Hardness is the property of a material to resist elastic and plastic deformation or destruction when another, harder body that does not receive residual deformation - an indenter - is introduced into the surface layer of the material.

Methods for determining hardness depending on the temporary nature of the application of load and measuring the resistance to indentation of the indenter are divided into:

- static

- dynamic

- kinetic

The most common are static methods, in which the load is applied to the indenter smoothly and gradually, and the holding time under load is regulated by standards for the corresponding methods.

In dynamic methods for determining hardness, the indenter acts on the sample with a certain kinetic energy expended on elastic recoil and/or the formation of an indent; dynamic hardness is often also called the hardness of the material upon impact. Impact hardness characterizes the resistance to penetration not only on the surface of the sample, but also in a certain volume of the material.

Kinetic methods for determining hardness are based on continuous recording of the process of indentation of the indenter with recording of the diagram “load on the indenter - depth of penetration of the indenter. The peculiarity of this approach is to record the entire kinetics of the process of elastoplastic deformation of the material during indentation of the indenter, and not just the final test result, as with other methods.

Based on the principle of load application, methods for determining hardness can be divided into indentation, rebound, scratching and cutting methods.

Indentation methods are the most common. Hardness in this case is defined as the resistance that the test body provides to the penetration of a harder indenter and primarily reflects the resistance of the surface layers of the material to plastic deformation.

Rebound methods are based on measuring hardness by the height of the rebound of the striker falling onto the test surface. In this case, hardness primarily reflects resistance to elastic deformation. Rebound hardness testing is widely used to control the quality of mill rolls, large products and structures using portable instruments.

Method for measuring hardness by scratching

In scratching and cutting methods, hardness is defined as the material's resistance to scratching or cutting, respectively. The scratching method was developed by Mohs at the beginning of the 19th century; they were given a scale of mineral hardness based on the ability of one to scratch the surface of another. This ten-point scale (from talc No. 1 to diamond No. 10) is used in mineralogy, as well as for assessing the hardness of technical ceramics and single crystals.

When determining hardness by all methods (except microhardness), the integral value of the material’s hardness (averaged for all structural components) is measured.

Hardness values cannot be unambiguously translated into values of other mechanical properties of the material. However, determining hardness is an effective way to compare materials of the same type with each other and control their quality.

How to determine the hardness of metal at home

Mechanical engineering parts and mechanisms, as well as tools intended for their processing, have a set of mechanical characteristics. Hardness plays a significant role among the characteristics. The hardness of metals clearly shows:

- wear resistance of metal;

- possibility of processing by cutting, grinding;

- resistance to local pressure;

- ability to cut other materials and others.

Hardness of metals

In practice, it has been proven that most of the mechanical properties of metals directly depend on their hardness.

Brinell hardness test

The Brinell hardness measurement method is regulated by GOST 9012.

When determining hardness by this method, a steel ball of a certain diameter D is pressed into the test sample under the action of a load P applied perpendicular to the surface of the sample for a certain time. After removing the load, the diameter of the indentation d is measured. The Brinell hardness number is designated by the letters HB and is determined by dividing the load P by the surface area of the spherical imprint F.

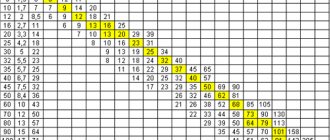

For convenience, there are tables of Brinell hardness numbers and dependence on the ball diameter D, indent diameter d and load P.

Polished (Ra < 0.04 µm) balls made of ShKh15 steel with nominal diameters D = 1 are used as indenters; 2; 2.5; 5 and 10 mm, the latter are considered more preferable, as they provide greater accuracy in hardness measurement.

The minimum permissible sample thickness for correct measurement of NV hardness must be at least ten times the indentation depth h.

Tests are carried out at room temperature in the absence of vibrations and shocks. The holding time under load t for ferrous metals is 10...15 s, and for non-ferrous metals and alloys from 10 to 180 s. The load on the indenter is selected taking into account the ratio K=P/D2:

Metals and alloys K, kgf/mm2

Steel, cast iron and other high-strength alloys………..30

Copper, nickel and their alloys……………………………………..10

Aluminum, magnesium and their alloys……………………………………………………5

For example, when testing steels and cast irons with a ball diameter D = 10 mm, the load should be 3000 kgf, and the holding time under load should be 10...15 s. The hardness number in this case is indicated by numbers followed by the symbol HB (for example, 250 HB). Sometimes after the letters НВ test conditions are indicated - НВ D/P/τ, for example: 250 НВ 5/750/25 - Brinell hardness 250, obtained with a ball diameter D = 5 mm, load P = 750 kgf and holding time under load t =25 s. Brinell hardness testing is not recommended for steel with a hardness of more than 450 HB, and for non-ferrous metals with a hardness of more than 200 HB

How to test the hardness of metal - the main secrets

When it comes to metals, an important indicator is its hardness.

A factor of this kind plays a significant role in the choice of whether or not to use a particular metal in production for the manufacture of products for a specific purpose.

It is worth understanding this issue in more detail, which requires testing the hardness of metal in the production line of various industries.

What is metal hardness

This concept refers to a characteristic closely related to metals and their alloys. This is the ability to resist damage when the top layer is synchronized with a harder metal.

Based on this knowledge, various equipment and parts are manufactured that play a role in the durability of objects, structures, machines, and tools. Simply put, resistance to deformation.

You can check this parameter in different ways.

Methods for testing metal hardness

Experts distinguish several options for checking characteristics:

- According to the Brinnell method, a steel ball takes part in the verification process. It is pressed under great pressure into a metal surface. Then a special magnifying glass comes into effect, and with its help the specialist measures the diameter of the hole. Hardness is determined from tabular data. This method is the first method for determining the nature of the metal. This is how soft alloys are measured.

- Rockwell's technique involves impacting a metal surface with a diamond cone. A special press is used to measure the hardness of soft, colored, thin Me. It is not considered very accurate, although it is successfully used for the study of hard alloys.

- Similar actions to the previous one are included in the Vikxer method, which involves turning to a diamond pyramid, only the angle of the top is not 120, but 136 degrees. The load is carried out strictly perpendicular to the metal and increases slowly. Refers to high-precision methods.

- Shore's method involves the presence of a striker with a diamond-coated tip. It falls from a specific height onto the surface of the material being tested. Hardness is measured by the height of the striker's rebound. This methodology is distinguished by a large scatter of readings; for the most part it is used to measure curved objects and large parts.

At home, the indicator is also measured, but you should not expect high accuracy. When you turn to professionals, you can get a highly accurate result, and this is a crucial moment.

Some conduct home education to determine this value, using an ordinary bottle and scratching it with a metal object, for example, a knife blade.

Metal of 62 units easily scratches glass, which cannot be said about 56 units.

What does the hardness of the metal indicate, what does it give

The question arises as to why this parameter needs to be measured at all. The characteristics of metals are important to those involved in the steel heat treatment industry. The conclusion about the mechanical properties of the weld is also obtained by studying the heat-affected surface.

The feasibility of the research being carried out is also predetermined by the intention of manufacturers to obtain high-strength products so that they can withstand different operating conditions, temperature changes, and ensure reliability. The hardness of a metal product is a primary structural characteristic.

Research is carried out with the following objectives.

- Analyze the state of the material under the influence of time.

- Obtain knowledge of likely destructive consequences to improve operational capabilities.

- Monitor the results obtained as part of the temperature treatment.

According to the information acquired during the experiments, it is possible to determine the resistance to abrasion and wear of the source material.

Conclusion

To carry out the analysis, certain conditions are imposed on the material being tested. In particular, the workpiece is selected to be level. It should fit tightly to the hardness tester, with carefully processed edges.

As a result, fundamental mechanical quality is achieved, which plays a role in the production of high-quality products.

Specialists use the results obtained during the study, compare them with previously known analysis, and this is a lot of work that helps determine the production methodology. Information is necessary for mechanical engineering, metalworking, and metallurgical enterprises.

The concept of “hardness” is associated with elasticity, plasticity, and strength, although there is no direct connection between mechanical qualities. It is important to turn to professionals to perform such work; the home method is only suitable for tasks of hardening knives.

Vickers hardness measurement

The Vickers hardness measurement method is regulated by GOST 2999. The method is used to determine the hardness of parts and metal products of small thickness, as well as thin surface layers with high hardness.

Vickers hardness is measured by pressing a diamond tip in the shape of a regular tetrahedral pyramid into the sample under the action of a load P for a holding time τ. After removing the load, measure the diagonals of the imprint remaining on the surface of the material – d1, d2 and calculate their arithmetic mean value – d, mm.

Vickers hardness values under standard loads depending on the diagonal length d (mm) are given in the corresponding tables.

During testing, the following loads P, kgf are used: 1; 2; 2.5; 3; 5; 10; 20; thirty; 50; 100. The Vickers hardness number is denoted by numbers characterizing the hardness value followed by the symbol HV (for example, 200 HV). Sometimes the load and holding time are indicated after the HV symbol, for example: 200 HV 10/40 - Vickers hardness obtained at a load P = 10 kgf and holding time under load t = 40 s.

GOST says that there is no exact conversion of Vickers hardness numbers to hardness numbers obtained by other methods or to tensile mechanical properties and such conversions (except in special cases) should be avoided.

Hardness concept

The hardness of a material is its resistance to destruction when a harder material is introduced into the outer layer. In other words, the ability to resist deforming forces (elastic or plastic deformation).

The hardness of metals is determined by introducing a solid body called an indenter into a sample. The role of the indenter is performed by: a metal ball of high hardness; diamond cone or pyramid.

After exposure to the indenter, an imprint remains on the surface of the test sample or part, the size of which determines the hardness. In practice, kinematic, dynamic, and static methods of measuring hardness are used.

The kinematic method is based on the compilation of a diagram based on continuously recorded readings that change as the tool is pressed into the sample. Here the kinematics of the entire process is traced, and not just the final result.

The dynamic method is as follows. The measuring tool acts on the part. The reverse reaction allows you to calculate the expended kinetic energy. This method allows you to test the hardness of not only the surface, but also a certain volume of metal.

Static methods are non-destructive methods that allow you to determine the properties of metals. The methods are based on smooth indentation and subsequent holding for some time. The parameters are regulated by methods and standards.

The applied load can be applied:

- pressing;

- scratching;

- cutting;

- rebound

Machine-building enterprises currently use the Brinell, Rockwell, Vickers methods, as well as the microhardness method, to determine the hardness of materials.

Based on the tests carried out, a table is compiled indicating the materials, the applied loads and the results obtained.

Rockwell hardness test

The Rockwell hardness measurement method is regulated by GOST 9013. When determining hardness by this method, the test sample under the influence of two sequentially applied loads - preliminary P0 (usually P0 = 10 kgf) and total P - is pressed by an indenter (diamond cone or steel ball). In this case, the total load is equal to the sum of the preliminary P0 and main P1 loads:

P = P0+P1

After holding under the applied total load P for 3...5 s, the main load P1 is removed and the depth of penetration of the indenter into the material A is measured under the influence of the total load P, then the remaining preliminary load P0 is removed.

Rockwell hardness is measured in arbitrary units. The unit of hardness is taken to be the value corresponding to the axial movement of the indenter by 0.002 mm. The hardness number is determined using an indicator scale (usually a dial type). The indicator shows the result of subtracting the difference in depths (h – h0) to which the indenter is pressed under the action of two sequentially applied loads from a certain constant. The value h0 is the depth of penetration of the indenter into the test sample under the influence of preload P0.

Depending on the shape of the indenter and the applied load, three measuring scales are introduced: A, B, C. The most commonly used scales are A and C.

The Rockwell hardness number is indicated by numbers characterizing the hardness value followed by the symbol HRA, HRB or HRC (depending on the measurement scale used), for example: 28 HRC

Scales used to measure Rockwell hardness

Types of Methods

Depending on the method and duration of pressing the identifier into the metal, all methods are divided into the following groups:

- Static

They are implemented in the following ways: according to Brinell, according to Rockwell, according to Knoop, according to Vickers.

- Dynamic

They are carried out in the following ways: according to Bauman, according to Shore, according to Schwartz, according to Grave, according to Morin. In recent years, indirect methods have also been actively used. Research is carried out using high-precision electronic instruments that record related characteristics, and not the hardness itself. One of these devices, a portable ultrasonic hardness tester, records the rate of attenuation of vibrations of a rod with an indenter. The method has no requirements for the weight, size or geometry of the object under study. The only limitation is the coarse-grained structure of the metal product.

Shore hardness measurement

The Shore hardness measurement method is regulated by GOST 23273. This is the main method for determining the surface hardness of rolling rolls during their manufacture, delivery to a metallurgical enterprise, as well as during the operation of the rolls at rolling mills.

When measuring Shore hardness, a striker of a certain mass with a diamond indenter at the end freely pushes vertically from a certain height h of fall = 19.0 ± 0.5 mm onto the test surface. The indenter is a diamond tip in the form of a body of rotation with a radius of curvature of the working end R = 1.0 ± 0.1 mm. The mass of the striker together with the diamond indenter is 36.0 g. The rebound height of the striker h is taken as the hardness characteristic. A certain rebound value of the striker h100 = 13.6 ± 0.5 mm is taken as 100 Shore hardness units. This hardness corresponds to the maximum hardness of carbon eutectoid tool steel stabilized after martensite quenching according to GOST 1435. According to the standard, Shore hardness is measured in the range from 20 to 140 units (HSD). The Shore hardness number is indicated by numbers characterizing the hardness value followed by the HSD symbol, for example 95 HSD. The hardness number is indicated rounded to the nearest whole number.

Microhardness measurement

The method for measuring microhardness is regulated by GOST 9450. Determination of microhardness (hardness in microscopically small volumes) is carried out when studying individual structural components of alloys, thin coatings, as well as when measuring the hardness of small parts. The device for determining microhardness consists of a mechanism for indenting a diamond pyramid under a small load and a metallographic microscope. A diamond pyramid is pressed into the test surface under a load of 0.05...5 N.

Microhardness is measured by pressing a diamond indenter into a sample (product) under the influence of a static load P for a certain holding time t. The hardness number is determined (as in Vickers) by dividing the applied load in N or kgf by the conditional area of the lateral surface of the resulting indent in mm2.

The main test option is the so-called reconstructed indentation method, when the dimensions of the indentations are determined after removing the load. In cases where it is necessary to determine additional characteristics of the material (elastic recovery, relaxation, creep at room temperature, etc.), it is allowed to test using the unrestored indentation method. In this case, the dimensions of the indentation are determined at the depth of indentation of the indenter during the application of the load.

In practice, microhardness is determined using standard tables of the specific indenter shape, load P and the dimensions of the indentation diagonals obtained in the test.

Diamond tips of different shapes and sizes are used as indenters, depending on the purpose of microhardness testing. The main and most common tip is a tetrahedral diamond pyramid with a square base (similar in shape to the indenter used in determining Vickers hardness).

The microhardness number is indicated by numbers characterizing the hardness value with the symbol H in front of them indicating the tip shape index, for example, H□ =3000. It is allowed to indicate after the tip shape index the magnitude of the applied load, for example: Н□ 0.196 =3000 - microhardness number 3000 N/mm2, obtained by testing with a four-sided pyramid under a load of 0.196 N. The microhardness dimension (N/mm2 or kgf/mm2) is usually not indicate. If microhardness was determined using the unrestored print method, then the letter h (H□h) is added to the tip shape index.

Hardness value ratio

When comparing hardness values obtained by different methods with each other and with the mechanical properties of materials, it must be remembered that the tables or dependencies given in the literature for such a comparative translation are purely empirical. This translation has no physical meaning, since when pressing indenters of different shapes and sizes and with different loads, the hardness is determined under completely different stress states of the material. Even with the same hardness measurement method, the value is highly dependent on the load: at lower loads, the hardness values are higher.

The main methods of hardness control were discussed above.

There are other control methods that are based on indirect measurements of mechanical properties. For example electrical, magnetic, acoustic, etc. All these methods are based on the compilation of experimental correlation tables “measured parameter - parameter of mechanical properties”, where all parameters are constant (chemical composition of the metal, heat number, amount of contaminants), and only the tabulated parameters change. Such methods practically do not work in production, because... for example, the chemical composition of metals according to GOST standards is required in the selection, i.e. can be within a given limit and vary from heat to heat. Compiling calibration tables for each batch of metal is a very labor-intensive job. Pla plastic solvent - https://www.dcpt.ru