Change in structure upon addition of carbon

Indicators of strength and ductility depend on the structure and its changes with increasing carbon content.

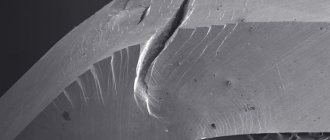

At a proportion of up to 0.2%, ferrite and tertiary cementite are formed; a further increase leads to the formation of eutectoid ferrite and cementite (pearlite). The perlite index value gradually increases and at 0.8% carbon only perlite is contained. If the content is more than 0.8%, needles of secondary cementite and perlite appear.

The formation of cementite occurs up to 2% carbon, while the strength decreases due to the fragility of the cementite network along the boundaries of pearlite grains. When this value is exceeded, a eutectic mixture is formed.

What does the carbohydrate contained in steel provide?

The amount of cementite will increase as the carbon content of steel increases. In this case, the proportion of ferrite will simultaneously decrease. If the ratio between the components is changed, the ductility will decrease, and the strength and hardness will increase. The strength will increase as long as the carbon content is 1%, but after that it will certainly decrease because a cementite coarse network will be formed.

In simple Russian terms, carbon has a direct effect on viscosity properties. If the amount of carbon in the alloy is increased, the product will not succumb to sudden brittleness, and the impact strength will decrease.

In addition, there are other processes that can cause an increase in carbon composition:

- — electrical resistance will increase;

- — coercive force increases;

- — the permeability of magnets will be reduced;

- - the induction of magnets will become less dense.

In addition, we must remember that carbon can also affect technological processes. In addition to all the positive aspects described above, the casting properties of steel will be significantly deteriorated as soon as the carbon content in the composition increases. Moreover, weldability will be significantly worse and cutting and forming such steels will be much more difficult. But this does not mean that if the steel does not contain carbon, then no problems will arise with it. Steels with a low carbon content will also be difficult to cut.

But, in addition to carbon, steel may contain other impurities, which must also be kept in mind. Such impurities are divided into three permanent groups:

1. Standard. These include silicon, sulfur, phosphorus, manganese. In this case, the first and last are considered technological type impurities. These impurities are introduced during the steel smelting process itself to deoxidize it.

2. Hidden. This includes gases such as oxygen, hydrogen, nitrogen. They will enter the steel directly during smelting. Thanks to them, the resistance to brittle fracture will be reduced.

New properties and advantages of the alloy

Carbon in steel gives it additional advantages, primarily:

- sufficient hardness of the surface layer and relative softness of the inner layer;

- good machinability;

- durability;

- affordable price.

With an increase in the proportion of carbon, hardness and strength increase and ductility decreases, therefore, the more carbon there is, the more difficult the cutting process, and the worse the deformation and welding performance. Based on this, the following types of steel are distinguished:

- Low carbon, with a share of less than 0.25%. They are quite plastic, easy to deform and process.

- Medium carbon, with a share of 0.3-0.6%. This type is also plastic and has an average strength rating.

- High carbon, with a share of 0.6-2%. With low viscosity and high strength. Welding is carried out only with preheating to 225 degrees.

In addition to the basic mechanical properties, an increase in carbon content increases the cold brittleness threshold.

Other classification features

By deoxidation method

There are three types of steels: boiling, semi-calm, and calm. With equal carbon content, these alloys have the same strength characteristics and different ductility characteristics.

- Manganese is used to deoxidize boiling steels. They are characterized by: significant chemical and structural heterogeneity of the ingot. Due to their low silicon content, steels can be cold formed. Not used to create products for use in cold climates.

- Semi-calm (ps). They are deoxidized with manganese and in a ladle with aluminum.

- Calm (sp). Silicon, manganese, and aluminum are used for deoxidation. The yield is approximately 85%. The ingot is characterized by a dense, homogeneous structure.

By quality

- Carbon steels are of ordinary quality - their marking is carried out according to GOST 380-2005. They are designated by the index St and a number - the brand number. The higher the number, the higher the carbon content, the greater the hardness and the less ductility. At the end there is a designation for the deoxidation method: kp, ps, sp. Used in the manufacture of non-critical building structures, fasteners, pipes, sheets, flanges.

- High-quality carbon structural steels are designated by double-digit numbers equal to the amount of carbon in hundredths of a percent. At the end, the deoxidation index is indicated (except for mild steels).

Application of carbon steel

Applications depend on the mechanical properties, and therefore on how much carbon there is in the steel. With an index of 0.7-1.3%, carbon steel is used for the manufacture of cutting and impact tools. They are marked with the letter “U”, the subsequent number characterizes the share, for example, U13. The higher the indicator, the greater the influence of carbon on the mechanical properties of steel.

Low-carbon steels are divided into subgroups depending on their purpose:

- Low carbon: 05, 08, 10. Due to their plasticity, they are used in cold stamping for the manufacture of washers, gaskets, casings and other parts.

- Low-carbon: 15, 20, 25. This value of carbon in the steel composition gives increased hardness and sufficient toughness; they are used for the manufacture of small-sized parts (cams, pushers, lightly loaded gears).

- Medium carbon: 30, 35, 40, 45, 50, 55. Used for the manufacture of crankshafts of low-speed engines, gears, flywheels - parts whose performance is determined by fatigue resistance. They are used after normalization and surface hardening, which increase viscosity and ductility, and accordingly, the machinability index improves.

- High carbon: 60, 65, 70, 75, 80, 85. Used for the manufacture of springs, eccentrics and springs. They are pre-hardened and moderately tempered, which improves the elastic properties necessary for manufactured parts.

- Boiler rooms: 12K-22K. Used for the manufacture of equipment operated at high temperatures (vessels and boilers for turbines and combustion chambers).

- Automatic steel. It has found application for the manufacture of automotive fasteners under static loads (studs, nuts, bolts).

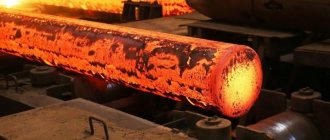

Deoxidation, degassing and alloying of steel

STEEL ALLOYING

INFLUENCE OF ALLOYING IMPURITIES ON STEEL PROPERTIES

According to the chemical composition, steels can be divided into carbon and alloy. Steel is called alloyed if its given composition determines the content of elements that are absent in ordinary carbon steel in significant quantities, or if there is an increased content of silicon and manganese compared to what is allowed in carbon steel.

The composition of ordinary carbon steel includes the following elements: C, Si, Mn, Al, S, P, O, H and N. The carbon content determines the grade and properties of carbon steel. Silicon, manganese and aluminum are introduced into this steel in small quantities, mainly to deoxidize it. Manganese and silicon also provide the specified mechanical properties of steel. The remaining listed elements enter the finished steel from charge materials or furnace gases and are harmful impurities. In addition to the indicated elements, carbon steel always contains small amounts of chromium, nickel, copper and molybdenum introduced by the charge. In carbon steel smelted at machine-building plants or plants that produce large quantities of alloy steel, the content of these elements is higher.

The most common alloying elements are: Cr, Mn, Ni, Si, W, Mo, V, Ti, Cu, Co, Al, B, Nb, Zr, N, As, S, P.

In modern practice, steel is especially often alloyed with the first eight elements.

The influence of various elements on the properties of steel is summarized below.

Carbon is contained in steel of all grades in an amount from 0.02 to 1.5%. With increasing carbon content, the hardness and strength of steel increase and the ductility of steel decreases. An increase in the amount of carbon by every 0.1% up to 0.85% increases the yield strength by 2.8 kg/mm2, the tensile strength by 6.5 kg/mm2, reduces elongation by 4.3% and cross-sectional compression - by 7.3%. When the carbon content increases to more than 0.85%, its effect on the mechanical properties of steel appears to a lesser extent. Carbon increases the cutting ability of steel, increases electrical resistance, coercive force, and slightly reduces the density of steel; reduces the melting point of steel by approximately 90 ° C for every percentage of carbon. Under the conditions of the steelmaking process, it is a deoxidizing agent and determines the content of oxygen dissolved in liquid steel. In solid steel, carbon forms various structural components with iron, which determines the properties of the steel and is the basis for its subsequent heat treatment.

Manganese is found in all types of steel and is a deoxidizer or alloying element. Manganese in the form of ferromanganese is widely used in steelmaking processes. It facilitates hot processing of steel by pressure, forming refractory compounds with sulfur and oxygen. The residual amount of manganese (0.25-1.0%), dissolving in ferrite and partially forming carbide, has a positive effect on the mechanical properties of steel. Within these limits, manganese improves the hardenability of steel, increases the yield strength of the metal and has almost no effect on elongation. Up to 1.8% Μη is introduced into structural alloy steels. Manganese is an austenite-forming element. High-carbon steel with 13% Μη has an austenitic structure in the hardened state and has good abrasion resistance under impact loads. In combination with tungsten and molybdenum, manganese serves as a substitute for nickel in structural steels, and with nitrogen in stainless steels.

Silicon, which is a stronger deoxidizer than manganese, is introduced into steel for deoxidation in small quantities (0.2-0.4%). With a content of more than 0.8%, silicon is an alloying element. In an amount of about 1%, silicon increases the tensile strength and yield strength of steel without reducing the viscosity of the metal, therefore carbon steel with the specified silicon content is used for the manufacture of springs and springs. Silicon-manganese steels containing silicon and manganese in the range of 1-1.3% have good plastic and strength properties and serve as substitutes for chromium-nickel steel. Silicon increases magnetic permeability and electrical resistance, reduces hysteresis losses, which is why electrical steels contain silicon (1.5-2% in dynamite steel, up to 4% in transformer steel). Silicon, being a ferrite-forming element, increases the acid resistance of the metal. An alloy containing up to 14% silicon (thermosilide) is used for acid-resistant casting.

Aluminum is a powerful deoxidizer. To deoxidize and regulate the size of the primary austenite grain, no more than 0.2% Al is usually introduced into the steel. Aluminum prevents the aging of steel and increases its plastic properties. In chrome-molybdenum and chromium steels intended for nitriding, 0.7-1.2% Al is introduced.

Sulfur in conventional steel grades is contained in an amount of 0.01 - 0.05% and is almost entirely in the form of non-metallic inclusions. It causes red brittleness of steel, reduces mechanical properties, increases the susceptibility of steel to rusting and abrasion, and reduces the ability of steel to deep drawing (stamping). At a higher content, sulfur facilitates the machinability of steel on machines, so 0.1–0.3% S is introduced into special grades of steel (automatic steel).

Phosphorus in steel is usually present in an amount of 0.02-0.1%. It causes cold brittleness in steel. In medium and high carbon steels this manifests itself at lower phosphorus contents than in low carbon steels. In steels operating only at elevated temperatures, a higher phosphorus content is allowed. About 0.1% P is added to nut and bolt steel to improve machinability. Phosphorus increases the corrosion resistance of steel and prevents sticking of thin sheets when rolling sheet iron.

Chromium is one of the most common alloying elements; it is used both independently and in combination with other elements. The chromium content in alloy steel ranges from 0.5 to 30%. Chromium is a ferrite-forming element; its addition leads to an expansion of the temperature range of metal solidification. At a content of 1.5%, chromium increases the hardness and strength of steel without reducing its ductility. To improve the mechanical properties of steel, about 1% Cr is introduced. Chromium increases the strength of steel at high temperatures and increases oxidation resistance. Steel containing about 5% Cr is heat resistant. In acid-resistant steel, the chromium content is 17-20%, in heat-resistant steel - 23-28%. Chromium increases the hardenability of steel and somewhat reduces the tendency to overheat, increases the abrasion resistance of steel; in an amount of 0.15-0.3% prevents sticking of thin sheets of boiling steel when rolling in batches.

Nickel is used for alloying steel in concentrations from 1 to 25%. It increases strength, especially the toughness of steel and oxidation resistance, increases hardenability, and has little effect on the strength of steel at high temperatures. Nickel is an austenite-forming element. 8-12% Ni is added to acid-resistant steel, and 18-20% to scale-resistant steel; serves as a stabilizer of the austenitic state at high and low temperatures. Nickel is used in large quantities to produce alloys (nichromes) intended for the manufacture of heating elements. Nickel is an expensive and scarce metal, so work is constantly underway to create steels and alloys in which nickel would be replaced by other elements.

Molybdenum for alloying steel is introduced in an amount from 0.2 to 5%. Molybdenum up to 0.6% increases the strength and hardness of steel, improves plastic properties. Molybdenum greatly increases the hardenability of steel and has the property of eliminating temper brittleness. Structural steel contains 0.2-0.4% Mo. Molybdenum increases the strength of steel at high temperatures and therefore it is introduced into heat-resistant (0.4-0.6%) and heat-resistant (2-5%) steels. Some heat-resistant alloys contain more than 5% Mo. Molybdenum is a very expensive and scarce metal, so a lot of research is being done to replace molybdenum in steel with other elements.

Tungsten is used in steels operating at high temperatures and high shock loads. 8.5 and 18% W are added to high-speed tool steel, 1-8% to die and tool steel, and 2-3% to heat-resistant steel. Tungsten is a carbide-forming element, so steel containing tungsten has great strength and hardness. The cost of tungsten is very high, so it is used only for some steels.

Vanadium is a carbide-forming element that greatly refines the austenite grain, increases the strength and toughness of the metal. Steel containing vanadium resists impact loads well. Structural steel contains 0.15–0.4% V, and high-speed tool steel contains 1–2% V. Vanadium is a scarce metal. When processing iron ores containing vanadium, it oxidizes and turns into slag, which is specially processed to extract vanadium.

Titanium forms strong carbides and nitrides and greatly refines the austenite grain. 0.4-0.7% Ti is introduced into acid-resistant steel to bind carbon into strong carbides, as a result of which the tendency of this steel to intercrystalline corrosion decreases. Structural steels contain 0.1–0.15% Ti. Titanium is introduced into steel intended for electric welding in order to reduce self-hardening. In ferritic high-chromium steel, titanium refines the grain and prevents the formation of austenite.

Niobium is a highly carbide-forming element. Increases the strength and hardness of low-alloy steel, and also significantly increases the steel's resistance to oxidation at high temperatures. It is attached to stainless steel to eliminate the tendency to intergranular corrosion, and to carbon (0.1%) and manganese structural steel (0.25%) to eliminate temper brittleness.

Copper increases the strength of ferrite. In an amount of up to 0.5% it increases the ductility of steel in a cold state, in an amount of 0.2% it increases the resistance of carbon steel to atmospheric corrosion. 3-4% Cu is introduced into chromium-nickel stainless steel to increase its corrosion resistance, 0.2% Cu is introduced into steel intended for the manufacture of ship hulls, since copper prevents algae and shells from sticking to the underwater part of the vessel; In addition, copper increases the yield strength of these steels. When the copper content is above 0.3%, areas of a eutectic alloy are formed in the steel, rich in copper and having a low melting point. This alloy is deposited along grain boundaries and causes red brittleness in the metal during forging and rolling.

Boron in an amount of 0.002-0.004% is introduced into structural steel intended for heat treatment in order to increase hardenability. The effect of 0.002% B on increasing hardenability is equivalent to the effect of 0.2% Mo or 1% Ni, therefore boron is introduced instead of scarce elements into high-strength structural steels. The number of steel grades containing boron is increasing every year.

Cobalt is an expensive metal. High-speed steel containing cobalt remains very hard at high temperatures (the cutting edge retains its properties even at red-hot temperatures). Hard magnetic alloys (alnico) contain up to 24% Co. Cobalt increases the resistance of steel against oxidation at high temperatures, and therefore is included in steels from which turbine blades, exhaust valves of internal combustion engines, etc. are made. The cobalt content in the manufactured alloys reaches up to 55%.

Zirconium is introduced into carbon and structural steels. amount 0.1-0.25%. Zirconium, like aluminum, refines the grain of steel, increases the temperature threshold for the onset of grain growth and the hardenability of steel. Increases the endurance limit of steel in air and in a corrosive environment and increases strength characteristics, impact strength at temperatures below zero and improves the weldability of steel. Zirconium increases the heat resistance of steel at temperatures up to 500° C. Complex alloying with zirconium and other elements (vanadium, titanium) affects the properties of steel more strongly than alloying with zirconium alone. Due to its high cost and high waste (~50%), zirconium is not widely used in metallurgy, although several grades of steel have now been developed and recommended to the industry.

Calcium in an amount of 0.2-0.5% is introduced into carbon and structural steels for deoxidation. In high-alloy steels, calcium acts as a modifier. It is usually introduced into steel in the form of silicocalcium, less often in the form of metallic calcium. In the presence of aluminum or rare earth metals, calcium promotes the formation of globular nonmetallic inclusions.

Lead (up to 0.25%) is added to some steels to facilitate cutting. The mechanical properties of steel are affected very little. Lead does not dissolve at all in liquid steel and forms an emulsion; Some of it evaporates when interacting with steel. Lead is placed in molds. Lead oxide fumes are poisonous, so measures must be taken to capture them.

Zinc is used as a coating on thin sheet steel and pipes to protect against rust. It cannot be introduced into liquid steel, since it evaporates at steelmaking temperatures.

Tin is not used as an alloying element, but is used as a coating for very thin (white) tin. Tin enters the steel from the charge. Tin in an amount of 0.06% causes brittleness of steel at forging and rolling temperatures (red brittleness); in amounts up to 0.1% it does not affect the mechanical properties of steel, however, in steel intended for deep drawing, the tin content should not exceed 0.02 -0.03%.

Arsenic gets into steel from iron ores. Especially a lot of arsenic is contained in steel smelted from cast iron obtained from the ores of the Kerch deposit. Arsenic in steel is not a harmful impurity, and its effect is similar to that of copper. At a content of up to 0.1%, arsenic increases the tensile strength and elastic limit of steel (for every 0.01% increase in arsenic content, 0.4 kg/mm2). At the same time, ductility and impact strength are reduced slightly. Up to 0.25% arsenic does not change the weldability of steel. Arsenic, when solidified, is liquidated like sulfur and phosphorus. The addition of arsenic slightly increases the resistance of steel to atmospheric corrosion.

Rare earth metals (cerium, lanthanum, etc.), introduced into steel in the form of mischmetal or ferrocerium, significantly affect the mechanical and technological properties of steels. Cerium and lanthanum are used as modifiers for various steels; at the same time they are desulfurizers and degassers of steel. The amount of mischmetal or ferrocerium introduced into the ladle ranges from 1-3 kg per ton of liquid steel. With the introduction of such a quantity of rare earth metals in ingots and castings of carbon, structural and high-alloy steels, the dendritic structure disappears. At the same time, the fluidity of steel increases, which facilitates the rapid removal of cerium and lanthanum sulfides formed during interaction with liquid metal. The most complete desulfurization of acid steel (approximately 50%) is achieved by introducing cerium (0.2-0.3%) and silicocalcium (0.2-0.3%) directly into the metal stream during release into the ladle. The presence of rare earth metals in steel improves its weldability and deformability in a hot state. The addition of 0.1-0.2% ferrocerium to steel X23N18 helps to refine the cast metal structure and improve the malleability and rollability of ingots. The introduction of 0.05–0.1% misch metal into 40N steel weakens the off-axis zonal heterogeneity of ingots and castings; the addition of 0.15–0.2% alloy practically prevents the formation of whiskers in the ingots. Cerium helps improve the properties of cast steel to the level of forged steel. The more contaminants in liquid steel, the more effective the effect of treating it with cerium. The more alloyed the steel, the lower the optimal amount of additives: cerium. For critical castings made of carbon steel, this value is 0.2-0.3%, for steel alloyed with nickel, chromium, silicon - 0.1-0.15%.

Other elements of the periodic table in the form of impurities may also be present in steel, but their content is so insignificant that they do not have any noticeable effect on the properties of the metal. It is interesting to note that even technically pure iron contains about twenty different elements, although their total content does not exceed 0.25%.

Influence of other impurities

Like carbon, other chemical elements in steel affect its mechanical properties:

- silicon – used as an active deoxidizer;

- manganese – reduces the influence of oxygen and sulfur, reduces resistance to stress;

- sulfur and phosphorus – increase the red brittleness index and belong to the category of harmful impurities;

- titanium – improves strength and ductility;

- chromium – increases heat resistance and abrasion resistance;

- nickel – improves viscosity and elasticity;

- copper – affects corrosion resistance.

The mechanical properties of steel depend entirely on its composition and the presence of certain impurities. It is these characteristics that must be taken into account when using steel in industrial production. Some negative effects of element content can be reduced by additional improvement methods - thermal hardening of the surface (cementation) or the addition of anti-corrosion protection, in other words - galvanization, the coating of which increases the service life of the product.

Steel classification

Steels are classified according to their intended purpose for further use, chemical composition, quality, and structure.

According to their purpose, steels are usually divided into structural, corrosion-resistant (stainless), instrumental, heat-resistant, and cryogenic.

- Alloyed - steel containing specially introduced, in certain quantities, elements that provide the required physical or mechanical properties. These elements are called alloying elements. As a rule, alloying increases the strength and corrosion resistance of steel and reduces brittleness. Alloy steel according to the degree of alloying is divided into: low-alloy (alloying elements up to 2.5%); medium alloyed (from 2.5 to 10%); highly alloyed (from 10 to 50%).

- Structural steel is used in the manufacture of various parts, mechanisms and structures in mechanical engineering and construction, and has certain mechanical, physical and chemical properties.

- Stainless steel is an alloy steel that is resistant to corrosion in the atmosphere and aggressive environments.

- Tool carbon - steel with a carbon content of 0.7% and higher. It is characterized by high hardness and strength and is used for making tools.

- Heat-resistant steel is a type of steel that can be used at high temperatures (from 30% of the melting point).