04/30/2021 Author: VT-METALL

Issues discussed in the material:

- How laser cutting works

- Types of laser cutting

- Pros and cons of laser cutting of metal

- The nuances of using laser cutting for some metals

- Laser cutting quality parameters

- How can you improve the quality of laser cutting?

Understanding how laser cutting works is essential to performing or evaluating laser cutting. It is also necessary to know the quality requirements for laser cutting, permissible deviations in size and roughness.

In addition to the above, laser cutting of some metals has its own characteristics, and to carry out this work you need certain knowledge in setting up the equipment. Only all this together will help to obtain high-quality products.

How laser cutting works

The very name “laser cutting” reveals to us the essence of the process, which consists of cutting metal with a laser beam emitted by a special installation. The laser beam has a number of properties that allow it to be focused on the surface being treated, and the beam will carry a high-density energy charge. Under its influence, almost any material actively burns, melts, evaporates, etc. - in general, it is destroyed.

The beam energy with a density of 108 watts per 1 cm2 created by a laser cutting machine is concentrated on the metal surface. To understand the essence of the process and, in particular, how this effect is obtained, you need to learn about all the properties of the laser beam.

Unlike light waves, a laser beam has a constant wavelength and frequency. This property is called monochromaticity, and the radiation itself is monochromatic. It makes it possible, using simple optical lenses, to easily focus the beam on the surface being treated.

Another property of the laser beam is its very high directivity, as well as a small divergence angle. This property helps the equipment create a highly focused laser beam.

The next important property of a laser beam is its coherence. Its essence lies in the consistency of a large number of wave processes occurring in the beam, as well as in their resonance with respect to each other. This allows you to significantly increase the total radiation power.

Under the influence of the beam, the metal surface heats up very quickly and then melts, leaving an even cut.

Due to a number of factors, one of which is thermal conductivity, the melting zone of the metal quickly spreads deep into the workpiece. The laser beam works by affecting the surface of the part and brings the temperature at the cutting point to a boil, at which point the metal begins to evaporate.

There are two types of laser cutting of metal:

- Melting.

- Evaporation.

Evaporation of metal requires the operation of high-power equipment, which results in large expenditures of energy resources. This is not always economically feasible. In addition, this method is not suitable for processing thick workpieces, which is reflected in the rather strict cutting requirements. Therefore, its use is limited to cutting thin-walled products.

Laser cutting by melting metal is used much more often. Recently it has been improved by using various gases such as air, oxygen, nitrogen or inert gases. Special installations blow them into the laser cutting area. You can view a video recording of this type of work by typing the appropriate request on the Internet.

The innovation made it possible to reduce energy costs, increase cutting speeds and use low-power equipment to process thicker material. However, it would be more correct to change the name of this method from laser to gas laser.

Let's consider a number of advantages that allow the use of oxygen as an auxiliary gas for laser cutting:

- oxidation of the metal is activated and makes it possible to reduce its reflectivity;

- the thermal power of the processing zone increases due to a more active process of metal combustion in an oxygen environment;

- oxygen supplied under pressure helps to blow combustion products and small metal particles out of the processing zone, which simplifies the entry of new waves of gas into the cutting zone.

Purpose and selection criteria

This method of work is also used for processing plywood, linoleum, polypropylene, and rubber. Even artificial stone and glass can be subjected to this treatment. This type of cutting is used in the construction of cars, ships, numerous electrical appliances, as well as agricultural machines. This processing option is also suitable for making signs, signs, tokens, and interior decorative elements.

Laser cutting machine GCC LaserPro FMC280 200 W

- Dimensions, mm 1125 x 720 x 1800 mm

- Maximum power consumption 1800 W

- Display 4-line LCD panel

- Max. motor speed 500 mm/s

- Maximum load size 786 x 542 x 120 mm

- Laser tube power 200 W

- Memory capacity 32 MB

- Axes 3

- Emitter manufacturer Germany

- Working field 712 mm x 370 mm

- Resolution, DPI 3000

- Laser type: optical fiber 1070 nm

- Laser tube cooling type: air

Go to product

When choosing the type of processing, you need to rely on the material being processed. For example, carbon dioxide lasers are more suitable for welding, engraving and cutting metal, glass, rubber and plastic.

But solid-state machines process metal perfectly, but are not at all suitable for non-metals.

Types of laser cutting

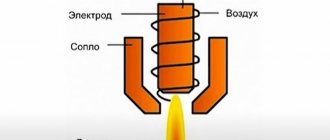

The intensity of radiation, the composition of the gas used for work and the pressure when processing different metals must differ. Therefore, several types of cutting have been developed.

1. Laser-oxygen cutting.

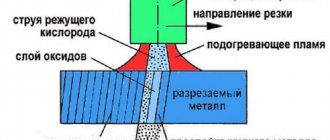

The oxygen used in this type of treatment is a cutting gas. During its interaction with hot metal, an exothermic oxidation reaction occurs. And the oxides formed during the same process are instantly blown away by an oxygen stream.

Features of work using this type of laser cutting are the speed of work and the diameter of the focused beam, which affect the width of the cut. At the same time, the diameter of the beam is smaller than the diameter of the oxygen jet (usually from 1 to 2 mm). The cut becomes narrower as the speed increases and the thickness of the workpiece decreases. The cut has a minimum width of just under 100 µm. There is an inverse relationship between the pressure of the oxygen flow and the thickness of the material - as the thickness of the metal decreases, the pressure increases.

VT-metall offers services:

The pressure in the process of cutting a thin sheet reaches 3-4 atm, and when the thickness increases to 25 mm or more, it becomes about 0.3 mm. The jet forms a gap between the nozzle cut. Its size depends on the thickness of the metal being processed. Fluctuations in the size of the gap can be from 0.5 mm for sheets of thin metal to 3 mm for metal with a thickness of 2.5–3 cm. The maximum thickness of a steel sheet cut by a laser with a power of 6 kW is 3 cm. The process speed for a given thickness is minimal , about 0.5 m per minute. If the operating speed continues to decrease, the quality of cutting decreases even faster.

2. Oxygen cutting with laser beam support (LASOX).

To work with thick steel sheets, it makes sense to use a technology that has become widespread in recent years, in which a laser beam heats the surface of the metal until it reaches a temperature of +1,000 ° C, after which a jet of oxygen is used, which cuts the metal at supersonic speed. The use of this method makes it possible to significantly increase the depth of the cut when compared with simple oxygen laser cutting.

A supersonic oxygen jet is formed by high pressure, reaching 6–10 atm. The cut has a width equal to the diameter of the oxygen jet. It has a size ≥ 3 mm. The distance from the nozzle exit to the surface should be approximately 7 mm. The cutting speed is reduced to 0.2 m per minute. The operating speed when using the presented technology is significantly reduced compared to oxygen laser cutting. But the thickness of the processed metal reaches 10 cm.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

3. Laser cutting in inert gas.

If oxidation of the edges of the metal being processed cannot be allowed, then inert gas laser cutting technology works great. It is suitable for metals such as titanium, stainless steel, aluminum alloys. This technology does not provide for the use of an additional heating source, which, unfortunately, reduces the efficiency of metal cutting.

The speed of work in an inert gas environment, which can be argon, used when cutting titanium, or nitrogen, used in other cases, is quite low. The cutting gas pressure must be more than 10 atm. The diameter of the nozzle depends on the width of the sheet of metal being processed. And it, accordingly, influences the amount of gas used, increasing it. Which affects the increase in cutting costs.

4. Laser thermal splitting of glass.

This technology works well for cutting fragile and brittle materials such as glass. The laser beam heats the material unevenly, and then a jet of inert gas works to cool it. As a result, a crack forms. The direction of its advancement can be controlled by moving the heat source along the surface of the material. The result of the work is a smooth, even edge.

5. Sublimation cutting (evaporative laser).

If it is necessary to minimize the thermal effect on the substrate, sublimation cutting technology is used. Its main application is microtechnology. The laser radiation intensity for this type of cutting must be very high. Let's take a look at how a laser cutting machine works. In short, the equipment operates on radiation of picosecond and nanosecond pulse durations, that is, very short ones. The radiation wave has a length of less than 1 micron. For such radiation, excimer and solid-state lasers are used, as well as those that operate on metal vapors. The efficiency of such processes is minimal.

Consequently, oxygen laser technology is the most common and standard type of cutting materials. The remaining types are specific in nature and solve individual problems.

Guide to preparing files for laser engravers and cutters

There are particularly important rules that you must follow when it comes to laser engraving. A very popular aspect of laser engraving is text engraving. When text is sent to the controller, the machine automatically adds a border around the letters, so it's important to remember:

- Make sure letters are spacing correctly

- Minimum text size 2 mm

- Narrow fonts are preferred

Laser cutting programs

Pros and cons of laser cutting of metal

The use of laser cutting technology for materials occurs everywhere in various sectors of industrial production, such as aviation, mechanical engineering, medicine, etc. The reason lies in its advantages, such as:

- high-precision cutting of metals;

- laser cutting equipment works to create curved structures of all degrees of complexity, as well as volumetric parts and shaped products;

- the surface of the workpiece does not heat up during operation;

- a high quality cut is formed;

- there is no deformation of the material during work;

- there is no mechanical impact on the workpiece;

- a non-contact working method is used;

- the technology copes with the creation of even fragile and complex parts;

- work is carried out without creating dust;

- the technology has proven itself to be excellent when working with any metals, including those with a high level of thermal conductivity, and their alloys;

- it is possible to perform work in automatic mode;

- the method is used for cutting not only metals, but also plastic and wood, cardboard, textiles and leather, and other materials;

- the products come out of high quality and do not require additional processing;

- the method is almost ideal for working with workpieces that are easily deformed during mechanical work;

- the heating zone of the product surface is minimal;

- there is no overheating of products during operation;

- production times are very short;

- The equipment is extremely easy to operate.

In addition to its advantages, the technology also has disadvantages. They are high cost compared to other types, uneven production speed and strict restrictions on the size of the workpiece being processed. Sheets with dimensions of no more than 15x30 m can be subjected to laser cutting. Another limitation is the thickness of the material - the workpiece should not be thick-walled. It is also necessary to take into account that the type of laser greatly affects the cutting efficiency and other parameters.

What equipment is used today for laser cutting of sheet metal?

With the advent of laser cutting machines, the production of metal structures has become much cheaper and faster. Laser cutting ensures the highest accuracy and speed of work. This technology is optimal for processing metal sheets of small and medium thickness. It is used in the metallurgical industry and in almost any machine-building industry.

In Russia there are laser machines manufactured by Mitsubishi, Durmazlar, Trumpf, TST LASER, Mazak, FINN-POWER, Knuth, Halk, Mattex.

The most popular equipment is:

- Laser machines ARAMIS.

- Laser equipment from Durmazlar.

- Installation 2D/3D CO2 Space GEAR MarkII manufactured by MAZAK.

- CNC machines for welding and laser cutting of sheet metal Laserdyne manufactured by PRIMA NORS.

The cost of laser cutting equipment averages 350,000 rubles.

A laser beam is a concentrated stream of high-energy light particles. It hardly dissipates and creates a tiny spot of light on the surface of the material being cut, the size of which is usually several microns. At this point, the metal instantly melts, boils and evaporates, while the rest of the surface is not heated. These features make it possible to achieve an extremely narrow cut, while the dimensions and shape of the part are maintained with an accuracy of tenths of a millimeter.

The nuances of using laser cutting for some metals

- Aluminum.

The high thermal conductivity of aluminum and poor ability to absorb a laser beam due to the optical and thermophysical characteristics of the metal determine the features of its processing.

All this leads to difficulties in cutting metal. The equipment is computer controlled and easy to set up.

When working with aluminum, the laser beam power must be greater than for other materials.

However, the power indicators and speed of work are greatly influenced by the thickness of the metal, as well as the percentage of aluminum contained in the material being processed.

Let's look at how laser cutting of this metal works. It occurs on solid-state equipment of various operating modes and power, as well as on gas devices.

The latter are more powerful and can operate in pulsed or continuous mode.

And solid-state equipment, as a rule, operates in a point (pulse) mode.

The technological process has a number of features. Aluminum is cut better by a laser beam than conventional metal cutting equipment. The reason is that when working with a laser, the equipment does not touch the workpiece, unlike other equipment.

The laser beam is a focused beam of light with which cutting occurs. Precise focusing allows processing of aluminum at high speed. Gas is supplied to the work site and its influx is created. A jet of gas blows away pieces of molten metal from the cut site, preventing them from settling, and makes the surface even and smooth.

High-quality results can be achieved by working at a lower speed. Because it eliminates any deformations, both large and small.

To eliminate any roughness on the cut edges, even minor ones, nitrogen is used when operating the equipment.

The equipment is equipped with software that makes it possible to carry out ultra-precise, high-quality work. In addition, the workpiece does not need to be secured before starting work, since there is no physical contact between the equipment and the product. The part lies on the surface without moving.

Automatic equipment works as follows: a drawing is entered into the computer, the required parameters are set, and then the cutting is completed.

- Brass.

Brass is an alloy of red copper and zinc. The fragility and hardness of the alloy are determined by the percentage of zinc in it - the more of this metal, the higher these indicators. However, an increase in the amount of zinc makes brass unsuitable for technical purposes, since it is practically impossible to cut. It has been established that zinc in brass can be no more than 42%.

Brass has a high melting point because it is a two-component alloy, that is, it consists of zinc and copper. The temperature required to melt brass typically ranges from +880 °C to +950 °C. In addition, brass has significant thermal conductivity, resistance to laser radiation and increased hardness.

The setting of an industrial laser machine depends on the thickness of the processed brass workpiece:

- for brass with a thickness of less than 5 mm, pulse mode is used;

- if the workpiece has a thickness from 5 to 12 mm, then the plasma cutting mode is used.

The pulse mode heats the surface in short intervals (pulses), rather than constantly. This reduces the heating area, resulting in a minimized cutting width and higher quality edges. When cutting brass, which is highly reflective, the equipment operates in pulse mode, delivering a low laser beam power at a threshold intensity.

The melt (plasma) mode allows you to apply heat evenly to the cut area. The laser beam heats the metal using an inert gas. The plasma that is formed during operation maintains the temperature throughout the entire thickness of the workpiece.

If the end of the product has roughness or porosity, this can be removed from the underside of the product. A copper sheet absorbs radiation very poorly. And cutting equipment operates at low speed. In addition to the precise selection of the operating mode, it is necessary to correctly fulfill the conditions for laser cutting of metal sheets of various thicknesses. They differ for aluminum, steel, copper, as well as its alloys with tin, that is, bronze, and with zinc, that is, brass.

High-quality results are obtained when using fiber units or Nd:YAG lasers with a wavelength of 1.06 microns. CO2 lasers are not suitable for cutting brass, since its surface completely reflects them.

Advantages and disadvantages

Laser cutting of metal has a number of advantages:

- There is no mechanical contact with the surface of the processed material. This makes it possible to process even fragile materials, as well as those that are easily deformed.

- Suitable for cutting materials with different thicknesses.

- The process happens quickly.

- Parts with any configuration can be manufactured.

- There is minimal waste and the edges are clean and neat.

- The operating accuracy reaches 0.1 mm.

- Sheet material is consumed economically due to the dense distribution of parts on the sheet.

REFERENCE! The main disadvantages of laser cutting are expensive equipment and high energy consumption.

Laser is one of the modern methods of processing materials. There are several options that are selected according to several criteria. The most important selection criterion is the material being processed and its properties.

- November 30, 2020

- 688

Laser cutting quality parameters

Indicators of the quality of metal cutting are roughness, width of the cut, depth of temperature exposure, non-perpendicularity of the edges, accuracy of parts, burrs on the edges. They are influenced by the thickness and type of metal being processed, cutting speed, auxiliary gas, and laser radiation parameters. For a certain material thickness, the processing speed is selected, which should approach the maximum, but maintain the best cutting quality indicators.

The cutting quality deteriorates significantly with increasing diameter of the focused radiation, and, as a result, the thickness of the melt of the rake surface increases.

How can you improve the quality of laser cutting?

1. It is necessary to clean the lens or protective glass in accordance with all rules.

Each type of laser has its own cleaning procedure. When working with a disk or fiber laser, technicians should clean the glass that protects the cutting head lenses.

Operators working with carbon dioxide lasers need to clean the lenses. Industrial professionals prefer Topol polish from TRUMPF when cleaning lasers. However, a large number of specialists do not even know how to work with it. It happens that the lenses are seriously scratched. And instead of regular polishing, workers buy a new lens. But frequent replacement is very expensive.

How to work with lens polish correctly? Do not press too hard on the lens as scratches may occur. But at the same time, polishing must be carried out under pressure sufficient to remove dirt. The most important thing is to teach balance.

You need to work in a circular motion, applying polish in moderation.

To properly polish a lens, a specialist must know and see all its imperfections. It is recommended to supplement the carbon dioxide laser equipment with an expensive polarizer, the cost of which amounts to hundreds of dollars. Despite the high price of the device, its operation will more than pay for the investment, and very quickly.

The laser technician needs to place the lens on a device that illuminates it with bright light from below. Most of all, the device's operation resembles a school projector. When you turn the lens of the device, it polarizes the laser lens placed at the top. This way you can see all its flaws: scratches, internal cracks, etc.

2. It is necessary to check the focusing (centering) of the nozzle.

To check, a specialist must break through the tensioned tape. For a second, he directs a low-power laser beam at it, after which he examines the hole and its location.

The worker shines a light on the tape, trying to understand how exactly the hole is located in the center. Its shift should not exceed 1 mm. How can you accurately determine that the hole is in the center of the nozzle? To do this, use a 10x magnifying glass equipped with a backlight.

Accurate centering of the nozzle allows you to increase the speed by 20–80% of the initial speed if the other settings are correct.

3. Focus should be checked regularly.

Most modern equipment allows automatic focus testing. And on older machine models, manufacturers recommended doing tests in various ways. Some machines use a "light test".

An example would be the old Mazak machine. During the testing process, the specialist turns on the laser beam at low power, then turns the knob to look for absolute focus. He watches the light of the beam turn blue as the handle rotates in a circle. Then he writes down the number. Returns the cutting head to its original place and repeats the procedure three times. As a result, the specialist calculates the arithmetic mean of the obtained numbers, which is loaded into the controller.

The worker is required to find the thinnest strip on the test sample, and then make sure that for this strip the controller focus is 0. If the thinnest strip corresponds to the number 3, the specialist moves the focus point by 3 mm and returns to the test again. The operation is carried out until the thinnest strip corresponds to zero.

When working with a laser, it is necessary to study factors such as gas consumption or the use of additional optical protection in carbon dioxide systems. However, the principles we have discussed are just a starting point from which you can begin setting up the necessary cutting conditions. In the future, specialists will understand that there are many circumstances affecting the operation of the laser: from the material being processed to the location of the enterprise.