An attentive buyer will notice that most factory compressors offered on the market are additionally equipped with cylinders of different cylindrical shapes and capacities. Some installations are offered without them. “What are these containers for and is it worth purchasing them for your compressor?” - we will look into this in this article.

These cylinders are called receivers and are pressure vessels. Containers that fall into this category must be tested and meet specific requirements and regulations. Color and shape in this case do not matter, but the thickness of the wall of the cylinder and its volume are significant technical parameters. The receiver equipped with the compressor unit performs several functions. Let's take a closer look at some of them to understand why it is needed.

Receiver - sump

When the compressor operates for a long time, the air supplied through its discharge pipe has an increased temperature in contrast to the ambient temperature. Therefore, when it comes into contact with the metal surface of the container, it condenses into water. Moreover, the compressed air pumped by a piston-type compressor often contains fine droplets of oil. All that moisture and oil won't do any good to the compressed air line or the air tools. They linger at the bottom of the receiver and are easily removed through the condensate drain valve, which is located at the lowest point of the container. So, the first and simplest purpose of the receiver is as a sump that cleans compressed air from unnecessary impurities.

How to choose the optimal receiver parameters

Like any technical product, the receiver has a number of technical parameters. Among them are:

- Volume, l.

- Humidity.

- Operating parameters, that is, limit values of humidity and temperature.

- Characteristics of the installation location of the compressor unit. It must be installed away from sources of heat, fire and explosive substances. The presence of foreign particles in the air is undesirable, for example, in procurement areas.

Safety rules state that it is unacceptable to use receivers that have not passed the appropriate test, on the surface of which there are mechanical damage in the form of cracks and traces of corrosion.

The selection of a receiver is carried out on the basis of a fairly simple calculation:

- The required flow rate of the air mixture, the duration of the flow rate, and the maximum operating pressure are determined.

- Using special calculation tables, they exist both in paper form and as Internet applications. For example, with a productivity of 0.1 cubic meters per minute, a maximum load duration of 5 minutes and within a pressure range of 3/4 (min/max), the volume of the receiver will be about 500 liters.

This method of calculation is focused on the time required to completely empty the container.

There is another technique based on the ratio of the volume of the vessel and the power of the air compressor. In practice, the following ratios are used:

- Power 5 kW, volume max – 100 l.

- Power 10 kW, volume max – 300 l.

- Power 20 kW, volume max - 550 l.

There are also experimental dependencies, for example, the volume of the receiver cannot be less than the amount of air that the compressor can produce for 8 seconds of operation. For example, the flow rate is 400 liters per minute, respectively, the volume of the poppy must be at least 53 liters.

Here you can select and buy air receivers for compressors.

Receiver - storage

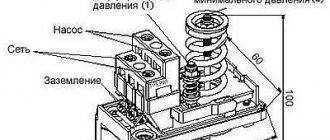

Most pneumatic devices operate with a wide range of compressed air, the pressure of which can range from 0.2 to 1 MPa. Therefore, the receiver is often used as a storage device for uninterrupted supply of air under pressure to a working pneumatic tool. This ensures continuous operation of devices powered from the pneumatic line. It also creates an optimal cyclic operating mode for the compressor with long periods of inactivity and short-term activation to build up the required pressure. To ensure safe operation of the compressor unit, the receiver is equipped with:

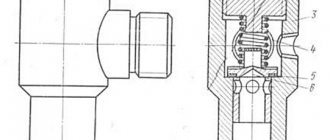

- a pressure gauge for measuring air pressure;

- check valve;

- a safety or relief valve to reduce the pressure in the container to a safe level.

Advantages of dry storage tanks

The ideal ratio of wet and dry air in the air system is 1/3 wet air and 2/3 dry air. Without a dry storage tank, the dehumidifier is at risk of accumulating too much condensation during periods of high load as the system attempts to draw in more air than the dehumidifier can produce. If the dryer is overloaded, water may enter the compressed air system. The only example where a dry storage tank is not necessary is in systems with constant air flow.

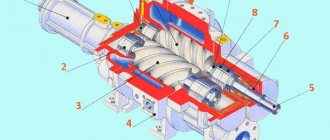

Receiver - damper device

While rotary and screw compressors are characterized by softer and smoother operation, piston compressors supply air in a jerky manner. When pumping up the slope of a car, this will not create any particular inconvenience, but it will have an undesirable effect on the operation of a pneumatic tool or the result of painting the surface with a spray gun. Thus, the receiver dampens air pulsation during operation of the compressor, as well as when it is turned on. The degree of pulsation damping or smoothing depends on the volume of the receiver on the compressor, which should be 15-25% of the installation capacity, measured in l/min. For example: for a compressor with an air supply of 200 l/min, a receiver with a volume of 50 l is needed, and for a unit with a capacity of 500 l/min, the optimal solution is a 100 liter cylinder.

1What is an air receiver and what is it for?

Air receiver or air collector

– a special tank for temporary storage of compressed gas during peak load periods before its further preparation (filtration, drying) or immediately before use.

Theoretically, a pneumatic system can operate without an air collector.

For example, in industries where a constant and stable supply of working fluid is not required. In such cases, the use of filters and dryers will be mandatory, otherwise the compressor unit will quickly fail. In the process of turning the compressor on and off, a certain number of load and unload cycles of the device invariably occur. The cycles directly depend on changes in the need for compressed air at each enterprise, for example, when several consumers are simultaneously connected to one pneumatic network. As a result, pressure differences and air pulsations occur, and the compressor begins to work more intensely at increased loads. To prevent such phenomena, air after compression must be “dumped” into special containers in order to stabilize the pressure in the pneumatic network.

This leads to the second important function of air collectors - they help stabilize the control of the compressor, eliminating pressure fluctuations in the system and short on-off cycles.

Other important functions of the receiver:

- Additional cooling of the working environment and dehumidification of condensate. When air enters the receiver after compression, it naturally cools, during which condensate settles on the walls of the receiver and flows down. Thus, the receiver works as a second dehumidifier.

- Protection of equipment from corrosion. Due to the formation and accumulation of condensate in the receiver, the pipeline and other devices of the pneumatic network are more protected from corrosion due to moisture.

- The accumulation of compressed air in the receiver allows you to reduce the number of compressor on/off cycles and ensure a uniform supply of gas to the consumer.

- Reduced air pulsation and engine vibration. Reducing vibration leads to a decrease in the level of noise “pollution” of the working area, and allows you to keep the floor base longer without destruction.

- Preventing disruptions in the production process.

- Neutralization of turbulence in the working environment resulting from changes in pressure and temperature.

- Additional purification of compressed air. Large dry particles are retained along with the condensate and are then discharged outside.

- Reducing overall production costs for drying and cleaning compressed air.

The receiver can be supplied as a separate device (Figure 2):

Or supplied already complete with the compressor. This configuration is intended for premises with limited space or for small production tasks where the accumulation of large volumes of compressed gas is not required (Figure 3):

Or supplied already complete with the compressor. This configuration is intended for premises with limited space or for small production tasks where the accumulation of large volumes of compressed gas is not required (Figure 3):

Compressors with a built-in receiver have compact dimensions, high reliability, low noise and vibration levels. With their help, you can rationally use the production area. Most often, this configuration is found in compressors with a power of up to 26 kW.

How do receivers affect the efficiency of the production process?

Using a receiver in a pneumatic network allows you to increase the efficiency of all equipment. This happens due to the fact that the air collectors:

- Reduce pressure on the compressor. The air collector reduces critical pressure levels. This increases the efficiency of the equipment, since every 0.29 kPa increase in pressure leads to a loss of 1% of energy and increased load on the engine.

- They reduce the number of “on/off” operating cycles, thereby almost completely eliminating the loss of compressed air when unloading the compressor during system purging.

- Reduces the load on the dehumidifier. Due to the formation of condensate, which is discharged through a special tap in the receiver, the air enters the dehumidifier without foreign particles and is almost completely dry. This reduces the load on the dryer.

Price on request

Request CP

Write by email

We offer receivers with pressures of 10-16-40 bar and tank volumes from 3 to 900 liters. Receivers with a volume of 250-500-900 liters are always available. Go to section >>>

Is it beneficial to place the receiver outdoors?

- depends on the climate zone,

- the receiver is more effective as a second heat exchanger if it is located in the open air,

- can reduce high temperatures in the compressor room.

Placing the receiver outside allows you to save space in the compressor room. However, this is only justified if the outside air temperature never drops below 0°C. At subzero temperatures, the receiver may freeze up and rupture if it lacks thermal insulation and the thermal energy created inside the receiver is not enough to maintain a positive temperature of the receiver. In such cases, it is necessary to provide heating and constant monitoring.

If climatic conditions are in your favor, you can place the receiver outside. This is beneficial since the air outside will likely be colder than the air in the compressor room. This will help improve the efficiency of the dehumidifier by lowering the air temperature as it approaches the dehumidifier.

Another advantage of placing the receiver outside is the reduction in temperature in the compressor room due to the fact that the heat generated during receiver operation is generated outdoors.

Classification

In addition to the fact that there are mobile and stationary receivers, experts note other design features of air collectors that allow them to be considered different types of products. So, there are horizontally and vertically oriented containers.

At the same time, horizontal receivers are more compact and make it possible to economically accommodate a pump, electric motor and other auxiliary equipment. A characteristic feature of this arrangement is the minimum length of connecting pipelines. Thanks to these features, horizontal receivers are widely used both in household compressors and in automotive pneumatic systems.

Whereas in vertical air collectors it is easier to drain accumulated condensate. In addition, they are more convenient when installing compressor units consisting of several receivers, since they take up less space than horizontal tanks. Therefore, such air collectors are more often used in industrial enterprises that require large amounts of compressed air.

Interestingly, if necessary, receivers of the same type can be easily combined with each other using a parallel or serial connection method . At the same time, containers interconnected in series provide a higher degree of air drying and purification from various impurities. Whereas the parallel connection of receivers increases the maintainability of the entire system, since to restore the functionality of one tank it is not necessary to completely turn off the compressor equipment. The faulty tank is simply disconnected and repaired. This connection option is also characterized by the highest throughput.

Tags

Compressors Screw Compressors Piston Compressors Mobile Compressors Scroll Compressors Explosion Proof Compressors Compressor EquipmentAir Compressor Screw Compressors Piston Compressors Compressed Air SupplyThis Compressed Gas

oil-freeremezatoolcopcoarticlesoperationquestionpartsvalvepurposeselectionmachinescompanyseriesapplicationperformancecylindermodelmainparameterspneumaticspare partshandsfireplacebackkwrefugeeapparatusscrewbargasabacsourcegeneratorsproductsatlasmachines

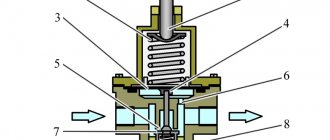

Schematic diagram of operation

In general, the operation of the receiver can be described as follows.

- Using the inlet pipe, air from the compressor is supplied to the tank, where it accumulates until the required operating pressure is reached.

- During the accumulation process, the air cools, as a result of which condensation accumulates at the bottom of the tank - thus, additional drying of the working environment is carried out, which helps reduce the effect of corrosion on all elements of the system. The condensate that collects at the bottom of the tank is drained through a special tap.

- When the required pressure is reached, compressed air enters the outlet pipeline and is supplied through it to the connected pneumatic tool.

On a note! In practice, the operation of the receiver is controlled by a reducer, which regulates the pressure of the air leaving the tank.