Channels and I-beams are the most reliable types of long products used for tying foundations, strengthening walls, and installing floors in building structures.

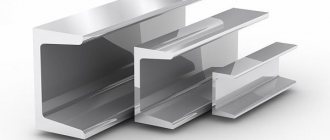

An I-beam is a wall with perpendicular flanges of the same length (it is sometimes called an “H-profile” due to its external resemblance to a letter). A channel is a profile in the form of a wall with two shelves, externally resembling the letter “P”.

Channel or I-beam

It should be borne in mind that the comparison is only reasonable for beams and channels with the same wall height and profile thickness. There is no point in comparing, for example, beam No. 14B1 and channel 24P.

What are the differences between these profiles, and what advantages does each of them have?

Strength

The I-beam profile evenly distributes the load on the shelves, and the wall rigidity is ensured on both sides. One beam can replace two channels if the load goes:

a) on the cross section of the beam (X axis),

b) at the end (if the beam is used as a support column).

If the load is applied from the side (Y axis in the figure), the channel wins.

For design structures, not only the width of the shelves is taken into account, but also derived characteristics: the thickness of the walls and shelves, the radius of curvature between the walls and the shelf.

To select a suitable profile, you should look in the tables to GOST to see the moments of resistance relative to the X and Y axes (Wx and Wy). It is this parameter that characterizes the resistance to torsion and bending in the specified plane. The higher it is, the stronger the product.

Sometimes welding of two channels wall to wall is used. The resulting homemade I-beam will be 10% less durable than a factory-made one. The method of welding channels in the form of a rectangle, with the ends of the shelves, is also used. However, in this case, a profile pipe would be preferable.

There are also channels with oblique flanges, the characteristics of which are close to those of I-beams.

Approximate comparison of I-beams and channels of similar sizes.

Main characteristics of an I-beam

The I-beam is produced with inclined edges of the shelves in accordance with GOST 8239-89, the range of products with parallel edges corresponds to the tables of GOST 26020 or STO ASChM 20-93. The products are characterized by high rigidity and strength, the value of which, in addition to the cross-sectional dimensions, is influenced by:

- grade of steel from which metal products are made; for operation under high loads and in difficult temperature conditions, low-alloy steels of type 09GS are used;

- span length - the larger this value, the lower the load-bearing capacity of the I-beam;

- method of securing the beam, direction and nature of the load.

Price

Wholesale depots measure the cost of rolled products in tons. Note that due to the lower specific gravity, one ton of channel will include more linear meters.

The price of profiles for industrial use depends on the material and manufacturing method. If rolled steel is purchased on the market “by eye,” then the price per linear meter of a simple channel will definitely be less than the price of a beam of the same section.

Thus, determining which profile is used in a particular situation should be based on the above factors. If the structure requires many years of reliable service, then it is better to order calculations and selection of rolled metal from specialists.

Main characteristics of the channel

This type of rolled metal is produced by hot rolling and bending of strip blanks. In accordance with the tables of GOST 8240, the wall height of a steel channel is 50-400 mm. Hot-rolled products with inclined inner edges of the flanges have an increased cross-sectional area and, in terms of strength characteristics, are close to analogues with an I-beam profile. To increase strength and resistance to low temperatures, rolled products are made from high-quality carbon and low-alloy steel grades.

The channel is convenient for installation on flat surfaces. Rolled steel is used for reinforcing concrete structures, creating frame buildings, and in the production of light machines and mechanisms. In private construction, the best choice is a channel rather than an I-beam, which is explained by the combination of sufficient strength and affordable cost of the U-shaped profile. The I-beam, due to its massiveness and high strength characteristics, is mainly used in large-scale industrial and civil construction.

Where is it better to use a channel, and where is an I-beam?

For use in metal structures, the channel is more versatile. It is more convenient to work with it because its shelves are located on one side. Because of this, it is easier to connect to other structural elements.

But the I-beam is stronger and stiffer. It is easier to lay other components on it. However, for load-bearing structures it should be installed vertically. With this arrangement it will have the greatest strength.

When choosing, the decision mainly depends on the intended places of their use. The I-beam has a higher price, but also greater rigidity. It is used for floors that will be subject to high loads. These include skyscrapers, subways, bridge structures, and industrial buildings.

The channel is less rigid; it is better to use it to create small structures, including country houses, garages and other light buildings. It is also used in the construction of cars, ships and various vehicles.

What then to choose?

Many builders and developers are wondering what is better for low-rise buildings - a channel or an I-beam?

The I-beam is more reliable and durable. This is achieved thanks to the features of its “H”-shaped design: the shelves protrude in 2 directions, which allows you to distribute the load evenly and minimize bending loads. This makes the product indispensable when strengthening a structure. Also, this type of rolled metal is characterized by compressive and bending strength, and it is light in weight. All this makes it popular and in demand.

I-beams are deformable and can be used for constructing bridges and strengthening tunnels. Susceptibility to welding makes installation quick and inexpensive. You can also connect parts with bolts. Transportation of products is also not difficult - the length of the I-beam is from 4 meters.

The channel has less rigidity, but it is not without advantages. The product can withstand lateral loads better than an I-beam. In addition, it is a universal profile. It is used in production, during assembly, and construction of metal structures, while double-taper is used to strengthen the structure.

You can create any design from this profile without welding. The product is light in weight, which does not allow it to be used for bulky buildings.

The disadvantage of the channel is its intolerance to welding. The material is too durable, although there are technologies that can still make the seam even, but this is quite expensive.

Channel

How are they visually different?

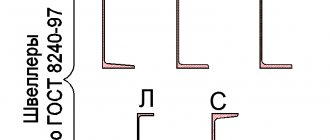

First, it’s worth understanding what each rental is. Channel - a product with 2 shelves fixed to the wall, has the shape of the letter P. A similar profile is divided into:

Regardless of the type, the production of channels is regulated by GOST 8240, which also indicates the regulatory characteristics of existing brands and subtypes of channel blanks.

An I-beam is a metal product consisting of two vertical shelves, the centers of which are connected by a wall . It is characterized by increased deflection strength and reliability, is available in lengths from 4 to 12 meters and has a solid section in the shape of the letter H.

The production of such elements is regulated by two regulatory documents: GOST 8239 and GOST 26020.

Location of the point of action of the total forces

The channel and I-beam react differently to equal lateral loads. The unequal perception is explained by the location of the center of gravity.

For the channel, the point of application of forces is shifted towards the ends of the flanges. The center of gravity of the I-beam passes along the wall, is directed along the long axis, and is located inside the real contour.

The purpose of both structures is to perceive vertically directed forces: compression and tension. For this reason, the rods do not withstand large torsional moments.

The statement is valid for traditional use of products:

To ensure that the result reflects reality, several similar profiles working under equal conditions are compared. The calculation shows that if the load is directed perpendicular to the longitudinal axis (to the side of the beam), the channel has greater strength. The shelves are located on one side. The center of gravity of the product is located behind the actual cross-section.

In order for rolled metal to withstand large lateral loads, the product is laid with the wall down. The method is used for lightweight building elements. The second option for positioning the channel is on its side. If large forces are applied, it is desirable that the ends of the shelves come into contact with the base of the structure or strong supports.

Conclusion. If a beam is needed to withstand vertical and lateral loads, a channel is purchased. When the profile operates under conditions of increased resistance to compression and tension, I-beams are chosen.

For both designs, a safety factor (20-30%) is included in the calculation.

Pros and cons of channel and I-beam

When comparing the strength of two structures, the method of collecting all acting forces is used. The formulas are used to calculate the values and direction of voltages. The nature, duration, and mutual influence of moments are taken into account. It is important to use the I-beam for its intended purpose: for erecting columns, laying rail tracks.

Factors influencing the strength of two structures:

Regulatory documents contain requirements for hot-rolled beams. The maximum and minimum sizes of profiles of different types are indicated in the table.

Source

Does the channel have analogues?

What can be used instead of a channel? This question often arises when choosing such a material. A material similar to a channel, an I-beam is a steel beam with parallel edges and an end in the shape of the letter “H”. This structure provides it with some advantages when compared with a closed square profile. Namely:

- the cross-sectional area is almost 7 times larger;

- rigidity is 30% better.

Even externally, I-beams look like a strong structure, thanks to the H-shaped profile. This shape allows you to combine important characteristics for construction: low weight and high mechanical strength.

But the strength of the I-beam can be reduced due to the following factors:

- material fastening option;

- steel grade and production method;

- structure length;

- I-beam configuration.

The strength of constructed spans decreases in direct proportion to their length. But with lower construction costs, it is still better not to experiment and not increase these dimensions.

Comparison of I-beam and channel strength, depending on the applied load

The main difference between the properties of an I-beam and a channel is the different response to loads, in particular torsion, which is explained by the difference in the location of the center of gravity.

- I-beam . The maximum volume of metal, especially in products of the wide-flange and column series, is concentrated in the shelves. The I-beam flanges, symmetrical relative to the wall, absorb the main vertical loads and provide a high moment of inertia. The wall works mainly in compression. This symmetrical profile can only be subject to torsion in cases where a floor with an uneven load is laid on it. The I-beam, due to its massiveness, high cost and strength characteristics, is used mainly in large-scale construction to create floors that experience high loads.

- Channel . Its main feature is the mismatch of the main axis of inertia with the wall. Such products work well with oblique bending. To create a light and durable metal structure, the channel is welded into a box with the seam reinforced with metal plates. Creating such metal products requires a lot of labor. The channel is most often used to create frame structures, make floors for small buildings - cottages, garages, outbuildings - as well as stairs.

Both the channel and the I-beam belong to profile rolled products, which are not designed to withstand serious forces directed perpendicular to the wall.

Clash of the Titans: Channel or I-beam, which is better? Full FAQ

Hello colleagues! I-beams and channels are metal profiles used in construction and various types of heavy industry. Both types of products are made of durable steel and are intended to strengthen the structure.

In construction, they are used to reinforce concrete structures and strengthen walls. The area in which both I-beams and channels are most often in demand is the floors of buildings.

By the way, when ordering the construction of a warehouse from metal structures, an office building, a shopping pavilion or a center, including turnkey construction from us at RAMKON LLC, you receive an optimal estimate, excellent quality, and the possibility of original design! More details: https://ramcon.ru/stroitelstvo-iz-metallokonstruktsij.html >>>

Differences in Application

I-beams are rolled products in demand in construction, which are used as load-bearing beams in the construction of large objects:

The channel is best used in low-rise construction. It is also often used in the construction of outbuildings. It is worth noting that, regardless of their purpose, both elements are used both as floors and as roofing elements.

Common features of different types of shaped profiles

These types of profiles are made from the same material. Structural, low-alloy, carbon steel is used for their production. Alloy steel is most often not used for this type of product.

A feature of low-alloy steel is its constant performance at very high and very low temperatures. Products made from it retain their properties in the temperature range from -70 to +450 degrees, and they can also withstand significant mechanical stress.

These types of shaped steel have several more common features:

- Preparation method. Products can be manufactured by bending, welding and rolling. It is quite simple to determine the method by looking at the bend: if the product has been bent, all the corners will be rounded, but for rolled parts they are almost even.

- Further application. Shaped products are immediately sent for final use, while long products undergo additional operations and are used for the manufacture of other parts.

Channels, I-beams and angles are actively used in the assembly of load-bearing structures. This is their general purpose: the main function is to ensure the stability of the structure and increase the load-bearing capacity.