buildingbook.ru

Calculation of building structures depends on the choice of steel grade. Many people simply take steel grade C245 as the lowest in their calculations and don’t worry about it - if the required grade is not available, they replace it with a stronger one, and leave the same cross-section, which leads to excessive consumption of metal and an increase in construction costs.

Also, many people mistakenly believe that because the lowest grade is cheaper, the design will be cheaper. In fact, an increase in steel strength leads to a decrease in the total weight of the structure and the final cost of all rolled products may be lower. In addition, the load on the foundation and seismic loads are reduced. However, the use of high-strength steels is not justified for elements whose cross-section is selected based on stability conditions.

In addition, when selecting a steel grade, it would be a good idea to call suppliers for availability and the possibility of supplying a profile from the required steel grade, since when replacing a steel grade with a less durable one, you will have to change the profile and components, which will take some time, and when replacing with a stronger one, there will be an overconsumption of steel. Some of the most common steel grades for rolled profiles on the market are 09G2S and St3sp/ps5.

First of all, to select a steel grade, we need to determine which group the future building element belongs to. The description of the groups is written in Appendix B SP 16.13330.2011. There are 4 of them in total:

1) Welded structures or their elements operating under particularly difficult conditions (according to GOST 25546), including those that maximally restrict the development of plastic deformations or those directly exposed to dynamic, vibration or moving loads. This list includes crane beams, work platform beams, transport track beams, structural elements of bunker and unloading platforms that directly bear loads from rolling stock, main beams and crossbars under dynamic loads, spans of conveyor galleries, truss gussets, walls, bottom edges , stiffening rings, floating roofs, coatings of tanks and gas tanks, bunker beams, shells of parabolic bunkers, steel shells of free-standing chimneys, welded special supports of large transitions of power lines (VL) with a height of more than 60 m, elements of guy masts and guy units.

2) Welded structures or their elements operating under static load in the presence of tensile stresses. This list includes trusses, frame crossbars, floor and roof beams, stair stringers, silo shells, overhead line supports, with the exception of welded supports of large transitions, busbar supports for open switchgear substations (OSD), supports for transport galleries, floodlight masts, elements of combined antenna supports structures (AS) and other tensile, tensile-bending and bending elements, as well as structures and their elements of the 1st group in the absence of welded joints and suspended track beams made of I-beams in accordance with GOST 19425 and TU 14-2-427 in the presence of welded installation joints .

3) Welded structures or their elements operating under static load, mainly in compression. This list includes columns, racks, support slabs, floor decking elements, structures supporting technological equipment, vertical connections along columns with stresses in the design sections of the connections exceeding 0.4Ry, anchor, load-bearing and fixing structures (supports, crossbars, clamps ) contact network of transport, supports for outdoor switchgear equipment, except for supports for switches, elements of NPP shafts and towers, columns of concrete trestles, coating purlins and other compressed and compressed-bending elements, as well as structures and their elements of the 2nd group in the absence of welded joints .

4) Auxiliary structures of buildings and structures. This list includes connections, other than those specified in group 3, half-timbered elements, stairs, ladders, platforms, fences, metal structures of cable ducts, auxiliary elements of structures, etc., as well as structures and their elements of group 3 in the absence of welded joints .

Next, we need to determine the climatic region of construction, or rather, we need to find out the estimated outside air temperature. It can be found in SP 131.13330.2012 (Updated edition of SNiP 23-01-99*).

The temperature of the coldest day with a probability of 0.98 is taken as the design temperature for determining steel according to SP 16.13330.2011.

The temperature of the coldest five-day period with a probability of 0.92 was taken as the design temperature for determining steel according to SNiP II-23-81.

Why does temperature affect the choice of steel grade? Because as the temperature decreases, the brittleness of steel increases.

Since July 1, 2015, SP 16.13330.2011 is mandatory, so it is necessary to use the data on it. Let's compare the requirements of SP 16.133302011 and the no longer valid SNiP II-23-81.

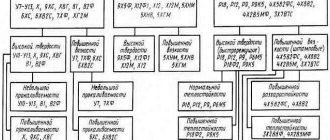

According to Table B.1 SP 16.13330.2011, the following steel grades are assigned in the designed structures:

From the table we see that there are 3 columns with standards for choosing a steel grade. The steel grade according to GOST 27772 characterizes the yield strength of the metal (C235 means that the steel has a yield strength of 235 N/mm²), markings according to GOST 353, GOST 14637 and GOST 19281 indicate the chemical composition, the strength characteristics of this grade can be viewed in these GOSTs. Steel made according to one GOST can fully correspond to the grade of steel made according to another GOST, the difference lies only in the method of steel quality control. There is no single standard for designating steel grades in the world - in Russia there are some standards, in the USA there are others, in Europe there are still others, but this does not mean that our steel is different.

According to Table 50 of SNiP II-23-81, the following steel grades are assigned:

Group 1:

Group 2:

Group 3:

Group 4:

Designations adopted in table. 50* SNiP II-23-81:

a) shaped steel with a thickness of up to 11 mm, and upon agreement with the manufacturer - up to 20 mm; sheet - all thicknesses; b) the requirement to limit the carbon equivalent according to GOST 27772-88 for thicknesses over 20 mm; c) requirement to limit carbon equivalent according to GOST 27772-88 for all thicknesses; d) for region II4, for unheated buildings and structures operated at outdoor temperatures, use rolled products with a thickness of no more than 10 mm; e) with a rolled product thickness of no more than 11 mm, category 3 steel may be used; f) except for the supports of overhead lines, outdoor switchgear and KS; g) rolled products up to 10 mm thick and taking into account the requirements of section. 10; i) except for area II4 for unheated buildings and structures operated at outdoor temperatures. The “+” sign means that this steel should be used; the sign “-” means that this steel should not be used in the specified climatic region.

As we see in SNiP II-23-81, the temperature gradation is 5 degrees lower than in SP 16.13330.2011, but the temperature here is not the coldest day, but the coldest five-day period. If you look at the joint venture “Construction Climatology”, we will note that in most cases the conditions for choosing a steel grade will be the same, but there are cases when SNiP imposes more stringent requirements, and there are cases when the requirements in the joint venture are higher. Therefore, for examination, it is necessary that the steel grade complies with SP 16.13330.2011, but if SNiP II-23-81 imposes more stringent requirements, then I recommend using this document.

To select the pipe steel grade, you can use table B.2 Sp 16.13330.2011

You can also select the steel grade according to the impact strength indicators given in Table B.3 Sp 16.13330.2011

The steel grade for connections of steel structures should be selected in accordance with Appendix G SP 16.13330.2011

From the table we can determine the recommended steel grades and make calculations.

If you have the opportunity to choose a steel grade, then it is better to try several options and, based on a technical and economic calculation, choose the best option. Posted in Steel structures Tagged Steel grade, Strength calculation, Steel structures

Types of steel according to purpose

The scope of application of a steel alloy depends on its composition and properties. There are universal materials used in various industries, and highly specialized ones for specific tasks.

There are three categories based on purpose:

1. Structural - spring-spring, upgradeable, cemented or high-strength alloys, which are used in construction, instrumentation, and mechanical engineering.

2. Instrumental - carbon or alloyed for the manufacture of measuring, impact, cutting tools; hot, cold stamping.

3. Special – corrosion-resistant, heat-resistant, heat-resistant, electrical (mainly high-quality structural steels with alloying additives).

Copper in construction steels

Copper increases the strength of steel and its resistance to corrosion. The copper content in low-alloy steel reaches 0.65%. The properties of steel also depend on the method of its manufacture. According to the method of smelting, construction steels are divided into open-hearth and converter (Bessemer and Thomas), and according to the method of deoxidation - into calm, boiling and semi-quiet (the latter is almost never produced).

Thomas steel, which has very low impact strength at normal temperatures, is not used in building structures. Open hearth steel is less porous than Bessemer steel and contains fewer harmful impurities.

Boiling open hearth steel, compared to calm steel, is more clogged with gases and has a less uniform structure. The strength of Bessemer steel is no less than the strength of open-hearth steel, but the latter, especially the quiet one, is more reliable against brittle fracture and aging.

Manganese in construction steels

The content of manganese in building steels in an amount of up to 0.8% increases the tensile strength and yield strength, although to a lesser extent than carbon, but does not cause a noticeable decrease in ductility.

When the manganese content is more than 1%, the impact strength and corrosion resistance of steel decreases, its hardness increases and weldability deteriorates. Very low manganese content reduces tensile strength. In promising low-alloy steels, the manganese content reaches 1.8%.

Construction steel grades and areas of their application

The steel produced by the metallurgical industry is divided according to quality and purpose into standard grades called grades.

Steel grades must meet the requirements of the standards and the additional customer requirements provided for therein. These requirements determine the basic and additional characteristics of the mechanical and technological properties of steel, as well as its chemical composition.

For building metal structures the following are used:

- Carbon steel of ordinary quality, group I, supplied according to mechanical properties: open hearth - grade St. 0, St. 2, Art. Zkp, St. 3, Art. 4, Art. 5;

- Bessemer - grade BSt.Zkp;

- G - manganese,