Cold welding for plastic – polymer adhesive made of amine and epoxy resins with a mineral or metal filler. No heat required during use. It is an indispensable tool for repairing plastic parts that have cracked, split or a small piece has fallen off. After welding, the seam is not inferior in strength to a monolithic object.

Where is it used?

You can repair the connector of a household appliance, repair individual elements, eliminate defects and chips.

These properties are used for cosmetic and full repair of such products:

- plastic heating pipes;

- fishing rods, travel equipment;

- plastic insulation on electrical wiring;

- housings and accessories of household devices;

- car bumpers, plastic interior elements;

- garden, household or household utensils.

Advice from experienced welders

For the best adhesion of parts, it is recommended to apply glue to a wet surface. The method is more in demand in problems with pipe leaks. Therefore, when performing repair work, you can not turn off the water.

There are some useful tips to remember:

- When repairing pipes and pipeline components, it is necessary to purchase only a moisture-resistant composition, taking into account constant contact with liquid.

- If you have to urgently repair a leak in a plastic pipe, such a patch must be changed later - the adhesion will be poor.

- To harden the mass faster, you can use a hairdryer with warm air.

- It is worth purchasing only products from trusted manufacturers.

- You should not use material that has passed its expiration date.

Advantages of cold welding:

- There is no heating, which means the structure of the metal will not change.

- You can create a strong seam.

- Cold welding can be used in emergency fire and explosion hazardous areas.

- There is no need for special preparation to perform the work.

Advantages of cold welding

- The glue is easy to use. Welding for plastic allows you to repair almost any item made of this material without the need for heat. The use of welding is possible at home, since you do not need welding equipment or additional knowledge.

- Suitable for joining complex, fire and explosive structures.

- After welding, a sealed, waterproof, high-strength seam is obtained.

- The amount of waste is minimal.

- Affordable price and availability of glue in many construction stores.

- It does not require electricity to operate, so it can be used even in field conditions.

- Good elasticity. The composition can connect parts subject to vibration loads, shear or rupture.

- Withstands high temperatures. Universal mixtures – up to +260 °C, specialized – up to +1000 °C.

The consistency is:

- Liquid welding. Packaged in vials, bottles or boxes.

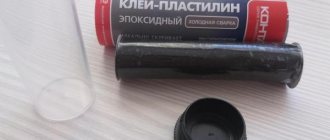

- Plasticine. Available in the form of an adhesive stick, cylindrical rod or tube. The outer layer is a hardener, and the inner layer is epoxy. To use the product, you need to cut off a piece of the tube, knead it with your fingers until you obtain a solid, homogeneous mass and apply it to the prepared surface.

The composition of the plastic welding agent is:

- One-component. This liquid product has a consistency similar to office glue. It is used to connect small parts because it has weak adhesive ability.

- Two-component. A more reliable solution. It consists of resin and hardener, which are mixed in equal proportions before use. Once the components are connected and a reaction begins between them, the user only has a few minutes to glue the plastic together.

Details

Advantages of liquid welding

During the process of joining parts, no heating will occur. The chemical process is taken as the basis, or rather, the adhesive composition begins to seep into the surfaces being joined, and after some time, hardens, thereby creating a monolithic seam. To carry out such work there is no need for expensive equipment and lengthy training. Successfully used in construction and industry, liquid welding for plastic products once found a niche in everyday life. Thanks to its incredible properties, its popularity, as well as its versatility and fast bonding, is growing every day.

We propose to consider some of the reasons due to which the popularity of the cold welding method will continue to grow:

It can always be found in special shopping centers, as well as in stores at affordable prices.- There is no need to have special skills or knowledge to apply.

- There is no requirement for equipment that runs on electricity in the field.

- Parts of the remaining structures and buildings can be connected even though they will be subject to shear or rupture.

- Cold welding for plastic is perfect for working on almost all types of material.

One of the main advantages, along with the strength of the connection, is the absence of heating during operation, ease of use where special skills are not required, as well as the ability to carry out repairs on devices that have a high level of vibration from heavy loads. Moreover, the adhesive composition for plastic has an attractive cost, and welding, which does not require high temperatures, plays an incredibly important role during installation or repair, and especially if such work is carried out in a room with a high degree of explosion hazard.

Varieties and classification

Cold welding can be of two types - two-component and one-component. But according to its consistency, welding can be divided into plasticine-like and liquid. The latter contain a hardener and glue, and before direct use, both components should be thoroughly mixed. Plasticine-like ones can be either one-component or two-component. If the composition is of the second type, then the components will be mashed and mixed, which will cause a chemical reaction between them.

On the counter these days, cold welding can be found in three varieties:

- In the form of a tube, the inner part of which is epoxy resin, and the outer part plays the role of a hardener. The way to work with such welding is to cut a small piece from the tube and start kneading it in your hands until you get a soft and homogeneous mass that is very reminiscent of plasticine. The homogeneity of a substance can be judged by the uniformity of color.

- Two-component mixtures - filler and resin are in different containers, and before work they should be mixed until a homogeneous composition is obtained.

- One-component - the composition will be immediately ready for use, and in appearance it strongly resembles a regular stationery adhesive composition. It can be considered universal because it is most used in everyday life, and it can also glue almost all types of plastics.

To speak about the area of application, or more precisely about the purpose, welding can be universal or highly specialized, dedicated to a specific material. For special welds, the strength will be much higher than for universal ones, but before starting work you will need to make sure what specific materials it is intended for, because otherwise the product may not give the expected effect. For example, gluing metal parts with a compound intended for plastic or wood will be completely ineffective. Most users are very interested in the temperature conditions that the adhesive composition can withstand. As a rule, all the information is indicated on the packaging, and usually for inexpensive universal products this indicator is approximately 2600 degrees, and for highly specialized expensive formulations this parameter will be 4 or even 5 times higher.

Instructions for use

The most important task before using the product is to thoroughly familiarize yourself with the safety measures.

- You will need to protect your eyes from getting the adhesive composition underneath, and also avoid getting it on open areas of the skin. For this reason, you will need to wear protective gloves and goggles before starting work.

- Keep the tube with cold welding on plastic away from animals and children.

- The product should be stored in a dark place.

- Please note that the adhesive composition should be as far as possible from food.

Please note that if you suddenly find that the composition inside the tube has become very hard, this can easily be eliminated by heating for 1/3 hour. For example, you can keep the tube in hot water to warm it up.

By the way, the cold welding process is extremely simple, and before gluing the surface on which the composition will be applied, everything should be treated with sandpaper to increase the degree of roughness, which will greatly influence the adhesion parameters of the plastic. Next, you should degrease such surfaces, and any solution containing alcohol is perfect for this. Cold welding will be distributed over the surface of the product, to which the second plastic part should be pressed. Within four minutes, the products will begin to adhere to each other, and after 15 minutes they will be completely connected with the required strength.

Selection rules

When choosing adhesive for plastic, you need to pay attention to the following criteria:

- Operating temperature. If the item will be used in extreme conditions, the adhesive seam must withstand both high and low temperatures.

- Permissible pressure on the seam. The indicator is indicated on the packaging by the manufacturer. If the glued plastic is subjected to higher loads than allowed by the instructions, the connection will break.

- Freezing time. If the item needs to be repaired for a long time, the gluing mixture must have a long hardening time. For gluing small parts, 3-5 minutes per coupling is enough.

- Release form. For gluing thin plastic elements, it is better to use a liquid substance, and it is more convenient to carry out rough work using thick plasticine-like welds.

How to use

To obtain a strong connection using cold welding, you must follow the basic rules for using this product. Exact instructions for use are usually included with the purchased product. The generalized algorithm for connecting two metal parts is as follows:

- Clean the surfaces of parts from dirt, rust and scale..

- Degrease clean surfaces.

- Put rubber gloves on your hands.

- Unfold the wrapper and cut off a piece of the bar (rod).

- Wet your fingers with water and thoroughly knead a two-layer piece of the mixture..

- Apply the resulting mass to the surfaces to be joined and compress them..

- Maintain fixation for 15-20 minutes.

- Complete hardening occurs within 1 hour to 24 hours..

- After complete hardening, sand the seam and paint if necessary.

Suitable brands

- Poxipol. A two-component compound that resists shear and tear stress. Retains plasticity for 10 minutes, primary hardening occurs after 1 hour, and complete hardening occurs after 24 hours.

- EDP. Can be used at temperatures of +20…+25 °C, and the temperature at which the created seam retains its characteristics is -60…+150 °C. The polymerization time of the composition is 30-60 minutes.

- H.G. Can even be used underwater. It can be used to weld oil surfaces. Primary adhesion occurs in 5 minutes, the polymerization process takes place in 15 minutes, the seam acquires full strength in 1 hour. The resulting connection can withstand temperatures up to +204 °C.

- EP380. Dries in 4 minutes and hardens in 15 minutes. The seam can be operated at +93 °C. Packaged in 14 ml containers.

Other brands that are especially popular are:

Instructions for use of cold welding for plastics

Cold welding adhesive for plastic has become indispensable in construction and repair. The convenience is that you don’t need any special equipment or skills for the job. High adhesive strength, can easily compete with other compounds. The advantage of cold welding is the absence of thermal effects on the plastic. The density of the treated surface is not of key importance and does not affect the quality of the connection.

Advantages and disadvantages

The main advantage of such products is that they can repair plastic of any size. In addition to this, restoration work does not require welding equipment, special welding courses, etc.

In addition, the parts themselves do not require complex and lengthy preliminary preparation before proceeding with their surface.

In addition to these significant advantages, cold welding has other strengths. They are:

- Large selection of different brands.

- Reasonable price tag for adhesives.

- The composition can be used at high temperatures.

- Almost all mixtures are not afraid of moisture.

- The result is a tight and reliable connection.

- Fast setting.

- Can be used for those elements that are subject to vibrations and various mechanical influences.

However, the adhesive also has disadvantages. The most significant disadvantage is considered to be that the coupling point most likely will not withstand high pressure.

Application area

The rapid development of industry using plastic materials has provoked the popularity of cold welding adhesive.

Main areas of use:

- Repair of plastic casings of technical products;

- Alignment and gluing of car body parts;

- Repair of fishing gear;

- Setting up sewer systems;

- Connecting plastic parts and assemblies.

Cold welding adhesive is used not only for joining plastic, it also firmly connects metal structures, wood, and other materials.

Safety measures and conservation rules.

Before you start working with cold welding, it always makes sense to carefully read the safety precautions. Just to protect yourself from the negative effects of the glue components.

- Cold welding should not be used to repair food contact surfaces.

- When working, it is recommended to protect your hands with thick gloves. They prevent resin from getting on your skin and prevent time-consuming cleanup.

- At the end of work, after removing gloves, you should thoroughly wash your hands under running water.

- If glue accidentally comes into contact with your skin or eyes, rinse immediately.

- Storage of “cold welding” must be carried out according to the rules indicated on the packaging, otherwise the composition will lose its original qualities. The glue should be kept out of the reach of children.

As you can see, the requirements are elementary and easy to fulfill.

Types of cold welding for plastics

Manufacturers of this plastic gluing technique offer several types of cold welding for plastic:

- A one-component composition, capable of gluing any type of plastic. It has the consistency of regular office glue. Often used in everyday life, it is considered universal.

- Two-component. The name itself speaks for itself; it consists of resin and filler. For use, mix in equal parts.

- Rod, produced in the form of a pencil with internal filler. Before use, it requires additional kneading until it becomes a homogeneous substance.

Based on consistency, they are divided into liquid and plasticine-like. They are used depending on the complexity of the work and the thickness of the weld.

Cold Welding Selection

Various manufacturers offer a wide range of this product. The choice of composition must be approached with special care, taking into account all the parameters of the materials being glued.

- Temperature regime . When planning work under high thermal conditions, it is important to clarify the maximum temperature conditions that the glue will withstand. Standard - 200-260 degrees, depending on the brand. If you do not pay attention to the characteristics of the composition, malfunctions in the operation of the elements being repaired are possible.

- Maximum loads . Assume acceptable standards of pressure force after using cold welding. Shear and tear data will help you avoid poor-quality connections and make the seams very strong.

- Drying speed . For long-term repairs, slow-cooling adhesives are suitable - about 1 hour, and for quick repairs, cold welding of instant gluing is used - 3-10 minutes.

- Consistency . Using a liquid composition, it is convenient to glue thin parts and the body of any equipment. Plasticine-shaped, designed for rougher work, leveling bumper surfaces, connecting heating and sewer systems, and rain drains.

Separately about specific cases

There are always difficult cases that you definitely need to know about. Below are a few of these situations and how to deal with them correctly.

PVC pipes

Heating structures or pipes through which water runs are often damaged. If they are made of plastic, they can be repaired using cold welding.

In such cases, manipulations to restore products occur as follows:

- Remove all debris, moisture, etc. from the surface, thereby preparing the coating for further work.

- Calculate how much the edge deviates. If the pipe structure has a diameter of 4 millimeters, then this deviation should not be more than 2 millimeters.

- Apply dry adhesive to the damaged area. Secure the product with a special tourniquet.

This technique allows you to eliminate the leak only for a certain period of time. In addition to this, the method only works when everything was done correctly.

Typically, the method is used as a temporary repair to delay the replacement of pipes for some time.

Floor linoleum

This fabric can be glued using cold welding. In this case, the algorithm of actions is as follows:

- Lay the pieces of the canvas so that they overlap by about 10 centimeters. Both elements are cut using a knife and a metal ruler.

- Next, you should remove the remnants of the canvases that were cut off.

- Peel back the linoleum. Here you will need tape that sticks on both sides, as well as a partner, with whom it will be easier to work. The product is glued to the floor, after which linoleum is laid on top.

- Roll over the surface several times with a roller.

- Wipe and dry the joints. Apply masking tape to the joints and also roll over it with a roller.

- Cut the tape at the joint to make it easier to apply the glue.

- Apply adhesive solution to the connecting parts. This must be done carefully so that the composition does not get on the surface of the linoleum.

- Peel off the masking tape after 20 minutes.

If the composition is sufficiently thick, then all manipulations can be carried out without adhesive tape.

Instructions for use

The durability and quality of bonding depends on proper preparation of surfaces. Instructions for use are written step-by-step by the manufacturer on the box or tube. To avoid skin damage, it is recommended to wear gloves. The execution sequence affects the quality of further work of the glued element.

Before applying cold welding, you need to rub the area of the damaged surface with fine sandpaper or a file. Degrease the area with solvent or acetone. Failure to do this procedure may cause a rupture.

Quickly apply a small layer of glue. The remaining composition cannot be reused, so first calculate the required amount. After application, you will need a tourniquet or a press for strength. After a few hours, the tourniquet or press can be removed and further work can be carried out.

The temperature conditions indoors or outdoors affect the welding time. The higher it is, the faster the material will dry.

Kinds

Depending on the consistency, the cholesterol may take the form of a liquid or a soft bar (like plasticine).

The choice of one type of welding or another depends on the place of its application. For example, liquid welding is used to restore threads, as well as, if metal or fabric reinforcement of a seam is necessary. In many other cases, soft-bar welding is preferable.

In liquid form

A cold welding kit in liquid form usually consists of two tubes - one of them contains a solution of epoxy resin with fillers, and the other contains a hardener. Before use, an equal amount of resin and hardener is squeezed out of each syringe or tube, which is then thoroughly mixed. The resulting solution is applied to the parts to be glued.

Plasticine-shaped (in the form of a bar)

Plasticine-shaped cold welding usually takes the form of a two-layer bar or cylinder. The cylinder consists of two layers. The top layer (shell) is usually darker in color and consists of epoxy resin. The inner core is the hardener. The core also contains metal dust, which reinforces the composition and increases its resistance to temperature and mechanical influences.

Before use, the required piece of two-layer paste is cut from the bar, which is then thoroughly kneaded and applied to the desired location.

The time when the composition retains plasticity is quite short. Therefore, the gluing operation must be carried out quickly.

By purpose

According to their intended purpose, cold welding compositions are:

- Specialized.

- Universal.

Compositions of the first type can be intended for gluing specific materials:

- metal;

- plastic;

- linoleum;

- concrete.

Universal welding has a composition that is suitable for working with any material. However, the quality of universal welding is inferior to the quality of welding intended specifically for a given material.

Cold welding for metal is widely used in industry and in everyday life. At the household level, this glue is used to repair plumbing fixtures, heating radiators, and cars.

Approximate cost of cold welding for metal on Yandex.market

For plumbing repairs, there is a special subgroup of cold welding that does not react to the presence of moisture. After hardening, the composition almost does not react to heat.

Using cold welding, a motorist can urgently repair a radiator or cylinder head so that they can get to a workshop. Such repairs are usually temporary, since the product cannot withstand mechanical stress and vibration for long.

When repairing metal products, it is necessary to take into account the type of material from which the structure is made and select the appropriate welding grade. Depending on the type of material for which the welding grade is designed, the appropriate filler is added to it. For example, for welding steel, iron powder is used as a filler, and for welding aluminum, aluminum powder is used.

Cold welding for plastic is not as popular as welding for metal. However, it is also often used, for example, for repairing polyethylene pipes.

Approximate cost of cold welding for plastic on Yandex.market

When repairing floors, welding is sometimes used for linoleum. Its use allows you to quickly attach linoleum to the floor. The quality of such repairs is significantly superior to the use of double-sided tape or liquid glue.

Approximate cost of cold welding for linoleum on Yandex.market

Welding for concrete allows you to fix a part to a concrete wall without drilling. But concrete is highly hygroscopic, which sometimes prevents the creation of good fastening.

Approximate cost of cold welding for concrete on Yandex.market

More often, such welding is used to connect fragments when restoring damaged monuments or concrete statues.

Useful tips

If contact with skin occurs while welding, it is necessary to immediately soap the area and rinse with cold water. Oil or any cream will help soften a possible burn.

The composition should be stored in a cool, dry place, out of direct sunlight; it hardens quickly in warm conditions. When drying or hardening, heat on any warm surface for half an hour.

To get a quick effect, exposing the area to be bonded with hot air, such as a hairdryer, will help.

When purchasing a product from an unknown manufacturer, study the composition and expiration date.

Cold welding adhesive for plastic, an indispensable product. It has a wide range of uses both in everyday life and on construction sites. Due to its high strength and ease of use, it is used in gluing plumbing fixtures, repairing bumpers, and any plastic products with different characteristics.

Selection and application of cold welding for plastic

Do not throw away plastic products if they break or crack. Cold welding for plastic will help return it to its original condition. In this case, nothing needs to be heated; the connection will occur due to the complex chemical composition of the mass.

Where to store and what is the composition of the fastening material?

First of all, cold welding comes in different degrees of thickness: pasty and liquid. Based on the nature of the action, they are divided into one- and two-component ones. The composition of glue for plastic includes the following components :

- Epoxy resin. The basic element of glue, which is responsible for the uniformity and plasticity of the working mass.

- Metal or mineral filler. An important component that gives strength during polymerization. Thanks to the metal component, the composition is called “cold welding” - the appearance of the joint resembles a weld seam from manual arc welding.

- Fillers. The most common element is sulfur. The composition also includes other components responsible for product quality. Manufacturers keep them secret.

Manufacturers recommend storing cold welding in a dark and dry place out of reach of children and animals.

The optimal storage temperature depends on the manufacturer. If the product has dried during storage, you can try heating it at a temperature of 60-70 Cº. If the external properties of the product have not been restored within half an hour, it is not suitable for use.

Types of cold welding for plastics

In terms of viscosity, the product is liquid, plasticine-like. The composition is produced in one-component or two-component form. Thus, the material is produced:

- In the tube version, the outer layer of which is a hardener, the inner layer is epoxy mastic. The method of application is as follows: a small piece is cut from the tube, the size of which will cover the surface to be repaired, then the mass is kneaded by hand until soft and homogeneous.

- In the two-component version, fillers and resins are produced in different containers. To obtain a working composition, they are mixed in equal proportions.

- Liquid welding for plastic is one-component, the consistency is similar to silicate glue. It is used to connect small, lightweight structures, as it does not have powerful properties. At home it is used as a universal adhesive.

How to weld any plastic product at home?

Welding has long been widely used in industry, construction and everyday life. One of the most interesting inventions of man is cold welding for plastic; in everyday life, this invention greatly facilitates the repair of any household items. The invention of cold welding is a huge step forward in the field of repairing plastic products.

One of the most useful properties of cold welding is the ability to effortlessly glue a broken piece, seal a crack, and much more. At the same time, the joint is equivalent to plastic in strength and solidity. Thanks to these properties, many household items, after being repaired using cold welding, seem to be reborn and take on a new life, as their owners change their minds about throwing them away.

- Where is it used?

- Advantages of liquid welding

- What types are there?

- Instructions for use

- Useful tips

Suitable brands and selection rules

Cold welding for plastics is subject to less stringent conditions than welding for metal materials. The following brands have won leadership positions in the market:

- Poxipol is a two-component universal compound used for joining parts of different structures. Produced in two tubes contained in a cardboard package. Suitable for outdoor use at low temperatures. But such conditions affect the hardening period.

The mass can be applied in varying thicknesses. At the same time, cold welding will not spread or wrinkle.

The composition does not contain solvents, so it is safe for the body and is used in residential areas. Application requires careful cleaning of the bonded surfaces.

- Tytan is a cold welding, the base of which consists of epoxy resin with the addition of hardeners and plasticizers. Thanks to them, the hardening time is reduced to half an hour. The part can be put into operation within an hour. The operating temperature is -60 - +130 degrees, so Titanium welding is used for emergency repairs of devices and mechanisms that are designed to operate at elevated temperatures. Waterproof composition.

- Mastix is a multicomponent composition consisting of epoxy polymer, plasticizer, filler, and hardeners. When applying a thin layer, hardening occurs in 7 minutes. Operating temperature -60 - +200 degrees. It efficiently glues not only plastic, but also metal elements.

Cold welding grades Moment Super Epoxy, Skol, Almaz, Secunda are also widely used.

When choosing a material, attention is paid to the operating temperature so that the weld can withstand bonding. If the work is intended to last for a long period of time, then it is better to buy a composition with a quick, strong setting, which will significantly reduce repair work.

“Cold welding” as a technology for joining linoleum sheets.

Almost every homeowner has at least once encountered linoleum flooring. Unfortunately, it is not always possible to purchase the material for the external design of a vending machine, but the required length and width.

And therefore, when paving, it becomes necessary to join two screens.

To solve this problem, two main methods are used today - the use of diffuse “hot” welding of adjacent plates, for which a special tool is used, or “cold welding” using a liquid chemical composition. Available for sale in tubes with special attachments. In this case, the gluing “mechanism” differs from what we saw above. A special organic composition penetrates the structure of the linoleum coating and causes chemical melting of its edges, followed by mutual diffusion and hardening. As a result, after complete polymerization, a strong joint with a uniform, sealed seam is obtained.

The sale includes “cold welding” of linoleum or other polyvinyl chloride (PVC) products from domestic and foreign manufacturers. However, single-component Tarkett preparations, presented in three types, have gained particular popularity. This material has already been briefly mentioned above and will now be discussed in more detail. Each type of such glue is designed for a certain width of the joint between the floor sheets. And in this regard, each of them is equipped with a special nozzle for supplying the composition to the gluing line.

| Type “A” has a liquid consistency and a tip in the form of a durable steel needle (somewhat reminiscent of a medical syringe needle). Thanks to this device, using such “cold welding” it is convenient to join sheets of linoleum to obtain a minimum seam thickness of less than 2 mm. The consumption of the package of this composition is calculated for a seam length of 20 meters. | |

| Type "C" is a thicker compound and is best used for seams larger than 2mm. The tube of this "cold joint" has a wider tubular nozzle through which the thick mass flows easily into the joint. In addition to joining two sheets of flooring together, adhesive is used to repair damaged areas of the material. The consumption of one package of glue is calculated for a seam length of 15 meters. | |

| Type “T” is the thickest in consistency (even thicker than type “C”). A pipe with such a “cold seam” is equipped with a T-shaped nozzle. This kit is designed for the chemical fusion of two sheets of PVC linoleum on a felt or polyester base. The consumption of one package of this composition is calculated for a seam length of up to 7 meters. |

Thus, cold welding can be called a unique universal material that can solve a large number of problems. However, it should not be forgotten that for the repair of some functional products, glue can only be used as a temporary measure, only to “survive” until they are replaced or overhauled. Therefore, after repairing, for example, a heating battery at home, a cooling radiator or a fuel tank in a car, you should also carefully monitor the tightness of the patch and do not forget about the need for more radical measures.

How to use welding

When performing work, you must follow the instructions for cold welding for plastic. It provides the proportions for mixing the base with hardeners. The quality of adhesion depends on proper mixing.

The mixture should be applied to a thoroughly cleaned surface. Step by step use:

- Mixing resin with components. The amount of kneaded mass should cover the glued area.

- Carry out a thorough warm-up of the mass.

Kneading is carried out using moistened, thick rubber gloves.

- When the mass has acquired a brown tint, it is applied to the area to be glued.

- The elements are connected and fixed.

- After 4 minutes setting will occur, after 15 minutes it will be firmly attached.

Safety of use

After hardening, the adhesive seam is absolutely harmless to humans, but you should follow safety precautions when working with it.

- Avoid contact with skin; wear thick clothing and gloves.

- Work only in personal protective equipment - masks, respirators.

- In the room where plastics are bonded, high-quality ventilation or at least ventilation must be provided.

- The mixture for welding is combined only in those containers that will not subsequently come into contact with food and drinking water.

- Any adhesive that gets on your skin should be washed off immediately with soap and water. You can soften the injured area of skin with vegetable oil or rich cream.

- If the product gets on mucous membranes, in particular the eyes, it is recommended to immediately rinse them with water and consult a doctor.

Security measures

Cold welding for plastic does not contain solvents or other toxic compounds, so the seams after drying are absolutely safe for people.

Carrying out work requires compliance with safety measures:

- Do not allow the mixture to come into contact with exposed skin. Use IZ means.

- Work is carried out in well-ventilated areas with proper ventilation.

- Welding seams should not come into contact with food.

- If the mass gets on the skin or mucous membranes, immediate rinsing with water is required; in severe cases, consult a doctor.

- When working, it is unacceptable to leave the material in a place exposed to direct sunlight.

Useful recommendations from leading experts

Choosing the most suitable brand of product is quite difficult due to the incredible variety of adhesive compositions in the form of cold welding, and it is very difficult to list all types. To make the right choice, you should start from the technical characteristics of the product. If you plan to use high-temperature welding, it is advisable to know this characteristic in advance. Sometimes it is even less than that of plastic, and this can greatly deteriorate the quality of work in the future.

So, let's look at useful recommendations for using plastic:

In order for the final result to be as good as possible, it is necessary to slightly warm up the plastic surfaces to be joined.- The second point follows from the first point, or rather, what you should remember about the following rule is that the higher the temperature, the faster the cold weld will harden, and because of this, the strength of the weld may be reduced. For this reason, before heating everything, it is recommended to think about how this will all be done. For example, using a hairdryer for this would not be a good idea.

- In the case when all the parts that you plan to connect to each other are subject to a high degree of vibration, you should think about the fact that they need to be replaced with new ones. The fact is that there is a high probability that cold welding will not be able to withstand such loads. In addition, it is important to carefully approach the selection of the product, for example, use not a universal adhesive-sealant, but a specialized one that can withstand strong vibrations.

- In addition, such a characteristic as the appearance of the welded joint will not be in the last place, because sometimes this can ruin the entire appearance. In this case, as in the third point, it may make sense to think about installing all new parts.

- Through cold welding, you can carry out repair work on a wet surface, but this will require the use of a special composition that is not universal. This way, you can eliminate leaks in plastic pipes through which water moves under low pressure. But here you should remember that such welding will only be a temporary solution to the problem.

- If we are talking about repairing a pipeline or even highways that are made of plastic pipes, then a reasonable solution would be to use a composition that can withstand constant contact with water.

- If the welding begins to harden strongly, then before using it you should warm it up slightly, and for this you can use a hairdryer, or simply put the tube on the radiator/in direct sunlight, and 1/3 of an hour will be enough.

It will be equally important before purchasing to study the label on the packaging of cold welding plastic, which indicates the composition, date and instructions on how to work with them. Thus, you can conclude that cold welding is an ideal material that will help connect plastic parts without problems in our time. The process will be simple, the composition itself will be relatively inexpensive, but the most important thing is that when working with cold welding, you must comply with all the manufacturer’s requirements, which are specified in the instructions.

Expert advice

Experts recommend performing plastic repairs with extreme precision and reliability when correcting problems with pipes. This process requires a water-resistant mixture that will withstand constant exposure to liquids. The surfaces must be dried before application, which will increase adhesion. When repairing a leak in a plastic water pipe, you need to understand that this repair is temporary and you need to think about a major repair of the breakdown.

If the part to be glued is constantly exposed to vibration, then an additional pad should be applied to the joint.

You should not buy material that has expired. This will significantly reduce the performance of the seam on plastic.

We recommend watching the video:

Instructions for use

Yandex.RTB RA-1479455-3

This substance must be used in accordance with the manufacturer's recommendations, which are shown in the instructions. It is quite simple to use, so it is possible to connect even cracked glass. For these purposes, colorless welding is available.

To make a reliable seam, you must correctly follow the following rules:

- Preparation. It is recommended to free the work surface from dirt and remove large protrusions. It is better to pre-dry wet parts if possible. It is necessary to degrease the parts. This is a very significant stage, which guarantees the utmost quality of the connection.

- Next you need to prepare the composition. Liquid adhesive must be combined with a hardener, and dry welding must be mixed until smooth. When mixing, use disposable gloves pre-moistened with a small amount of water.

- After preparing the consistency, you need to quickly apply it.

- After painstakingly connecting the components, it is necessary to level the plane. After complete drying, you can further clean the seam.

Such a simple technique can become indispensable in everyday use, which, if the instructions are followed, is not inferior to classical welding methods.