produces casting steel 110G13L , which is also called manganese steel. This grade of steel is the most wear-resistant and belongs to the austenitic class. Its appearance is due to the English metallurgist R.A. Hadfield. It is used to create elements that are subject to significant mechanical loads. For example, bucket teeth are cast from this grade of steel, crusher tracks and jaws, tram tracks and a host of other products that work, as they say, “wear and tear” are made from it.

The initial state of 110G13L steel has an austenitic structure with a hardness of about 250HB. Steel of this grade in liquid form has increased viscosity and hardens extremely quickly. The impact of dynamic loads and forces causing deformation in products leads to 110G13L steel becoming twice as hardened. Products made from this steel working in the following conditions:

Send your drawings or sketches to

Or call 8-800-250-88-72. Delivery throughout Russia and the CIS!!!

- high,

- low pressure,

- increased deformation acquire even greater wear resistance.

Garfield steel is obtained by adding the following elements to the metal:

- manganese,

- silicon,

- copper,

- chromium,

- nickel,

- carbon,

- sulfur,

- phosphorus.

Directly after casting, the steel does not have a strong structure, but mainly consists of excess carbides. To obtain increased wear resistance, products cast from steel 110G13L are hardened in water. From this steel you can order from us all types of castings from ferrous and non-ferrous metals from 1 kg . Once dissolved in water, carbides are completely removed, and the steel acquires legendary toughness and strength.

Casting steel 110g13l

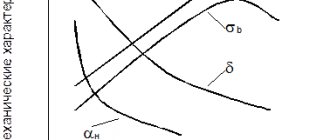

The tensile strength of steel grade 110G13L is approximately 800-900 MPa, its plasticity is 15-20%, the initial hardness is about 200 HB, the density is 7820 kg/m3, the elasticity approximately reaches 200,000 MPa.

Send your drawings or sketches to

Or call 8-800-250-88-72. Delivery throughout Russia and the CIS!!!

The structure of steel assumes the temporary resistance of the metal when exposed to forces equal to 800-900 MPa; fluidity (its conditional limit) σ0.2 = 320-360 MPa; elongation (relative) δ = 15-20%; narrowing (relative) ψ = 50-30%; initial hardness of the material is 200 HB; after “hardening” it reaches 600 HB; modulus of elasticity E = 200000M Pa; Shear modulus G = 78000 MPa; density of grade 110G13L - 7820 kg/m3.

Manganese steel production

For the production of austenitic manganese steels, furnaces with a basic lining are used exclusively. Smelting of manganese steel in acid furnaces is not carried out due to the rapid erosion of the acid lining. For example, a high-frequency acid-lined furnace can withstand 160 heats of ordinary carbon steel. When smelting manganese steel in it, the furnace lining could not withstand even 20 heats. The reason for this is the active reduction of silicon oxide in the steel lining with manganese according to the equation 2Mn + Si02 = 2MnO-f-Si, which causes, on the one hand, severe erosion and, on the other hand, contamination of steel with manganese oxides. Therefore, manganese steel is smelted in the main furnaces: high-frequency, electric arc and open-hearth.

When smelting it, it must be taken into account that the carbon content should not be high for reasons of reducing the amount of gases and non-metallic inclusions in the bath formed during the interaction of carbon with other elements; At the same time, it is desirable to use cheap additives and, first of all, ferromanganese with a high carbon content. Electric arc furnaces and open hearth furnaces fully satisfy these requirements. High-frequency furnaces are less suitable, since to obtain the required Mn:C ratio = 10 it is necessary to use a charge consisting only of mild steel and low-carbon additives. These furnaces are used very rarely for the production of austenitic manganese steels.

Before electric furnaces found widespread industrial use, manganese steels were usually produced in open hearth furnaces. In the latter, high-quality steel can be obtained, but due to difficulties in deoxidizing steel after removing phosphorus and carbon, these furnaces are used only in cases where electric furnaces are not able to produce a sufficient amount of steel for the production of very large castings. At one Czechoslovak metallurgical plant, the duplex process has recently been introduced. Steel is made in an open-hearth furnace, and ferromanganese is melted in a cupola furnace. The liquid steel and molten ferromanganese are then poured into a ladle, which completes the process of making manganese steel.

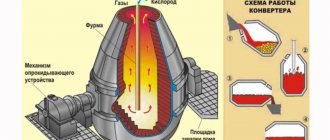

Another plant used a different method. Ferromanganese was melted in a small cupola furnace, and a charge consisting of cast iron and steel scrap was melted in another cupola furnace. The molten cast iron was poured into a Bessemer converter, in which the carbon was burned to a content of 0.1%. The mild steel thus obtained was mixed with molten ferromanganese in a foundry ladle. By this method it is often impossible to obtain manganese steel containing less than 1.5% carbon with a content of 0.14% phosphorus. Interestingly, this old method, which has not been used recently, is being used again in England in the production of various parts for hinge chains.

It can be argued that austenitic manganese steel is currently produced mainly in electric arc furnaces. The process of producing steel of this type in electric furnaces occurs as follows: the charge is made up of steel shavings and lump scrap in a ratio of 1: 4. Typically, such a charge already contains 4 - 6% of additives that create slag. After melting, the carbon and manganese content in the steel is determined, then the slag is removed and iron scale or iron ore is thrown onto the bath mirror. Thus, deoxidation, degassing and dephosphorization of steel are carried out. To obtain the maximum carbon content (maximum 0.05%), the oxidizing slag is removed and coke, anthracite or electrode waste with a small amount of ferromanganese is thrown into the furnace. After calming the bath and preliminary determination of the carbon and manganese content, the smelting is completed by adding the required amount of ferromanganese.

Casting technology. Based on production experience, it was determined that the optimal temperature for releasing steel from the furnace into the ladle should be 1520 - 1570 degrees, and the temperature of the steel when pouring molds should be 1440 - 1500 degrees (temperatures were measured with an immersion thermocouple). In reality, the melting point of high manganese steel is much lower.

Similar articles

- Manganese steels Manganese is one of the elements that expand the solid solution region and reduce the temperature of the critical point of the steel. Manganese refines the steel structure during secondary […]

- Technology for manufacturing castings from pyroferal Melting of pyroferal in a direct-heating electric arc furnace was carried out using the following technology: after melting the charge consisting of steel scrap and cast iron, […]

- Characteristics of manganese steel The specific gravity of steel with a content of 8 - 10% MP increases compared to the usual by about 1.6%. The specific gravity of manganese steel in a non-magnetic state is always greater than the specific gravity of that […]

- Mechanical properties of steel castings The required mechanical properties of castings with proper melting can be obtained at a cooling rate of 133 - 166 °C/min; Thus, for small castings it is sufficient [...]

- Austenite decomposition and properties of manganese steel Although austenite in Hadfield steel is very stable (provided the cooling rate is sufficient), in some cases, especially in large castings, […]

According to GOST 977-88, when casting steel 110G13L the following is produced:

- excavator components,

- mining industry components,

- hammers,

- cheeks,

- cones,

- crushing and abrasive plates,

- beaters for mills and crushing machines,

- armor bolts and plates,

- crowns,

- beds,

- gear wheels,

- skating rinks,

- grinding balls and much more.

produces not only products from steel 110G13L, but also carries out quality control of products, and also offers cast iron to order . For this purpose, there is a certain laboratory at the plant that carries out strict control over all stages of casting from manganese steel. The resulting products comply with all standards and requirements, including GOST.

After casting, all manufactured products undergo high-quality heat treatment. When paying for products we produce, we always meet the client halfway and select convenient transaction options. In addition to casting grade 110G13L, our plant carries out repairs of mining equipment, including work on turning and welding equipment. It also delivers manufactured parts to all cities of Russia and the CIS.

Manganese casting

Our company produces castings from manganese steel 110G13L (Hadfield steel), made according to customer drawings and used in crushing and grinding equipment, excavator equipment, in the cement industry and mining processing enterprises.

The main method of casting this steel is gasified mold casting (GMC). Only in the most extreme cases, castings made from manganese steels are subjected to mechanical processing, so this technology makes it possible to obtain castings with minimal slopes and high surface quality that do not require subsequent mechanical processing.

To date, we have developed the following products:

Spare parts for crushing and grinding equipment

| Name | Drawing no. |

| Cone crusher KSD-2200, KMD-2200 | |

| Fixed armor | 1272.07.313 |

| Upper armor | 1272.05.204-1 |

| Fixed armor | 1275.07.415 |

| Mobile armor | 1272.05.203 |

| Mobile armor | 1275.05.317 |

| Fixed armor | 1273.07.305 |

| Mobile armor | 1239.05.206 |

| Fixed armor | 1275.07.429 |

| Fixed armor | 1272.07.320 |

| Cone crusher KSD-1750, KMD-1750 | |

| Mobile armor | 1250.05.202 |

| Fixed armor | 1250.07.201 |

| Fixed armor | 1279.07.301 |

| Fixed armor | 1278.07.301-1 |

| Fixed armor | 1280.07.309 |

| Fixed armor | 1249.07.101 |

| Fixed armor | 1277.07.316 |

| Mobile armor | 1277.05.311-1 |

| Mobile armor | 1249.05.107 (1280.05.206) |

| Jaw crusher SMD-118 | |

| Movable crushing plate | 3450.02.011.00 |

| Movable crushing plate | 3450.02.021.00 |

| Fixed crushing plate | 3450.01.111.00 |

| Jaw crusher SMD-111 | |

| Movable crushing plate | 3440.02.010.00023SB |

| Movable crushing plate | 3440.02.020.0023SB |

| Fixed crushing plate | 3440.01110.0023SB |

| Jaw crusher SMD-110 | |

| Fixed crushing plate | SMD110.00.00002 |

| Movable crushing plate | SMD110.02.00.019 |

| Upper right wedge | SMD110.02.00.004 |

| Upper left wedge | SMD110.02.00.006 |

| Jaw crusher SMD-109 | |

| Fixed crushing plate | SMD109.00.00.002 |

| Movable crushing plate | SMD109.02.00.016 |

| Upper right wedge | SMD109.00.00.004 |

| Upper left wedge | SMD109.00.00.005 |

| Jaw crusher SMD-108 | |

| Movable crushing plate | SMD108.02.00.022 |

| Fixed crushing plate | SMD108.00.00.009 |

| Wedge top right | SMD108.00.00.002 |

| Wedge top left | SMD108.00.00.003 |

Casting for the cement industry

| Name | Drawing no. |

| beat | 166.00.00 |

| Chain link | 1196 |

| Chain link | 1975.20.192.003 |

| Chain link | 2005.20.611.00 |

| Wedge | 1049002014 |

| Wedge | 1049002015 |

| grate | 3.297.00.001 |

| Left side grate | |

| Sharp blast grate | Р61.07.011 |

| Private grate | |

| Grate with corner projection | 3.310.00.000 |

| Special grate | |

| Plate | 0915.01.803 |

| Armor plate | 1.07.42.95.06.01 |

| Armor plate | 1.07.42.95.06.01.004 |

| Lining plate | MS-04.945 |

| Lattice | 4845803002 |

| Disc feeder | 24-570-1k |

Spare parts for ECG excavator

| Bucket tooth curve | 1085.52.06-1 |

| Bucket tooth | 1080.02.11 |

Offers its customers both finished products from stock and custom-made products. We carry out steel casting to order based on the finished product and according to drawings provided by customers.

Technological process

Manganese casting is a complex technological process that involves filling molds with liquid metal and including its further processing. Casting of steel 110G13L is carried out by various methods, among which there are die casting, carbon casting, manganese casting and steel casting. Before casting, a special mold is made that completely follows the contours of the future casting. Then it is filled with a melt, which, having hardened, turns into a casting. If it is necessary to create internal cavities or holes in the casting, special rods are used. The mold filled with the melt is shaken, pressed and placed in a device designed for cooling. After the casting has cooled and hardened, it is removed from the mold and subjected to thermal and mechanical treatment.

Send your drawings or sketches to

Product Catalog

POLICY FOR PROCESSING AND PROTECTION OF PERSONAL DATA

This Policy for the processing and protection of personal data (hereinafter referred to as the Policy) was developed in accordance with the Federal Law “On Personal Data” and applies to any information that the site located at emz74.ru can receive about the User (personal data subject) during use A user of the site’s website, as well as the site’s programs and products.

- DEFINITION OF TERMS

1.1 The following terms are used in this Policy:

1.1.1. “Site Administration” - authorized employees of the company who organize the processing of personal data, and also determine the purposes of processing personal data, the composition of personal data to be processed, actions (operations) performed with personal data, etc.

1.1.2. “Personal data” - any information relating to a directly or indirectly identified or identifiable individual (subject of personal data).

1.1.3. “Processing of personal data” - any action (operation) or set of actions (operations) performed using automation tools or without the use of such means with personal data, including collection, recording, systematization, accumulation, storage, clarification (updating, changing), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data.

1.1.4. “Confidentiality of personal data” is a requirement for the Site Administration or any other person who has access to personal data to comply with the requirement not to allow their distribution without the consent of the subject of personal data or the presence of another legal basis.

1.1.5. “User of the site website (hereinafter referred to as the “User”) is a person who has access to the site via the Internet and uses the site.

1.1.6. “Cookies” are a small piece of data sent by a web server and stored on the user’s computer, which a web client or web browser sends to the web server each time in an HTTP request when an attempt is made to open a page on the corresponding site.

1.1.7. “IP address” is a unique network address of a node in a computer network built using the IP protocol.

- GENERAL PROVISIONS

2.1. The User's use of the site means his full agreement with this Policy and the terms of processing of the User's personal data.

2.2. In case of disagreement with the terms of the Policy, the User must immediately stop using the site.

2.3. This Policy applies only to the site. The site does not control and is not responsible for third party sites that the User can access via links available on the site.

2.4. The site administration does not check and is not responsible for the accuracy of personal data provided by Site Users.

- SUBJECT OF THE POLICY

3.1. This Policy establishes the obligations of the Site Administration to non-disclose and ensure a regime for protecting the confidentiality of personal data that the User provides at the request of the Site Administration when registering on the site or when filling out a request for a call back or message.

3.2. Personal data permitted for processing under this Policy is provided by the User by filling out a form on the website and includes the following information:

3.2.1. last name, first name, patronymic of the User;

3.2.2. User's contact phone number;

3.2.3. email address (e-mail);

3.3. The site protects the following data, which is automatically transmitted when viewing advertising blocks and when visiting pages on which the system’s statistical script (“pixel”) is installed:

— IP address;

— information from cookies;

— information about the browser (or other program that provides access to display advertising);

— access time;

— address of the page on which the advertising unit is located;

— referrer (address of the previous page).

3.4. Any other personal information not specified above (purchase history, browsers and operating systems used, etc.) is subject to secure storage and non-distribution, except for the cases provided for in paragraphs. 5.2. and 5.3. of this Policy.

- PURPOSES OF COLLECTING USER'S PERSONAL INFORMATION

4.1. The Site Administration may use the User’s personal data for the following purposes:

4.1.1. Identification of the User registered on the site to place an order and (or) gain access to the service and (or) conclude a purchase and sale agreement for a particular product remotely.

4.1.2. Providing the User with access to personalized website resources.

4.1.3. Establishing feedback with the User, including sending notifications, requests regarding the use of the site, provision of services, processing requests and applications from the User, etc.

4.1.4. Determining the location of the User (if he has given his consent) to ensure security and prevent fraud.

4.1.5. Confirmation of the accuracy and completeness of personal data provided by the User.

4.1.6. Providing the User with effective customer and technical support if problems arise with the use of the site.

4.1.7. Providing the User, with his consent, with special offers, newsletters and other information on behalf of the site or on behalf of the site’s partners.

4.1.8. Carrying out advertising activities with the consent of the User.

4.1.9. Providing the User with access to sites or services of site partners in order to receive products, updates and services.

- METHODS AND TERMS OF PROCESSING PERSONAL INFORMATION

5.1. The processing of the User's personal data is carried out without a time limit, in any legal way, including in personal data information systems using automation tools or without the use of such tools.

5.2. The User's personal data may be transferred to authorized bodies of state and municipal authorities of the Russian Federation only on the grounds and in the manner established by the legislation of the Russian Federation.

5.3. In case of loss or disclosure of personal data, the Site Administration informs the User about the loss or disclosure of personal data.

5.4. The site administration takes the necessary organizational and technical measures to protect the User’s personal information from unauthorized or accidental access, destruction, modification, blocking, copying, distribution, as well as from other unlawful actions of third parties.

5.5. The site administration, together with the User, takes all necessary measures to prevent losses or other negative consequences caused by the loss or disclosure of the User’s personal data.

- OBLIGATIONS OF THE PARTIES

6.1. The user is obliged:

6.1.1. Provide information about personal data necessary to use the site.

6.1.2. As necessary, update and supplement the provided information about personal data if this information changes.

6.2. The site administration is obliged to:

6.2.1. Use the information received solely for the purposes specified in clause 4 of this Policy.

6.2.2. Ensure that confidential information is kept secret, not disclose it without the prior written permission of the User, and also not sell, exchange, publish, or disclose in other possible ways the transferred personal data of the User, except for the cases specified in paragraphs. 5.2. and 5.3. of this Policy.

6.2.3. Take precautions to protect the confidentiality of the User's personal data in accordance with the procedure usually used to protect this type of information in existing business transactions.

6.2.4. Block personal data relating to the relevant User from the moment of application or request from the User or his legal representative, or the authorized body for the protection of the rights of personal data subjects for the period of verification, in the event of detection of unreliable personal data or unlawful actions.

- RESPONSIBILITY OF THE PARTIES

7.1. The site administration, which has not fulfilled its obligations, bears the responsibility provided for by current legislation for the unlawful use of the User’s personal data, except for the cases provided for in clauses. 5.2., 5.3. and 7.2. of this Policy.

7.2. In case of loss or disclosure of Confidential Information, the Site Administration is not responsible if this confidential information:

7.2.1. Became public domain until it was lost or disclosed.

7.2.2. Was received from a third party before it was received by the Site Administration.

7.2.3. Was disclosed with the consent of the User.

7.2.4. It was provided based on a request from an authorized government agency.

- DISPUTE RESOLUTION

8.1. Before filing a claim in court regarding disputes arising from the relationship between the Site User and the Site Administration, it is mandatory to submit a claim (a written proposal for a voluntary settlement of the dispute).

8.2. The recipient of the claim, within 30 calendar days from the date of receipt of the claim, notifies the claimant in writing of the results of consideration of the claim.

8.3. If an agreement is not reached, the dispute will be referred to a judicial authority in accordance with the current legislation of the Russian Federation.

8.4. The current legislation of the Russian Federation applies to this Policy and the relationship between the User and the Site Administration.

- ADDITIONAL TERMS

9.1. The site administration has the right to make changes to this Policy without prior notice and consent of the User.

9.2. The new Policy comes into force from the moment it is posted on the website, unless otherwise provided by the new edition of the Policy.

Finished products of LMZ "Luch"

Our plant produces cast iron products using casting technology. We offer a wide selection of finished products, namely products and model equipment from:

- SCH (gray cast iron);

- VChShG (high-strength cast iron with nodular graphite).

LMZ "Luch" is a large supplier of cast iron hatches. Our company produces hatches for inspection and cable wells, storm water inlets of various configurations. Our production capacity allows us to produce casting products of any complexity that strictly comply with GOST standards.