How to choose the right size anchor bolt and how to navigate the markings correctly. How will the size of the anchor bolt affect the operation? These questions are heard especially often from buyers who are encountering these fasteners for the first time. When choosing them, there are several nuances, the observance of which will allow you to select an anchor bolt that ideally meets the assigned tasks. Let's try to look at them.

Wedge - for high loads

This is the most common category of anchor bolts, widely used in private and capital construction. In appearance, it is a metal rod, wedged on one side and threaded on the other. There is a spacer sleeve on the conical part; the basic package includes a nut and washer.

Wedge anchors are used for mounting loaded structures on concrete surfaces.

This could be the arrangement of elevator shafts, staircases, installation of utilities. In domestic conditions, such anchor bolts are used for ceiling mounting of large and heavy chandeliers.

| Advantages | Flaws |

|

|

Also, the disadvantages include “non-removability”: the installed anchor cannot be dismantled and reused.

In the table you will find designations and descriptions of anchors from well-known manufacturers.

| Manufacturer | Type | Manufactured diameters and lengths of anchors, (mm) | Examples and explanations of designations (dimensions are indicated in mm) | Peculiarities |

| Fischer (Germany) | FBN | 6…20 (40…421) | FBN 12/100[+120] [GS] 12 – diameter of anchor and thread; 100 – useful length t – standard; 120 – maximum length t (not always specified); GS – equipped with a wide washer DIN 9021 (not specified with a regular washer DIN 125 ). FAZ 12/10[GS] FAN 10/100 FB 16/25 A4 | Fischer Bolzen. Steel 6.8 galvanized or A4 stainless. The most common due to its low cost and high reliability. |

| FB | 6…16 (65…173) | Limited production (mainly from A4 ) | ||

| FAZ | 8…24 (75…234) | Fischer Ankerbolzen Patented special expansion sleeve design allows applications in stretched and fractured areas of concrete | ||

| FAN | 10…12 (90…193) | Limited edition (made of A4 ) | ||

| Hilti (Liechtenstein) | HST | 8…12 (75…235) | HSA-F M16x190/75[/95] 16 – diameter of anchor and thread; 190 – full length of the anchor; 75 – useful length t – standard; 95 – maximum length t (not always specified); HST M12x115/20 | Hilti Stud Anchor. Steel of strength class 6.8 galvanized (5 microns). A4 stainless steel . |

| HSA | 6…20 (50…300) | |||

| Mungo (Switzerland) | MSD | 6…20 (50…270) | m3 12x113 12 – diameter of anchor and thread; 113 – full length of the anchor. MSD 10x120 MSD-C 16×300 – with wide washer DIN 9021 MSDr 10×70 – A2 stainless steel | Stahlbolzen.. Galvanized steel |

| m3 | 6…20 (50…170) | The special design of the spacer sleeve ensures high reliability against rotation of the anchor and maintains load-bearing capacity in cracked concrete. | ||

| Sormat (Finland) | S-KA | 6…20 (40…280) | S-KA 8×50 8 – diameter of anchor and thread; 50 – full length of the anchor. S-KAK D 12/65 12 – diameter of anchor and thread; 65 – useful length t; D – anchor with two spacers | Kiila-ankkuri Made from steel 6.8 according to DIN 1654 or 1651 , electro-galvanized. |

| S-KAK | 6…20 (40…280) | Same as S-KA anchors, but hot-dip galvanized. | ||

| S-KAH | 6…20 (40…220) | The same, but made of stainless acid-resistant steel A4 . | ||

| Tox (Germany) | B.A. | 6…16 (65…315) | BA 12/30/125 12 – diameter of anchor and thread; 30 – useful length; 125 – full length of the anchor. | Bolzenanker galvanized steel |

| Allfa (Germany) | 72000 | 6…12 (40…180) | 72000-10150 10 – diameter of anchor and thread; 150 – full length of the anchor. | Wedge anchor. Galvanized steel yellow passivated. |

| NOBEX (Italy) | TM TMX TMXX | 6…20 (40…220) | TM 8×115 8 – diameter of anchor and thread; 115 – full length of the anchor. | Ancoranti TM – galvanized steel, TMX – stainless steel A2 , TMXX – stainless steel A4 |

| Koelner (Poland) | S.R. | 6…20 (40…250) | SR-12×130 10 – diameter of anchor and thread; 130 – full length of the anchor. | Wedge anchor. Steel 4.6 galvanized, yellow passivated. |

| Technox (Poland) | BZ | 6…16 (75…300) | BZ 10/130 [A4] 10 – diameter of anchor and thread; 130 – full length of the anchor | Kotwa stalowa Galvanized steel (stainless bushing) or all stainless steel A4 |

| B | 6…20 (40…350) | B 16/115 16 – diameter of anchor and thread; 115 – full length of the anchor | Steel A45 galvanized | |

| B.L. | 8…16 (75…175) | |||

| Anchor Fasteners (Taiwan) | WAM | 6…20 (40…300) | WAM-10125 10 – diameter of anchor and thread; 125 – full length of the anchor. | Wedge anchor . Galvanized steel, yellow passivated. |

| INKA (Türkiye) | IDKL | 6…16 (75…145) | IDKL12110 12 – diameter of anchor and thread; 110 – full length of the anchor. | Klipsli Dubel Steel 5.6 galvanized |

Characteristics of steel 35x

Application of steel 35X

This steel has a very specific application environment, but it is of great importance, since it is from this steel that the most important parts of various mechanisms are most often made, including shafts of internal combustion engines, gear transmissions of rotational motion, as well as axles and, in some cases, rings. rails.

- The designation “steel” makes us understand that the steel falls under the “Quality” category. This means that the amount of harmful impurities in 35X steel is lower than that of ordinary quality steel.

- The number 35 refers to the percentage of carbon in the alloy - on average 0.35 percent.

- The letter “X” at the end of the abbreviation tells us about the increased content of an alloying element such as chromium in the steel.

Chemical composition

As in any other case, the characteristics of 35X steel are very dependent on the alloying elements included in its composition. It is they who endow steel with the basic properties necessary for certain conditions. For 35X, the composition of chemical additives is as follows:

- Carbon - significantly increases the strength and hardness of steel, reducing ductility - 0.35%.

- Silicon – slightly increases strength, without affecting the overall fragility – 0.22%.

- Manganese - adds strength to steel, resistance to impact loads, without reducing its ductility - 0.65%.

- Chromium – slightly increases the hardness of steel and protects it from corrosion by forming an oxide film – 0.95%.

- Copper also has a positive effect on the corrosion resistance of steel - up to 0.3%.

- Nickel - similarly increases oxidation resistance, as well as strength and flexibility - up to 0.3%.

The so-called “harmful impurities” contained in 35X steel, such as sulfur and phosphorus, adversely affect the structure, and, as a result, the quality of the resulting steel. However, their content is often negligible and in this case amounts to only 0.035% each.

Driven - for fixing communications

Installation of such products is carried out using the driving method. These are ordinary dowels, only they are made not of plastic, but of high-carbon steel. In appearance, it is a seamless metal sleeve with a conical inner surface and longitudinal slits.

The anchor is driven into a pre-prepared hole with a hammer; during installation, the petals form support arms that have a high load-bearing capacity. After this, a bolt of a suitable diameter is screwed into the anchor, which passes through.

Such anchors are used for installing formwork, cable ducts and utilities, gratings, splinker and ventilation systems, and when installing pipelines.

| Advantages | Flaws |

|

|

Products in this group are conventionally divided into 2 categories: ordinary and special. The second group includes products of the “Zikon” series, which are highly expensive and require special tools for installation.

| Manufacturer | Type | Available thread diameters, mm | Examples and explanations of designations (dimensions in mm) | Peculiarities |

| Fischer (Germany) | E.A. | 6, 8, 10, 12, 16, 20 | EA M 8 8 – M 8 internal thread diameter EA SM 10 | Fischer Einschlanganker Steel 1.4401/1/4571, galvanized yellow-passivated or stainless steel A4 |

| EAS | 6, 8, 10 | Lightweight version of the EA anchor made of sheet steel, with collar | ||

| Hilti | HKD-S | 6, 8, 10, 12, 16, 20 | HKD-S M12/50 12 – M 12 internal thread diameter 50 – anchor length. | Flush Anchor Steel strength class 5.8. |

| HDI | Drop-in Anchor | |||

| Mungo | ESA | 6, 8, 10, 12, 16, 20 | ESA M 8 8 – M 8 thread diameter; | Einschlanganker Galvanized steel, yellow-passivated or stainless steel A4 |

| Sormat (Finland) | LA, LAH | 6, 8, 10, 12, 16, 20 | LA 12 12 – M 12 internal thread diameter. | Ly ö ntiankkuri LA – structural steel, electro-galvanized LAH – made of stainless acid-resistant steel A4. |

| Tox (Germany) | T.E. | 6, 8, 10, 12, 16, 20 | TE M16x65 16 – M 16 internal thread diameter. | Einschlaganker Galvanized steel, yellow passivated. |

| NOBEX (Italy) | DROP | 6, 8, 10, 12, 16 | DROP 12×50 [INOX] 12 – M 12 internal thread diameter 50 – anchor length. | |

| Koelner (Poland) | ST | 6, 8, 10, 12, 16, 20 | ST-08 08 – M 8 internal thread diameter. | Drop in anhor Galvanized steel, yellow passivated. |

| Wkret-met (Poland) | T.S.W. | 6, 8, 10, 12, 16 | TSW 10 10 – M 10 internal thread diameter. | Galvanized steel, yellow passivated. |

| Technox (Poland) | TSR | 5, 6, 8, 10, 12, 16 | TSR 8x30 | Tuleja stalova. Galvanized steel |

| Anchor Fasteners (Taiwan) | DRM | 6, 8, 10, 12, 16, 20 | DRM-12 | Drop in anhor Galvanized steel, yellow passivated. |

| INKA (Türkiye) | IDCA | 6, 8, 10, 12, 16 | IDCA08 | Çakmali Dubel |

STEEL GRADE 35

Quality medium carbon steel

This type of steel is used for parts that require high ductility and impact resistance.

High-quality carbon steels of type 35 are manufactured according to GOST 1050-88 and are marked with two-digit numbers that indicate the average carbon content in hundredths of a percent.

For example, steel 35 (0.35%). It has high strength (σв = 640...730 MPa, σ0.2 = 380...430 MPa) and relatively low ductility (δ = 9...14%, ψ = 40...50%).

In addition, this type of steel is not susceptible to medium stress, is resistant to deformation and wear, and is not subject to cracking and corrosion.

Therefore, steel 35 is used in the production of high-strength fasteners and flange connections. Temperature range: from - 40 to + 450 degrees Celsius.

Methods of welding RDS, ADS submerged arc and gas shield, ESW. We recommend heating and subsequent heat treatment. CTS without restrictions

Weldability of steel grade 35

Structural grade 35 has limited weldability.

With an increase in carbon in the steel, the heat-affected zone and the weld are hardened, hardness increases, and welded joints become more brittle and prone to cracking.

Satisfactory steels have a carbon content of 0.25 to 0.35%. They are less prone to cracking and, with the correct welding conditions, a high-quality seam is obtained. To improve the quality of welding, heating is often used.

Steel application temperature 35

The minimum application temperature (the temperature of the coldest five-day period in the region) is minus 40.

Maximum application temperature plus 425.

Chemical - innovative option

Chemical anchors are a metal fastening sleeve or reinforcing rod made of galvanized or stainless steel. The fastener is fixed by injecting a special adhesive composition into the hole, which, after hardening, ensures reliable adhesion of the concrete and the stud.

Chemical anchors are used almost everywhere. They can be used for mounting suspended structures, fences, equipment and any additional elements.

Thanks to the use of an adhesive composition, the anchor easily withstands dynamic loads and vibration, and is not subject to corrosion in an aggressive environment.

| Advantages | Flaws |

|

|

The price of such anchors is noticeably higher than that of other analogues.

| Manufacturer | Type | Dimensions | Peculiarities |

| Fischer (Germany) | R.M. | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M14, M16(18x125), M20(25x170), M24(28x210), M30(35x280) | Reactionsanker An ampoule with resin, inside an ampoule with a hardener. Used with FCR-A anchors or RG studs. |

| FHP | Capsules: 10 (13x90), 12(15x110), 16(18x125), 20(24x180) | Hammerpatrone The ampoules have two cavities: with resin and with hardener. Used when installing fittings. | |

| FIS V 360S | 360 ml composition + 2 mixers | Injections-Mörtel Double cartridge. A special mixing gun is required. | |

| FIS VS 150 C | 150 ml of composition + 2 mixers + adapter | Injections-Mörtel Special cartridge. A standard sealant gun is used. | |

| Hilti (Liechtenstein) | HVU | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M16(18x125), M20(24x170), M24(28x210), M27(30x240), M30(35x270), M33(37x300) , M36(40×330), M39(42×360) | Adhesive Capsule Anchor Ampoule with polyurethane meta-acrylic resin, hardener, quartz sand. |

| HIT- HY150 | 330 ml + 2 mixers | Fast Curing Injection System Two special double tubes (Acrylic resin with additives and hardener). For extrusion, a special Hylti dispensing gun is required. | |

| HIT-HY50 | 330 ml + 2 mixers | ||

| HIT-HY20 | 330 ml + 1 mixer | ||

| Mungo (Switzerland) | MSP | Capsules: M8 (10x80), M10 (12x90), M12(15x95), M16(18x95), M20(25x125), M20(25x175), M24(28x240) | Schlagpatron The ampoules have two cavities: with resin and with hardener. |

| MVA | Capsules: M8 (10x80), M10 (12x90), M12(15x95), M14(16x95), M16(18x95), M20(24x135), M20(25x175), M24(28x210), M30(35x 280) | Verbunanker An ampoule with resin, inside an ampoule with a hardener. | |

| MIT-P | 150 ml + 2 mixers | Injectionstechnik Special cartridge. A standard sealant gun is used. | |

| MIT-P | 235 ml + 2 mixers | Injectionstechnik Double cartridge with parallel arrangement of containers for resin and hardener. A special mixing gun is required. | |

| MIT-SF | 380 ml + 2 mixers | ||

| MIT-EA | 825 ml + 2 mixers | ||

| Sormat (Finland) | KEM | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M16(18x125), M20(25x170), M24(28x210), M30(35x280) | Kemiallinen ankkuri An ampoule with polyester resin, inside an ampoule with a hardener. Used with KEVA studs. |

| KEMLA | Capsules: M10 (12x90), M12(14x110), M16(18x140), M20(22x180) | Kemiallinen ly ö ntiampulli Ampoule with polyster resin and hardener. For horizontal and floor mounting only. VSS studs. | |

| ITH | 150 ml, 380 ml | Injektointitekniika Injection mass based on polyester resin. Large cartridges (380 ml) require a special gun. | |

| KEW (Germany) | VAR | Capsules: M8 (10x80), M10 (12x90), M12 (14x110) | Verbundankerpatrone An ampoule with resin, inside an ampoule with a hardener. For use with AS studs. |

| V.M. | 150 ml, mixer SM | Verbundm örtelkartusche Special cartridge with adhesive mass and adapter. A standard pistol is used. | |

| Tox (Germany) | TVA | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M16(18x125), M20(25x170), M24(28x210), M30(35x280) | Verbund-Anker An ampoule with resin, inside an ampoule with a hardener. Used with TVA-G studs. |

| THP | Capsules: M10 (12x85), M12(14x105), M16(18x135), M20(24x160) | Hammerpatrone The ampoules have two cavities: with resin and with hardener. | |

| TVM-K | 150 ml, 380 ml | Verbundm örtel Injection mass. Large cartridges require a special gun. | |

| NOBEX (Italy) | NCF NCS N.C.E. | Injection formulations NCF and NCE – 380 ml NCS – 150 ml | Fissaggi chimici estremamente efficaci |

| Technox (Poland) | SVA | Capsules: M8 (10x80), M10 (12x85), M12(14x95), M16(18x95), M20(24x175), M24 (28x210) | Ładunek chemicalzny |

| INKA (Türkiye) | IDKIN | Capsules: M12(14x95), M16(18x95), M20(24x170) | Normal Tip Kimyasal Dubel |

Cost and wholesale discounts

For wholesale orders, discounts are provided depending on the volume of the required batch and other delivery conditions.

When you cooperate with the Alliance of Bolt and Nut Companies for more than 1 year, you receive individual discounts through your personal manager and additional preferential terms of service.

Free delivery terms

For buyers of our products over 1 ton, when sending cargo through the transport company Business Lines, we compensate up to 50% of transportation costs.

When purchasing from 30,000 rubles, delivery within the city of Moscow and the nearest Moscow region is free and within 24 hours.

Anchor sizes for concrete

It is impossible to say with certainty, without knowing the nuances of the situation, what size anchor bolt will be needed. This indicator is influenced by the wall material, type of fastening element, expected load and other parameters.

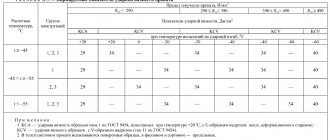

The table will help you roughly navigate the variety of fasteners.

| Type of anchor bolt | Optimal sizes |

| With hook |

|

| With nut |

|

If you are in doubt which bolt you need, measure the thickness of the wall, the expected load and tell them to the salesperson in the store. They will help you choose the best option.

Application of Anchor Bolt

Mechanical anchors are good for low-porosity substrates. Chemical models are indispensable for materials with an abundance of gas capsules, for example, cellular types of concrete. Installing an anchor bolt If you focus on the structure of the fastener: -A bolt with a hook or ring is good for fixing hinge systems, objects on cables and chains. It is important to be able to remove the item from the bolt to move it to a new place, or wash it and hang it back. -A bolt with a nut is used for dense and monolithic bases, since the spacer fastening system is not effective in porous and soft materials. The nut perfectly holds gates and stairs, secures cables and pipelines.

In everyday life, a concrete anchor bolt is useful for periodically dismantled structures. These are doorways and suspended ceilings. - Wedge bolts are also used in dense and monolithic foundations, both for capital construction and private farmsteads. Wedges are used to attach advertising boards to foundations, posters to house facades, warehouse consoles to walls, and light fixtures to ceilings. In everyday life, wedge bolts are often used when installing punching bags and home sports corners. -Anchors-studs hold ceilings and partitions, supporting consoles, masts, cables and antennas. Some types of anchors for dense foundations are divided into those suitable for true monoliths and those that have cracked.

The stud bolt, for example, comes in the HAS and HST categories. Models of the latter allow you to securely fix objects to cracked concrete and make through fastenings. This increases the "weight" of HST anchor bolts in the eyes of builders. The nuances of using anchors depend on their weight, size, and material. There are, for example, brass or steel bolts. If the fastener is made of an iron alloy and is an M-6 size, it will withstand up to 2.8 kilonewtons of pullout. The shear anchor will withstand 3.6 kilonewtons. As a rule, the performance characteristics of anchor bolts are indicated on their packaging. It remains to correctly calculate the stress forces in the walls and ceilings. If you are not confident in your abilities in the exact sciences, it is better to order calculations from professionals or play it safe by taking the most reliable fasteners. They appear to be useful in most areas of construction, since they can even withstand load-bearing structures such as ceiling beams.