It is difficult to imagine carrying out construction and repair tasks without drilling various holes. If for drilling wooden and plasterboard structures a conventional electric drill will be quite sufficient, then for concrete it is worth using a hammer drill, since it is capable of not only drilling the surface, but also performing an impact action.

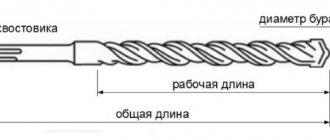

But to make a hole, of course, you need to use a specialized tool - a drill, it has different design features and shank diameter. It is the shank that is used to securely fasten the drill directly to the chuck, so it must be selected based on the parameters of the equipment (perforator or drill).

The most common shank mounting system is SDS (Steck-Dreh-Sitzt). This system was created by Bosch and is designed to quickly replace drills in equipment. Just insert the drill, turn it a little, and it will be secured and ready for use. At the same time, this drill can move without problems along the axis of the chuck, thereby protecting it from shock loads and ensuring a longer service life of the equipment. Therefore, today we can say that SDS drills are the most popular in the construction industry.

For what purposes are SDS cartridges needed?

Universal SDS chucks are designed for drilling concrete structures. The tool is quite simple to secure, and in the shortest possible time.

The most popular cartridges are SDS-PLUS and SDS-MAX. In the first case, the products are designed for small, lightweight hammer drills (up to 4 kg), so they are widely used in performing a variety of household and repair tasks.

SDS-MAX cartridges are already suitable for equipment weighing over 5 kg, that is, they are designed for larger-scale drilling and rapid destruction of concrete and brick structures. Therefore, they are most often used by construction teams on large projects.

SDS cartridge structure

Structurally, the shank is equipped with 4 grooves, 2 of which are open, and the rest are closed. In the first case, the grooves act as guides, that is, they provide the necessary location of the tool, and in the second they are responsible for fastening in the chuck.

Also, the design of the chuck includes special balls, which are also responsible for the correct position of the drill. That is why the drill needs to be turned a little until the balls fit into the closed grooves.

To ensure that the SDS chuck lasts as long as possible, it is recommended that the shanks be cleaned and lubricated regularly. It is worth understanding that there is a slight backlash between the shank and the cavity of the cartridge. This is necessary to protect the instrument from impacts. And to prevent contamination, all cartridges are equipped with rubber boots.

If during operation of the hammer drill you notice frequent stops, cranking, or hear an extraneous knock, then the rubber gasket may have worn out, so the mechanism needs to be cleaned or the boot needs to be replaced. The ball may also wear out, but most often you just need to use a new cartridge.

For drilling particularly hard surfaces, it is recommended to additionally use special lubricants or emulsions.

The best SDS-Max rotary hammers with an impact force of 12-20 J

These are units for the most difficult tasks. With their help, it is easy to knock down walls, punch large holes (expand window and door openings), remove layers of concrete from floors, etc. But the increased impact force affects the impact and ease of working with the tool. Here are the best hammer drills with the SDS-Max cartridge and an impact force of 12-20 J.

Makita HR 4511 C

The first place in the ranking of the best is given to the Japanese Makita hammer drill. The product is notable for its power of 1350 W, impact force of 13 J, electronic speed control from 130 to 280 per minute and impact frequency of 1250-2750. The hammer drill weighs 8.5 kg. A long cable of 5 m allows you to do without carrying it in most cases. To make holes in concrete, you can use drills with a cross-section of up to 45 mm and crowns of 125 mm.

Watch the product video

+ Pros of Makita HR 4511 C

- Adjustable impact force from 2.7 to 13 J, for materials of different densities.

- Network cable 5 m.

- The product is manufactured at production facilities in the UK.

- Good anti-vibration performance.

- Cable fault indicator and power button.

- The rubberized body will last a long time, despite repeated impacts and falls.

— Cons of Makita HR 4511 C

- There is no reverse.

- Your hands get tired quickly.

- The screws in the case are gradually unscrewing - you need to tighten them.

- The mode slider is difficult to switch.

- Periodically shuts down due to overheating.

Conclusion. The main difference between this hammer drill and other participants in the rating is its compactness. The case length is 458 mm, although most competitors have this figure from 600 mm. This SDS-Max unit is suitable for working in cramped conditions (installation of plumbing in bathrooms, drilling in the attic, basement or inside a panel room). Here you can also choose not only the number of strikes, but also the level of force. This will help you carefully make a hole in both brittle and very hard materials.

Bosch GBH 8-45 D

Powerful hammer drill with 1500 W motor. The maximum diameter of the equipment is allowed: drill - 80 mm, crown - 125 mm. The impact force is 12.5 J, and the number of shocks is adjustable from 1380 to 2750 per minute. The cartridge rotates at a speed of 305 rpm. The kit comes with a plastic case and a tube of lubricant. For clean drilling there is a soft start. The housing behind the cartridge is heavily perforated for faster heat dissipation. When the drill bits, the fuse is triggered and the chuck does not rotate with the engine.

Watch the product video

+ Pros Bosch GBH 8-45 D

- Double main handle that can be held with both hands.

- There is a locking start button for constant chiselling, so as not to keep the trigger pressed.

- Recessed mode switch.

- A long additional handle with a 360-degree change in position relative to the barrel.

- A stable platform for placing the tool on a plane.

- Easily drilled into concrete foundation screed.

— Cons of Bosch GBH 8-45 D

- You have to rest your elbow on your leg or stomach, otherwise it’s difficult to keep your weight up.

- Strong kickback in the hands during chiseling mode.

- Grease flies out of the SDS-Max cartridge.

- Weight 8.2 kg is heavy to operate and transport.

- Power cord 3 m.

- Without vibration protection.

Conclusion. The product is worth a closer look for those who often work with equipment 500-600 mm in length. Typically, towards the end of drilling, the speed of the equipment may drop due to increased resistance. This model is equipped with a Constant Electronic system, which will not allow the speed to drop even with increasing load.

Makita HR5212C

Makita produces this hammer drill with the SDS-Max chuck as the flagship among the representatives of the professional line. The power of the device is 1510 W and it is capable of striking up to 1100-2250 times per minute with a force of 20 J. The rotation of the equipment occurs at a speed of 150-310 revolutions. The housing is equipped with anti-vibration inserts. It is allowed to work with drills with a diameter of 52 mm and hollow bits of 160 mm. All controls are located within reach of the left hand. An indicator light indicates the need to replace the brushes.

Watch the product video

+ Pros of Makita HR5212C

- Almost completely rubberized body.

- Comfortable grip and non-slip handle.

- Long trigger for all fingers of one hand.

- The mode switch does not catch on clothes.

- Clear operation of operator protection when biting equipment.

- The auger, 11 m long and 62 mm in diameter, easily passes through clay (suitable for drilling wells).

— Cons of Makita HR5212C

- The wind from the cooling system blows straight into your face.

- Loud engine operation.

- Weight of 12 kg requires frequent breaks from work.

- No reverse.

- Large dimensions 599x140x287 mm.

- It will be inconvenient for lefties.

Conclusion. This hammer drill is a leader in performance and impact force. Its rating is 20 J. This makes it easy to destroy wall materials and ceilings, remove top layers or drill stone. User reviews like the constant chiseling button, which relieves the finger during long-term use.

Drill SDS-MAX

This drill has a shank diameter of 18 mm, therefore it is intended for use with professional powerful equipment, the weight of which starts from 5 kg.

Features of SDS-MAX

These cartridges have certain design features, namely:

- presence of 5 grooves;

- there are 3 guide grooves, that is, open, as well as 2 closed;

- entry into the cartridge is 0.9 cm.

Also, the difference between SDS-max and SDS-plus is based on the asymmetry of the grooves. This is an excellent option for carrying out large-scale construction tasks, as it allows you to quickly and efficiently make holes in ceilings made of any material.

Blog about construction and renovation

To choose the right hammer drill, you should consider that they come in three types: light, medium and heavy. Each of them differs in size, impact force, as well as the types of shanks used on the cartridge, which are SDS plus and SDS max. In order to understand the main differences between the most popular SDS type shanks, you first need to consider their design features and application. SDS plus They are used in most cases in light and medium-class rotary hammers, and are widely used in everyday life. Designed for rotary hammers weighing 2-4 kg. Drills holes up to 26 mm. Features of SDS plus 1) 4 grooves: 2 open, for inserting drills, 2 closed, for fixing them; 2) diameter of shanks 10 mm; 3) fits into a 40 mm cartridge; 4) recommended drill length: min 110 mm, max 1000 mm; 5) contact area of the wedges is 75 mm2. SDS max Used by professionals for more complex work with a hammer drill weighing from 5 kg. Heavy-duty tools are equipped with this type of fastening. Designed mainly for impact work, without drilling. Drilling with a diameter of more than 20 mm is carried out. SDS max rotary hammers have two modes: drilling with impact and impact without drilling. Features of SDS max 1) has 5 grooves: 3 open, guide the equipment, 2 closed, fix it; 2) shank diameter 18 mm; 3) insertion into the cartridge by 90 mm; 4) the contact area of the wedges is 389 mm2. Larger shank diameter increases tool reliability. This is one of the reasons why rotary hammers with SDS max chuck can handle more complex tasks. Which hammer drill company should you choose? There are about ten foreign and domestic brands on the hammer drill market, offering good quality products in the middle price segment. Foreign manufacturers include BOSCH, Metabo, Makita, DeWalt, and Russian manufacturers include Vikhr and Zubr. First of all, you should pay attention to the impact force of the model. It will determine what materials you can work with, how long the process itself will last and how comfortable it will be. A tool with low (up to 2 J) or medium (4 to 10 J) impact force is suitable for home use. Professionals should take a closer look at hammer drills with a stronger impact of 17 J and a power of 1500 W. Another important parameter for any master is the ergonomics and weight of the device. Naturally, the heavier the instrument, the more powerful it is. Therefore, professional hammer drills can weigh from 7 to 12 kg. You won’t be able to hold such a tool in your hands for a long time, which may affect the pace of work. But you can’t do without such a hammer drill, for example, if you make socket boxes or make a groove in a concrete wall. Option two: choose an easier hammer drill. The optimal weight for home is 3-5 kg. Last but not least, the factor is the type of food. It is logical that there are wired and wireless devices. The first ones are perfect for home repairs, since the outlet is most often at hand. Cordless hammer drills are useful in a de-energized facility where there is no electrical wiring yet. Conclusion: When studying different models, we pay attention to the price-quality characteristics, technical parameters and user reviews about the tool. Here are the brands of rotary hammers for work, including middle-class models that are popular among buyers. They are more affordable and suitable for home repairs or outdoor activities. • BOSCH • Makita • DeWalt The price of a hammer drill varies from 6,000 to 50,000 rubles. If you buy one that is too cheap, it may not handle the power or have a short service life. Too expensive, on the contrary, often contains inflated parameters that are not needed, but you will have to overpay for them. The best option in this situation would be to contact a company that provides rental construction tools. Renting power tools designed for various tasks is of interest to professional builders, no less than to home craftsmen. In case of failure of standard equipment, seasonal increase in volumes, or solving complex problems, rental tools save you from image and financial losses. Hammers, drills, crowns, adapters, peaks you can select and order via the link

How to choose the right SDS drill?

To select a suitable drill, you must consider the following recommendations:

- Expediency, that is, it is worth understanding for what specific tasks the drill will be used. To select an SDS chuck for concrete, it is worth considering the hole parameters, that is, depth and diameter.

- Compatibility of SDS-plus and SDS-max with the tool. It is clear that the drill shank should be inserted into the equipment chuck without any problems.

- Quality. In this case, it is necessary to take into account the manufacturer of the drill, because only reliable products made from high-strength and wear-resistant materials are designed for long-term operation. Everyone understands that inexpensive equipment quickly becomes unusable and requires replacement.

It’s better not to save money and buy really good products for performing various construction tasks.

SDS-top

One of the less common types of shanks, which is intended for medium-sized hammer drills. Shank diameter - 14 mm. There are 4 grooves: two open and 2 closed. The contact area with the wedges is 212 square meters. mm.

Drills with SDS-plus shanks often failed when drilling holes larger than 16 millimeters, and in 1999 Bosch introduced the SDS-top standard. For SDS-top drills, four-kilogram hammer drills with a replaceable chuck are used.

How do chucks for hammer drills work?

To effectively use different hammer drill bits, you need to ensure that they are securely attached. A special cartridge is used for this. Its first models began to be developed back in the 30s of the last century, when hammer drills appeared on the market, the mass production of which was mastered by the world famous company Bosch.

Such a manual device as a hammer drill was almost immediately appreciated by consumers, since it can be used to combine drilling with pulse chiselling, which significantly increases the efficiency of the processing performed. The main drawback of the first models of rotary hammers was precisely due to the fact that the weakest link in their design was the cartridge, which quickly became unusable under the influence of shock loads.

As a result of long-term development, manufacturers of hammer drills and chucks have come to the following conclusion: the simpler the design of the clamping device, the more reliable it is in operation.

Externally, the hammer chuck is a completely closed clamping device

As a result, three main types of cartridges for rotary hammers were created, which in turn are divided into subtypes.

There are chucks in which the working attachment is fixed using a special key that activates cams that reliably clamp the shank of the tool being used. The most significant advantage of this type of chucks is that they provide reliable fastening of the tool used in conjunction with the hammer drill. Meanwhile, to replace the working tool in such a chuck for a hammer drill, you will need to spend significantly more time than when using other types of clamping devices.

Main types of hammer drill chucks

The working attachment of the hammer drill can also be fixed on it using a quick-release chuck (KLC), which is activated only by the force created by the operator’s hands. Depending on the design, cartridges of this type can be single- or double-clutch, the operating principles of which also differ.

Single-socket chucks are easier to use, but they can only be used in conjunction with drills that have the ability to automatically lock the working shaft. To activate such a cartridge, the effort of one hand is sufficient. To use a double clutch clamp, you need to hold the rear clutch with one hand and rotate the front clutch with the other.

About attachments for rotary hammers

Theoretically, a tool with a shank for SDS-plus chucks and even a tool with an even smaller seat diameter can be installed on a hammer drill chuck of the SDS-max category. To solve this problem, a special attachment (adapter) is used, which today can be purchased on almost any construction market. Meanwhile, it is strictly not recommended to use such adapters for a rotary hammer, since using a tool of a smaller diameter on heavy-duty rotary hammers will quickly render it unusable.

As a rule, tools for rotary hammers are sold immediately in packages and cannot be restored after failure. However, it should not be confused with conventional drills, which differ from it in the shape of the sharpening and the structure of the spiral.

Power tools designed for making holes of different diameters and depths in various materials are divided into two types - impact drills and hammer drills. The fundamental difference between them is that the drill was originally designed for drilling holes with drills with a sharp edge, and the impact function is auxiliary.

For a hammer drill, the main mode is impact, and the replacement tool is a drill, the rotation of which ensures removal of the knocked-out material from the hole. Thanks to this, the hammer drill becomes almost indispensable when chiseling or drilling (drilling) superhard materials

REPLACEABLE EQUIPMENT ATTACHMENT SYSTEMS

The main feature of an electric hammer is its high impact energy and amplitude. Achieving this effect can be achieved through the use of an electromagnetic or pneumatic mechanism.

In the first case, two electromagnetic coils are used to ensure reciprocating movement of the core, which, through a special striker, strikes the end part of the working nozzle.

Evidence of benefit

| European competitor | Bosch 5X | Chinese competitor |

| ||

5X vs. Eurocompetitor:

| 5X vs. Chinese drills:

| |

Evidence of benefit

- 2 times larger sludge removal area, less heating, wear, faster speed and service life

- Tungsten carbide cutting edge is 20% longer, increased impact resistance, longer service life

SDS plus-5X Reliable drill for working in reinforced concrete

| Centering point For deep and stable drilling in concrete | 4 cutting edges The geometry of 4 cutting edges prevents the drill from jamming in the reinforcement. The drill tip does not break | |

| Patented carbide insert seating design coupled with large and wide dust channels provide rapid drainage of drilling dust, ensuring drilling speed and less wear | 4 Spirals Rapid extraction of drilling dust for increased productivity and reduced wear |