ANO-21 electrodes: characteristics, decoding

Among the huge number of various electrode brands, ANO-21 electrodes are especially popular among both beginners and professionals. Such enormous popularity is not without reason, because ANO 21 electrodes can be welded in any spatial position and with any welding machine, be it a DC inverter or a transformer machine.

The main purpose of ANO-21 electrodes is welding of various structures made of low-alloy and carbon steels. You can also weld pipes with these electrodes; the only limitation is that electrodes of this brand are not intended for welding pipelines under pressure.

This article on the site about manual arc welding will discuss the main characteristics and application of ANO-21 electrodes.

Characteristics of ANO-21 electrodes

As mentioned above, the main application of ANO-21 electrodes was found in welding low-alloy and carbon steels. The electrodes discussed in this article can be used to cook in any position, metals of various thicknesses and even with an oxidized surface.

Technical characteristics of ANO-21 electrodes are as follows:

- Electrode diameter from 1 to 5 mm;

- The main coating is rutile;

- Recommended welding current - both alternating and direct current, of any polarity;

- Spatter coefficient - no more than 4%;

- Electrode consumption - 1.65 kg.

ANO-21 electrodes have an easily excited arc and stable combustion, which is why they have earned popularity among welders.

The interpretation of electrodes E46-ANO-21-d-UD looks like this:

- E46 - electrode type;

- ANO - brand of electrodes used;

- D—electrode diameter;

- U - for welding low-alloy and carbon steels;

- D - electrodes with a thick working coating;

- 43 is the time gap coefficient.

Advantages and disadvantages

Like any consumable material, ANO-21 welding electrodes have advantages and disadvantages. Let's start with the advantages:

- Available in the market and very popular;

- Low cost;

- Regardless of operating conditions, easy ignition of the arc is ensured;

- A light layer of slag is formed, which subsequently separates from the deposit without any problems during the control procedure;

- A sealed seam is created.

These advantages distinguish these electrodes from the line of consumables . But we should not forget about the disadvantages, including:

- Narrow scope of application;

- The coating is not reliable enough. Because of this, it is necessary to use additional fluxes and preparation of workpieces;

- The seams may not be strong enough, which is why they cannot withstand serious pressure and loads;

- Working with workpieces of significant thickness is unprofitable, since the result is a poor-quality seam.

We figured out the advantages and disadvantages of this consumable. But most of the disadvantages can be avoided if you use electrodes in a specific area and do not try for structures of significant thickness. And additional parts are relatively inexpensive and can be supplied to ensure the strength of the electrodes.

Electrodes ANO-21 - reviews

In general, ANO-21 electrodes received positive reviews from both professional welders and newcomers to electric welding:

Welder Sergey from Samara : I always use ANO-21 brand electrodes in everyday life. What can I say, along with a reasonable price, quality and stability during welding are guaranteed. The slag flies off completely and quickly, the welding seam is smooth and neat, especially if you weld with an inverter using direct current.

Welder Vasily Petrov : ANO-21 electrodes work for me even on a homemade welding machine. What cannot be taken away from this brand of electrodes is “omnivorousness”. Only positive emotions from use.

Welder Alexander from Moscow : my experience of using ANO-21 electrodes turned out to be extremely negative. I purchased 3 mm electrodes under the Tigarbo brand, so while I was cooking, I didn’t give a damn. Not only does the weld seam form bubbles, but also metal mixed with slag comes out. The only plus is easy ignition of the electrodes and stable arc burning. I recommend using ANO 21 electrodes only for household needs.

Share on social networks

Selection criteria

Unfortunately, Russian electrodes are inferior to many foreign analogues in most parameters. However, “breakthroughs” in this area have already emerged. Russian electrode products, produced at the still few joint ventures, are no longer inferior to many venerable brands in terms of quality stability. Some factories of domestic subordination also began to “catch up” to them. However, in cases where it is necessary to confidently ensure high quality of the seam, professionals still prefer to use more expensive, but also higher quality, foreign-made electrodes. Electrodes of any type are suitable for welding inverters; not all types are suitable for AC welding machines.

When selecting the best electrodes for review, we were guided by the following criteria:

- production volumes;

- product quality;

- the manufacturer's inclusion in reviews of the electrode industry;

- reviews from professionals.

For a fair comparison of prices, we included in the review only the most commonly used electrodes with a diameter of 3 mm.

The main parameter of any welding electrode, which determines most of its properties - from ease of ignition to the quality of the seam - is the composition of its coating. The most common types of coatings today are:

- Rutile electrodes (and electrodes with a mixed coating on this basis - rutile-cellulose and so on) have become one of the most popular due to their ease of ignition, including re-ignition, and reduced (within reasonable limits) sensitivity to dampness. They can be used on both alternating and direct current in all directions of the seam, but when choosing a rutile electrode you need to be careful - you can buy both a good electrode and one that contaminates the seam with a huge number of slag pits, suitable only for tack welding.

- Basic coated electrodes are most often used for DC welding in critical areas. When the coating burns, carbon dioxide is released in large quantities, which reliably protects the weld pool from exposure to oxygen. The seam itself is more ductile than when welding with common types of rutile electrodes. The other side of the coin is increased sensitivity to humidity and difficult ignition: it is much more difficult to cook with such electrodes.

General information

First, let's look at the technical characteristics of the ANO-21 brand. Produced according to GOST 9467-, type E46. The coating is rutile, which stabilizes the arc and reduces the pulverization of the metal.

So, when working with ANO-21, we have a stable arc and low spatter. The rutile coating prevents oxidation processes from starting by protecting the weld from interaction with oxygen.

It is possible even for a non-professional to obtain a quick and even seam with minimal likelihood of pores forming in it. About 1.5 kilograms of electrodes are needed per hour, which indicates the high productivity of the process.

Analogues of this type can be ANO 4, MR-3, OZS-6 or OZS-12. Usually they stop at the ANO 21 3mm and 4mm types. Reasonable prices for rods from manufacturers LEZ, ChZSM, which will cope with welding at home and for those trying their hand at this business.

Design and main characteristics

Structurally, the electrode is a metal rod of a certain diameter and length, made of Sv-08 or Sv-08A welding wire, which is coated with a rutile or rutile-cellulose type coating with high sanitary, hygienic and technological properties.

Figure 1 — Electrodes ANO-21

They are manufactured by various domestic manufacturers in accordance with the requirements of GOST 9466-75, GOST 9467-75 and according to the technical specifications of the manufacturer registered in Gosstandart. In addition, they comply with the requirements for such products as set out in the European and international standards ISO 2560:2009, DIN 1913-1984 and AWS A5.1. Supplied in cardboard packages weighing 1.0, 2.5, 3.0 and 5.0 kg. Such packages should be stored in rooms where the temperature does not fall below 15 °C.

Technical characteristics of ANO-21 are indicated in the table:

| Name | Unit | Index |

| Capacity (for Ø 3 mm) | g/min | 14 |

| Deposition factor | g/Ah | 7,0÷8,0 |

| Consumption of electrodes per 1 kg of deposited metal | kg | 1,65 |

The electrode material participates in the formation of the weld and ensures easy separation of the slag crust. The chemical composition of the deposited metal after its cooling is indicated in the table:

| Item name | Percentage, no more |

| Carbon | 0,1 |

| Manganese | 0,5÷0,8 |

| Silicon | 0,3 |

| Sulfur | 0,040 |

| Phosphorus | 0,045 |

The mechanical properties of the seam after welding ANO-21 are indicated in the table:

| Indicator name | Unit change | Quantity, no less |

| Tensile strength | N/mm² | 450 |

| Relative extension | % | 18 |

| Impact strength | J/cm² | 78 |

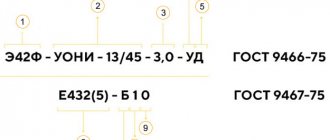

Explanation of the symbol

Electrodes of the ANO-21 brand are specially marked in the technical documentation, drawings and packaging. It consists of letters and numbers:

| E46-ANO-21-Ø-UD |

| E 43 2(3) - P 11 |

or

| E46-LEZANO-21-Ø-UD |

| E 43 1(3) - RC 13 |

- E46 – type according to GOST 10051-75 (E – electrode, 46 – weld strength limit, indicated in kgf/mm²);

- ANO-21 is a brand (sometimes they put letters in front of it that indicate the manufacturer of the electrodes). ANO stands for Academy (A) of Sciences (N) of General Purpose (O), the number 21 is the number;

- Ø – diameter indicated in mm (1.6; 2.0; 2.5; 3.0; 4.0; 5.0);

- U – purpose of the consumable material (for welding carbon and low-alloy steels);

- D – type of coating (thick);

- E 43 2(3) or E 43 1(3) – a group of indices indicating the degree of corrosion resistance of the seam and the type of test, the maximum temperature the seam can withstand in terms of heat resistance and heat resistance;

- R or RC – type of coating (R – rutile, RC – combined, rutile-cellulose);

- 11 or 13 – universal for welding in all possible positions (11) and in all positions, including horizontal (13).

Usage

ANO-21 welding electrodes are suitable for types of steel: from “St3kp” to “St20k”. They are used both when working with structural and carbon steel. The thickness of the metal that can be worked with is no more than 5 millimeters.

The type of connection (corner, butt, lap) does not matter for ANO-21 rods. It is possible to work with them in any spatial position, even vertically when forming a seam from top to bottom.

These rods will cope with both simple home or training manipulations and industrial needs. As a result of the work, the resulting seams will meet all quality requirements, despite the spatial position during the welding process.

conclusions

The brand of welding electrodes ANO-21 will be of help to both novice welders and professionals. Some will not have to worry about igniting the arc, while others will not have to worry about the stability of the main process. The result will be high-quality welded joints.

Not the last advantage will be the price criterion. When choosing, you need to carefully inspect the rods for deformation and dampness.

Giving preference to brands of a low price category is a dubious decision. It is better to pay attention to brands of well-known manufacturers.

When purchasing welding rods in basement stores, you may encounter failure to comply with favorable storage conditions. Do you have experience working with ANO-21 brand electrodes? Share it in the comments below. We wish you success in your work!

Electrode storage

The products are supplied in packaging and a special film that protects the products from moisture. However, in order for the electrodes to remain in working condition for a long time, storage conditions must be observed. They must be in a dry place at a temperature not lower than 15°C. It is very important to prevent them from getting wet or excessive humidity in the room. Also make sure that nothing falls on them and does not cause mechanical deformation. Otherwise, the coating will be damaged and it will be impossible to use the electrodes.

If it turns out that the electrodes are wet, they should be dried. This is done in a special oven. Place them there for half an hour. The calcination temperature should be 150 - 160°C.