Mechanical engineering parts and mechanisms, as well as tools intended for their processing, have a set of mechanical characteristics. Hardness plays a significant role among the characteristics. The hardness of metals clearly shows:

- wear resistance of metal;

- possibility of processing by cutting, grinding;

- resistance to local pressure;

- ability to cut other materials and others.

In practice, it has been proven that most of the mechanical properties of metals directly depend on their hardness.

How is hardness measured and how is it designated?

For most hardness measurement methods, the basic unit of measurement is kgf/mm2

However, you should understand that there are methods with their own unit.

The designation of hardness also depends on the method.

The letter “H” always denotes “hardness” (from the English Hardness), and then the letters indicating the determination method are indicated. The most popular designations:

- HB – Brinell method (pressing a steel ball)

- HRA - Rockwell method, A scale (diamond or steel cone indentation)

- HRB – Rockwell method, B scale

- HRC - Rockwell method, C scale

- HV – Vickers method (diamond pyramid indentation)

- HSD – Shore hardness, etc. (rebound method)

Hardness Units

Each method of measuring the resistance of a metal to plastic deformation has its own methodology, as well as units of measurement.

The hardness of soft metals is measured using the Brinell method. Non-ferrous metals (copper, aluminum, magnesium, lead, tin) and alloys based on them, cast iron (except for white) and annealed steel are subjected to this method.

Brinell hardness is determined by indentation of a hardened, polished ball made of ShKh15 ball bearing steel. The circumference of the ball depends on the material being tested. For hard materials - all types of steel and cast iron - 10 mm, for softer materials - 1 - 2 - 2.5 - 5 mm. Required load applied to the ball:

- iron alloys – 30 kgf/mm²;

- copper and nickel – 10 kgf/mm²;

- aluminum and magnesium – 5 kgf/mm².

The unit of hardness measurement is a numerical value followed by a numerical index HB. For example, 200 NV.

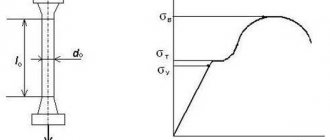

Rockwell hardness is determined by the difference in applied loads to the part. First, a preliminary load is applied, and then a general load, at which the indenter is introduced into the sample and held.

A pyramid (cone) of diamond or a ball of tungsten carbide (hardened steel) is introduced into the test sample. After removing the load, the depth of the indentation is measured.

The unit of measurement for hardness is conventional units. It is generally accepted that one is the amount of axial displacement of the cone, equal to 2 μm. The hardness designation is marked with three letters HR (A, B, C) and a numerical value. The third letter in the marking indicates the scale.

The technique reflects the type of indenter and the load applied to it.

| Scale type | Tool | Applied load, kgf |

| A | Diamond cone with 120° apex angle | 50-60 |

| IN | 1/16" ball | 90-100 |

| WITH | Diamond cone with 120° apex angle | 140-150 |

Basically, measurement scales A and C are used. For example, the hardness of steel is HRC 26...32, HRB 25...29, HRA 70...75.

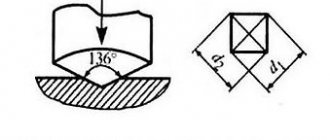

Products of small thickness or parts with a thin, hard surface layer are measured by Vickers hardness. The blade used is a regular tetrahedral pyramid with an apex angle of 136°. The display of hardness values is as follows: 220 HV.

Hardness measurement using the Shore method is carried out by measuring the rebound height of a fallen striker. Indicated by numbers and letters, for example, 90 HSD.

Microhardness is determined when it is necessary to obtain the values of small parts, thin coatings, or individual alloy structures. The measurement is made by measuring the imprint of a tip of a certain shape. The value notation looks like this:

Н□ 0.195 = 2800, where

□ — tip shape;

0.196 — tip load, N;

2800 – numerical value of hardness, N/mm².

What are the requirements for the product to be measured?

Hardness is directly proportional to the load to determine it. High hardness – high load.

The more accurate the method, the higher the requirements for preparing the surface of the product. The surface of the product on which hardness is determined must meet a number of requirements:

- The thickness of the sample must be at least 10 times the depth of penetration of the tip after removing the main force.

- At the inspection site, it must be cleaned to a shine, be smooth and flat, and must be free of scale, rust, oil, fat and paint contamination, potholes and scratches. Roughness Ra is not more than 2.5 µm according to GOST 2789, unless there are other requirements of regulatory and technical documentation.

- The surface on which the sample “lays” on the object stage of the device must also be clean and level. Both surfaces must be parallel to each other.

- The product must be securely fastened, excluding the possibility of displacement of the sample relative to the axis of load application.

Conversion of hardness units according to Rockwell, Brinell and Vickers (table)

SVERLA.info » Articles » Hardness - conversion of units

| Rockwell | Brinell | Vickers | Shore | To break | ||

| HRA | H.R.C. | HB(3000H) | Print diameter, mm | H.V. | HSD | N/mm² |

| 89 | 72 | 782 | 2.20 | 1220 | ||

| 86.5 | 70 | 1076 | 101 | |||

| 86 | 69 | 744 | 2.25 | 1004 | 99 | |

| 85.5 | 68 | 942 | 97 | |||

| 85 | 67 | 713 | 2.30 | 894 | 95 | |

| 84.5 | 66 | 854 | 92 | |||

| 84 | 65 | 683 | 2.35 | 820 | 91 | |

| 83.5 | 64 | 789 | 88 | |||

| 83 | 63 | 652 | 2.40 | 763 | 87 | |

| 82.5 | 62 | 739 | 85 | |||

| 81.5 | 61 | 627 | 2.45 | 715 | 83 | |

| 81 | 60 | 695 | 81 | 2206 | ||

| 80.5 | 59 | 600 | 2.50 | 675 | 80 | 2137 |

| 80 | 58 | 2.55 | 655 | 78 | 2069 | |

| 79.5 | 57 | 578 | 636 | 76 | 2000 | |

| 79 | 56 | 2.60 | 617 | 75 | 1944 | |

| 78.5 | 55 | 555 | 598 | 74 | 1889 | |

| 78 | 54 | 2.65 | 580 | 72 | 1834 | |

| 77.5 | 53 | 532 | 562 | 71 | 1772 | |

| 77 | 52 | 512 | 2.70 | 545 | 69 | 1689 |

| 76.5 | 51 | 495 | 2.75 | 528 | 68 | 1648 |

| 76 | 50 | 513 | 67 | 1607 | ||

| 75.5 | 49 | 477 | 2.80 | 498 | 66 | 1565 |

| 74.5 | 48 | 460 | 2.85 | 485 | 64 | 1524 |

| 74 | 47 | 448 | 2.89 | 471 | 63 | 1496 |

| 73.5 | 46 | 437 | 2.92 | 458 | 62 | 1462 |

| 73 | 45 | 426 | 2.96 | 446 | 60 | 1420 |

| 72.5 | 44 | 415 | 3.00 | 435 | 58 | 1379 |

| 71.5 | 42 | 393 | 3.08 | 413 | 56 | 1317 |

| 70.5 | 40 | 372 | 3.16 | 393 | 54 | 1255 |

| 38 | 352 | 3.25 | 373 | 51 | 1193 | |

| 36 | 332 | 3.34 | 353 | 49 | 1138 | |

| 34 | 313 | 3.44 | 334 | 47 | 1076 | |

| 32 | 297 | 3.53 | 317 | 44 | 1014 | |

| 30 | 283 | 3.61 | 301 | 42 | 965 | |

| 28 | 270 | 3.69 | 285 | 41 | 917 | |

| 26 | 260 | 3.76 | 271 | 39 | 869 | |

| 24 | 250 | 3.83 | 257 | 37 | 834 | |

| 22 | 240 | 3.91 | 246 | 35 | 793 | |

| 20 | 230 | 3.99 | 236 | 34 | 752 |

Indentation of a diamond cone with an angle of 120° at the apex and measurement of the relative depth of immersion into the material under study.

Scale A - load 60 kgf, for tungsten carbide (VK)

Scale C - load 150 kgf, for hard steel HRB>100

The advantage is simplicity. Disadvantage: low accuracy.

Brinell hardness

The diameter of the imprint of a metal ball in the material.

Disadvantage: hardness up to 450HB.

Vickers hardness

The area of the imprint from a diamond pyramid.

Shore hardness

Rebound of a ball from a surface in a scleroscope (rebound method). A very simple and convenient method.

Determining the hardness of a material is an important part of the technological process for manufacturing parts of any complexity.

Various methods for searching for the hardness of a metal are primarily associated with the difference in their structure and shape. Working with a regular blank in the form of a blank is not difficult, but sheet material requires a special approach, given its small thickness.

Only using the Vickers method is it most convenient to search for the hardness of nitrided and cemented surfaces.

Calculation of the service life of a metal-cutting tool, its durability, is always carried out primarily taking into account tabular indicators.

It is thanks to the increased hardness (about 71 HRC) that carbide drills and cutters made from VK8 alloy make it possible to process super-hard materials.

What methods exist for determining hardness?

Conventionally, all methods can be divided into 3 groups:

- Indentation (implementation) methods

- Scratching Methods

- Elastic rebound methods

Indentation (implementation) methods. The meaning of the methods is to press a so-called indenter - a solid object of a certain shape (usually a steel ball or a diamond pyramid) into the test metal with a certain force. After indentation, the diameter (for a ball) or depth (for a pyramid) of the resulting imprint is measured.

In this case, hardness is defined as the ratio of the load to the area of the indentation after indentation.

The most common are the Brinell (HB) and Rockwell (HRA, HRB, HRC) methods.

Indentation thickness measurement methods:

- Brinell device

- Rockwell device

- Vickers device

- Ludwick method

- Hertz method

- Drozd method

- Shor's Monotron

- Berkovich method

- Egorov's method

- Khrushchev's method

- Leeds method

- Zeiss-Hahnemann microhardness tester

- PMT-2, PMT3 (Khrushchov, Berkovich)

- Emerson, Knoop, Peters method

Scratching methods. Simple methods. If the tip used to make the scratch leaves a mark on the metal being tested, then the hardness of the metal is less than the hardness of the tip. In this case, the hardness of the tip is initially known (corundum, diamond, gypsum and other tips are used). The most popular is the Mohs method.

Scratching methods:

- Mohs test

- Martens device

- Bierbaum microcharacterizer

- File test, Barba

- Hankins device

- PMT-3 (Berkovich)

- PMT-3 (Grigorovich)

- O'Neill sclerometer

Elastic rebound methods. Rarely used. The firing pin falls freely onto the test surface from a fixed height. Under the action of elastic recoil of the material, the firing pin rebounds to a certain height. The hardness of the material is proportional to the height of the rebound. The most popular is Shor's method.

Elastic rebound methods:

- Shore Scleroscope

- Martel method

- Nikolaev vertical pile driver

- Shopper spring device

- Bauman spring device

- Poldi device

- Walzel pendulum pile driver

- Herbert pendulum

- Kuznetsov pendulum sclerometer

Hardness of metals. Metal hardness table

In order for parts and mechanisms to serve for a long time and reliably, the materials from which they are made must meet the necessary operating conditions.

That is why it is important to control the permissible values of their main mechanical parameters. Mechanical properties include hardness, strength, impact strength, and ductility.

The hardness of metals is a primary structural characteristic.

Concept

The hardness of metals and alloys is the property of a material to create resistance when another body penetrates its surface layers, which does not deform or collapse under accompanying loads (indenter). Determined for the purpose of:

- obtaining information about acceptable design features and operational capabilities;

- state analysis under the influence of time;

- monitoring the results of temperature treatment.

The strength and aging resistance of the surface partly depend on this indicator. Both the source material and finished parts are examined.

Research options

The indicator is a value called the hardness number. There are various methods for measuring the hardness of metals. The most accurate studies involve the use of various types of calculations, indenters and corresponding hardness testers:

- Brinell: the essence of the apparatus is pressing a ball into the metal or alloy being tested, calculating the diameter of the indentation and subsequent mathematical calculation of the mechanical parameter.

- Rockwell: Uses a ball or diamond cone tip. The value is displayed on a scale or determined by calculation.

- Vickers: The most accurate measurement of metal hardness using a diamond pyramid tip.

To determine parametric correspondences between indicators of different measurement methods for the same material, there are special formulas and tables.

Factors that determine the measurement option

In laboratory conditions, if the necessary range of equipment is available, the choice of research method is carried out depending on certain characteristics of the workpiece.

- Approximate value of the mechanical parameter. For structural steels and materials with low hardness up to 450-650 HB, the Brinell method is used; for tool, alloy steels and other alloys - Rockwell; for hard alloys – Vickers.

- Dimensions of the test sample. Particularly small and thin parts are examined using a Vickers hardness tester.

- The thickness of the metal at the measurement location, in particular the cemented or nitrided layer.

All requirements and compliance are documented by GOST.

Features of the Brinell technique

Hardness testing of metals and alloys using a Brinell hardness tester is carried out with the following features:

- Indenter - a ball made of alloy steel or tungsten carbide alloy with a diameter of 1, 2, 2.5, 5 or 10 mm (GOST 3722-81).

- Duration of static indentation: for cast iron and steel - 10-15 s, for non-ferrous alloys - 30, a duration of 60 s is also possible, and in some cases - 120 and 180 s.

- Limit value of the mechanical parameter: 450 HB when measured with a steel ball; 650 HB when using carbide.

- Possible loads. Using the weights included in the kit, the actual deformation force on the test sample is adjusted. Their minimum permissible values: 153.2, 187.5, 250 N; maximum – 9807, 14710, 29420 N (GOST 23677-79).

Using formulas, depending on the diameter of the selected ball and the material being tested, the corresponding permissible indentation force can be calculated.

| Alloy type | Mathematical load calculation |

| Steel, nickel and titanium alloys | 30D2 |

| Cast iron | 10D2, 30D2 |

| Copper and copper alloys | 5D2, 10D2, 30D2 |

| Light metals and alloys | 2.5D2, 5D2, 10D2, 15D2 |

| Lead, tin | 1D2 |

Example notation:

400HB10/1500/20, where 400HB is the Brinell hardness of the metal; 10 – ball diameter, 10 mm; 1500 – static load, 1500 kgf; 20 – period of indentation, 20 s.

To establish accurate figures, it is rational to examine the same sample in several places, and determine the overall result by finding the average value of the obtained ones.

Determination of hardness using the Brinell method

The research process proceeds in the following sequence:

- Checking the part for compliance with the requirements (GOST 9012-59, GOST 2789).

- Checking the health of the device.

- Selecting the required ball, determining the possible force, installing weights for its formation, and the period of indentation.

- Starting the hardness tester and deforming the sample.

- Measuring the diameter of the recess.

- Empirical calculation.

HB=F/A,

where F – load, kgf or N; A – print area, mm2.

НВ=(0.102*F)/(π*D*h),

where D is the diameter of the ball, mm; h – indentation depth, mm.

The hardness of metals measured by this method has an empirical connection with the calculation of strength parameters. The method is accurate, especially for soft alloys. It is fundamental in systems for determining the values of this mechanical property.

Features of the Rockwell technique

This measurement method was invented in the 20s of the 20th century, and is more automated than the previous one. Used for harder materials. Its main characteristics (GOST 9013-59; GOST 23677-79):

- Availability of a primary load of 10 kgf.

- Holding period: 10-60 s.

- Limit values of possible indicators: HRA: 20-88; HRB: 20-100; HRC: 20-70.

- The number is visualized on the dial of the hardness tester and can also be calculated arithmetically.

- Scales and indenters. There are 11 different scales depending on the type of indenter and the maximum permissible static load. The most common in use: A, B and C.

A: diamond cone tip, apex angle 120˚, total permissible static influence force – 60 kgf, HRA; Thin products, mainly rolled products, are being studied.

C: also a diamond cone, designed for a maximum force of 150 kgf, HRC, suitable for hard and hardened materials.

B: 1.588 mm ball, made of hardened steel or hard tungsten carbide, 100 kgf, HRB, used to evaluate the hardness of annealed products.

A ball-shaped tip (1.588 mm) is applicable for Rockwell scales B, F, G. There are also scales E, H, K, for which a ball with a diameter of 3.175 mm is used (GOST 9013-59).

The number of tests performed with a Rockwell hardness tester on one area is limited by the size of the part. A repeat test is allowed at a distance of 3-4 diameters from the previous place of deformation. The thickness of the tested product is also regulated. It should be no less than the tip penetration depth increased by 10 times.

Example notation:

50HRC is the Rockwell hardness of a metal, measured using a diamond tip, its number is 50.

Rockwell Study Design

Measuring metal hardness is more simplified than for the Brinell method.

- Assessment of the dimensions and surface characteristics of the part.

- Checking the health of the device.

- Determination of tip type and permissible load.

- Sample installation.

- Implementation of a primary force on the material of 10 kgf.

- Exercising full appropriate effort.

- Reading the resulting number on the dial scale.

A mathematical calculation is also possible to accurately determine the mechanical parameter.

Provided that a diamond cone is used with a load of 60 or 150 kgf:

HR=100-((Hh)/0.002;

when performing a test with a ball under a force of 100 kgf:

HR=130-((Hh)/0.002,

where h is the penetration depth of the indenter at a primary force of 10 kgf; H – indenter penetration depth at full load; 0.002 is a coefficient that regulates the amount of movement of the tip when the hardness number changes by 1 unit.

Rockwell's method is simple, but not accurate enough. At the same time, it allows the measurement of mechanical properties for hard metals and alloys.

Characteristics of the Vickers technique

Determining the hardness of metals using this method is the simplest and most accurate. The hardness tester works by pressing a diamond pyramidal tip into the sample.

Key Features:

- Indenter: diamond pyramid with apex angle 136°.

- Maximum permissible load: for alloy cast iron and steel - 5-100 kgf; for copper alloys - 2.5-50 kgf; for aluminum and alloys based on it - 1-100 kgf.

- Static load holding period: from 10 to 15 s.

- Test materials: steel and non-ferrous metals with a hardness of more than 450-500 HB, including products after chemical-thermal treatment.

Example notation:

700HV20/15,

where 700HV is the Vickers hardness number; 20 – load, 20 kgf; 15 – period of static force, 15 s.

Vickers study sequence

The procedure is extremely simplified.

- Checking the sample and equipment. Particular attention is paid to the surface of the part.

- Selection of permissible force.

- Installation of the test material.

- Putting the hardness tester into operation.

- Reading the result on the dial.

The mathematical calculation for this method is as follows:

HV=1.8544*(F/d2),

where F – load, kgf; d – average value of the print diagonal lengths, mm.

It allows you to measure high hardness of metals, thin and small parts, while providing highly accurate results.

Ways to switch between scales

Having determined the diameter of the print using special equipment, you can use tables to determine the hardness. The metal hardness table is a proven assistant in calculating this mechanical parameter. Thus, if the Brinell value is known, the corresponding Vickers or Rockwell number can be easily determined.

Example of some match values:

| Print diameter, mm | Research method | ||||

| Brinell | Rockwell | Vickers | |||

| A | C | B | |||

| 3,90 | 241 | 62,8 | 24,0 | 99,8 | 242 |

| 4,09 | 218 | 60,8 | 20,3 | 96,7 | 218 |

| 4,20 | 206 | 59,6 | 17,9 | 94,6 | 206 |

| 4,99 | 143 | 49,8 | — | 77,6 | 143 |

The metal hardness table is compiled on the basis of experimental data and is highly accurate. There are also graphical dependences of Brinell hardness on the carbon content in an iron-carbon alloy. So, in accordance with such dependencies, for steel with an amount of carbon in the composition equal to 0.2%, it is 130 HB.

Sample requirements

In accordance with the requirements of GOSTs, the tested parts must meet the following characteristics:

- The workpiece must be flat, lie firmly on the hardness tester table, its edges must be smooth or carefully processed.

- The surface should have minimal roughness. Must be sanded and cleaned, including using chemical compounds. At the same time, during machining processes, it is important to prevent the formation of work hardening and an increase in the temperature of the treated layer.

- The part must comply with the selected method for determining hardness using parametric properties.

Fulfillment of primary requirements is a prerequisite for measurement accuracy.

The hardness of metals is an important fundamental mechanical property that determines some of their other mechanical and technological features, the results of previous processing processes, the influence of temporary factors, and possible operating conditions. The choice of research methodology depends on the approximate characteristics of the sample, its parameters and chemical composition.

Hardness of electroplated coatings

In the case of electroplated coatings, it should be noted that due to their small thickness, many methods (especially indentation methods) may not be suitable. The most common methods are Mohs and Vickers.

To measure hardness, a coating with a minimum thickness of 2 µm is required. If a smaller thickness is required, use GOST 9013-59, GOST 9012-59, GOST 22761-77

The measurement principle is the same. After applying the coating and drying it, the quality control department takes measurements and makes a decision - to ship the product or send it for recoating.

An important role here is played by both the electrolyte in which the coating is applied and the coating application mode (temperature, current density). For example, in one chrome plating electrolyte it is possible to obtain a chrome coating with a hardness from 500 to 1100 kgf/mm2.

If we talk about the electrolyte, the most important role is played by the quantity and quality of the brightening agents in it. A matte zinc coating will be much softer than a shiny one. Therefore, if you want a super-shiny coating, keep in mind that it will be hard, and there is a possibility of it cracking or peeling off at the slightest bending of the product.

Hardness is the main indicator of tool quality

When choosing a tool for work, we are faced with such a characteristic as hardness, which characterizes its quality.

The higher this indicator, the higher its ability to resist plastic deformation and wear when exposed to the material being processed.

It is this indicator that determines whether the saw tooth will bend when sawing workpieces, or what kind of wire the wire cutters can cut through.

Rockwell method

Among all existing methods for determining the hardness of steels and non-ferrous metals, the most common and most accurate is the Rockwell method.

Carrying out measurements and determining the Rockwell hardness number is regulated by the relevant documents of GOST 9013-59

.

This method is implemented by pressing indenters—a diamond cone or a carbide ball—into the material being tested.

Diamond indenters are used for testing hardened steels and carbide alloys, while carbide balls are used for testing less hard and relatively soft metals. Measurements are carried out using mechanical or electronic hardness testers.

The Rockwell method provides for the possibility of using a number of hardness scales A, B, C, D, E, F, G, H (54 in total), each of which provides the greatest accuracy only in its own relatively narrow measurement range.

To measure high hardness values with a diamond cone, the “A” and “C” scales are most often used. They are used to test samples made of hardened tool steels and other hard steel alloys. And comparatively softer materials, such as aluminum, copper, brass, and annealed steel are tested with ball indenters on the “B” scale.

Example of Rockwell hardness designation: 58 HRC or 42 HRB.

The numbers in front indicate a number or a conventional unit of measurement. The two letters after them are the Rockwell hardness symbol, the third letter is the scale on which the tests were carried out.

(!)

Two identical values from different scales are not the same thing, for example, 58 HRC ≠ 58 HRA. Rockwell numerical values can only be compared if they belong to the same scale.

Rockwell scale ranges according to GOST 8.064-94:

| A | 70-93 HR |

| B | 25-100 HR |

| C | 20-67 HR |

Locksmith tool

Tools for manual metal processing (chopping, cutting, filing, branding, punching, marking) are made from carbon and alloy tool steels. Their working parts are subjected to hardening to a certain hardness, which should be within the following limits:

| Hacksaw blades, files | 58 – 64 HRC |

| Chisels, crosspieces, bits, center punches, scribers | 54 – 60 HRC |

| Hammers (head, toe) | 50 – 57 HRC |

Installation tool

This includes various wrenches, screwdrivers, and pliers. The hardness standard for their working parts is set by current standards. This is a very important indicator, which determines how wear-resistant the tool is and can resist crushing. Sufficient values for some instruments are given below:

| Wrenches with jaw size up to 36 mm | 45.5 – 51.5 HRC |

| Wrenches with jaw size from 36 mm | 40.5 – 46.5 HRC |

| Phillips, slotted screwdrivers | 47 – 52 HRC |

| Pliers, pliers, duckbills | 44 – 50 HRC |

| Nippers, side cutters, metal scissors | 56 – 61 HRC |

Metal cutting tool

This category includes consumable equipment for metal cutting, used on machine tools or with hand tools. For its manufacture, high-speed steels or hard alloys are used, which retain hardness in cold and overheated states.

| Taps, dies | 61 – 64 HRC |

| Countersinks, countersinks, counterbores | 61 – 65 HRC |

| Metal drills | 63 – 69 HRC |

| Titanium nitride coated drills | up to 80 HRC |

| HSS cutters | 62 – 66 HRC |

Note:

Some milling cutter manufacturers indicate in the marking the hardness not of the cutter itself, but of the material that it can process.

Fasteners

There is a relationship between the strength class of a fastener and its hardness. For high-strength bolts, screws, and nuts, this relationship is reflected in the table:

| Bolts and screws | Nuts | Washers | |||||||||

| Strength classes | 8.8 | 10.9 | 12.9 | 8 | 10 | 12 | Art. | Zak.art. | |||

| d16 mm | d16 mm | ||||||||||

| Rockwell hardness, HRC | min | 23 | 23 | 32 | 39 | 11 | 19 | 26 | 29.2 | 20.3 | 28.5 |

| max | 34 | 34 | 39 | 44 | 30 | 36 | 36 | 36 | 23.1 | 40.8 |

If for bolts and nuts the main mechanical characteristic is the strength class, then for such fasteners as lock nuts, washers, set screws, hardness is no less important.

The following minimum/maximum Rockwell values are established by the standards:

| Retaining rings up to Ø 38 mm | 47 – 52 HRC |

| Retaining rings Ø 38 -200 mm | 44 – 49 HRC |

| Retaining rings from Ø 200 mm | 41 – 46 HRC |

| Lock toothed washers | 43.5 – 47.5 HRB |

| Spring steel washers (grover) | 41.5 – 51 HRC |

| Bronze spring washers (grover) | 90 HRB |

| Set screws of strength class 14H and 22H | 75 – 105 HRB |

| Set screws of strength class 33H and 45H | 33 – 53 HRC |

Relative hardness measurement using files

The cost of stationary and portable hardness testers is quite high, so their purchase is justified only by the need for frequent use. Many craftsmen, if necessary, practice measuring the hardness of metals and alloys relatively, using improvised means.

Filing a sample with a file is one of the most accessible, but far from the most objective, ways of checking the hardness of steel parts, tools, and equipment.

The file must have a non-blunted double cut of medium size No. 3 or No. 4.

The resistance to filing and the accompanying grinding noise makes it possible, even with little skill, to distinguish unhardened steel from moderately (40 HRC) or hard-hardened (55 HRC).

For testing with greater accuracy, there are sets of calibrated files, also called scratch hardness testers. They are used for testing saw teeth, milling cutters, and gears. Each such file carries a certain value on the Rockwell scale.

Hardness is measured by briefly scratching the metal surface alternately with files from the kit. Then two close ones are selected - a harder one, which left a scratch, and a less hard one, which could not scratch the surface.

The hardness of the metal being tested will be between the hardness values of these two files.

Hardness conversion table

To compare Rockwell, Brinell, Vickers hardness numbers, as well as to convert the indicators of one method to another, there is a reference table:

| Vickers, H.V. | Brinell, H.B. | Rockwell, HRB |

| 100 | 100 | 52.4 |

| 105 | 105 | 57.5 |

| 110 | 110 | 60.9 |

| 115 | 115 | 64.1 |

| 120 | 120 | 67.0 |

| 125 | 125 | 69.8 |

| 130 | 130 | 72.4 |

| 135 | 135 | 74.7 |

| 140 | 140 | 76.6 |

| 145 | 145 | 78.3 |

| 150 | 150 | 79.9 |

| 155 | 155 | 81.4 |

| 160 | 160 | 82.8 |

| 165 | 165 | 84.2 |

| 170 | 170 | 85.6 |

| 175 | 175 | 87.0 |

| 180 | 180 | 88.3 |

| 185 | 185 | 89.5 |

| 190 | 190 | 90.6 |

| 195 | 195 | 91.7 |

| 200 | 200 | 92.8 |

| 205 | 205 | 93.8 |

| 210 | 210 | 94.8 |

| 215 | 215 | 95.7 |

| 220 | 220 | 96.6 |

| 225 | 225 | 97.5 |

| 230 | 230 | 98.4 |

| 235 | 235 | 99.2 |

| 240 | 240 | 100 |

| Vickers, H.V. | Brinell, H.B. | Rockwell, H.R.C. |

| 245 | 245 | 21.2 |

| 250 | 250 | 22.1 |

| 255 | 255 | 23.0 |

| 260 | 260 | 23.9 |

| 265 | 265 | 24.8 |

| 270 | 270 | 25.6 |

| 275 | 275 | 26.4 |

| 280 | 280 | 27.2 |

| 285 | 285 | 28.0 |

| 290 | 290 | 28.8 |

| 295 | 295 | 29.5 |

| 300 | 300 | 30.2 |

| 310 | 310 | 31.6 |

| 320 | 319 | 33.0 |

| 330 | 328 | 34.2 |

| 340 | 336 | 35.3 |

| 350 | 344 | 36.3 |

| 360 | 352 | 37.2 |

| 370 | 360 | 38.1 |

| 380 | 368 | 38.9 |

| 390 | 376 | 39.7 |

| 400 | 384 | 40.5 |

| 410 | 392 | 41.3 |

| 420 | 400 | 42.1 |

| 430 | 408 | 42.9 |

| 440 | 416 | 43.7 |

| 450 | 425 | 44.5 |

| 460 | 434 | 45.3 |

| 470 | 443 | 46.1 |

| 490 | — | 47.5 |

| 500 | — | 48.2 |

| 520 | — | 49.6 |

| 540 | — | 50.8 |

| 560 | — | 52.0 |

| 580 | — | 53.1 |

| 600 | — | 54.2 |

| 620 | — | 55.4 |

| 640 | — | 56.5 |

| 660 | — | 57.5 |

| 680 | — | 58.4 |

| 700 | — | 59.3 |

| 720 | — | 60.2 |

| 740 | — | 61.1 |

| 760 | — | 62.0 |

| 780 | — | 62.8 |

| 800 | — | 63.6 |

| 820 | — | 64.3 |

| 840 | — | 65.1 |

| 860 | — | 65.8 |

| 880 | — | 66.4 |

| 900 | — | 67.0 |

| 1114 | — | 69.0 |

| 1120 | — | 72.0 |

Note:

The table shows approximate ratios of numbers obtained by different methods. The error in converting HV to HB values is ±20 units, and the error in converting HV to HR (scale C and B) is up to ±3 units.

When choosing a tool, it is advisable to prefer models from well-known manufacturers. This gives confidence that the purchased product is manufactured in compliance with technology, and its hardness meets the declared values.

Articles about products 09.23.2019 16:32:41