At the design stage of critical objects and loaded structures, it is important to correctly determine the fastening elements that meet the requirements. Let's look at what a chemical anchor is and why it is considered the best solution compared to its metal counterparts. Let's get acquainted with the features of various modifications that can be found on modern trading platforms. Read to the end, and you will learn about the main rules for using liquid dowels and recommendations for choosing the right products.

Installing a mount on a hollow block using a chimanker Source stroyfora.ru

Operating principle of a chemical anchor

The operating principle of liquid anchors is simple. A hole with a diameter 2-4 mm larger than the metal element is drilled in the wall or floor. Then the hole is cleaned, filled with adhesive and the fastener is placed there. The substance binds tightly to the metal rod and base, fills all the roughness of the material and hardens, forming a monolithic compound.

Tips for use

Based on the properties of liquid dowels, let’s consider several examples where it is most advisable to use a chemical anchor for concrete:

- Installation of barriers on the finished road surface.

- For installation of floor railings and staircases.

- Fastening of utility networks, if their fastening was not provided for in advance.

- Installation of reinforcement outlets in ready-made concrete structures.

- Installation of monolithic structures, brackets on the facades of finished buildings.

A chemical anchor can be used to secure and monolith a lot of other things; all its properties and applications are countless.

Return to contents

Composition of chemical anchor

Manufacturers usually do not disclose the exact composition of the chemical anchor, but most often it includes a synthetic resin, a hardener and a filler. Synthetic resin is made from polyester, vinylester, acrylic, polyurethane and other organopolymers. The hardener is necessary for the speed of polymerization of the adhesive composition, and the filler, which is used as quartz sand and cement, is necessary for strength.

The final hardening time of different adhesives varies from several hours to a day. The type and composition of the liquid anchor is selected for a specific task, taking into account loads, base material, climatic conditions and other characteristics.

How to choose a chemical anchor

Positive and negative sides

The advantages of a chemical anchor include:

- ease of installation;

- hole tightness;

- possibility of use indoors due to the absence of hazardous substances;

- wide scope of application;

- high strength;

- possibility of installation in aquatic environments;

- durability.

The listed advantages come with a number of disadvantages. These include:

- high cost;

- short shelf life;

- long hardening process.

Despite their negative aspects, chemical dowels are actively used in construction

Types and installation of chemical anchors

There are two types of chemical anchors: ampoule and injection.

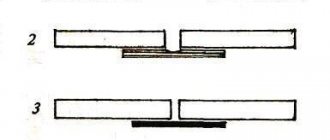

Ampoules are available with one- and two-component compositions. The contents are in a glass capsule. The ampoule is placed in the hole and a fastening element is inserted, which breaks it. The glue sets, and the glass fragments additionally reinforce the connection. For each fastening unit, a new capsule is used, which is selected according to the depth and diameter of the hole. This type of anchor is used for working with dense materials such as solid brick and concrete.

Injection anchors or injection masses are a volumetric cartridge with two compartments filled with different compositions based on organic polymers. The mixer is put on the tube, then it is inserted into a special gun. Injection masses are suitable for working with both solid and hollow bases: concrete, cellular concrete, aerated concrete and expanded clay concrete, porous ceramics, hollow brick, limestone, sandstone and others. Before filling holes in blocks and bricks with voids, a plastic sleeve or metal sleeve is inserted into it, otherwise the adhesive composition will fill large voids in the material.

Video instructions for installing chemical anchors

Rules for installation work

Let's look at how to use a chemical anchor. Here it is important not only to follow the instructions for using dowels, but to properly prepare the work site. Thus, the arrangement of boreholes is carried out taking into account the accuracy and responsibility of installation work. In any case, the seat drilled with a hammer drill must be kept as free from debris and dust as possible. It is easier to complete the task by pre-cleaning with a metal brush and then blowing. Then the pores will be freed to form a more reliable adhesion of the chimanker to the base.

Pneumatic blow gun Source instrumentvs.ru

Another option for cleaning boreholes is washing. This method is relevant for working with a base with a closed-cell structure. Here, not just water is used, but special solutions containing surfactants (surfactants). The principle is this: the composition forms a large amount of foam, from which dirt and dust are subsequently removed. This is done by blowing.

If the work is carried out at a site with increased responsibility, the fastening is carried out on load-bearing elements, then in addition the craftsmen recommend using a special conductor during drilling. This is a small cylinder, which is fixed strictly perpendicular to the supporting platform. To form cone-shaped holes you will need a swinging jig or a special drill. This way the input diameter will remain the given shape and diameter.

Immediately after cleaning the prepared hole, you can start working with a concrete mortar. If it is a capsule, then after it is immersed, a pin is screwed in. If the base is porous or has voids, then first the mesh sleeve is inserted, then the fasteners, and finally the injection composition is introduced. To navigate relative to the volumetric part of the released mass, you can use a pistol with a dispenser.

Gun for injection anchor with dispenser Source vsmete.ru

Application areas for chemical anchors

- Fastening and replacement of reinforcement during the construction of critical structures (bridges, floors, stairs, support columns, overpasses, etc.)

- Inserting working reinforcement outlets when building up the foundation, connecting walls, floor slabs, enlarging columns and stairs

- Fixing steel elements

- House construction (installation of roofing, balconies, gates, gazebos, etc.)

- Installation of auxiliary equipment (satellite dishes, plumbing, lanterns, railings, balustrades, etc.)

- Installation of equipment that requires electrical insulation, such as installing handrails in tunnels

- Fastening structures under water and at high humidity

Hilti injection anchor systems

Such chemical anchors are marked HIT and are presented in a plastic cartridge with foil containers (one contains glue, the other contains a hardener composition). The Liechtenstein manufacturer Hilti offers a choice of seven types of such anchors. This type of Hilti glue for anchors differs in the following characteristics:

- scope of use;

- glue component and hardener type;

- cartridge volume (330 ml or 500 ml);

- permissible load on the stud.

A striking example of the company’s products from Liechtenstein is HIT-MM-Plus glue, which is the most popular and inexpensive (a 330 ml container costs about 700-1000 rubles). Two-component adhesive made from urethane methacrylate.

The manufacturer recommends using it for mounting studs, the thread of which varies from M6 to M16. Installation is carried out in the following types of bases:

- brick;

- concrete;

- block;

- stone (artificial and natural stone).

The most expensive type of product is HIT-RE-500-V3 glue, the cost of which is about 3,000 rubles. It is used for installation of releases of load-bearing reinforcement elements of floors, foundations, stairs, columns. The glue is made on the basis of epoxy resin with additives, due to which it is capable of holding reinforcement with a diameter of 10 to 55 mm.

Advantages of chemical anchor

Chemical anchors differ from conventional ones in a number of advantages. Fastenings using injection masses are resistant to vibration, dynamic and static loads. In such connections, the tensile strength is 2-3 times higher than when using mechanical analogues.

Unlike expansion dowels and anchors, chemical ones do not cause stress in the base material, so they can be fastened close to a corner without fear of chipping and cracking, and also leave a minimum distance between the fastening points. No other fastener will provide such a high load when installed in cellular bricks and other hollow and porous materials.

In addition, the chemical anchor fills all cracks and chips in the base and increases the contact area of the metal product with the material, so even if one or more internal partitions are destroyed, the load-bearing capacity is not lost. For this reason, the injection mass is optimal for dilapidated foundations.

It allows you to install fasteners in holes of any configuration, including cone-shaped ones, and use non-standard hardware and fittings. In the case of traditional installation using plastic dowels or wedge metal anchors, only standard product sizes are used. The adhesive does not harden immediately, so the position of the metal rod can be adjusted. This is not possible when working with conventional anchors and dowels. Another advantage is the tightness of the connection and the resistance of chemical anchors to aggressive environments; they are also often used to fix structures under water.

In short, the following features of chemical anchors can be distinguished:

- Suitable not only for threaded fasteners, but also for fittings

- Vibration resistance

- High load-bearing capacity and tensile strength

- Can be used in aggressive environments and underwater

- There are no strict requirements for the shape of the installation hole

- Monolithic connection, equal strength to the base material

- Ideal for porous and hollow materials

- Tightness and durability of the connection (about 50 years according to EU regulations)

- Easy installation without special skills

Did you like the material?

comments powered by HyperComments

Pros and cons of using

Chemical anchor is more versatile compared to rod and wedge anchoring. Suitable for use with most materials, but most suitable for use with hollow or brittle ones. Examples of such materials include: hollow brick, aerated concrete, and so on.

Chemical anchoring is used to install metal structures, frames of door and window openings. After the glue hardens in the hole, strong chemical adhesion occurs, that is, the adhesion of solids due to intermolecular forces, which allows it to withstand heavy loads.

Adhesive anchor Hilti HIT-RE-100

This type of Hilti glue for anchors is made on the basis of epoxy resin and hardener, and is two-component (the components are mixed during installation).

Using these products, the following construction and installation work is performed:

- installation of additional metal structural parts;

- installation of load-bearing metal structures (beam, column and other types);

- replacing incorrectly installed reinforcing bars or installing missing reinforcement;

- installation and connection of concrete reinforcement bars.

The Hilti anchor HIT-RE-100 has a wide operating temperature range: from -40 to +70° C. These products can be stored and transported at temperatures from +5 to +25° C. Tools for its installation are: HDM, HDE 500-A22.