Mechanical engineering parts and mechanisms, as well as tools intended for their processing, have a set of mechanical characteristics. Hardness plays a significant role among the characteristics. The hardness of metals clearly shows:

- wear resistance of metal;

- possibility of processing by cutting, grinding;

- resistance to local pressure;

- ability to cut other materials and others.

In practice, it has been proven that most of the mechanical properties of metals directly depend on their hardness.

Hardness concept

The hardness of a material is its resistance to destruction when a harder material is introduced into the outer layer. In other words, the ability to resist deforming forces (elastic or plastic deformation).

The hardness of metals is determined by introducing a solid body called an indenter into a sample. The role of the indenter is performed by: a metal ball of high hardness; diamond cone or pyramid.

After exposure to the indenter, an imprint remains on the surface of the test sample or part, the size of which determines the hardness. In practice, kinematic, dynamic, and static methods of measuring hardness are used.

The kinematic method is based on the compilation of a diagram based on continuously recorded readings that change as the tool is pressed into the sample. Here the kinematics of the entire process is traced, and not just the final result.

The dynamic method is as follows. The measuring tool acts on the part. The reverse reaction allows you to calculate the expended kinetic energy. This method allows you to test the hardness of not only the surface, but also a certain volume of metal.

Static methods are non-destructive methods that allow you to determine the properties of metals. The methods are based on smooth indentation and subsequent holding for some time. The parameters are regulated by methods and standards.

The applied load can be applied:

- pressing;

- scratching;

- cutting;

- rebound

Machine-building enterprises currently use the Brinell, Rockwell, Vickers methods, as well as the microhardness method, to determine the hardness of materials.

Based on the tests carried out, a table is compiled indicating the materials, the applied loads and the results obtained.

The Hardest. Mohs scale. Chemistry - Simple

How to determine the hardness of a material? Very simple! To do this, you need to use a hardness scale.

The video describes what the Mohs hardness scale is and how to use it. Enjoy watching!

Possible duplicates found

17 minutes is too much)))

The Mohs hardness of a material is the resistance its surface exhibits when someone tries to scratch it with another material. Hardness depends on the degree of cohesion of the intra-atomic structure of the material.

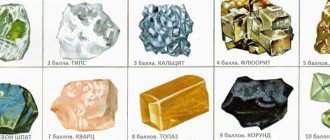

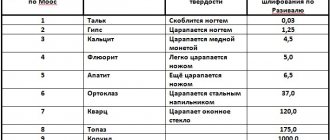

The Mohs scale is a conventional scale of reference minerals for assessing the hardness of materials by scratching. The scale itself is presented below.

Mohs hardness scale

Hardness Units

Each method of measuring the resistance of a metal to plastic deformation has its own methodology, as well as units of measurement.

The hardness of soft metals is measured using the Brinell method. Non-ferrous metals (copper, aluminum, magnesium, lead, tin) and alloys based on them, cast iron (except for white) and annealed steel are subjected to this method.

Brinell hardness is determined by indentation of a hardened, polished ball made of ShKh15 ball bearing steel. The circumference of the ball depends on the material being tested. For hard materials - all types of steel and cast iron - 10 mm, for softer materials - 1 - 2 - 2.5 - 5 mm. Required load applied to the ball:

- iron alloys – 30 kgf/mm2;

- copper and nickel – 10 kgf/mm2;

- aluminum and magnesium – 5 kgf/mm2.

The unit of hardness measurement is a numerical value followed by a numerical index HB. For example, 200 NV.

Rockwell hardness is determined by the difference in applied loads to the part. First, a preliminary load is applied, and then a general load, at which the indenter is introduced into the sample and held.

A pyramid (cone) of diamond or a ball of tungsten carbide (hardened steel) is introduced into the test sample. After removing the load, the depth of the indentation is measured.

The unit of measurement for hardness is conventional units. It is generally accepted that one is the amount of axial displacement of the cone, equal to 2 μm. The hardness designation is marked with three letters HR (A, B, C) and a numerical value. The third letter in the marking indicates the scale.

The technique reflects the type of indenter and the load applied to it.

| Scale type | Tool | Applied load, kgf |

| A | Diamond cone with 120° apex angle | 50-60 |

| IN | 1/16" ball | 90-100 |

| WITH | Diamond cone with 120° apex angle | 140-150 |

Basically, measurement scales A and C are used. For example, the hardness of steel is HRC 26...32, HRB 25...29, HRA 70...75.

Products of small thickness or parts with a thin, hard surface layer are measured by Vickers hardness. The blade used is a regular tetrahedral pyramid with an apex angle of 136°. The display of hardness values is as follows: 220 HV.

Hardness measurement using the Shore method is carried out by measuring the rebound height of a fallen striker. Indicated by numbers and letters, for example, 90 HSD.

Microhardness is determined when it is necessary to obtain the values of small parts, thin coatings, or individual alloy structures. The measurement is made by measuring the imprint of a tip of a certain shape. The value notation looks like this:

Read also: DIY spark generator

0.196 — tip load, N;

2800 – numerical value of hardness, N/mm 2.

ORIGIN

Origin telluric (terrestrial) iron is rarely found in basalt lavas (Uifak, Disko Island, off the western coast of Greenland, near Kassel, Germany). At both locations, pyrrhotite (Fe1-xS) and cohenite (Fe3C) are associated with it, which is explained by both the reduction by carbon (including from the host rocks) and the decomposition of carbonyl complexes such as Fe(CO)n. In microscopic grains, it has more than once been established in altered (serpentinized) ultrabasic rocks, also in paragenesis with pyrrhotite, sometimes with magnetite, due to which it arises during reduction reactions. Very rarely found in the oxidation zone of ore deposits, during the formation of swamp ores. Findings have been recorded in sedimentary rocks associated with the reduction of iron compounds with hydrogen and hydrocarbons. Almost pure iron was found in lunar soil, which is associated with both meteorite falls and magmatic processes. Finally, two classes of meteorites - stony-iron and iron - contain natural iron alloys as a rock-forming component.

Hardness of base metals and alloys

The hardness value is measured on finished parts sent for assembly. Control is carried out for compliance with the drawing and technological process. Tables of hardness values have already been compiled for all basic materials, both in the initial state and after heat treatment.

Non-ferrous metals

The Brinell hardness of copper is 35 HB, the values of brass are 42-60 HB units, depending on its brand. For aluminum, the hardness is in the range of 15-20 HB, and for duralumin it is already 70 HB.

Black metals

The Rockwell hardness of cast iron SCH20 HRC 22, which corresponds to 220 HB. Steel: tool – 640-700 HB, stainless steel – 250 HB.

To convert from one measurement system to another, tables are used. The values in them are not true, because they are derived imperially. Not the full volume is presented in the table.

| HB | H.V. | H.R.C. | HRA | HSD |

| 228 | 240 | 20 | 60.7 | 36 |

| 260 | 275 | 24 | 62.5 | 40 |

| 280 | 295 | 29 | 65 | 44 |

| 320 | 340 | 34.5 | 67.5 | 49 |

| 360 | 380 | 39 | 70 | 54 |

| 415 | 440 | 44.5 | 73 | 61 |

| 450 | 480 | 47 | 74.5 | 64 |

| 480 | 520 | 50 | 76 | 68 |

| 500 | 540 | 52 | 77 | 73 |

| 535 | 580 | 54 | 78 | 78 |

Hardness values, even if produced by the same method, depend on the applied load. The lower the load, the higher the readings.

PHYSICAL PROPERTIES

| Mineral color | iron black |

| Stroke color | grey |

| Transparency | opaque |

| Shine | metal |

| Cleavage | imperfect in |

| Hardness (Mohs scale) | 4,5 |

| Kink | hackly |

| Strength | malleable |

| Density (measured) | 7.3 – 7.87 g/cm3 |

| Radioactivity (GRapi) | |

| Magnetism | ferromagnet |

Hardness measurement methods

All methods for determining the hardness of metals use mechanical action on the test sample - indentation of an indenter. But this does not destroy the sample.

The Brinell hardness method was the first to be standardized in materials science. The principle of testing samples is described above. It is subject to GOST 9012. But you can calculate the value using the formula if you accurately measure the imprint on the sample:

HB=2P/(πD*√(D 2 -d 2 ),

- where P is the applied load, kgf;

- D – ball circumference, mm;

- d – imprint circumference, mm. The ball is selected relative to the thickness of the sample. The load is pre-calculated from accepted standards for the relevant materials: iron alloys - 30D 2; copper and its alloys - 10D 2; babbitts, lead bronzes - 2.5D 2.

Symbol of the test principle

Schematically, the Rockwell research method is depicted as follows according to GOST 9013.

Rockwell hardness test method

The final applied load is equal to the sum of the initial load and that required for the test. The device indicator shows the difference in penetration depth between the initial load and the test load h –h0.

The Vickers method is regulated by GOST 2999. It is schematically depicted as follows.

Mathematical formula for calculation: HV=0.189*P/d 2 MPa HV=1.854*P/d 2 kgf/mm 2 The applied load varies from 9.8 N (1 kgf) to 980 N (100 kgf). The values are determined from the tables relative to the measured print d.

The method is considered empirical and has a wide range of readings. But the device has a simple design and can be used when measuring large-sized and curved parts.

The Mohs hardness of metals and alloys can be measured by scratching. Mohs at one time proposed making scratches on the surface of an object with a harder mineral. He classified known minerals by hardness into 10 positions. The first is occupied by talc, and the last by diamond.

After measurement using one method, transfer to another system is very conditional. Clear values exist only in the Brinell and Rockwell hardness ratios, since machine-building enterprises widely use them. The dependence can be observed when the diameter of the ball changes.

| d, mm | HB | HRA | H.R.C. | HRB |

| 2,3 | 712 | 85,1 | 66,4 | — |

| 2,5 | 601 | 81,1 | 59,3 | — |

| 3,0 | 415 | 72,6 | 43,8 | — |

| 3,5 | 302 | 66,7 | 32,5 | — |

| 4,0 | 229 | 61,8 | 22 | 98,2 |

| 5,0 | 143 | — | — | 77,4 |

| 5,2 | 131 | — | — | 72,4 |

As can be seen from the table, increasing the diameter of the ball significantly reduces the readings of the device. Therefore, machine-building enterprises prefer to use measuring instruments with the same type of indenter size.

If you find an error, please select a piece of text and press Ctrl+Enter.

The hardness of a metal is its property of resisting plastic deformation during the contact action of a standard tip body on the surface layers of the material.

Read also: Repair of a Chinese soldering iron with temperature controller

Hardness testing is the main method for assessing the quality of heat treatment of a product.

Determination of hardness using the Brinell method . The method is based on inserting a steel ball into a flat surface under load. Hardness number HB

determined by the ratio of the load to the spherical surface of the print.

The Rockwell (HR) method is based on statically pressing a tip into the test surface under a certain load. Steel balls are used as tips for materials with hardness up to 450 HR. In this case, the hardness is designated as HRB

.

When using a diamond cone, hardness is designated as HRA

or

HRC

(depending on load).

Vickers hardness (HV) is determined by statically pressing a diamond tetrahedral pyramid into the test surface. During the test, the indentation is measured with an accuracy of 0.001 mm using a microscope, which is an integral part of the Vickers instrument.

Shor's method . The essence of this method is to determine the hardness of the sample material by the height of the rebound of the striker falling onto the surface of the test body from a certain height. Hardness is assessed in conventional units proportional to the height of the striker's rebound.

PROPERTIES

In its pure form under normal conditions it is a solid. It has a silver-gray color and a pronounced metallic luster. The mechanical properties of iron include its level of hardness on the Mohs scale. It is equal to four (average). Iron has good electrical and thermal conductivity. The last feature can be felt by touching an iron object in a cold room. Because this material conducts heat quickly, it removes most of it from your skin in a short period of time, which is why you feel cold. If you touch, for example, wood, you will notice that its thermal conductivity is much lower. The physical properties of iron include its melting and boiling points. The first is 1539 degrees Celsius, the second is 2860 degrees Celsius. We can conclude that the characteristic properties of iron are good ductility and fusibility. But that's not all. Also, the physical properties of iron include its ferromagnetism. What it is? Iron, whose magnetic properties we can observe in practical examples every day, is the only metal that has such a unique distinctive feature. This is explained by the fact that this material is capable of magnetization under the influence of a magnetic field. And after the end of the action of the latter, the iron, the magnetic properties of which have just been formed, remains a magnet for a long time. This phenomenon can be explained by the fact that in the structure of this metal there are many free electrons that are able to move.

HRC hardness numbers for some parts and tools

| Parts and tools | Hardness number HRC |

| Hinged bolt heads, hex nuts, clamping handles | 33. 38 |

| Hinge screw heads, setscrew ends and heads, hinge axes, clamping and removable strips, screw heads with internal hex holes, drive chuck pin | 35. 40 |

| Round nut splines | 36. 42 |

| Gears, keys, clamps, crackers for machine grooves | 40. 45 |

| Spring and retaining rings, tension wedges | 45. 50 |

| Self-tapping screws, turning centers, eccentrics, mushroom supports and support plates, mounting pins, collets | 50. 60 |

| Installation nuts, locknuts, blockers for machine grooves, circular eccentrics, eccentric cams, clamps for dividing devices, replaceable jaws for vices and chucks, gear wheels | 56. 60 |

| Working surfaces of gauges - plugs and staples | 56. 64 |

| Copiers, carbon rollers | 58. 63 |

| Jig bushings, rotating bushings for boring bars | 60. 64 |

NOT ONE BLOOD

Oddly enough, the most accessible material for protecting dials has nothing to do with glass - at least at the molecular level. Plastic, which is called organic glass, sometimes plexiglass, is actively used in various inexpensive mechanical and electronic watches. The material under the Plexiglas brand was created in 1928, and its industrial production began in 1933. The appearance of plexiglass in the period between the two world wars was not accidental, and the engine of its spread was the development of aviation, which required a combination of strength, optical transparency, shatterproofness, that is, safety for the pilot, resistance to moisture and technical fluids.

Organic glass consists entirely of thermoplastic resin, and the production process is represented by two main methods: extrusion (extrusion of a hot polymer mass through a gap of a certain width and thickness) and casting (when a hot polymer mass is poured between two layers of glass or metal, and the size of the gap between the sheets is determined thickness of the future sheet).

Plastic glass is easy to scratch, but not so easy to break

The main advantage of plastic for the watch industry is its ability to easily take any shape, obediently following the will of designers. The relative softness is also reflected during use: plexiglass is easy to scratch, but not so easy to break. Plexiglas is easy to manufacture and maintain: polishing or replacing such glass is easy and inexpensive. It is a pity that it will have to be changed or polished often, especially if the owner of the watch leads an active lifestyle.

Table of relationships between hardness numbers according to Brinell, Rockwell, Vickers, Shore

Rockwell, Vickers and Shore hardness values indicated correspond to Brinell hardness values determined using a 10 mm diameter ball.

| According to Rockwell | According to Brinell | Vickers (HV) | By Shore | |||

| H.R.C. | HRA | HRB | Imprint diameter | HB | ||

| 65 | 84,5 | – | 2,34 | 688 | 940 | 96 |

| 64 | 83,5 | – | 2,37 | 670 | 912 | 94 |

| 63 | 83 | – | 2,39 | 659 | 867 | 93 |

| 62 | 82,5 | – | 2,42 | 643 | 846 | 92 |

| 61 | 82 | – | 2,45 | 627 | 818 | 91 |

| 60 | 81,5 | – | 2,47 | 616 | – | – |

| 59 | 81 | – | 2,5 | 601 | 756 | 86 |

| 58 | 80,5 | – | 2,54 | 582 | 704 | 83 |

| 57 | 80 | – | 2,56 | 573 | 693 | – |

| 56 | 79 | – | 2,6 | 555 | 653 | 79,5 |

| 55 | 79 | – | 2,61 | 551 | 644 | – |

| 54 | 78,5 | – | 2,65 | 534 | 618 | 76,5 |

| 53 | 78 | – | 2,68 | 522 | 594 | – |

| 52 | 77,5 | – | 2,71 | 510 | 578 | – |

| 51 | 76 | – | 2,75 | 495 | 56 | 71 |

| 50 | 76 | – | 2,76 | 492 | 549 | – |

| 49 | 76 | – | 2,81 | 474 | 528 | – |

| 48 | 75 | – | 2,85 | 461 | 509 | 65,5 |

| 47 | 74 | – | 2,9 | 444 | 484 | 63,5 |

| 46 | 73,5 | – | 2,93 | 435 | 469 | – |

| 45 | 73 | – | 2,95 | 429 | 461 | 61,5 |

| 44 | 73 | – | 3 | 415 | 442 | 59,5 |

| 42 | 72 | – | 3,06 | 398 | 419 | – |

| 40 | 71 | – | 3,14 | 378 | 395 | 54 |

| 38 | 69 | – | 3,24 | 354 | 366 | 50 |

| 36 | 68 | – | 3,34 | 333 | 342 | – |

| 34 | 67 | – | 3,44 | 313 | 319 | 44 |

| 32 | 67 | – | 3,52 | 298 | 302 | – |

| 30 | 66 | – | 3,6 | 285 | 288 | 40,5 |

| 28 | 65 | – | 3,7 | 269 | 271 | 38,5 |

| 26 | 64 | – | 3,8 | 255 | 256 | 36,5 |

| 24 | 63 | 100 | 3,9 | 241 | 242 | 34,5 |

| 22 | 62 | 98 | 4 | 229 | 229 | 32,5 |

| 20 | 61 | 97 | 4,1 | 217 | 217 | 31 |

| 18 | 60 | 95 | 4,2 | 207 | 206 | 29,5 |

| – | 59 | 93 | 4,26 | 200 | 199 | – |

| – | 58 | – | 4,34 | 193 | 192 | 27,5 |

| – | 57 | 91 | 4,4 | 187 | 186 | 27 |

| – | 56 | 89 | 4,48 | 180 | 179 | 25 |

Threaded holes

Table of drills for holes for cutting cylindrical pipe threads.

Wrench nut sizes

Basic spanner dimensions for hex bolt heads and hex nuts.

Read also: Identification of the spotlight on the diagram

G and M codes

Examples, description and interpretation of L and M codes for creating control programs on CNC milling and lathes.

Thread types

Types and characteristics of metric, pipe, thrust, trapezoidal and round threads.

Drawing scales

Standard scales for images of parts on mechanical engineering and construction drawings.

Cutting modes

Online calculator for calculating cutting conditions during turning.

Threaded holes

Table of drills and holes for cutting metric threads with large (main) pitch.

CNC machines

Classification of CNC machines, CNC machines for metal for turning, milling, drilling, boring, threading, reaming, countersinking.

Cutting modes

Online calculator for calculating cutting conditions when milling.

Drawing formats

Table of side sizes of main and additional formats of drawing sheets.

CAD/CAM/CAE systems

CAD computer-aided design systems, 3D programs for design, modeling and creation of 3D models.

History of creation

To create the scale, Mohs used 10 standard minerals - talc, gypsum, calcite, fluorite, apatite, orthoclase, quartz, topaz, red corundum and diamond. He placed the minerals in order of increasing hardness, taking as his starting point that a harder mineral scratches a softer one. Calcite, for example, scratches gypsum, and fluorite leaves scratches on calcite, and all these minerals cause talc to crumble. So the minerals received the corresponding hardness values on the Mohs scale: chalk -1, gypsum - 2, calcite - 3, fluorite - 4. Further research showed that minerals whose hardness is below 6 are scratched by glass, those whose hardness is above 6 scratch glass . The hardness of glass on this scale is approximately 6.5.

Stones with a hardness greater than 6 are processed with diamond.

The Mohs scale is intended only as a rough estimate of the hardness of minerals. A more accurate indicator is absolute hardness.