A welding electrode is a rod made of metal or other material that conducts electricity. It is designed to conduct current to the workpiece being welded. Today there are many different types of them. Most of the products on the market are required for manual arc welding.

There are two types of welding electrodes: consumable and non-consumable. The latter are made from a refractory material (tungsten). Meltable ones are made from welding wire. A special coating is applied to the metal rod to protect it from atmospheric pressure.

Differences between welding electrodes

Electrodes have many differences depending on the brand and subspecies to which they belong. This tool is suitable for welding steels with a carbon content of up to 1/4 percent. They are also used when welding low-alloy steel. The difference between the electrodes is visible in many parameters, for example, in the tendency to pore formation, in the way the weld seam is located or in what its surface is covered with: basic, cellulose, etc.

In this article we will consider the features and possible differences between rutile MR electrodes and rods with the main coating -UONI.

Description and technical characteristics of welding electrodes ANO-21

ANO-21 electrodes are popular among both professional welders and amateurs. They are easy to work with, they do not require special skills from the worker, but provide strong and durable seams. Electrodes of the ANO-21 brand are suitable for all welding positions and welding directions (including vertically from top to bottom), and provide minimal splashing of molten metal. Balanced for operation with direct and reverse polarity, as well as alternating current.

- Technical specifications

- Advantages and disadvantages

- Areas of application

- Chemical composition

- Features of work

- Labeling and manufacturers

- Technological features of welding

- Comparison with others

- With LEZ MP3-S and LEZ UONI 13/55

- S Monolit RC

- MR-3S (SZSM) and ANO-21 (Tigarbo, KOMZ)

- Conclusion

MR electrodes

This type of equipment is used when joining carbon steels. For example, MP-3 is often used if it is necessary to carry out installation work on a critical structure. MR electrodes differ from SSNI in that they can be used to weld in conditions of high humidity. Even rusty and poorly purified metals are sold for welding. Long arc welding is possible.

The most popular brand of this type is MP-3 electrodes. With them it is possible to install critical structures, as they guarantee a very reliable seam. They can be used when working with connections made of carbon steel and low-alloy steel. It is possible to work with any current with reverse polarity. Welding can be done in any position, excluding vertical.

We recommend! Technical characteristics of welding electrodes ANO-4

The area in which MR electrodes are most often used is the welding of pipelines supplying hot water or steam, as well as pipes carrying oil and fuel oil. Electrodes of this group can be used for welding, which is provided by conventional household welding current sources.

UONI or rutile (MP3, ANO-21, OK 46 ESAB, OZS) - what is the difference

All brands of the listed electrodes are the same in application - they are used for welding carbon and low-alloy steels, widely used in industry and everyday life. The difference between SSSI and their rutile counterparts is the manufacturability of the welding process and the technical parameters of the connection .

If there is a need to repair or install by welding the frames of homemade equipment (circular saw, pipe bender and other similar devices), the horizontal bar on which you are going to spin the “sun,” then it is better to use electrodes with a basic coating. Welding seams made with these consumables guarantee more reliable and safe operation of these devices than using technology with rutile consumables.

If you do not have the skill to work with consumables with a basic coating, there are many welding jobs using rutile electrodes. The ease of initial and re-ignition of the arc, the absence of the need to control its length, gives beginners the opportunity to experience belonging to a contingent of people who know welding. At the same time, unlike consumables with a basic coating, there is no need to clean the welded edges from rust, coating residues and other contaminants. In a private house, it is sometimes necessary to repair leaking pipelines - the presence of moisture is not an obstacle to repair welding work using rutile consumables. It is better for beginners to weld thin-walled workpieces such as, for example, profile pipes with rutile electrodes.

SSSI electrodes

This type of welding equipment is used in circumstances where the structure being welded must be as shockproof as possible. They are used for the installation of very important structures, since when they are used, the welds are of high quality and ductility.

One of the main advantages of SSSI is that the welds obtained during the work process can withstand very low temperatures (down to -40).

Welding work can be carried out in various positions. All representatives of this species are distinguished by the presence of a base coating. The most commonly used are SSSI 13/45 and SSSI 13/55.

UONI 13/55 is applicable for installation work on structures that require the ability to withstand high dynamic loads. They are also used to produce seams that are resistant to low temperatures. UONI 13/55 can weld thick metals together. Their use is possible in the construction of ships and the installation of tanks and vessels under high pressure.

UONI 13/45 is used for working in cold weather. When working with them, it is necessary to take into account that the surfaces for welding must be very well prepared: cleaned of oils and other contaminants.

Selecting welding electrodes for steel: comparison of the main brands

Often, it is difficult for a person who is far from welding or just starting to master this industry to understand the features of using different brands of welding electrodes.

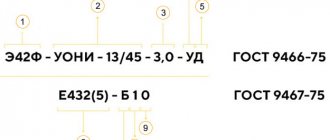

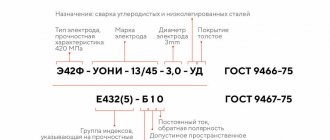

We hope this article will help you sort out information about the main brands of electrodes used for welding steel structures and help you decide on your choice. This article will discuss the features of the following brands of electrodes: MP-3, MP-3C, UONI-13/45, UONI-13/55, OZS-4, OZS-12, ANO-4, ANO-21 and OK-46. The classification of welded electrodes is based on state standards 9466-75, 9467-75, 10051-75, and regulatory international documents DIN 8555, EN 499. Some of the most common electrodes in the national economy and industry are: MP-3, MP-3C, UONI -13/45, UONI-13/55, OZS-4, OZS-12, ANO-4, ANO-21, OK-46. They are used for welding structural low-alloy carbon steels. Provides high strength of welded joints. The choice of a specific electrode depends on the welding method, operating conditions and the specific type of metal.

Detailed characteristics of OZS-12 and OZS-4

If the metal being joined contains carbon in an amount of no more than 0.25%, and the production technology involves creating a weld of increased strength, then OZS-4 and OZS-12 rutile rods are used. They are suitable for welding with alternating current and under any spatial position. Tensile strength reaches 450 MPa.

Rutile electrodes are especially actively used in joining profile and sheet materials, in welding containers, building structures and pipelines. The process of weld formation is very easy, the rods interact with the steel even at extremely low currents. If their diameter is small, then welding can be carried out from a regular network into which household appliances are connected.

OZS-4 and OZS-12 can be used when welding with an extended arc. They form a small slag crust, which can be easily and quickly removed. There is no tendency to cracking or the formation of deep foreign inclusions. Before work, the OZS-4 rod must be calcined at a temperature of 120-160 degrees Celsius. Rod OZS-12 - at a temperature of 150-180 degrees Celsius.

The treated area must first be cleaned of debris and small deposits. The presence of oxides on the metal surface is acceptable. If you follow the technology, the seam will turn out smooth and beautiful.

Low cost is one of the advantages of rutile electrodes. They can be successfully used to create T-joints. They can form a concave, finely scaly seam.

- Buy welding electrodes OZS-4

- Buy welding electrodes OZS-12

Detailed characteristics of UONI-13/45 and UONI-13/55

When special requirements for impact strength and ductility are imposed on the connecting weld, then UONI-13/45 and UONI-13/55 rods are used to create it. They are effective for arc welding at low temperatures. Work with them is possible due to direct current with reverse polarity. They can be used in any spatial position.

With the regular cyclic process of stretching and compressing metal, fatigue cracks form. This leads to rapid deformation and failure of the structure. The electrodes create a seam that is extremely resistant to such alternating loads. Also, it practically does not contain hydrogen components in its structure, and does not crack due to the formation of crystalline layers.

The coating material of the UONI-13/45 and UONI-13/55 rods, at high temperatures, turns into a melt, which displaces slag from the joint zone and prevents the formation of stress concentrates such as slag pits.

The tensile strength of the UONI-13/45 rod is 460 MPa, the UONI-13/55 rod is 540 MPa. Welding is performed only with a short arc. The pre-calcination time of the electrodes is 1-2 hours. The calcination temperature should be between 450 and 500 degrees Celsius.

- Catalog of electrodes UONI-13/45

- Catalog of electrodes UONI-13/55

Detailed description of MP-3 and MP-3C

Cellulose-rutile rods are used to join low carbon steels in critical and conventional structures. Seams can be created in any spatial position of the electrodes. They are smooth, of high quality and meet the increased requirements of regulatory documents. They can be welded to metal using alternating current or direct current with reverse polarity.

MP-3 and MP-3C are most often used in domestic conditions and do not require thorough cleaning of the edges of the metals being joined. Easily welds on wet, oxidized, dirty, dusty and rusty surfaces. Point connecting clamps are made from them when creating a steel structure. It is strictly forbidden to use rods for welding plumbing elements, pipes, containers and boilers.

The arc can be directed in any direction, the ignition of the electrodes occurs quickly, and there is no tendency to form slag pores and ulcers. If the metals being welded contain a large amount of carbon, the resulting weld does not recrystallize. Sensitivity to dampness is low. The slag crust formed as a result of welding is easily removed after cooling.

The tensile strength of the MP-3 is 490 MPa, the resistance of the MP-3C rod is 450 MPa. The first type of electrodes must be calcined at a temperature of 170-200 degrees Celsius, the second - at a temperature of 140 degrees Celsius. Calcination time – 1 hour. Both are welded using an extended arc and can be easily re-ignited. MP-3S differs from MP-3 in the presence of ionizing additives in the coating structure, which simplify the ignition process despite the connection to weak household electrical networks. Also, MP-3S provide more stable arc operation even at low voltage.

- Buy MP-3 electrodes

- Buy electrodes MP-3S (blue)

Description of the properties of ANO-4 and ANO-21

These are rutile-carbonate and rutile-cellulose rods used for welding metals with a thickness of 1 to 5 mm in any spatial position. Ideal for joining low-carbon products that are at an angle, parallel or overlapping relative to each other. Uses alternating or direct current with direct and reverse polarity.

The tensile strength of ANO-4 is 430 MPa, for ANO-21 this figure is 460 MPa. Their melting ability is extremely low. They allow welding of wet, oxidized, dusty and dirty surfaces. Before use, the rods must be calcined at a temperature of 140-180 degrees Celsius (for ANO-4) and 140-160 degrees Celsius (for ANO-21). The duration of the burning is half an hour.

The electrodes differ in their fast primary and re-ignition. Suitable for medium length arc welding. If vertical connections of metal products are made using the “top to bottom” method, then the rutile electrodes should be located in the so-called bisector plane. That is, at an angle of 40-70 degrees relative to the welded edge.

ANO-4 and ANO-21 do not create splashes during operation, provide excellent detachability of slag accumulations, have an optimal deposition coefficient, and form a high-quality and beautiful seam. They do not form crystals and pores in the root of the T-joint. Can be used at elevated welding conditions.

- Buy ANO-4

- Buy ANO-21

Characteristics of OK-46 electrodes

These are universal rutile-cellulose rods that provide high quality welds when welding low-carbon alloy metals. Quickly and easily ignite the first time and when used again. Using OK-46, spot clamps of steel structures are made. The reduced heat input of the electrode allows it to be used when connecting products with a large gap to each other. It is actively used for welding sheet products with galvanic coating.

The temperature calcination mode for OK-46 rods is 70-90 degrees Celsius, and the calcination duration is 60 minutes. At idle, the voltage is within 50V. The electrodes are insensitive to oxides, rust, dust and dirt. They can be used when welding from household electrical networks, since the arc burns stably. The yield strength of the OK-46 rod is 400 MPa, the deposition rate is 95%, and the tensile strength is 510 MPa.

The electrodes form a smooth and even seam. All slag is easily removed from the joint surface. The minimum current threshold allows them to be used for welding parts using the top-down method. Often found when connecting thin-sheet products, pipes and building structures.

- Buy welding electrodes OK-46

Summary table of the main indicators of electrodes

The current indicator directly depends on the diameter of the rod. Based on the data in this table, you can select electrodes for specific welding tasks.

Conclusion

If you need to carry out welding in domestic conditions without increased requirements for the quality of the seam and with little experience in welding work, then MP-3S electrodes are ideal for these tasks, which are easy to use, reasonable in price and suitable for most household tasks. If welding work is carried out with the aim of forming a high-quality connection with increased resistance to loads or is performed by professionals, then it is worth considering other electrodes with characteristics specific to a particular situation.

How do UONI electrodes differ from MR electrodes?

The main differences between the listed types can be identified:

| Electrode type | MR-3 | SSSI |

| Coverage type | Rutile | Basics |

| Type and polarity of current | Alternating and direct current of any polarity | Constant reverse polarity |

| Working conditions | It is not necessary to clean the surfaces before welding | Surface cleaning is required |

| Can work in wet conditions | The coating is sensitive to moisture |

We recommend! Technical characteristics of welding electrodes UONI 13/55

Thus, the difference between the electrodes of the UUSI and the MR is visible. Each of these types is individual and suitable for certain jobs. It’s up to you to decide which one to choose: UON or MP3, depending on your needs and goals.

Choosing electrodes: ANO or UONI?

When welding, you must always remember that the characteristics of the equipment used directly affect both the process of performing the work and the final result. The most popular and well-known electrodes are UONI and ANO. So why are they so in demand on the market and what are their fundamental differences, and what should be preferred for work? Here you can rely both on your own impressions and on the experience of professionals.

Professionals unanimously say that the SSSI is ideally suited for permanent use. They somewhat dislike the second type of equipment, despite the fact that ANO reduces the spattering of metals during the welding process to a minimum, and the seams after them are of excellent quality. It is thanks to this quality that they carry out welding work where they are entrusted with maximum responsibility and the slightest defect can lead to irreparable consequences. However, if you use ANO electrodes, then you should be prepared for this. That the workflow will slow down to some extent. This is due to the large amount of waste they leave behind. You will be forced to constantly clean surfaces of it, and, therefore, interrupt the work process.

If working time is valuable to you, then the welding process will go much faster with electrodes marked UUNI. Their main distinguishing feature is a kind of cleanliness of the seam. You will not be forced to interrupt work to clean the metal from the resulting slag, and therefore, if the scope of work is especially large, this will speed up its completion by an order of magnitude. However, it is worth remembering that such electrodes can only operate on direct current - this makes them less universal than ANO. The latter cope equally with their task both using direct and alternating current.

What to choose?

You can already notice that both of the most popular welding electrode markings on the market have both their disadvantages and advantages. You should focus only on your own feelings and professional skills. In addition, it is worth paying attention to the nature of the work for which the equipment is purchased. Professionals in their field, who are confident that the seams they make are in any case of the highest quality, as a rule, give their preference to SSSI - this saves their working time. If you do a very responsible job. But if you are not completely confident in your abilities, you should not choose this brand. It is better to do your work more slowly, but better.