The expansion anchor can rightfully be called a new generation fastener. Using such anchors made of high-strength metals, you can obtain reliable connections between elements of building structures, perform reliable fastening of large and heavy objects on various surfaces, and also solve a number of other problems related to construction, repair, installation and finishing work. Modern industry offers a wide variety of anchor-type bolts, the requirements for the parameters and characteristics of which are specified by the provisions of the relevant GOST.

There are many modifications of the expansion anchor (other names: “sleeve anchor” or “sleeve anchor”)

High-load anchor

High-load anchors are used to create high-strength fasteners with a class of 8, 8 and higher. The most commonly used are classes 8.8 and 10.9. The composition uses steels with low carbon content, as well as high-alloy steels. To protect the anchor, it is coated with zinc with a layer thickness of at least 5 microns. Its design allows for reliable fixation of the base in solid materials (concrete, brick) and provides the possibility of bonding with other materials. Fastening occurs due to the expansion of the walls of the anchor inside the material and its close contact with the latter. This design is highly adjustable and allows for fairly easy installation. In this case, the expansion of the walls occurs due to the wedge advancing as the screw rotates. This makes it possible to obtain high-strength fasteners even in stressed concrete, thereby increasing the reliability of the created structure.

There are several main types of anchors, which have significant differences in their structural components. Namely the anchor series:

- SZ-B and SZ-S – for high loads

- BLS – self-cutting anchor

- FHII – for high loads

In addition, there are other series of anchors that have a narrow specialization and are used if it is necessary to obtain special parameters. These can be highly efficient anchors of the TA series with an increased washer diameter, as well as many others. The anchors of the SZ series are used more often than others, since they have the best price-quality ratio and at the same time guarantee long-term preservation of technological parameters.

Application area

Types of bolts, their classification and designation

Anchors, which in accordance with the regulatory document (GOST 26778-90) are called self-anchoring expansion bolts, are strong fasteners with which you can securely fix various objects on structures made of solid materials. The high reliability of fixation provided by such an anchor is explained by the fact that its entire outer part adheres to the inner surface of the hole with a high friction force, forming exceptional holding power.

The spacer fastener will demonstrate its high efficiency only if it is installed in a material that has a high density. Thus, the principle of operation of such an anchor is fundamentally different from the principle of operation of a dowel, the outer part of which is in contact with the inner surface of the hole only at individual points, and not along its entire length. Accordingly, spacer-type fasteners can provide significantly greater reliability of the formed connection.

GOST 28778-90 Self-anchoring expansion bolts for construction. SpecificationsDownload

Expansion anchors are used to secure a variety of structures that are under significant load.

Unlike dowels, which are predominantly made from polymer materials, strong metals are used for the manufacture of anchors - carbon steel, brass, etc. If such a fastening element is made of steel, it is additionally protected from corrosion by applying a zinc coating to its surface white or yellow.

The working part of the spacer type is a hollow sleeve, on the side of which there are longitudinal cuts that form expandable petals. In the inner part of such a sleeve there is a spacer element, which, when driving the anchor into a previously prepared hole, opens the petals, which contributes to reliable fixation of the fastener in the hole. The upper part of such a fastener is a pin, on the threaded part of which there is a washer and an adjusting nut.

The figure shows the simplest design of an expansion anchor, which has a solid sleeve along its entire length

Installation of an expansion anchor does not present any particular problems and does not require the use of complex equipment or special skills on the part of the contractor. This process consists in the fact that such a bolt is carefully driven into a previously prepared hole until it stops, and after securely fixing the objects that need to be fixed are hung on its threaded part.

It is most effective to use such various objects on structures made of dense materials that have good adhesion (concrete, brick, natural stone, etc.). If there are internal cracks in structures made of concrete or any other materials into which such a bolt will be mounted, the load that the fastening element can withstand will be significantly reduced.

The design of the anchor for critical fastenings is more complex, but allows the use of fasteners even under vibration loads

Today, anchor-type spacer bolts, the parameters of which must comply with the requirements of GOST 26778-90, are successfully used to install such items and products as:

- heavy and oversized window and door frames;

- elements of staircase structures;

- elements of suspended ceilings of various types;

- lamps and chandeliers;

- scaffolding for construction and finishing works;

- gates and gates;

- elements of various communications (air ducts, cable routes, water pipes, etc.);

- balustrades and consoles;

- various products made of steel and characterized by significant weight.

Attaching the joist to the expansion anchor

The most significant characteristics of expansion anchors, for which experts value them, are:

- exceptionally high strength and reliability;

- resistance to mechanical damage and exposure to negative environmental factors;

- Ease of use;

- speed of fastening creation.

Self-anchoring expansion bolt (BSR)

Construction and materials

The BSR bolt has a special design with a cylindrical spacer fixing element, put on a threaded rod (that is, directly on the bolt itself) and pressed at the other end with a nut.

When installing a foundation bolt into a prepared hole, rotation of the nut leads to tightening and expansion of the wedging element. As a result, the fastener is firmly fixed in the material, leaving a rod with a nut on the surface.

For the manufacture of foundation bolts of the BSR type, high-quality carbon or alloy steel 20, steel 35, 09G2S or 40X is used.

Unlike foreign analogues, domestic anchor bolts “bsr”, manufactured strictly in accordance with GOST, better resist load (due to its uniform distribution along the entire working length of the rod) and are more firmly fixed in concrete or brick - this is facilitated by the special design of the wedging element (an elastic spiral tape made of become). To increase resistance to corrosion, the surface of the BSR anchor bolts is additionally coated with an oxide film.

Technical requirements for the dimensions, design, production conditions and packaging of self-anchoring spacer bolts "BSR" are subject to GOST 28778-90.

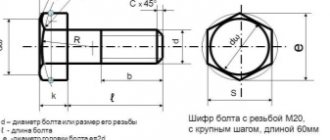

- the standard specifies the size range of bolts - from M6x65 to M24x300 (respectively, metric thread and its diameter, and the second digit is the length of the bolt);

- general design - indicating the shape of all components and the ratio of their sizes;

- the design of the spacer element is given in detail (with a table of sizes of all characteristic sections relative to the base diameter of the anchor thread);

- a method for controlling dimensions and coating is indicated;

- Recommendations for packaging, transportation and storage of BSR spacer bolts are provided.

Application

In addition to the above, GOST 28778-90 contains detailed recommendations for the installation, installation and use of BSR bolts in conjunction with other components or parts of attached structures.

- Thus, installation of self-anchoring bolts is allowed in concrete grade M150 (or similar with a compressive strength of at least B15).

- A hole in the concrete is drilled to a depth sufficient to install the anchor (with the necessary overhang to allow external parts to be attached to it). The diameter of the hole should not be more than 2 mm greater than the diameter of the wedging element of the bolt.

- The anchor is installed in the hole so that the wide turns of the wedging element face the bolt head. When installing, you can tap the bolt head with a hammer (always through a mandrel!).

- External parts of building structures, pipelines, etc. are attached to the free threaded end of the BSR anchor. To increase load-bearing capacity, it is recommended to tighten the nut to 20% greater than the nominal torque.

Source: https://traiv-komplekt.ru/techinfo/bolt-samoankeruyushchijsya-raspornij-bsr/

Concept, purpose and use of anchor fasteners

Main types of oil

An anchor is a type of fastener that is driven, screwed or inserted into the base and is capable of not only being fixed in it, but also holding an additional structure.

Translated from German, anchor means “anchor”. In terms of the way they act on the base, fasteners of this type really resemble an anchor - the working part of the anchor, when fastened, expands and holds the connection to the base.

Fasteners of this type are used when working with hard base materials - concrete, brick, natural stone. The anchor allows you to hold fairly massive structures or structures that are subject to dynamic loads, for example, plumbing fixtures, air conditioners, wall-mounted televisions, sports equipment, suspended ceilings, etc.

Expert opinion Pavel Maksimovich Torsunov

The versatility and reliability of the anchor connection allows them to be used when working with other materials. For example, there are anchors for fastening in porous and lightweight materials, for connecting furniture elements. This type of fastening connection has found its application even in dentistry - an anchor pin is fixed in the root canal of the tooth and serves as a support for a filling or microprosthesis.

Expansion anchor: types, parameters, installation, GOST

Main types of metal cutting

The expansion anchor can rightfully be called a new generation fastener.

Using such anchors made of high-strength metals, you can obtain reliable connections between elements of building structures, perform reliable fastening of large and heavy objects on various surfaces, and also solve a number of other problems related to construction, repair, installation and finishing work. Modern industry offers a wide variety of anchor-type bolts, the requirements for the parameters and characteristics of which are specified by the provisions of the relevant GOST.

Technical characteristics of anchor bolts

The bolt is held in the body of the base by friction, abutment and gluing, if a chemical substance was used that turns the connection into a monolith. Bolt marking - 8*6*60 - means: 8 - outer diameter; 6 – internal diameter; 60 – total length.

Pull-out force (minimum permissible for an anchor in concrete - from 10.5 to 18.30 kilonewtons). Breakout with an anchor involves: a) partial removal of a bolt or conical nut while maintaining the structure; b) complete destruction of the connection - when placing the connection close to the edge.

The permissible bending moment relative to the thickness of the bolt rod is 5.2 to 25.7 Nm.

Torque (maximum) - 10.0–40.0 Nm. The strength of the anchor bolt is characterized by sufficient reliability if it does not exceed the calculated permissible moment.

The production and supply of non-standard anchor bolts is allowed, due to the specifics of the technology used or the design of the facility. In this case, a design of fasteners is developed in accordance with SNiP2.09.03.

Anchor bolts are not painted, but are coated with a protective layer of 45 microns of zinc to prevent rusting and vulnerability in aggressive environments.

Types of heat blocks. Read about this building material in this article. And this article talks about how to glue wallpaper on plasterboard.

Anchor bolt GOST 28778-90 self-anchoring, expansion (BSR)

Anchor bolt GOST 28778-90 is used in construction. The area of application is large construction projects that require the creation of strong and reliable fastenings. This could be: construction work on the installation of pipelines, equipment to load-bearing structures, installation of components and assemblies inside and outside buildings.

The product according to GOST 28778-90 is a self-anchoring spacer bolt (abbreviated BSR), so it can be used with materials such as concrete, brick, reinforced concrete, etc. Application to hollow materials is prohibited.

The operation of the anchor bolt also depends on climatic conditions. In this regard, products are marked as follows:

- UZ.1 – bolt made of steel, strength class 4.6 and higher;

- UZ – a bolt made of steel intended for the manufacture of foundation bolts;

- UHLZ is also a steel product for foundation bolts (in accordance with GOST).

The jamming elements of the GOST 28778-90 anchor are made from a spiral-shaped strip blank. They increase in diameter as they are immersed in the finished holes, which increases the quality of fastening during upsetting.

Installation of anchor bolts GOST 28778-90 requires a pre-prepared hole. In this case, after installation, the threaded end of the BSR must protrude outward sufficiently so that the connection can be strong and withstand high loads. Note that if a feasibility study is available, it is possible to allow changes in both the length of the bolt and the jamming elements.

Standard size M6x65 M8x85 M10x100 M12x110 M16x150 M20x200 M22x250 M24x300

| Bolt thread diameter d | 6,00 | 8,00 | 10,00 | 12,00 | 16,00 | 20,00 | 22,00 | 24,00 |

| Bolt head diameter D + 1.0 | 9,00 | 11,00 | 13,00 | 15,00 | 19,00 | 23,00 | 25,00 | 27,00 |

| Length L | 65,00 | 85,00 | 100,00 | 110,00 | 150,00 | 200,00 | 250,00 | 300,00 |

| Length ZE N | 45,00 | 60,00 | 70,00 | 75,00 | 100,00 | 125,00 | 150,00 | 180,00 |

| Theoretical mass of bolts 1000 pcs., kg | 31,92 | 60,92 | 90,61 | 134,02 | 192,29 | 456,90 | 740,60 | 1159,52 |

Source: https://krepeg-optom.ru/catalog/bolty-vinty/bolt-samoankeruyushchiysya-raspornyy-dlya-stroitelstva-bsr-gost-28778-90/

Types of stud anchors

We'll talk about the most common Hilti stud anchors on the market. The entire range of these products is divided into several types:

- HST;

- HSA;

- HSV.

Each of them has its own nuances, characteristics, standard sizes and has certain operating criteria.

Fasteners from have a reliable design that inspires confidence

HST

This stud anchor is designed for installation of structures in specific areas and is used in tension and compression types of concrete. HST is produced from carbon, stainless or highly corrosive steel types.

This type is the only stud anchor from the manufacturer that is approved for use in concrete that is cracked.

All of the named varieties of these elements are used for the installation of beams, floors, various equipment, columns, as well as structures that are constantly subject to shock loads.

This high quality stud anchor features stainless steel tab spacers with anti-corrosion coating. Due to the presence of a series of highly corrosive material, the presented type of fastener can be used in aggressive environmental conditions.

The main advantages of HST are:

- minimum center distance and length to edge;

- the presence of a head on the threaded part for additional protection;

- wide choice of diameter sizes from M8 to M24;

- matching the length of the drill and the anchor.

The design of the anchor is not complicated

HSA

This mechanical fastener has a unique expansion mechanism. It is pre-connected with a nut and washer. This type of fastener is suitable for working on a concrete base without flaws, as well as on natural stone.

Thanks to the presence of additional markings, during installation you can monitor the immersion length of the fasteners. This makes meeting planting performance requirements much easier. The size of this type of stud anchor corresponds to the length of the Hilti drill.

The advantages of this type of anchor products are:

- diameter difference from M6 to M20.

- possibility to choose the type of coating: galvanized or stainless steel.

- the ability to withstand both standard and reduced planting depths.

HSA series anchor with length markings

HSV

This is a “Standard” type stud anchor for installation in concrete and natural stone. A distinctive feature of this model is that it is used for medium-type loads and has high flexibility.

HSV is manufactured from carbon steel and equipped with DIN 125, DIN 9021 nuts and DIN 127b spring. Due to the production of steel using the cold forming method, the possibility of breakage when bent is eliminated.

This type of fastener differs from those presented in smaller diameters. He has them ranging from M8 to M16.

Features of HSV:

- saving time due to the possibility of assembling fasteners in advance;

- presence of a mark to control the planting depth;

- protection of the threaded part with a large head;

- zinc coating of the surface with a thickness of up to 5 microns;

- possibility of applying load immediately after installation.

Studs with a threaded head can only be used in dry conditions. They can be installed through through or pre-installation.

Galvanized fastener with pre-assembled nut and washer

Expansion anchor: choice depending on application

An expansion anchor is a fastening element made of stainless or carbon steel. One end of the mounting bolt has a thread for fixation, and the other is equipped with a special sleeve that expands due to the impact of the fastener. This anchor design allows for maximum connection strength.

Another advantage is the ability to remove fasteners without destroying the surface of the elements being connected. Where expansion anchors are used and how to choose the right device for specific purposes, read on.

Area of use of expansion anchors

The main advantages of an anchor bolt with a spacer sleeve are:

- ease of installation and dismantling. No special tools are required to install/remove the fastener. It is enough to prepare a puncher and a hammer;

- strength. Products are made of steel (carbon or stainless steel) and for additional strength are coated with a layer of zinc, which protects the steel from corrosion;

- resistance to mechanical damage and chemical attack;

- fastening efficiency.

Expansion anchors are used:

- in construction. Using fasteners of this type, you can assemble and install individual elements of large prefabricated structures, for example, electrification poles, scaffolding, road fences, and so on, as well as fasten finished structures to vertical or horizontal bases;

- at home. Using anchors with spacer sleeves, window frames, doors, stairs, lamps and other fixtures are fastened.

How to choose an expansion anchor

The choice of anchor should be made based on the following parameters:

- types of bolt;

- overall dimensions of the fastening element;

- manufacturing company.

Anchor type

Modern manufacturers produce expansion anchors of the following types:

- Bolts and washer are the most common type of fastening anchors. Wide popularity achieved due to ease of fastening and maximum strength. Anchors with washers can be used for concrete, brick and other monolithic bases, as well as bases with slight porosity.

- Anchors with fixing nuts are mainly used for fastening heavy and large-sized objects, since a pre-installed nut allows you to reduce the time for fixing and, accordingly, holding the object “in weight”.

- Expansion anchor with ring or hook. This fastening element is used when it is necessary to hang individual objects, for example, a ceiling lamp. The fastening element is pre-installed into the base (ceiling) and after that any structure is hung.

- A stud anchor is used for through fastening of structures or individual parts. Studs are usually equipped with washers and fixing nuts.

Fastener dimensions

For strong fixation, it is necessary not only to choose the right type of anchor bolt, but also to first determine the dimensions of the fastening element.

Currently, bolts are produced in different lengths and diameters. The selection of overall dimensions is made depending on the weight of the structure being fixed. The greater the weight of the object being fixed, the larger the expansion anchor must be used.

Popular manufacturers and their features

Many parameters of the anchor bolt (dimensions, safety factor, etc.) depend on the manufacturer of the fastener. The main manufacturers of expansion anchor bolts at present are:

- Hilti company (Liechtenstein). Fastening elements are made of zinc coated steel. The diversity of the line of spacer bolts allows you to fix structures with different dimensions (HSA or HSV for small shapes and HSL 3 or 3G for large objects), as well as use bolts in seismic zones (HST marking).

- Fischer company (Germany). Anchors are characterized by increased strength, which allows the use of fastening bolts in various climatic conditions.

- (Russia). A wide range, reasonable price range, as well as high quality allow you to select expansion anchors for both industry, construction, and domestic needs.

Thus, expansion anchors are the most common types of anchor fasteners, as they can be used in almost any conditions and are capable of holding even objects that are heavy and large in size.

Features of the design of a double-expansion anchor

Two spacer bushings with longitudinal slots are mounted on the cast stud, which, as a result of installation, rest against the walls of the solid building material. It is by increasing the area of “embedding” of fastening elements into concrete, stone and other bases that the resulting fastening is able to withstand greater loads.

When the nut is screwed in, the conical part at the end of the anchor moves up the stud, helping to expand the edges of the sleeve.

The lower bushing also has a conical part and thereby serves as a spacer for the second bushing. When tightened, the hex nut pulls out a cast pin with a conical part on the opposite side of the nut, which is made according to GOST and DIN standards. Thus, no special tools are required for installation.

The pressed washer serves to increase the area of contact with the attached material, distributing the stress that occurs when screwing in the anchor.

What is the main advantage of a double-expansion anchor?

This fastener is designed for reliable operation of heavy structures, as well as those elements that are under constant tension. From the comparative table below you can see that on the GOSKREP website you can buy double-expansion anchors in sizes ranging from M10x100 to M25x350.

When comparing anchor bolts of the same size, keep in mind that the working pull-out load of a double-spread bolt is 6-8 times higher than similar standard ones.

Comparative data of standard and double-spacer anchor bolts:

| Pull-out labor force (B25 concrete) / Weight of attached structure | Exceeding the technical characteristics of the double-spacer over the standard | ||

| standard and double-spread: | |||

| Size 10 x 150 | 1.7 kN | 11.5 kN | 6.76 times |

| 173 kg | 1,173 kg | ||

| Size 12 x 300 | 2.5 kN | 21.7 kN | 8.68 times |

| 255 kg | 2,212 kg |

Another advantage is the speed of installation and the possibility of dismantling. A double-expansion anchor bolt should be used precisely in a dense load-bearing base, where the principle of spreading will work. The strength of the assembly/fastening will depend directly on the strength of the base material.

The cost of the fastener corresponds to the quality and this must be taken into account when calculating estimates.

The status of a more reliable fastener expands the scope of application of the double-expansion anchor to industrial scale and “responsible construction”. The most striking example is the fixation of production machines and other equipment that are subject to constant vibration. A double-expansion anchor can significantly reduce such mechanical stresses.

A reinforced anchor bolt will be indispensable when it is necessary to install heavy structures/elements on a small area of the load-bearing surface. An alternative solution - to use several less reliable hardware, which together would provide sufficient strength - may turn out to be ineffective due to the specific operating conditions.

As mentioned above, this fastener is used for highly loaded connections in materials such as concrete and natural stone. However, if cracks are observed in the concrete, the design load must be reduced by 40% to avoid pullout.

Installing a double-expansion anchor bolt

Installation of fasteners is simple, but practical requirements should not be neglected. Let's look at them in more detail at each installation stage.

| 1. Prepare a hole in the supporting surface using a hammer drill | The diameter of the hole should be slightly smaller than the diameter of the anchor |

| The drill should not be crooked to avoid “walking” in the diameter of the hole | |

| Free space will not allow the fasteners to wedge tightly into the base material and reliably hold the load. It is enough to re-process a narrow hole with the same drill diameter, but avoid drilling. | |

| 2. Clean the hole from construction dust | Use a construction vacuum cleaner, a pump or a rubber bulb |

| 3. Drive the anchor into the prepared fastening area | Use a hammer |

| 4. Tighten the anchor bolt completely with a wrench | When tightening the bolt, the bushings are expanded: the fastener is fixed in the working material |

| If you tighten the bolt too much, it will cause the material to break. Over time, small cracks will increase during use and the anchor bolt will tear out of the hole. If not tightened enough, the bonding force between the fastener and the working material will be low, which will also lead to tearing out and destruction of the connection. Use a torque wrench! | |

| 5. Unscrew the nut and washer and attach the structure; retighten the nut | The pin is already firmly installed in the supporting material; tighten the nut to complete installation. |

| By first firmly installing the anchor bolt into the load-bearing element, you can avoid poor-quality fastening of a heavy, oversized structure. |

The use of a double-expansion anchor bolt is the optimal solution for fastening heavy elements subject to constant mechanical stress into dense load-bearing structures such as concrete and natural stone.

Source: https://goskrep.ru/articles/ankernyy-bolt-dvukhraspornyy-obzor/

Application of expansion anchor: types, advantages and installation

An anchor is a fastening unit made of metal, the main task of which is to fasten individual structures and their parts together. They are used in work related to repair, decoration and construction; they have different types, shapes and sizes. The scope of its application will depend on the type. Produced on modern equipment using the latest technologies, durable and high-quality materials.

Areas of use

One of the reliable and high-strength means of fastening is an expansion anchor (anchoring expansion bolt). It can be used to attach various structures or equipment to bases that have solid material.

The bolt allows you to create uniform friction with great force along its entire length, due to this, high retention capacity is ensured, however, the material of the structure must have good density and solidity.

The main material of the bolt is carbon steel, treated with white or yellow zinc to prevent corrosion on its surface. The bolt has a sleeve made of metal, at one end there is a 4-segment spacer part, the other end has a thread on which there is a nut for adjustment and a washer.

The principle of operation of the bolt is quite simple: when the nail located inside the sleeve is driven into the structure, the lower part of the anchor expands and the bolt is attached to the base.

A bolt with spacers is usually used if it is necessary to attach any structural part to the base using a through-hole installation method. You can make facade fasteners. It is good if the base for fastening is made of concrete or stone with a high degree of adhesion. The presence of cracks in the material will affect the load of the bolt; they will reduce it several times.

Advantages

- The expansion anchor has a complex design.

- The four-segment sleeve is framed at one end by a spring that secures all elements, and at the other with a nut that helps the divergence of all segments when fastening begins.

- Anchoring can occur in two ways: friction (suitable for flat and solid structures) and form using a stop (must be used if the base material contains internal cavities).

- The large spacer gives the product versatility in use. Can be attached to both solid and hollow bases. There are restrictions only on the weight of the attached structures, since elements with high weight cannot be attached to hollow bases.

- High load-bearing capacity allows, subject to proper proportions, the fastening of super-heavy structures.

- A small anchorage depth is allowed.

- There is a possibility of dismantling.

- Holes for installation do not require high precision and are limited by generally accepted rules.

- Expansion anchors are used by professionals.