, rivets

A countersink is a cutting tool with a multi-bladed surface. Used in machining cylindrical/conical holes in workpieces to expand the diameter, improve surface characteristics and accuracy. This type of processing is called countersinking. This is a semi-finish cutting process.

Countering holes is the process of reworking the top of an opening in order, for example, to remove burrs from the edge of a hole or to create recesses to hide the head of a rivet or screw and level it with the surface of the part. The tool used for this task is called a countersink.

Countering a hole: basic rules

Countering a hole is an operation that is carried out on machines with a minimum stroke. The countersinking mode configured on drilling, turning, boring or other metalworking equipment is optimal for operation. In some situations, combined type tools are used, which perform several operations in one approach: drilling, countersinking, countersinking, countersinking, etc. All these processes are part of the drilling operation.

Image No. 8: Countering of valve seats

Despite the fact that cutting tools are mainly used on industrial equipment, counterbores are also purchased for home use. When working with such a tool, craftsmen should adhere to several rules.

- When machining open surfaces, secure the stop to the shank using a stop nut and lock nut.

- When counterboring holes for screw and bolt heads, use a tool with a 90-degree point angle. The need to reduce the angle is justified to maintain the cut on the surface of the holes being machined.

- Make indentations in 2 stages. First, drill the hole to the desired diameter, then give it the required shape and size.

- Make sure that the entire surface of the tool guide does not come into contact with the bushing. If this rule is not followed, the metal counterbore will become stuck in the bushing due to the intense heating of the material caused by the rotation of the spindle.