Prices and terms

- Production is located in the Sverdlovsk region;

- Delivery is carried out throughout Russia, CIS countries and Europe;

- Request a cost estimate for pipe bending and pipe processing.

Contract template 2021

Production capacity

- 250 mm, maximum bending radius;

- 190 degrees, maximum bending angle;

- 2 CNC pipe bending machines;

- 1 profile bending machine;

- 3800 mm, maximum length of installed pipe;

- 89 mm, maximum pipe size.

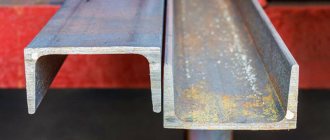

Features of channel bending

Device of a channel bending machine

The channel is symmetrical only along a conventional horizontal plane. This complicates its bending, which is performed in three directions:

- on the shelves;

- along the wall (with shelves outward or inward).

If you bend a metal channel along the shelves using special equipment, the risk of deformation of the shelves is eliminated. In the second case, their distortion is possible due to the increased pressure of the working element of the equipment.

There are three types of U-shaped channel bending:

- smooth (the workpiece turns into a curved product with one or several radii);

- local (the output is a part with a pair of straight ends connected at one specified angle).

At home, it is almost impossible to bend a channel smoothly - this requires profile bending machines, which are very bulky and expensive. The local bending method is used by many amateurs who need a bent profile for certain purposes. Moreover, for this, a couple of tools are enough, which a real craftsman always has at hand.

Bending of profile pipes, angles, rods, I-beams

The production arsenal includes equipment for processing pipes (aluminum, steel, stainless steel) and profiles. The quality of fitting products to the required dimensions and configuration is always at the required high level. The maximum pipe length that the working surface of the machine can accommodate is 3.8 meters. The permissible wall thickness of the part is 89 mm. Simultaneous deformation of tubular (rod) products occurs due to the rotation of a pair of support pressure rolls, while the third one sets uniform bends in a given place.

Bending of round and profile pipes

When bending round pipes, the deformation of the section of the round pipe is minimal, and the transition from a straight section to an arc is even and smooth. CNC pipe bending machines make it possible to bend a round pipe in several runs without jams or corrugations.

- The maximum cross-sectional diameter of the pipe is 250 mm;

- 190 degrees is the maximum bending angle of a steel pipe;

- The maximum length of the installed pipe is 3800 mm;

- Maximum pipe size 89 mm;

- Obtaining steeply curved bends of a round metal pipe with a small bending radius;

- Obtaining double bends of a metal pipe while maintaining the radius and angle between the arc and straight sections of the pipe;

- Bending of a steel pipe in a spiral with a constant and variable pitch and a constant and variable radius.

Bending a profile pipe along the radius

A profile pipe is one that has a cross section other than round. It can be rectangular, oval or square. The profile pipe has increased strength, since its edges act as stiffeners. Profile pipe is widely used as a frame for the construction of a wide variety of buildings.

The power of CNC pipe bending machines allows you to bend various steel and aluminum profile pipes with a constant and variable bending radius. Repeatability and radius accuracy are ensured by the reliable design of modern equipment.

- Bending along the radius of a profile pipe with a square cross-section;

- Bending along the radius of a profile pipe with a rectangular cross-section onto an edge;

- Flat bending of a profile pipe with a rectangular cross-section along the radius;

I-beam and channel bending

You can order bending of I-beams and channels in any bending plane:

- Simple bend of the I-beam along the radius flat;

- Complex bend of an I-beam along the radius onto the edge;

- Bending the channel along the radius flat;

- Bending along the radius on the edge.

Custom steel bar bending

Today, the market is in great demand for the production of metal gates, fences, railings, canopies and cornices, where rod bending is required. You can order bending of a steel bar of any shape. The company's specialists will quickly and efficiently fulfill your order.

Channel bending methods

The advantage of the smooth method is that it preserves the integrity of the workpiece.

There will be no welding seams on the channel, which will preserve its strength characteristics and corrosion resistance. Channel bending is carried out slowly, gradually, until the product takes on the required shape. There are the following ways to smoothly bend a profile:

- Manual. You will need a gas cutter or an acetylene torch and a template made of a sheet of metal on which the radius of the intended bend is drawn. Restrictors are welded to the sheet. One end is fixed with a vice. The profile section is heated and bent close to the limiters. The latter can also be welded on the convex side so that the deformable workpiece holds its shape better.

- Machine tool. Units whose task is to bend a dimensional channel are called profile benders. They are also suitable for other types of profiles. The operation of making a workpiece convex/concave is called rolling. The metal passes through large rollers fixed at a certain distance and is deformed. The advantages of the method are the ability to do without heating the workpiece, speed of operation, versatility (there are machines for the largest channels), bending accuracy. Disadvantages are the impressive size of the equipment and high cost. Roll benders are used only in enterprises producing rolled metal or similar products.

Bending an I-beam on an edge

Bending an I-beam on its edge (I-beam bending)

An I-beam bent across a section is a rather rare phenomenon due to the difficulty of implementing this technological process. But nevertheless, more and more specialists are learning that this is possible, and as a result, the use of bent I-beams on edges is growing every day. A service such as bending an I-beam across an edge is necessary for the manufacture of bent columns of noise-protective acoustic screens, dome structures, canopies and hangars with large clearance between columns, heavy-load bearing bridge elements, and in other areas of industry and construction.

The factory of bent parts provides services for bending an I-beam on an edge to beam No. 36 according to the client’s technical specifications in a short time and at a reasonable cost. The bent part retains all geometric dimensions in the bending section, there are no creases or deformations.

Bent racks for noise-proof acoustic screens

The FGD company provides services for bending an I-beam on an edge for racks of road acoustic screens on special conditions, so the cost of a part obtained by bending does not exceed the cost of a part welded from several segments. The production capacity of FGD allows us to produce a large number of parts. The company's principles do not allow violating agreements on the timing, cost and quality of products.

I-beam radius posts for road screens can be of different shapes; the image above schematically shows the most common ones. The bent parts factory bends the I-beam for the screen according to the drawing agreed upon with the customer. You can always look at samples of bent structures at our enterprise, thereby making sure that we really do all the work ourselves, and only after that place an order for execution.

Radial inclined noise barriers have long found popularity in developed and actively developing countries; they have improved noise reduction characteristics and also carry an aesthetic meaning. Some screen designs can even be called a work of art! The FGD LLC team for combining efficiency and aesthetics.

I-beam rolling for dome structures

The domes of churches and cathedrals have both ideological and visual meaning. Depending on the overall dimensions of the church or cathedral, a dome of comparable size is installed on it. Domes of large diameter and height must be strengthened with a power frame, due to their high-altitude location, where large wind loads are taken. Often this power frame is made of bent I-beams of various sizes, connected to each other by ties. The factory of bent parts implements in its production walls the rolling of an I-beam (I-beam bending) onto the edge for the load-bearing elements of the dome. I-beam rolling can be done at different angles and radii (from 3 heights to several tens of meters).

Rigid arched support made of I-beam or channel

Rigid arch support is used to ensure the rigidity of mine workings. Unlike flexible arched support, rigid support has better mechanical and resource characteristics and is installed for a longer service life.

Rigid arched support can be in the form of: a straight arch (two straight posts at the edges and a radius cap), a ring (usually assembled from 2, 3 or 4 parts) or a trapezoidal arch (two posts at an equal angle to the vertical and a radius cap). Other shapes are also possible, depending on the shape of the mine tunnel.

The cross-section of the rigid support is usually taken to be an I-beam from No. 14 to No. 20; it is also possible to make it from a channel or angle.

From us you can order the production of arched support from an I-beam (up to No. 40) or a channel (up to No. 40) with any geometric parameters.

Channel bending at home

Construction workers probably wondered how to bend this profile. In garage conditions, only local bending is possible, since there is hardly room for a bulky machine. To work, you will need a welding machine, as well as a grinder with both types of discs.

The sequence of work is as follows:

- Marking lines are applied on the channel flanges in accordance with the required angle of inclination (bending) of the profile;

- a triangular piece of metal is cut out on both sides with a grinder; it is important that the cutting is carried out accurately and symmetrically, otherwise the workpiece cannot be bent;

- the profile is bent at the selected angle at the cutout;

- to restore strength, the joint is welded;

- the weld seam is processed with a grinding disc.

This method is the only correct one that will allow you to bend a metal channel without the use of expensive equipment.

Advantages

We carry out both industrial and individual orders with a decorative component, and this can be designer metal furniture.

Pipe processing and bending is actively used in the manufacture of:

- Retail, parking and warehouse equipment;

- Platform carts, signs, road signs, trash cans;

- Railings, stairs, fences, gratings;

- Advertising and information boards.

Your designs with our hot-feed, smooth-bending tubes are guaranteed to be powerful and reliable, resulting in very high-quality products with a long service life.

Features of bending an I-beam

An I-beam is a standard profile that bends only radially (smoothly). Depending on the purpose of the deformed product, two types of work are distinguished:

- flat bending (for example, for rails);

- edge bending (for load-bearing structures).

I-beam bending is performed only on profile bending machines. The “on edge” method requires special machines that prevent the sides from collapsing and maintain the profile cross-section.

The smallest bending radius depends on the profile dimensions and is set by the machine manufacturer. The process is carried out by analogy with a channel with any type of beams (column or wide-flange).

To ensure that the workpiece does not turn out crooked, careful monitoring of each stage of work by the operator of the unit is necessary. Although modern machines do not require human participation in operations, they will not be able to affect the rigidity of the structure if the initial parameters are set incorrectly. Therefore, work on the machine is performed smoothly, preferably in leisurely approaches. If you need to obtain the minimum radius for a specific I-beam, it is better to divide the bending process into several stages.

At home, bending an I-beam is hardly possible. This is a dimensional and durable profile that will not be taken by devices for bending the same aluminum profile. The method described in the section “Bending a channel at home” will also not work, because the shelves extend on both sides of the transverse segment. If you make a cut on two parallel shelves, bending will cause the other two to break. If the latter are pre-cut, the structure of the material will be disrupted, and the I-beam will cease to perform its load-bearing function.

The tips above will help beginners bend a metal channel or I-beam. In many cities of the country there are enterprises that are ready to perform the described work on roll forming machines. Contacting them is much more profitable than buying equipment with your own money. Bending a channel at home is not difficult if you have the right tool at hand. If you know other ways to smoothly or locally bend profiles, share your skills in the comments to the article.

Bending

Bending an I-beam on its edge (I-beam bending)

An I-beam bent across a section is a rather rare phenomenon due to the difficulty of implementing this technological process. But nevertheless, more and more specialists are learning that this is possible, and as a result, the use of bent I-beams on edges is growing every day. A service such as bending an I-beam across an edge is necessary for the manufacture of bent columns of noise-protective acoustic screens, dome structures, canopies and hangars with large clearance between columns, heavy-load bearing bridge elements, and in other areas of industry and construction.

The factory of bent parts provides services for bending an I-beam on an edge to beam No. 36 according to the client’s technical specifications in a short time and at a reasonable cost. The bent part retains all geometric dimensions in the bending section, there are no creases or deformations.

Bent racks for noise-proof acoustic screens

The FGD company provides services for bending an I-beam on an edge for racks of road acoustic screens on special conditions, so the cost of a part obtained by bending does not exceed the cost of a part welded from several segments. The production capacity of FGD allows us to produce a large number of parts. The company's principles do not allow violating agreements on the timing, cost and quality of products.

I-beam radius posts for road screens can be of different shapes; the image above schematically shows the most common ones. The bent parts factory bends the I-beam for the screen according to the drawing agreed upon with the customer. You can always look at samples of bent structures at our enterprise, thereby making sure that we really do all the work ourselves, and only after that place an order for execution.

Radial inclined noise barriers have long found popularity in developed and actively developing countries; they have improved noise reduction characteristics and also carry an aesthetic meaning. Some screen designs can even be called a work of art! The FGD LLC team for combining efficiency and aesthetics.

I-beam rolling for dome structures

The domes of churches and cathedrals have both ideological and visual meaning. Depending on the overall dimensions of the church or cathedral, a dome of comparable size is installed on it. Domes of large diameter and height must be strengthened with a power frame, due to their high-altitude location, where large wind loads are taken. Often this power frame is made of bent I-beams of various sizes, connected to each other by ties. The factory of bent parts implements in its production walls the rolling of an I-beam (I-beam bending) onto the edge for the load-bearing elements of the dome. I-beam rolling can be done at different angles and radii (from 3 heights to several tens of meters).

Rigid arched support made of I-beam or channel

Rigid arch support is used to ensure the rigidity of mine workings. Unlike flexible arched support, rigid support has better mechanical and resource characteristics and is installed for a longer service life.

Rigid arched support can be in the form of: a straight arch (two straight posts at the edges and a radius cap), a ring (usually assembled from 2, 3 or 4 parts) or a trapezoidal arch (two posts at an equal angle to the vertical and a radius cap). Other shapes are also possible, depending on the shape of the mine tunnel.

The cross-section of the rigid support is usually taken to be an I-beam from No. 14 to No. 20; it is also possible to make it from a channel or angle.

From us you can order the production of arched support from an I-beam (up to No. 40) or a channel (up to No. 40) with any geometric parameters.