Natural wood is highly valued in construction, furniture production and other areas of the national economy. Even the waste is used after processing. One of the directions is the pressing of sawdust, which results in the formation of briquettes that have a longer burning period than firewood and other types of solid fuel.

The design of presses differs slightly depending on the type; in general, it is a mechanical device that has a base, a power frame and a drive. The operating principle is to compact raw materials and form briquettes, fillers for pet trays.

The sawdust preparation process deserves special attention. They are pre-sorted, dried and crushed. This helps produce better products. In addition to sawdust, briquettes may include paper waste, nut shells and sunflower seed husks.

Before deciding to purchase a press, it is worth understanding the feasibility of its use. The equipment justifies the costs if there are available raw materials and a solid fuel boiler (or a market for the products).

Among the advantageous characteristics of the presses:

- rational use of wood waste (for heating premises, greenhouses, utility rooms, ash is used as fertilizer);

- clear and accessible production process;

- simple and reliable device (hydraulic models have virtually no high-wear components);

- Maintenance does not require knowledge of complex technologies.

Disadvantages include:

- the use of equipment involves the preparation of raw materials;

- rapid wear of components in the screw extruder;

- Some types require the addition of binders.

Types of presses

Presses used for processing sawdust come in 4 types. Differences between devices are noted in the principle of operation and cost.

The requirements for preparing raw materials are the same:

- uniform grinding to obtain fractions of no more than 25x25x2 mm;

- humidity level is within 4-10%.

Each model has both advantages and disadvantages, so before choosing, you should carefully read the technical characteristics:

- The mechanical impact press is similar in principle to a hammer drill, where the crank mechanism transmits a series of shocks to the piston with a frequency of 20 times per second. The impacts cause sawdust to be forced through the die. The equipment copes with pressing not only waste wood, but also a mixture of coal dust, straw, peat, and residues after processing MDF. The main advantage of the press is long-term operation without human intervention. High productivity is also noted. The weak point is the crank assemblies, which is due to the simultaneous impact of two forces on them: impact and friction.

- A hydraulic press is a device consisting of two parts (mold, cylinder). According to the principle of operation, the equipment resembles the action of a jack, where a hydraulic cylinder exerts pressure with a piston on a mold filled with prepared raw materials. The result is a formed briquette. The equipment is considered simple and reliable to use, there are practically no wear parts. The pricing policy for this type of model is competitive. The downside is low performance. There is also a nuance in the production process - a binding component is added to the prepared sawdust.

- The principle of operation of a screw press (extruder) is similar to a meat grinder. Crushed and dried sawdust is fed through a screw through a die, as a result of which the mass is compressed and pressed under high pressure. The process involves exposure to high temperatures, without which the equipment may jam. The hot flow provokes the release of lignin (a natural binder) from the wood, which holds small raw materials together and is the key to high-quality molding. The screw device is considered a leader in terms of productivity; the production process is carried out continuously. One of the disadvantages is the need for warming up, which makes the preparation procedure lengthy. You also need to take into account that the finished product has a lower calorie content due to exposure to high temperatures (above 120°C). Components such as the screw and die wear out quickly due to increased friction during operation.

- The pellet press is similar in principle to a feed pellet mill, only sawdust is used instead of grain crops. Compared to other types, the equipment has a simple structure, but at the same time it has good performance and an affordable pricing policy. The press is equipped with various devices to improve the quality of the resulting product. These are: a mixer for mixing raw materials, a humidifier for overdried workpieces, various cutting attachments that change the shape of the briquettes. The production process involves the use of an additional binder to increase density. One of the disadvantages is the need to grind the raw materials during preparation to the smallest fraction. Using such equipment it will be possible to produce briquettes only of small size.

Each model has both advantages and disadvantages, so before choosing, you should carefully read the technical characteristics

High costs

Among the disadvantages of the screw pressing method, high operating costs and low operating time for loading equipment should be noted. There are several reasons for this:

- the need to stop to replace the auger;

- the need for manual control of several parameters - the gap between the die and the screw, the heating temperature of the die, humidity;

- impossibility of automation;

The operation of a screw press is accompanied by constant stops for adjusting gaps, cleaning, replacing the screw, etc. To perform the above work, qualified personnel are required, the influence of the human factor is high.

The actual achievable load factor of such equipment is significantly lower than that of other presses. In real production, the load on the Pini-key press is usually 0.5 or even 0.3 of the nominal capacity. This means that although the Pini-Kay press from some manufacturers can demonstrate above-nominal performance on good raw materials, the monthly or annual performance will be significantly lower.

The situation can be improved through organizational methods, but it is difficult and operating costs will still be high. To service the press: adjust gaps, replace screws, etc., you will need a team of qualified specialists. The influence of the human factor during the operation of this equipment is extremely high.

Equipment selection

When choosing a sawdust press, important factors to consider are:

- purpose of equipment;

- what raw materials does it work with;

- type of briquettes produced;

- device power;

- planned volume of finished products;

- complete with other equipment to obtain a high quality product;

- functionality of the selected model;

- operating mode of the unit and features of its maintenance.

You also need to pay attention to components that are subject to wear. Frequent repairs and their cost will help determine the rationality of purchasing a particular model.

When choosing a press for personal use, you should remember that the equipment should be simple with the ability to customize parameters. If the product is not planned to be put up for sale, then it is enough to purchase just one unit. To make your purchase cheaper, you can take advantage of interesting offers on the sale of used devices.

When choosing a press for personal use, you should remember that the equipment should be simple with the ability to customize parameters

Excursion into history

If you make several search queries on the topic of briquetting equipment on the Russian-language Internet, it is easy to notice that in most cases we are talking about the Pini-Kay press, and mainly made in Belarus. Historically, one such original press was brought to Belarus in the last century by a German entrepreneur, who hired local personnel to work on it. During the process of perestroika, the press was copied by these personnel, adapted (not for the better) to local production conditions and reproduced in drawings, which are now used by all its manufacturers represented on the Internet.

We consider it necessary to note that the information about their products from suppliers of this equipment is given inaccurately, shortcomings are downplayed or kept silent altogether. Contrary to the opinion they spread, there is nothing advanced in this technology; today, “Pini-key” presses are not produced anywhere in Europe; such equipment itself is not used almost anywhere in Europe and is considered uncompetitive. from Austria has not existed for a long time.

In addition to copies of the original Pini-Key, there are also companies in Russia and Ukraine that produce inexpensive screw presses, which are based on Soviet developments for briquetting silage. This equipment has all of the above-mentioned proprietary disadvantages of screw presses, plus it has a number of additional ones - it is unreliable and simply cannot withstand long-term work on such material as sawdust. Negative reviews of these presses can be found everywhere.

Do it yourself

The high cost of equipment does not always justify the cost of purchasing it, so craftsmen implement their designs to create homemade presses. It is worth noting that making a screw device is quite difficult, so not everyone undertakes this type of pressing.

At home, it is almost impossible to achieve the required level of pressure that would ensure the release of lignin. But it is quite possible to build hydraulic units and granulators with your own hands.

All homemade devices are divided into three main types:

- The sawdust briquetting technology itself is quite interesting and has its advantages, so owners do not deny themselves the desire to acquire a home press

from jacks;

- with manual drive;

- with hydraulic drive.

The sawdust briquetting technology itself is quite interesting and has its advantages, so owners do not deny themselves the desire to acquire a home press.

Thanks to the use of briquettes, it is possible to prevent the formation of debris near the firebox of a stove or boiler, as well as to eliminate frequent loading. The location of home-made units can be wall-mounted or floor-mounted, depending on how convenient it is for you.

Before you begin assembling the press, you need to take into account all stages of the production process to ensure drying and grinding of raw materials. It is also worth taking care of a utility room or shed for storing finished products.

To assemble a hydraulic press, you will need to prepare the following materials and tools:

- metal sheet 4-6 mm;

- corner 100x100 mm;

- channel;

- a pipe with thick walls (the diameter is determined by the size of the briquettes at the outlet);

- pipe 25-30 mm for making a punch rod;

- galvanized steel for forming trays;

- large pipe or sheet of metal for making the mixer body;

- welding machine and electrodes;

- grinder with discs;

- drill;

- hammer;

- measuring devices, etc.

Available methods of creating pressure (pressing)

There are about four ways that will help you organize the production of sawdust briquettes, namely:

- use of muscular strength and leverage;

- hydraulic jack;

- screw pressing mechanism.

Such equipment for creating briquettes from sawdust can be made at home and used for personal purposes. Sawdust pressed into briquettes has a higher calorific value than firewood, and accordingly, less of it will be needed to heat rooms.

Muscle Strength Method

In the method using muscular force, a metal element is chosen for the lever. It must be strong enough to withstand the applied load from a person. As a rule, pipes with the following parameters are most often used:

- with a wall thickness of 4 mm;

- with a diameter of 40-50 mm.

The length of the lever must correspond to the distance from the piston to the point of application of force. But do not forget about the depth of immersion of the piston into the glass. The structure should be designed in such a way that the immersion depth is acceptable for the production of sawdust briquettes, without repeated application of force. This will increase productivity.

The immersion depth is determined by the formula:

h = H × (1 – q1 / q2)

where, h – immersion depth;

q1—initial mass of raw materials in dry form;

q2—weight of raw material in the form of a briquette;

H – height of the glass.

Sometimes errors occur during calculations, most often due to incorrect determination of the density of the raw material. In this case, the immersion depth will not create products of the required shape and quality. To fix this, you can do two things:

- reduce the length of the glass;

- add sawdust.

In the first case, you will have high productivity; in the second, you will need to create Eurowood several times.

Hydraulic jack method

The technology for creating fuel from wood waste using a hydraulic jack is quite simple. Many car owners have these devices at home, but the load-bearing capacity of home jacks is not high enough, so you should find out in advance and take care of purchasing a tool with the required load-bearing capacity.

Since the jack is inexpensive, the necessary equipment can be purchased for about 5 thousand rubles. The carrying capacity of such a device will be about 30 or 40 tons, which will allow you to make fuel briquettes of large cross-section.

In order to make several Euro-firewood at once, the mold is placed in a row. The main requirement for a design using a jack is that the movable frame must have sufficient strength characteristics so as not to deflect over time. The best material for its implementation would be an I-beam or a thick pipe profile.

In terms of time, the process takes longer than using a lever, but the method using a jack makes it possible to exert more pressure on the workpiece. As a result, the finished product is denser and more even, and can be used in this form.

Method using a screw mechanism

This method of pressing sawdust into briquettes with your own hands is similar to the lever method. The significant difference is that the force is transmitted at a right angle. The pressure depends on the diameter of the handle and the thread pitch; the smaller it is, the higher the coefficient for increasing the pressure.

This technology for producing fuel briquettes has a number of positive and negative characteristics.

Advantages:

- simplicity of design;

- small dimensions;

- affordable price;

- high pressure.

Flaws:

- low speed.

It is important to remember that when working with such a device, you should not apply too much force. This leads to rapid thread wear.

To understand when it is necessary to stop working, you can make several test briquettes and be guided by their quality. The second method that will save you from damaging the device is to apply marks to the threads. This way you will mark the point of maximum immersion and can prevent rapid wear.

The design is made on the basis of a hydraulic installation

Step-by-step instructions for making a press

- To make the base, you need to connect the parts from the channel by welding.

- Cut 4 pieces 1.5 m long from the corners (they are used as stands). Weld them to the base at the same distance from each other (vertical location).

- Fix a drum made from a large diameter pipe to the corners. If such a pipe is not at hand, you can make the mixer body from a sheet of tin. To increase productivity, it is equipped with an electric motor.

- A box for filling raw materials is made from sheet iron. It is recommended to make the body shape in the form of a cone for spontaneous loading movement when filling the trays.

- The gearbox is fixed to the bottom of the cone-shaped body and a tray for the output product is welded.

- In a thick-walled pipe, make holes at intervals of 3-5 mm. When pressure is applied to the mass, air and water will escape through the holes. Weld a flange to the bottom of the workpiece that will hold the removable bottom. The bottom is made of a sheet of steel in the form of a circle with eyes.

- Weld the matrix to the base under the cone-shaped body.

- Cut a disk from a steel sheet of a size that would allow free movement in the matrix. It performs the function of a punch.

- Weld the prepared pipe for the rod to the punch. The other edge is attached to the hydraulic unit.

- The assembled unit is mounted on racks directly above the matrix.

- The receiving tray is installed in such a way that it does not interfere with the process of shooting and fixing the matrix bottom.

Pre-drying will be provided by heating elements installed around the perimeter of the machine. The briquettes will be ready for final preparation in an open area with low air humidity.

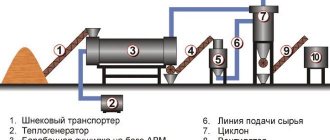

According to the technological process, raw materials need to be prepared before processing, which means a dryer and a grinding device are required

Homemade or purchased

The purchase of a press is justified in cases where it is planned to set up production. There is no need to purchase equipment for the production of briquettes, which will subsequently be used only for household needs. In addition, the cost of the units is high, not everyone can afford it. Yes, and installation requires a separate room.

According to the technological process, raw materials need to be prepared before processing, which means a dryer and a grinding device are required. In addition, after production, finished briquettes need to be stored in a dry room, which simply may not be available.

Handicraft production will not produce a high-quality product; the briquettes will have insufficient density, and this reduces the specific heat of combustion. Having weighed all the factors, we can summarize that there is no point in purchasing expensive equipment.

If your house has a boiler for solid fuel, you can build a press with your own hands. This will require available materials, as well as familiarization with design diagrams in order to choose the appropriate option.

Advantages of using ready-made presses for production purposes:

- simple equipment design;

- the ability to replace worn components;

- selection of models of different power and performance;

- the technological process does not require special knowledge and skills;

- You can set up a workshop in a small room.

When deciding to start production, it is worth considering important factors:

- type of raw material, its availability;

- approximate volume of processing for a certain period of time;

- required areas;

- scheme for selling finished products.

For large-scale production, it is recommended to purchase automatic and semi-automatic equipment. The units are characterized by high efficiency and wear resistance of working units.

The production of fillers for animal trays can be put into production using granulators. The diameter of the products produced just meets the standards, and high density is not required.

Blitz tips

- When making a homemade screw extruder, you should use only high-quality steel.

- It will not be possible to reproduce the process of producing briquettes with the release of lignin using homemade equipment , so it is recommended to add clay, cheap wallpaper glue or corrugated cardboard to the crushed raw materials. These components will be used as a binder.

- The simplest and most affordable are considered to be self-made devices equipped with a manual screw drive. The perforated form is filled with prepared sawdust mixed with a binder. Forming is carried out by tightening a screw. Such a press has one significant drawback - low productivity.

- Some craftsmen use a hydraulic jack to assemble a home press. It is worth noting that such a device is not capable of creating a pressure of even 300 Bar. A small amount of water and a binder added to the crushed raw materials will help improve the quality of briquettes.

- Crushed sawdust is used for the press, so the equipment should be supplemented with a rotary machine , on which the raw materials can be prepared for pressing. You can also make a shredder yourself from an old washing machine. To do this, it is enough to install knives instead of the activator.

High quality briquettes

Briquettes produced on a screw press have a square or octagonal cross-section with a technological hole in the center. The briquette is formed under the influence of strong pressure developed by the screw. Compared to other presses, it is the screw method that makes it possible to obtain the most dense (up to 1.4 kg/dm3) and, therefore, durable briquettes, which determines its excellent consumer qualities. This type of briquette is good for private consumers, it is similar to firewood, burns for a long time, and can be used in household fireplaces, stoves, and baths.