Welding work is in demand wherever the use of metal structures is implied. Not a single sector of the economy can do without them. And every year the need for such services only increases. Therefore, along with the old welding enterprises that have existed for several decades, new ones are being opened. Due to the low popularity of the welding profession, there is a shortage of specialists, especially highly qualified ones. At the same time, the requirements for specialists employed in production are increasing.

Welding process

Welding technological process : design principles

Design of a welding technological process is a complex optimization problem based on the use of computational analytical design methods. The optimal technological process for manufacturing a complex welded structure is selected from several design technology options. Depending on the main purpose, promising and operational technological processes are distinguished.

welding process

includes :

- sequence of technological operations;

- breakdown of the structure into individual technological units or elements;

- preliminary design of special devices and equipment;

- calculations of the modes of basic welding processes, calculations of expected welding stresses and deformations;

- comparative assessment of developed technology options.

After the final approval of the technical design and the accepted technology option, detailed design of the structure (drawing up design documentation) and development of working technology (drawing up technological documentation) are carried out.

The working welding process includes:

- clarifications and changes in the fundamental technological process associated with design changes at the detailed design stage;

- development of technological maps, which indicate all the parameters of the welding mode, the welding materials and equipment used;

- brief descriptions of technological methods for performing individual welding operations;

- requirements for the strength and quality of welded structures at individual stages of their manufacture;

- instructions on methods for checking the accuracy and quality control of connections, assemblies and finished structures.

Depending on the number of products covered by the process, two types of technological process have been established: standard and single. The rules for the development of working technological processes provide for the mandatory use of standard technological processes and standards for technological operations.

Depending on the degree of detail, each welding process can be route, operational or operational-route. Standard technological processes are developed based on an analysis of many existing and possible technological processes for typical representatives of product groups. A technological operation is part of a technological process, carried out at one workplace.

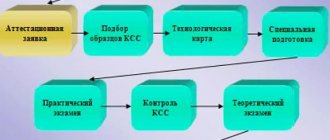

Welding process: development of a standard welding process

The main stages of development of a standard technological process include:

1) classification of production objects - select groups of objects that have common design and technological characteristics, and typical representatives of the groups;

2) quantitative assessment of groups of objects - assessment of the type of production (single, serial or mass);

3) analysis of the designs of standard objects according to drawings, technical specifications (TS), production programs and type of production; develop the main routes for the manufacture of structures, including procurement processes;

4) selection of a workpiece and methods of its manufacture with a technical and economic assessment, assessing the accuracy characteristics of manufacturing methods and surface quality, choosing a processing method;

5) selection of technological bases;

6) choice of type of production (welding, casting, pressure treatment, machining);

7) drawing up a technological processing route - determine the sequence of operations and select groups of equipment for operations;

development of technological operations, including:

development of technological operations, including:

- rational construction of operations;

- choosing the structure of operations;

- rational sequence of transitions in operations;

- selection of equipment that provides optimal performance and required quality;

- calculation of loading of technological equipment;

- choice of design of technological equipment;

- determining whether the selected design belongs to standard equipment systems;

- establishing the initial data necessary for calculations and calculating processing allowances and interoperational allowances;

- establishing initial data for calculating optimal processing modes and their calculations;

- establishing initial data for calculating time standards and their calculation;

- determination of the category of work and profession of performers;

9) calculation of accuracy, productivity and economic efficiency of standard technological process options with the selection of the optimal option;

1O) preparation of documentation for a standard welding technological process, its coordination with the interested services and approval.

The enterprise must have computer information retrieval systems to search for previously developed similar technological processes and individual technological operations.

All information is entered into the computer in encoded form. When developing a technological process, the manufacturability of welded products and structures is analyzed. Quantitative assessment of manufacturability is based on a system of indicators, including:

- basic indicators of manufacturability established in the technical specifications for product design;

- manufacturability indicators achieved during design development;

- level of manufacturability (ratio of achieved indicators to basic ones).

The main indicators of manufacturability are the labor intensity and technological cost of manufacturing a product.

Factors influencing the choice of indicators: requirements for the product, type of product, production volume, availability of information necessary to determine the indicators.

Requirements for a product determine what type of manufacturability the design should have: production, operational, or both, which, in turn, determines a group of manufacturability indicators.

Depending on the type of product (assembly unit, complex, kit or part), those indicators that can characterize the manufacturability of this type of product are selected from the groups.

Knowing the volume of output allows you to select indicators that characterize costs or expenses and are of the greatest importance for a given volume of output.

Welding training

A welder is a profession that requires intense thinking when performing work and the ability to make non-standard decisions. However, it is blue-collar occupations that play the main role. Training in the basics of welding at this level is essential.

The specialty of an expert in welding production can be obtained by completing the courses intended for this. They teach the basics of welding, including theory and practical exercises. This profession can also be acquired at a college or technical school where there are appropriate faculties.

Course programs include:

- Training in equipment and welding technology.

- Principles of electric arc welding.

- Semi-automatic welding.

- Gas welding and metal cutting.

- TIG welding.

- Argon welding.

- Types of defects, their control and correction methods.

- Safety rules and first aid.

After listening to lectures, practical training takes place under the guidance of experienced master teachers. Classes are group. To enroll in the courses, you must have a minimum education of 9 classes. The courses can also improve your existing rank. Retraining is possible. For example, a master in gas welding can acquire the more prestigious profession of an argon welder.

After the end of classes, it is time for the exam, where the commission evaluates the knowledge gained. If the decision is positive, the student is issued a certificate indicating the assigned rank. A welding production technician can have a rank from 1 to 6.

To obtain a higher education in welding, you will have to graduate from a higher educational institution of the relevant profile. The welding engineer must have more in-depth knowledge in this area. In addition, his responsibilities include general management of the process at all stages, so he must have organizational skills. His training program includes various disciplines that provide knowledge and broaden his horizons.

Higher education in welding production gives the right to perform the following work:

- Carry out your own developments and implement them into production.

- Actively participate in preparatory work. Procure the necessary consumables and equipment.

- Monitor the progress of the technological process and compliance with existing rules.

- Monitor the efficiency of consumables.

- Monitor compliance with safety rules.

- Select the correct equipment and ensure its correct operation.

- Select the necessary modes for a specific type of welding work.

- Participate in quality control of the resulting weld.

After obtaining a profession related to equipment and welding technology, who to work with is a wide choice. At a higher educational institution you can obtain the profession of engineer and welding technologist. Engineers and technologists are required to perform the duties specified in their job descriptions.

If a welder has to perform work that is new to him, then he needs additional preparation in terms of training. Since the competition in this field is not too great, over time you can make a career and grow to a higher and well-paid position.

The list of educational institutions teaching this profession is quite large. They are located in many large cities of Russia.

Labor organization at the welding site

Welding work is intended to eliminate cracks, ruptures, breakages, as well as attaching brackets, corners, etc. Electric arc and gas welding are used in ATP. Gas welding work is usually divided into welding of thick-sheet steel parts and welding of thin-sheet steel bodies, as well as thin-walled parts. Electric welding is used to repair massive parts (frame).

Preparing metal (parts) for welding.

The metal used for the manufacture of welded structures is pre-cleaned and straightened.

Cleaning must be done before assembly. At the welding site, the edges are thoroughly cleaned of rust, oil, moisture, scale, and contaminants, the presence of which leads to the formation of pores and other defects. Particular attention should be paid to cleaning in the gap between the edges. If dirt gets into the gap of an already assembled assembly, it should be thoroughly blown out with compressed air or burned with a torch flame.

Cleaning is carried out using manual and mechanical wire brushes, the flame of a multi-torch burner, abrasive wheels, etching in solutions of acids and alkalis, and washing with solvents.

Before welding, the edges of the parts, if provided for in the drawings, are trimmed, beveled and cleaned.

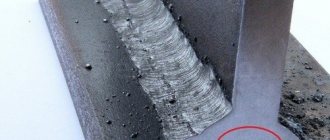

To ensure high-quality penetration and formation of a weld, edges are prepared for welding. The elements of the geometric shape of preparing edges for welding are: cutting angle of the edges, bevel angle of one edge, gap between the joining edges and bluntness. Existing methods of manual arc welding make it possible to weld metal of limited thickness - up to 6 mm - without cutting edges. Therefore, when welding metal of large thickness, it is necessary to cut the edges so that the welding arc can penetrate deep into the joint and completely melt the edges through the entire thickness.

Assembling parts for welding

More than 30% of the total labor intensity of manufacturing welded parts and assemblies is made up of labor costs for assembling parts for welding.

The assembly of parts for welding is carried out in order to establish the relative spatial position of the elements of welded structures. To reduce assembly time, as well as increase its accuracy, various devices are used: installation parts, clamping mechanisms, stands, jigs, etc.

Assembly of parts for welding is carried out in several ways. The most rational method is sectional assembly, which involves assembling and welding the individual components that make up the structure, and then assembling and welding the entire structure.

In the manufacture of welded structures, the so-called method of general assembly of a welded structure is widely used. It consists in the fact that first the entire structure is assembled from individual prepared elements, and then it is welded. If this fails, then the parts are sequentially attached to the already welded structure.

Workshop staff

Finding employees to carry out welding work is not an easy task, so this point is worth dwelling on in more detail. It is desirable that the enterprise employ generalists. This will allow you to reach a large target audience and provide clients with a wide range of services. The most popular are:

- welders of the third category - craftsmen working with the main areas of metal structures

- welders of the fifth category - carry out welding of important areas, work with high-pressure pipes, steam pipelines, etc.

- welders of the sixth category are the most valuable specialists performing welding work on critical sections of pipelines and metal structures

An employee can only be allowed to carry out orders if he has a number of documents:

- welder's certificate

- electrical safety certificate (group no lower than 2)

- certificate of completion of the PTM (fire-technical minimum) for hot work

A qualified welder must be able to read drawings, use regulatory and technical documentation, set up equipment, carry out welding work with control over compliance with specified parameters. Welding work has a harmful effect on the human body. This fact should be taken into account when setting tariffs for services and determining wages.

Organization of work of the welding shop

Any welding shop is a complex facility. To organize it, you will have to coordinate with the fire department and the sanitary and epidemiological station, because first of all, energy will be present here in pure open form, and this is electricity or fire from a gas burner.

Secondly, for the same reasons, there will be difficult working conditions here. Therefore, it is very important to study the rules of workshop organization and strictly observe them during the entire life of the welding area.

Where to begin

The design of welding shops is of paramount importance.

What is it? There are several positions here that will determine the technological process regarding welding work, as well as the assembly of components and parts. First of all, you need to sort out the equipment. It is clear that the main equipment for a welding shop is welding machines (gas, electric). Their cost is determined by the volume of work performed.

If the volumes are large, then it is better to purchase professional devices. If the welding shop is small, then you can get by with household analogues. A welding shop needs to be diverse to accommodate as much work as possible, so it's worth considering purchasing a resistance welder.

We must not forget about seemingly simple devices that will occupy a certain place in the welding shop. For example, a workbench or a welding table.

It must be properly organized not only in terms of the convenience of welding operations, but also in terms of quick access to additional tools and consumables. Moreover, a welder’s workplace is a single set of devices that are used daily.

Premises requirements

In addition to all the requirements described above, which mainly relate to safety, there are additional rules and regulations. One of the main ones is the strength and hardness of the floor in the welding shop. It should be finished with non-slip, fire-resistant material.

Each welder must have his own workplace with an area of at least 2 m2. Two welders are prohibited from working in it.

Although if the welding shop is small, then the workbench can be divided into two people with one condition - a partition made of non-flammable material must be installed between the welders. It is usually made from sheet metal.

The color finish of the welding shop is very important, especially when processes are carried out using electric welding. Glare and glare can disturb workers. The main color is yellow, white or gray. As for paint, it is better to use zinc or titanium white.

Location of equipment and fixtures

The equipment layout is strictly regulated by safety standards and regulations in welding shops. The layout determines safety, ease of movement of personnel, movement of parts, assemblies and finished products. There are several recommendations for arrangement:

- if a transformer is used in the workshop for electric welding, then it should be installed 5-7 m from the workbench and half a meter from the wall (minimum). The household inverter can be installed on a table surface;

- if welding is performed with gas, then cylinders with oxygen and acetylene are placed away from each other at a distance of at least 5 m. The same applies to propane equipment. The same distance is maintained between the welding site and the cylinders;

- gas hoses and electrical cables are laid away from passages so that they are not walked on. This is primarily a safety requirement, and secondly a way to preserve property;

- a distance of 1 m is left between equipment, tables, cabinets and other bulky objects for the convenience of moving people and transporting parts on carts.

Automatic welding equipment requires more space. It is necessary to take into account its movement around the welding shop and the access of performers to it.

Ventilation system

Ventilation of the welding shop is the most important component and one of the main requirements for organizing welding shops. With its help, heavy gases from the melting of metals and combustion of electrode rod coatings are removed from the welder’s workplace.

Many people make the mistake of installing a probe above a large workbench, which is connected to the general ventilation system by pipes or corrugations. The optimal and effective option is to install a side gas outlet so that they do not rise above the level of the workpieces being welded.

It is very important to make an accurate calculation of the ventilation system to ensure maximum air extraction from each workplace. It is better to install the fan outside the workshop. This will be especially true if the welding shop is organized in a garage.

A small room without ventilation will become a place where it will be impossible to stay without a respirator or gas mask. And the SES will not give permission to operate such a poorly equipped workshop. Therefore, it is very important not only to install a ventilation system, but also to correctly calculate the characteristics of the fan, especially the power of the device .

Plus, distribute the air ducts correctly so that they do not interfere when moving large parts. This means that you will have to make a drawing with the condition of the correct arrangement of all elements of the system.

Structural elements

It is very important to approach the structure of the assembly and welding shop correctly. This is a manufacturing facility in which various operations are carried out using a wide range of different materials.

In addition to the main workshop, the production structure should include storage facilities: for metal, for consumables.

In the procurement department, the metal is prepared for work: cutting to specified dimensions, cleaning, grinding, etc. Next, the products are delivered to an intermediate warehouse, where blanks are assembled by item.

Then comes the main workshop, where parts and components are assembled and welded into a single structure. The last department in the structure is the finished products warehouse.

For obvious reasons, this cannot be organized in small welding shops, but this is not necessary. For example, an intermediate warehouse is of no use here, the same applies to the procurement workshop.

As practice shows, all operations are usually carried out in one room. And the finished products are either stored outside under a canopy, or delivered right there to the customer’s hands.

Description of the structure with warehouses - a fairly large complex that can be located under one roof or in different buildings. In such conditions, it is impossible to do without a well-thought-out organization of logistics that allows you to save on vehicles.

In new industries, they try to arrange welding shops on a block or modular basis. The entire structural chain is located in line with the necessary sequence of movement, from raw materials to finished products.

The attitude of consumers towards welding shops is almost unambiguous - it is a dusty room in which people work in soiled overalls. But you shouldn’t think this way about all workshops.

The new requirements and rules represent a new approach to the competent organization of work, where, first of all, the emphasis is on the person, on his professionalism, on the conditions in which he works. The result largely depends on this.

Types of welding production.

Welding production is divided into the following types:

- Small-scale

- Serial

- Large-scale

Naturally, the first type does not include the possibility of production at an industrial enterprise, but most likely, welding work in domestic conditions: pipes, metal structures, etc., which require a certain number of repetitions of the same operations. In contrast, mass production includes special production lines with several workplaces to support welding work, and, moreover, they are often interconnected by vehicles. An example of such production is the production of propane cylinders using automatic submerged arc welding of steel with a thickness of no more than 3 millimeters on a lining. Large-scale production is a huge industrial production of identical structures, which in most cases is automated and does not require many welders to carry out assembly operations.

Technological process of modern welding

Welding is used quite widely both for commercial and production purposes, and for performing minor repairs in a private building or in a country house. Equipment and consumables for welding work are offered to consumers in specialized stores and are affordable. The process of making a welded joint depends on the type of welding. But arc welding has become most widespread. This is what is most often used in everyday life. But the quality and reliability of the welded joint, as well as the safety of the worker himself, depend on the correct execution of the welding process.

Electrode welding process.

Necessary equipment for laser metal welding

Laser welding equipment has different dimensions and power, but all of it operates on a solid or gaseous working fluid. The difference lies in the way the light emission occurs. Metal processing on any type of machine is performed in the same way.

- Solid state installations.

The devices are used in continuous radiation mode. They are characterized by higher operating frequencies, as well as limited efficiency and power. Solid-state equipment is used when working with small-sized and thin-walled products.

- Gas apparatus.

If it is necessary to weld thicker workpieces, equipment with a gaseous working fluid is required. Excitation of radiation in a gaseous medium occurs due to an electrical discharge. This equipment is suitable for working with workpieces up to 20 mm thick. With this technology, the beam power increases and the efficiency also increases. Equipment for welding work has a complex device with a fragile glass bulb.

- Hybrid installations.

Parts with complex configurations and thick sheet metals are processed using hybrid welding systems. In addition to the laser head, they have a semi-automatic electric arc burner.

The filler material is a wire that fills the welding gap and forms the weld.

Preparation and equipment

In order to make a weld using manual arc welding, you need to prepare consumables and a welding mask. The voltage in the electrical network must correspond to the nominal values required for normal operation of the welding equipment. If there are other units whose operation is not necessary, then it is advisable not to use them in the arc welding process. It is applicable for household use of arc welding. In production, electrical networks are carried out with a load reserve, so the operation of welding equipment during the arc welding process will not cause undesirable consequences.

Weld classification scheme.

In addition, the following must be available:

- A welding machine, which consists of a rheostat, a holder, and a grounding cable.

A rheostat, which provides the ability to change the supplied current. This parameter must correspond to the type of steel from which the metal parts to be welded are made. The amount of current supplied should depend on how deep the weld pool should be, what the cut seam will be, the degree of contraction, and deposition methods.

The cable used for such a connection can consist of 1, 2, 3 cores. The main thing is that the cable is designed for the expected loads, and with a margin. Otherwise, it may be damaged directly during the welding process. The grounding cable is necessary so that when the electrode comes into contact with the surface to be welded, the circuit is closed, thereby forming an arc for welding work.

General characteristics of the weldability of materials.

Such materials include several electrodes. Their number is determined by the size of the welded seam. Depending on the type and composition of the steel from which the parts to be welded are made, the type of electrode is selected. The composition of the electrode coating, proper storage conditions and other requirements that the manufacturer imposes on the consumer must be indicated on the packaging. The user needs to familiarize himself with them and strictly follow the requirements, which will ensure good performance of this consumable.

- Wire for welding.

The grade of wire and the chemical components that are inside it are also determined by the material from which the welding elements are made. All designations and areas of use of the wire must be indicated by the manufacturer on the packaging. This consumable must exactly match the grade of steel, otherwise the welded joint will be weak or impossible to make.

- If the welding process requires the use of flux, then the mixture must fully protect the working space being welded.

Some types of fluxes can only be used for specific work, if the elements for welding have a complex composition and special requirements for the quality of the resulting joint.

- When welding under special conditions or on certain metals, gas may be required.

Argon, helium and their mixtures, without affecting the chemical composition of the weld joint, nevertheless limit the access of oxygen to the working area.

Plasma welding equipment used

Equipment for welding work (for plasma processing) consists of the following elements:

- burners (plasmatron);

- power source (inverter);

- cylinder with plasma-forming gas;

- protective gas cylinder;

- water cooling systems;

- cable package.

A welding torch is a complex device consisting of electrodes, pipelines for supplying gases and coolant, and an electrical cable for supplying power to the electrode.

The design of the torch is influenced by the power of the welding equipment. Low-power devices are equipped with burners with a retractable cathode, which, through a control button, is connected to the anode nozzle and excites the arc.

Manual plasma welding is performed using a gun-shaped torch that is comfortable to hold in your hands. Plasma-water welding is carried out by a combustion device in the form of a gun, which also has a discharge chamber and a steam-generating device.

More powerful equipment for welding work is equipped with torches with a fixed cathode. It consists of:

- cathode;

- cavities for working gas;

- cavities for shielding gas;

- anode (with a cavity for cooling);

- housings.

Torches for high-power welding equipment do not have handles, as they are attached directly to manipulators or machines.

The power source in the equipment is inverters, which have almost completely replaced transformer energy sources. Thanks to modern pulse converters based on IGBT transistors, a stable operating current is provided, which is adjustable to operate the equipment in various modes.

Some features

The principle of gas welding.

When performing welding work, it is necessary to comply with safety requirements, thanks to which the welder is protected from the harmful effects of metal splashes and eye burns. Such protection can be provided by a welder’s mask, which is sold in specialized stores. Special glass, which is placed in the mask, reliably protects the eyes. Care must be taken to ensure that it is not damaged or scratched.

Any damage to the glass may burn the welder's cornea or may temporarily blind him.

If deformation of the glass occurs during work, it must be stopped until it is replaced.

Methods and modes of gas welding: A - baths; B - along qualifying edges.

If a temporary loss of vision occurs during welding, work is suspended until it is completely restored. In addition to the mask, you can protect your eyes with glasses. But they do not provide full protection of the head and eyes due to the fact that welding is based on creating an arc between the electrode and the part, for which an electric current must pass through the cable.

Desktops

Considering that small metal parts are welded at stationary work stations, special tables are provided for convenience. Structurally, industrial workbenches are designed for work in a standing or sitting position. If the table is made independently, then you need to take into account that the optimal height for working while sitting is 60 cm, and for standing – 90 cm.

The table cover is made of sheet steel or cast iron 2 cm thick. The total surface area is at least 1 square meter. It is important that the table has drawers in which the welder can store electrodes and other consumables, tools and small equipment. If there are none, then you need to additionally acquire a special plumbing trolley.

Rubber mats should be placed under the table itself and along its perimeter to prevent electric shock to the welder. And one more small touch - a metal chair with a dielectric seat, which allows you to do part of the work in a sitting position.

Welding technique

The principle of electric arc welding.

After all safety requirements have been met, materials and parts have been prepared, you can begin welding work.

On the welding machine, you need to set the operating current value at which welding will be performed. It is determined based on the brand of electrode, type of steel, type of weld, its location on the metal structure and in space. In order for an arc to form, the electrode must be brought to the starting point for welding. In this case, the electrode and metal must be perpendicular. After they touch, the electrode is lifted 2-5 mm from the metal, resulting in an arc.

This arcing process is used to start a seam. When it is necessary to light an arc already at the stage of making a seam, when the weld pool has already formed, this technological process looks somewhat different. In order for the seam to be continuous, the arc must be ignited by touching the electrode to it, stepping back slightly from the place where the arc broke along the seam. If the welder is experienced, the arc will rarely break, which helps ensure the integrity of the weld.

Types of welded joints.

The way the electrode is placed and its position depends on how the future weld seam will be located in space. The seams can be located below, on a vertical surface (vertical, horizontal), on the ceiling. Elements that need to be connected in a vertical plane are welded moving from top to bottom. When the welded joint is placed at the bottom, the electrode must be inclined in the direction of welding in a vertical plane, and the welding is done “towards you” or “away from you”.

The movements of the electrode along the surface to be welded by the welder can have a different trajectory. It depends on the size of the seam, the type of steel of the elements being welded, as well as on the skill of the welder. Movements can contribute to heating of the roots of the seam, heating of only one of the edges of the seam, or two edges.

Welding inverter device.

The way the electrode moves along the welded surface will determine the deformation of the welded joint and the stress that the seam will experience after completion of the work. The movements of the electrode themselves should be progressive and fairly smooth. However, stops during welding can form sagging, and frequent arc ignition can cause unnecessary damage to the surrounding surface.

In addition, the welds themselves can be long, medium or short. Their sizes are above 1000 mm, more than 350 mm and less than 1000 mm, less than 350 mm, respectively. If the seam must be of significant size, then it is performed in several sections to prevent significant heating of the metal edges and damage to the surface of the metal part (burning). It must be taken into account that the seam must remain without holes, intact and neat. The number and size of segments for a long seam depend on its size and is most often divided into 4-5 equal parts, if the design features of the part allow this. If the seam is short, then any side convenient for approaching can serve as a starting point. With an average length of seam, it starts from the middle and gradually moves to the edges. In this case, the direction of movement is determined only by the design features of the part.

Welding station equipment

Regardless of the functionality, be it a stationary or mobile welding station, the specialist’s place of work must fully comply with the following set of requirements:

- grounding of all energy-consuming devices is mandatory;

- good degree of illumination of the desktop. A combination of natural and artificial lighting is considered optimal;

- floors must be made of brick or concrete;

- the table top is made of cast iron or steel and is connected to ground;

- Drawers are provided for storing tools;

- in cases where sedentary work is required, a chair made of dielectric material is required;

- A rubber mat is spread under your feet.

When working in an open area, additional protection from sunlight, wind and precipitation will be required.

Stationary station equipment

A stationary workplace must meet a number of requirements:

- Such a workplace is made in the form of a cabin that does not have a roof. The total area of the allocated space should not be less than 3 square meters. The optimal height of the fences is 2 m. The entrance opening should be covered with a canopy made of fire-resistant tarpaulin.

- The lower part of the fence should be raised above the floor to a height of 25-30 cm.

- The material for the worktop tabletop can be steel or cast iron. The surface area is made no less than a square meter.

- It should be possible to adjust the height of the table so that the welder can change it to work while sitting (50-60 cm) or standing (90 cm).

- The perimeter walls are made of fire-resistant material. On the inside they are painted a light gray shade that absorbs ultraviolet radiation.

- It is necessary to provide a hood that would effectively remove combustion products. For effective air exchange, fresh ventilation will be required. According to safety requirements, the productivity of such a system is calculated to be no less than 40 cubic meters of air per hour.

- The standard lighting brightness is 60-80 lumens. It is ideal if it is possible to provide a combined illumination of the post: natural in combination with artificial.

All equipment connected to the power supply network must be grounded. In addition, one general switch is installed, which allows you to disconnect all equipment from the supply network at once.

Mobile post equipment

An excellent option for a production workshop or other large workspace, as well as when creating large-scale structures.

Primary requirements:

- Electric welding and additional equipment are combined on a mobile cart.

- The length of the power cable must be sufficient to move within the work area or facility.

- There is no need to install a ventilation system. On the street, combustion products of consumables are carried away as a result of the natural movement of air masses.

- The portable post is equipped with a canopy and protective shields that can be quickly assembled to protect from precipitation, wind or sun.

- In the same way, it is necessary to provide for the possibility of installing fences to protect bystanders from flashes of the welding arc.

- For ease of work, the welder must have a sufficient number of tool carts to store his equipment, additional equipment and equipment.

Practical recommendations

Seams can be made in one pass, and then such a solder is called single-layer. If the weld was formed by several passes of electrodes, then it is a multi-layer weld. The joint formed during single-layer welding is not ductile and looks quite rough. This is due to the fact that the metal in the area where the connection was made was very overheated. But at the same time, it is the seam obtained in one pass that is economical and productive.

Multilayer welding forms a neat seam as a result of the fact that each pass heats only a certain area of the metal. In this case, a thin seam is made, which increases slightly during the second pass. In multilayer welding, the layers can be arranged in a sequential or cascading manner, in a slide. With the sequential method, each of the following layers is applied to the previous one only after a complete pass along the entire seam has been completed.

The cascade method and the “slide” are used when welding thick layers of metal. With any of the multilayer welding methods, one pass must be performed especially carefully; the strength of the resulting joint depends on this.