Today, few garages and fences can do without reliable connections. It is their correct installation that determines how long they will function properly. We are talking about gate hinges that secure the gate to the frame and open it to the desired angle.

This article will discuss the main types of metal hinges and the features of their installation on various surfaces. Gate hinges are a mechanism consisting of two main elements that form a hinge. It allows the fence canvas to easily rotate relative to the base. Such connecting elements are capable of providing opening in the range from 90 – 180°. Some designs provide the ability to move in both directions, and this greatly increases the functionality of the structure.

Choosing material for garage hinges

Hinges for garage doors are made from metal profiles, black steel or low-alloy alloys. When choosing a material for fasteners, it is necessary to take into account the grade of steel of the body so that it can ensure high-quality weldability with the steel frame. Parts made of black steel are welded using electric welding by processing around the perimeter of the body or flange plates. Hinges made of alloyed materials are spot welded using argon or carbon dioxide welding.

There are no significant advantages that make it worthwhile to mount gates on stainless steel hinges, except that they are not subject to corrosion. In addition, the coefficient of friction in these joints is higher than that of carbon steel with standard characteristics.

Sash designs

Even such a simple design as a gate leaf or wicket can be made in different ways, and there are many options. First of all, the location of the jumpers differs:

Each method is tested and works, providing a sufficient degree of rigidity. Here you choose what seems more correct or reliable to you.

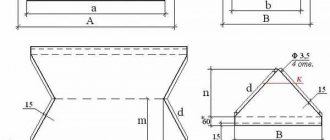

Gate design made of metal profiles with jibs

There is a difference in the design of the gate itself - with or without a stationary frame (top crossbar). With a frame, the gate is more stable, but then there are height restrictions: tall vehicles - trucks or special equipment - will not be able to enter the yard. With proper reinforcement of the racks (pillars) and properly made doors (with reinforcement in the corners), gates without a frame will also be reliable.

Gate design with top crossbar and crossbars

When installing a gate with a frame, the metal consumption is greater - per the length of the lintel, but the pillars can not be additionally reinforced: the load on them is less.

Cross-shaped lintels on metal profile gates

To make it more convenient to attach the profiled sheet, a thin-walled metal profile 1 cm wide is welded along the outer (sometimes internal, as in the figure above) perimeter of the sashes. This must be taken into account when determining the dimensions of the blanks for the sashes.

To make the structure as rigid as possible, so that it does not “walk” or make noise in the wind, reinforcements are made in the corners. And again there are two ways. The first is to weld the corners cut from sheet metal.

Reinforcement of sashes with metal plates

The second is to install short corner jibs from the same pipe that was used to weld the sash frame.

The second method of strengthening gate leaves

There is also a difference during assembly: at the joints, the pipes are connected at an angle of 45° or simply end-to-end. More professional - at 45°, easier - end-to-end. Some assembly methods do not provide for the possibility of connecting at an angle at all (if both doors are assembled in one piece, and only those hung on poles are sawn into two parts).

Different methods of joining pipes

Another subtlety that depends on the amount of snow in winter. As you can see in the photo, the bottom bar of the sashes is raised to different heights from the ground - somewhere a few centimeters, somewhere 20 cm and higher. Depends on the height of the snow cover in winter: if snow piles up and the gates are as high as the ground, you won’t open them. To prevent any living creatures from climbing into this gap in the summer, after the snow has melted, a plank is screwed onto the screws, and in late autumn it is removed again.

You can install automation on swing gates. Then you can control them from the remote control and there is no need to go out into the snow and rain.

Selecting the optimal size

In order for the hinges to hold the metal sheet, it is necessary to select their dimensions correctly. The diameter of the clamps varies between 10-32 mm. The loop diameter step is 2 mm per increase. The height of garage hinges ranges from 60 to 160 mm.

An important point when selecting dimensions is the reliability and ease of use of garage doors. To prevent the blade from jamming when opening and closing, it is recommended to leave a gap of 0.1-0.2 mm between the axis of the clamps and the opening of the housing . In terms of their dimensions and weight, the hinges must correspond to the material from which the doors are made. Depending on the canvas installed in the garage, the number of loops also depends, ranging from 2 to 4 elements.

What are the advantages of cylindrical hinges that have a support bearing?

This category has the usual form. They look like a cylinder in appearance. There is a pin on one side, and a hole is made for it on the other. This design is supplemented with a bearing ball. Such fastenings are often used for metal sashes that weigh no more than four hundred kilograms.

Smooth operation is ensured by a special ball bearing. Typically it is placed in a part with a hole. In order to be able to lubricate the bearing during operation, a hole is drilled on the other side. It can be closed with a suitable size plug. When it is necessary to improve the movement and mobility of this curtain, simply open the plug and lubricate the bearing.

Main types of garage hinges

The building materials market offers a wide variety of hinges for swing doors. Each variety has individual parameters and advantages of use. The first thing you need to do when choosing is to select an installation option. The following installation methods are available:

- welding - the hinges are fixed on the door leaf and frame;

- installation using bolts - used when working with wood material;

- fastening with self-tapping screws - suitable for structures made from profiled sheets.

Based on placement, clamps are divided into hidden and internal. Their main differences lie in the installation method and decorative characteristics. When choosing garage hinges, the weight of the door is of great importance. Incorrect calculation of the expected load provokes skew of the canvas and difficulties with opening. For dense sheet steel with a large mass, it is recommended to purchase reinforced clamps.

With support bearing

Hinges equipped with a support bearing are the basic type of cylindrical type fasteners. The support bearing and swivel joint are reliably protected from external influences by the main body made of metal alloys.

Models with support bearings are intended for lightweight swing structures. The maximum permissible load is 100 kg. The clamps with support bearings are attached to the sashes and frame using a welding machine.

When fixing, it is necessary to maintain the gaps between the frame and the sash. The element is centered not along the axis of rotation, but along the bearing.

Cylindrical with additional reinforcement

Reinforced clamps are equipped with additional plates, which helps distribute the load over a large surface of the sashes or pillar. It is recommended to use cylindrical hinges with improved plates for thin profile structures. The parts are fixed to the swing gate leaves and frame by welding or screw connection.

Depending on the side of location, cylindrical reinforced hinges are divided into right and left. The diameter of the element is 50 mm. The maximum total load reaches 600 kg.

End-to-end

If it is not possible to secure the hinges by welding or screwing to the frame, a through type is used. For installation in the gate frame, mounting columns are drilled along the entire length, into which part of the retainer is threaded. For final fastening, nuts of the appropriate size are used. Thanks to a special fastening scheme, through-type fasteners can withstand loads of up to 200 kg.

Three-section invoices

For massive swing gates, it is necessary to increase the number of latches and choose a type with increased wear resistance. The best option is three-section models that can withstand the load of a heavy structure. The main advantages of overhead three-section hinges are:

- smooth sliding when opening and closing the gate;

- no creaking;

- reliable protection against burglary;

- preventing the sash from warping and sagging.

Boom loops

Garage boom hinges are suitable for attaching large swing doors, gates and thin-profile structures. The main distinguishing feature is the increased area of the clamp, due to which it provides additional strength and prevents distortions.

At the connection points, the arrow loops are able to withstand increased stress. This is facilitated by uniform distribution along the entire length of the sash. The range of dimensions of the clamps varies up to 700 mm, which makes it possible to find the optimal option for any gate design. The fastening parts are made from durable sheet steel, which ensures a long service life.

Invoices

Despite the ease of installation, overhead types of hinges are highly reliable. The fasteners are made from durable materials, including steel alloys, brass and stainless steel, which significantly increases the variability of their use. Inside the housing there are 2-4 ball bearings necessary for smooth opening of the gate.

Other advantages of overhead parts include the complete absence of squeaks, prevention of sagging of the sashes, resistance to burglary and a long period of operation.

To fix the overhead hinges on the frame, you need to mark their exact location and secure it with self-tapping screws. The clamps are included in the universal category and are not divided into left- and right-handed ones. If after installation it becomes necessary to remove the canvas from the hinges, you will need to unscrew the screws.

Classification of products according to GOST

Manufacturers produce hinges in a wide range. To select a product, they use GOST, namely a table that shows the technical parameters of the product. GOST (state standard) is the main document by which the dimensions, weight, load, shape for each type are determined.

Cylindrical version

According to GOST they are divided into the following types:

- cylindrical;

- cylindrical reinforced;

- end-to-end;

- secret;

- three-section overhead;

- invoices.

Uniform weld seam

Cylindrical with bearing

The canopy is shaped like a cylinder, which has been divided in two. One part of the gate hinges has a hole, called “mother”, the other with a pin is called “father”. The two halves connect to each other and rotate in a circle.

Forms

Modern varieties of hinges come in several shapes. Each form has individual technical characteristics, advantages and disadvantages. When choosing a suitable shape, you should take into account a combination of parameters, your own preferences and the load created by the metal structure.

Cylindrical

Cylindrical hinges with a bearing inside the housing are suitable for standard models of swing structures that have a relatively low mass. The maximum load on the latch on each side should not exceed 400 kg. Depending on the class of loop purchased, the maximum holding weight may vary.

Despite its non-standard shape, the cylindrical variety is one of the most common options. The clamps are highly durable and are attached to the frame by welding. Before welding the main part of the body, it is necessary to weld the lugs for a more secure hold.

Square

Square hinges differ from other form factors in their increased surface contact area. Due to the large contact area, the clamps are easily welded to the body and can withstand the constant load of massive structures. Also, square-shaped fixing elements are used to fix various transverse elements, gates and other structures.

For the production of parts, galvanized metal with a smooth surface and low weight is used.

Hexagonal

Hexagonal elements are less common compared to other shapes. By analogy with cylindrical clamps, they require preliminary welding of metal ears, which provides additional convenience during subsequent installation. Hexagonal hinges are selected taking into account decorative properties, total weight and dimensions of swing gate leaves. Standard hexagonal elements are capable of supporting metal structures weighing about 400-500 kg.

teardrop-shaped

The teardrop shape is characteristic only of hinges with a built-in bearing. In addition to the aesthetic appearance, this type has additional advantages - a uniform welding seam and ease of installation, which are achieved due to its special shape.

When installing on massive swing structures, it is recommended to use teardrop-shaped hinges with a diameter of 30-32 mm and a length of about 250-300 mm. The length of the weld with which it is welded to the frame directly depends on the length of the loop. It is advisable that the clamps be equipped with grease nipples for lubrication so that the gates do not make any extraneous sounds when opening and closing.

Buying Tips

In order to make the right choice, you need to study the features of each type of loop . Reinforced options are usually in demand, but there is not always a need to purchase expensive products.

When choosing, take into account what material the doors are made of and what load the hinges need to withstand. Gates made of corrugated sheets have through or hidden hinges. Reinforced hinges are more suitable for heavy forged and metal doors.

For high gates made of corrugated sheets, choose classic products (in the shape of a cylinder). Hanging hinges are selected taking into account the load they will have to withstand. Products with an eccentric are chosen for the home (on doors, furniture or light gates). For automatic doors, induction magnetic hinges are purchased.

In areas with heaving soil, which increases during severe frosts, adjustable hinges for swing gates are installed. In winter, in such areas, the axle of garage door canopies is subjected to heavy load, so the hinges need to be constantly adjusted. Otherwise, the canopies may warp, which will damage the entire structure.

You should not purchase products from an unknown manufacturer or skimp on fittings, the quality of which also determines the reliability of the gate design.

Instructions for installing hinges on garage doors

Before you begin directly installing the clamps on the gate, you need to prepare a certain list of tools. In particular, for installation you will need:

- welding machine with a set of different electrodes;

- a grinder or grinder for smoothing seams;

- tape measure, plumb line and level for taking measurements;

- hammer;

- screwdriver

The instructions for installing hinges require sequential execution of a series of actions. To fasten the parts you need:

- Place the structure on a flat surface.

- Mark places for fastening. It is important to first check all the dimensions of the gate so that the gap between the leaf and the frame does not exceed 0.2 mm.

- Lubricate the hinges with grease or another type of lubricant.

- Use spot welding to fix both parts of the hinge, first from the bottom and then from the top of the gate.

Welding without unpleasant consequences

To ensure successful welding of hinges to gates, follow these recommendations:

- do not work with a faulty welding machine;

- you can cook only after the paint has completely dried;

- clothing should not contain traces of grease, gasoline, oil or any other flammable liquids;

- Do not cook parts under pressure;

- Do not hang rags soaked in flammable liquids on the welding machine cylinder. This often caused a fire.

How to weld

After carefully checking the location of the gate and preliminary fixing the hinge on both sides, you can begin welding work to ensure complete fastening to the frame. The convenience of opening the gate and the likelihood of door leaf skewing depend on correct fixation.

The most labor-intensive stage in the work is making vertical welds. To prevent the hinges from moving after the bayonet part of the part is secured, it is necessary to use a level to determine the location of the axis of the welded hinge.

After the final welding of the bayonet elements on the frame, you need to put the upper parts with steel bearings on them. Having pressed the baited part to the canvas, all that remains is to complete the welding and process the welding seams with a grinder to create a smooth surface.

Preparatory work

They start by welding the plates to the hinges. This step can be skipped if you are using ready-made canopies with mounting plates or when mounting them on round poles of small cross-section. The plates are cut from sheet steel using a grinder, choosing sheets with a thickness of at least 5 mm.

Before assembling the hinge, its internal part (the place where the bearing is located) is carefully treated with lubricant, and the area allocated for welding is cleaned of dust and rust. Cook on a horizontal surface. Two plates are laid side by side along the long side with a gap of 2–3 mm. Half of the canopy is placed on top, welded to one of the plates with a continuous seam. A similar operation is performed with the second half. The resulting seams are carefully cleaned.

Important: according to fire safety rules, welding work is carried out either on unpainted or fully painted, dry parts. Paint that is not completely dry can ignite from a spark.

Rules for caring for garage hinges

The main wear of garage door hinges occurs due to unevenly distributed load, negative external influences and untimely lubrication. To combat the effects of abrasion and corrosion, the following steps are recommended:

- remove the doors from the hinges and remove any rust that has formed;

- wipe off the old lubricant and remove dirt with fine sandpaper;

- treat the rotary axis with grinding paste;

- remove remaining paste with solvent and clean the hinge hole;

- apply a new layer of lubricant.

Properly selected hinges in size and material ensure a long service life. Timely maintenance of fasteners promotes ease of use and prevents rust.

Pros and cons of swing gates

Among the advantages of gates with a swing structure, the following should be noted:

- Simplicity of design. It is quite possible to make it yourself. It is enough to use a sheet of metal, a metal profile or fasten boards together to get gate leaves;

- Convenience. It lies in the fact that due to the simplicity of the design, you can always open your gate. They extremely rarely jam or otherwise break;

- Wide selection of locks - any will do, you can even use a simple bolt;

- Possibility of easy automation;

- Long service life;

- Possibility of adjusting the opening of the valves;

- Low cost.