Pipes made of stainless steel alloys are now actively used for the installation of heating, water supply and sewerage systems. By choosing the diameters of stainless steel pipes according to a special size table, you can successfully select such products to solve various problems.

For each type of stainless pipes there are maximum permissible deviations from the parameters defined by the relevant standards

All pipes for the production of which stainless steel is used are produced in strict accordance with the regulatory document. GOST stipulates not only the chemical composition of the material for their manufacture, but also their production technologies, sizes and assortment.

Classification options

The entire range of pipes made from stainless steel is divided into several categories. The parameters by which this division is carried out are:

- design features (suture and seamless);

- production technology (cold rolled, cold drawn and hot rolled);

- cross-sectional shape (round and profile);

- wall thickness (thick-walled and thin-walled).

Stainless steel pipes of various sizes are actively used for arranging communications through which cold and hot water is transported, as well as for installing sewer systems. Such pipes, which have a significant diameter, are successfully used for the installation of main oil and gas pipelines.

The ratio of outer to inner diameter for thick-walled stainless steel pipes is in the range of 0.05–0.1

The high popularity of rolled pipes made of stainless steel is explained by a whole list of its advantages:

- exceptional durability;

- possibility of operation under high pressure;

- resistance even to significant temperature changes;

- high plasticity;

- resistance to corrosion, demonstrated even during operation in conditions of constant exposure to aggressive environments.

It should also be noted that the minimum service life of stainless steel pipes is 10 years.

Main varieties

GOST also stipulates the range of stainless steel pipes, which includes the following products:

- used for transporting liquid and gas media – water and gas pipelines;

- coated with a special anti-corrosion compound;

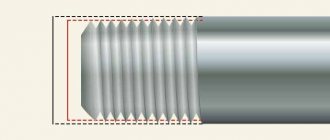

- characterized by a slight wall thickness and having threads at the ends (such steel pipes, the diameters of which can be different, also have a reduced weight);

- produced using welding technologies and having longitudinal seams;

- seamless, made using hot-rolled technology.

It is worth dwelling in more detail on each type of stainless pipes, the range and diameters of which are specified by GOST.

Water and gas pipes

The diameter of pipes of this type, as indicated by GOST, can vary within a fairly wide range: 15–50 mm. Depending on the pressure under which they are intended, such stainless steel pipes are divided into light, standard and reinforced.

Parameters of water and gas pipes

GOST stipulates that the ends of water and gas pipes must be cut at an angle of 90°, and the welds on their surface must be completely welded and sealed. In accordance with the standard, there may be minor chips on the surface of such steel pipes, but in general their walls should be smooth and free of cracks.

Pipes with anti-corrosion coating

Such pipes, which are also listed in the stainless steel product range, are distinguished by the fact that their surface is coated with zinc, which provides additional corrosion resistance. In accordance with the regulatory document, they should not have areas not coated with zinc, coating blisters, burrs and other defects.

The dimensions of the thread, if applied to the ends of such pipes, should not exceed 10 percent of the length of the product itself.

Thin-walled pipes with threads

These pipes, produced in various standard sizes, are used in cases where it is necessary to carry out repairs or change the design of the pipeline. Products of this type, which make it possible to obtain reliable and tight connections, are not thick-walled and are not produced with large cross-sectional dimensions.

Parameters of light series pipes manufactured for threading

Hot-rolled pipes

On the surface of hot-rolled pipes, which can be thick-walled, there are no welds, which gives such products high tightness and allows them to withstand even very significant pressure. These products, the standard sizes of which are also specified in the assortment, are distinguished by smooth walls and a minimal coefficient of thermal expansion.

The most common areas of application for such pipes, the sizes of which can vary quite widely, are:

- installation of pipelines for supplying cold and hot water;

- arrangement of sewer systems;

- installation of heating networks and communications for other purposes.

Dimensions of seamless hot-formed stainless steel pipes

It should be borne in mind that both thin-walled and thick-walled pipe products produced by welding can be used to supply water used for technical purposes, and not for drinking or cooking.

Hot rolled seamless steel pipes

The hot process gives finished products the following advantages:

- Ideal anti-corrosion properties.

- Durability and resistance to impact.

- Allows the production of products with walls up to 32 mm.

- Competitive price.

Standards for pipes according to GOST 9940-81

Hot-deformed pipes are cleaned of scale and have no external defects on both surfaces.

If products are subject to further welding, then the mass fraction of sulfur in the material is normatively limited to 0.02%. Table 5. Permissible deviations along the wall.

| Maximum deviations for manufacturing accuracy, % | |

| ordinary | high |

| ±1,5 | ±1,0 % |

Table 6. Permissible deviations in diameter.

| Pipe sizes, mm | Maximum deviations for manufacturing accuracy, % | |

| ordinary | high | |

| By wall thickness, mm | ||

| 8 or less | +20 -15 | +12,5 -15,0 |

| more than 8 to 20 | ±15,0 | +12,5 -15,0 |

| more than 20 | +12,5 -15,0 | ±12,5 |

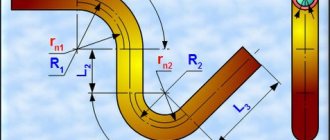

The curvature of finished hot-deformed products is established normatively. This value is indicated relative to the wall thickness per 1 m of pipe and is:

- with a wall less than or equal to 10 mm: 1.5 mm;

- with a wall of 10-20 mm: 2 mm;

- with a wall more than 20 mm: 4 mm.

The standard's requirements for passing the hydraulic test, tensile test and others are similar to the tests established for products produced by the cold-deformed method.

Hot rolling steel technology

Unlike the cold rolling method, which involves heat treatment of blanks and products at some stages, the hot rolling method is completely carried out on heated metal. For this purpose, special furnaces with a so-called walking hearth are used, in which an excess pressure of up to 29.4 Pa is formed.

Next, the workpiece goes through several deformation stages:

- crimping machine;

- piercing mill, in which the workpiece becomes a pipe with walls;

- rolling on a continuous mill;

- induction heating and reduction mill.

After reduction, the finished pipes are cooled and cut into the required lengths.

Dimensions of seamless pipes GOST 9940-81 - table

GOST has introduced additional restrictions on the diameter of products for some steel grades:

- 108 mm - 08Х20Н14С2, 08Х22Н6Т, 08Х18Н12Б.

- 140 mm - 08Х17Н15М3Т.

- 168 mm - 10Х23Н18.

- 219 mm - 10Х17Н13М2Т, 15Х28, 08Х17Т, 12Х17.

Standard sizes

The list of standard sizes of stainless pipe products includes the following parameters:

- nominal diameter - internal diameter, which can vary between 10–150 mm (the larger this parameter, the higher the permeability of the pipes);

- thread sizes (in accordance with the requirements of the standard, this parameter can vary in the range of 3/8–6 inches);

- outer diameter, which, taking into account the size of the weld, can vary in the range of 17–156 mm;

- The outer diameter of steel pipes, which are made without the use of welded joints, is 16–159 mm.

Main dimensions of stainless pipes

Stainless steel pipes, depending on their type, are produced in accordance with the requirements of various regulatory documents:

- GOST number 3262-75 – water and gas pipelines;

- 10705-80 – obtained by welding;

- 20295-85 – intended for laying main pipelines.

Each of the above regulatory documents contains tables that indicate the range and standard sizes of such products.

Cold- and heat-deformed seamless stainless steel pipes

The cold process has significant advantages:

- Minimal metal loss.

- Possibility of obtaining a wide range of pipe sizes from similar blanks.

- Allows the production of products with a wall thickness of 0.2 mm.

- Minimize wall thickness deviations.

- Excellent surface quality of finished products.

- Durability.

Requirements for pipes according to GOST 9941-81

The surface of the products should not have cracks, caps, or sunsets.

External damage resulting from deadening deformation must be cleaned (grinded) without going beyond standard limits. These indicators are reflected in tables 1 and 2. Table 1. Permissible deviations along the wall

| Pipe sizes, mm | Limit deviations for manufacturing accuracy | ||

| ordinary | elevated | high | |

| at wall: 0.2 | ±0.05 mm | ±0.03 mm | — |

| from 0.3 to 0.4 | ±0.07 mm | ±0.05 mm | — |

| from 0.5 to 0.6 | ±0.10 mm | ±0.07 mm | — |

| from 0.7 to 1 | ±0.15 mm | ±0.10 mm | — |

| St. 1 to 3 | +12,5% | ±12,5 | 12,5% |

| St. 3 to 7 | +12,5% | ±12,5 | 10% |

| St. 7 | +12,5% | ±10% | — |

Table 2. Permissible deviations in diameter.

| Pipe sizes, mm | Limit deviations for manufacturing accuracy | ||

| ordinary | elevated | high | |

| with diameter: from 5 to 10 | ±0.3 mm | ±0.2 mm | ±0.15 mm |

| St. 10 to 30 | ±0.4 mm | ±0.3 mm | ±0.2 mm |

| St. 30 to 95 | ±1,2 % | ±1,0 % | ±0,8 % |

| St. 95 | ±1,0 % | ±1,0 % | ±0,8 % |

For product sizes (diameter x wall thickness, mm):

- 100-102 x 1.5-2.9;

- 108-120 x 1.5-3.2;

- 130-150 x 2-3.2;

- 160-200 x 2.5-3.5;

- 220 x 3-3.5;

- 250 x 3-4 —

maximum deviations are specified specifically and are shown in Table 3.

Table 3. Permissible deviations in diameter and wall for individual sizes of seamless cold-formed products.

| Pipe sizes, mm | Limit deviations for manufacturing accuracy | |

| ordinary | high | |

| By outer diameter | ±1,2 % | ±1 % |

| Wall thickness from 1.5 to 2.5 | ±15 % | ±12 % |

| St 2.5 to 4 | 12,5 % | ±12,5% |

The standard sets requirements for the curvature parameter of products produced by the seamless cold-rolling method. This value is indicated per 1 m of pipe and is for the diameter:

- less than 15 mm: 1 mm.

- over 15 mm: 2 mm.

For products with a diameter of up to 15 mm and a wall of up to 0.5 mm, the maximum curvature is not normatively established: it can be any, without kinks.

The surface of the pipes is light. Features of the manufacturing process and metal grade may result in dull color.

Tubular products produced by the cold-deformed method must withstand a number of tests:

- for tension at a temperature of 350 degrees C;

- flattening/distributing to calculated parameters;

- hydraulic pressure at a stress of 40% tensile strength of steel type;

- for intergranular corrosion;

- ultrasonic testing.

Cold rolling technology for steel pipes

Direct deformation of the workpieces is preceded by chemical preparation - etching. Steel with chromium alloying content is etched with alkaline melts and acid solutions. The result is the transformation and removal of iron oxides and scale.

Next, the pipes are washed with hot and cold water, dried at a temperature of 170 degrees C, and special coatings are applied to prevent the occurrence of defects during further deformations. When rolled through a mill, the workpieces do not come into direct contact with the milling tools.

Billets pass through rolling mills several times. At intermediate stages they are subject to additional chemical influences. A significant role is played by heat treatment up to 700-800 degrees C, as a result of which the hardness of the metal decreases (annealing). After deformation, thermal hardening is carried out, as a result of which the mechanical properties of the products increase.

Dimensions of seamless pipes according to GOST 9941-81 - table

Brands and guaranteed parameters

The tables contained in the regulatory documents for pipe products made from stainless steel contain various parameters. In particular, from these tables you can take information about the grades of steel used for the production of such pipes.

Permissible deviations from dimensions must be within the values specified in the table

Knowing the brand of material from which the pipe is made allows you to get an idea of which of its parameters are guaranteed. These include in particular:

- A – mechanical characteristics of the steel used;

- B – its chemical composition;

- B – the relationship between the chemical composition and mechanical properties of the alloy used.

Processing methods

Surface treatment is the final stage in the production of corrosion-resistant pipes.

Accordingly, the following types of processing can be distinguished:

- thermal;

- chemical;

- mechanical.

After the finishing process we obtain a matte, polished, mirror surface. To add shine, parts are polished with brushes and grinding pastes on special machines. This operation significantly increases the price of the product, but at the same time the procedure makes the mirror pipe more competitive in comparison with its matte counterpart.

Such tubular products are used in cases of unavoidable contact with food and baby food. After all, these surfaces not only have an attractive appearance, but they also eliminate the possibility of harmful microorganisms settling on them.

In addition, the details give the premises and facades of houses a special decorative effect. And if you take corrugated corrosion-resistant elements, then they can be placed in the required directions. Thanks to this, they are used to equip kitchens and dining rooms.