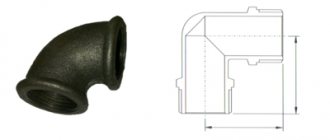

Steel bends are products that are used to change the direction of various pipelines. They are pipe segments bent at the desired angle. They are usually carried out using special pipe bending machines and are mounted on the pipeline by butt welding. The operational scope of these parts is incredibly wide, but they are most often used in the installation of oil, gas and water supply communications.

Bends for steel pipes are made of stainless steel, alloy steel, and they can also have a protective zinc coating

How are bends made?

Contents

A bend is a fitting designed to change the direction of flow of substances in a pipeline. The part allows you to connect pipes, bypassing obstacles, and create a compensatory bend.

A pipeline bend is an area of high pressure. The change in flow creates conditions for sediment to fall out, reducing flow capacity. For this reason, products are checked for compliance with the declared parameters. Fittings that do not pass technical control are written off as scrap.

Classification by production technology:

- Cold-formed;

- Hot-bent;

- Stamp-welded;

- Welded sectional.

Bent ones are produced in such a way that only the middle part of the pipe is subject to deformation. The cold bending method involves bending without preheating at a temperature of 20°C. The technology allows for bending up to 27°, so to achieve the required angle, the workpiece is bent in several places. Induction heating is used for the entire tube or part of it at a temperature of 1000-1100°C, depending on the steel grade.

Stamp-welded parts are cut from steel sheets. Then two halves are formed in a sheet bending machine and welded together. Since the method is quite labor-intensive, it is used only for the production of large-diameter inserts. If necessary, additional heat treatment is carried out.

With any method, cracks, chips and other flaws are unacceptable on the surface. Each product must undergo ultrasound testing, and sometimes an additional radiographic examination is carried out.

Description

A bend is a piece of pipe that is given a certain angle. Depending on the task, you can select a suitable outlet. There are many varieties, and this article is about them.

The bends are closely connected to the pipes by welding. According to GOST, such products are produced on special pipe bending machines.

WELDED SECTIONAL BENDS

Application

The scope of application of bends is very wide: from the installation of an oil pipeline to the installation of a boiler room in a residential building. Water pipelines, gas pipelines, oil pipelines - wherever pipes are used, bends are used.

Types of models

Bends differ according to some factors, for example, the material used:

- carbon steel;

- low alloy steel;

- stainless steel;

- corrosion-resistant steel;

- heat-resistant steel.

They also differ in their production method:

- created by welding;

- seamless.

Bends are of the following types:

- Steeply curved. Quite often during the manufacturing process of a pipeline line, it becomes necessary to turn the direction sharply. For this purpose, bends with a large rotation angle are specially created. In this case, the integrity of the pipe will be maintained and the required degree of rotation will be observed.

- Welded. The corners of this production can be bent or steeply curved. The difference is the weld seam, which remains on the pipeline after work. In addition, they come with thick or thin walls. The main purpose of the product is to transport gas materials. They are made from two types of steel: carbon or low-alloy. High-strength steel is rarely used for the manufacture of these bends.

- Bent. Modern companies do not produce these bends due to the fact that they are used quite rarely. The products have become unpopular due to their poor quality compared to new items. This type of part often undergoes corrosion in the form of small cracks that are inaccessible to the human eye. Consequently, there is a high risk of an accident occurring on the highway. They are also quite rarely purchased due to the limited size range. These spare parts are produced in sizes no larger than 50 mm. But there are also advantages - the price. Various types of steel are used for manufacturing: carbon, low-alloy, corrosion-resistant, heat-resistant, stainless. They are made in the style of seamless, welded and thin-walled pipes. Often used when laying utility networks.

- Steel. This type of parts is the most common due to its low cost. Ideally suited to a variety of work environments and difficult obstacles. To choose a steel bend, you should take into account all the nuances of the route being laid.

- Forged. They are also one of the most common. They are made from high-quality materials, which have already been repeatedly noted for their good reliability. Another feature is the wide size range up to 1400 mm. During manufacturing, the part is heated to a high temperature, then forged.

- Segmental. They differ from other parts in that they are made of several segments. To create a certain degree, different numbers of rings are used. Bends of this kind are reliable during operation and are sold in different diameters.

Before purchasing, you should consider what conditions and for what specific purposes this outlet will be used.

Legal registration of business

For this business, it is better to create an LLC, since in the case of an individual entrepreneur, the company’s obligations fall on its property.

In any case, for registration you need to submit an application to the local authorities of the Federal Tax Service, indicating the OKVED codes corresponding to the type of bends being produced:

- 22.21 – Production of plastic plates, strips, pipes and profiles;

- 24.20 – Production of steel pipes, hollow profiles and fittings.

Along with the application you must provide:

- photocopies and originals of documents: for individual entrepreneurs – personal (passports, TIN);

- for LLC – constituent ones, as well as a title deed for ownership of real estate, confirming the legal address.

If you register on your own on the Unified State Services Portal, you do not need to pay a fee. For an LLC, it is mandatory to deposit at least 10,000 rubles of authorized capital into the account.

Another document is a notice of transition to the selected tax regime. The general taxation system is extremely disadvantageous and is only necessary for very large companies. A small workshop for the production of bends is best suited for the simplified tax system according to the scheme of 6% of income.

Types of bends

Regardless of the manufacturer, all sewer outlets comply with accepted standards. Thanks to this, it is much easier to design sewerage systems, purchase its individual components and connect them into a working system.

Corner elements can be of different models: they differ in design features and cost

Polyethylene

Black material is used for their manufacture. The connection is made using couplings or end-to-end.

The couplings are equipped with a special spiral during the factory manufacturing process: it is heated with a welding machine for a hermetically sealed connection.

To make a butt connection, the ends of the outlet and the pipe are heated and joined until the material hardens completely.

PVC bends

They are the most common. They are connected by placing a socket on a smooth pipe.

Their advantage is the lack of need for special equipment, as well as a higher speed of installation of the entire system.

Structural elements for internal use (indoors) are gray, and for external use (sewage drainage in a private building) they are painted brown.

Otherwise, long and high-quality operation of the sewer system is not guaranteed. In some cases, special adapters are included in the circuit.

Polypropylene

They have smooth ends and sockets for joining each other.

They can only be used in conjunction with pipes made of similar material. The main purpose of the products is to drain wastewater and groundwater. They can pass water at speeds of up to 7 meters per second.

Bends for corrugated pipes

These elements have sealing rings on each side and are connected using couplings.

The outer part of the element at the bend has a smaller diameter.

Used for joining different pipes using sealing collars.

Vavin taps

This is a separately patented system that is a special type. On the outer side of the corrugated element there is a triangular recess that serves as a lock.

These products are made from high quality material that can withstand high pressure. Such products are guaranteed to last up to 50 years.

Magnum bends

They can have a bend angle of 90 and 45 degrees. The main distinguishing feature is that they do not have roundings, so they are fraught with blockages.

For this reason, these connecting elements are almost never used for the installation of sewer systems.

Sewerage

There are much fewer docking methods here.

Cast iron

Traditionally, chasing is used to connect cast iron sewers:

- The pipe is inserted into the socket of the fitting;

- The space between them is tightly caulked with kabalka - oiled organic fiber;

- Then the joint is covered with cement mortar or filled with molten sulfur.

Accordingly, fittings are a combination of bends with the same diameter as the pipes and sockets.

However, new cast iron sewer fittings and pipes are increasingly equipped with rubber seals, ensuring tightness during ordinary joining.

PVC and polyethylene

Both polyethylene and the much more common PVC pipes for sewerage, and fittings for them, are again equipped with rubber seals in the sockets.

There are two subtleties associated with docking:

- It is advisable to remove the outer chamfer from a pipe cut to size. Otherwise, it will be difficult to insert it into the rubber-sealed socket.

- A connection made with sealant is guaranteed not to leak due to drying of the rubber.

Tightness is ensured by a rubber seal; The sealant additionally fixes the pipe and protects against leaks when the rubber dries.

Installation of an outlet into a pressure system

If it is impossible to block the flow, use electric-welded or flanged saddles with a cutter. The method is available at a maximum network pressure of up to 16 MPa.

- Marking the area, cleaning the top dirty layer of plastic using a scraper, napkins and non-aggressive cleaning agents.

- Fastening the lower part of the saddle according to the clamp principle: it is put on the pipe, the clamping screws are tightly tightened for a tight fixation.

- The head element is attached, and the direction of the knee is set arbitrarily in accordance with the design documentation.

- If an electric welded product is used, welding is carried out using an electrofusion device, which melts the material on the surface. The flange method involves tightening the clamps and installing an additional seal.

- A locking mechanism is placed on the open end of the elbow so that when a hole is formed, the working fluid does not escape out.

- An incision is made through the head part. To do this, use a hexagon, when rotated the cutter begins to move. It is brought to the top of the outlet channel, after which it is closed with a lid. The function of the cover depends on its type: vandal-proof or sealed.

Advantages

With the advent of a large number of factory products for assembling galvanized steel chimneys, the need to make pipes with your own hands has decreased. However, homemade pipes allow you to reduce costs and choose the ideal diameter. In addition, they are used to equip drains, so the ability to make pipes with your own hands will be useful in everyday life. Metal chimneys have the following advantages over others:

- A light weight. Smoke exhaust ducts made from homemade galvanized pipes weigh much less than brick or ceramic ones. Therefore, to install this type of chimney, there is no need to equip a foundation, the cost of pouring which exceeds the cost of material and installation work.

- Fire safety. According to building codes, steel chimneys are completely fire safe. High quality metal can withstand heating up to 900 degrees, so it is suitable even for solid fuel stoves and fireplaces.

- Low cost. Chimney pipes made of steel are the most democratic way to organize smoke removal; the cost of installation is several times lower than the installation of brick and ceramic analogues.

- Easy to assemble. You can easily assemble a chimney made of galvanized steel with your own hands according to the instructions, thereby saving money spent on hiring professional workers.

Funnel making technique

If you understand that a seam connection is the essence of almost any tin product, you can give free rein to your imagination and assemble complex products from several simpler ones. An example of this is all kinds of funnels, tees and corner bends.

The funnel consists of two short pieces of pipe of a larger and smaller diameter. They are assembled like regular pipes, only their edges are flared outward by 8–12 mm. Subsequently, these bent sides are used for further production of folds, or, if there are no complaints about tightness, the hard edges are folded and fastened together with a cutter.

The riveting technique for different products may differ significantly, but in reality this is not as important as the correct drawing up of the pattern. All blanks should be cut only according to the template

For example, for the central part of a funnel - a truncated cone - the pattern is a ring segment, where the length of the inner arc is determined by the diameter of the drain, and the outer arc by the diameter of the receiving socket.

Unfortunately, the equipment for the production of such products has a very narrow specialization, and therefore is not available due to both its high price and low prevalence. However, all products made of tin and sheet metal, be it a bucket, a tank or an ordinary skate, can be made manually; machines only facilitate some operations.

You can buy galvanized pipes freely, but the cost of such products can be quite high, so the desire to make a galvanized pipe with your own hands is dictated, first of all, by considerations of economy.

At the same time, the production of galvanized pipes does not require the use of special efforts, special expensive devices and tools and any professional knowledge, so any home craftsman who has a set of standard carpentry tools can cope with this.

Pipes made of galvanized metal are used to equip chimneys; they are popular due to their light weight and, accordingly, ease of installation. Galvanized chimneys do not require the construction of a foundation, and this significantly reduces the cost of chimney equipment.

Such pipes meet fire safety standards, withstanding temperatures up to 900°, so they can even be used for smoke removal from solid fuel heating boilers and furnaces.

Galvanized pipes are also used in home construction to equip drains. Such pipes are already quite affordable in cost, but the process can be made even cheaper by using hand-made products.

Parameters of 90° steel bends

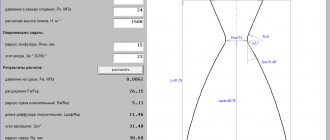

The 90° steel bend is produced according to the following standards:

- GOST 17375-2001. Regulates the production of 3D type products with a radius of 1.5DN. This type of product is created using the hot drawing method.

- GOST 30753-2001. Regulates the production of 2D products with a steep curved shape. This type of product is created by stamping or hot broaching. In addition, it has a bending radius of 1 DN.

The tap can be operated at temperatures from –70 to +450°C. For its manufacture, heat-resistant steel grades are used, intended for use in northern latitudes. Typically this is grade 09G2S, which is a high-quality and durable metal that is resistant to corrosion and temperature changes.

Advantages of 90° steel bends over plastic analogues

The 90° steel bend is used to change the direction of flow of working fluids in piping systems. It has found wide application in many industries. Many consumers are wondering about the possibility of using a less expensive plastic alternative.

When comparing a metal outlet with a plastic one, it is worth noting the following advantages of the more expensive option:

- Increased resistance to sudden temperature changes. Plastic products are less resistant to thermal shocks. Operating a plastic outlet under conditions of a possible temperature increase above 95°C is extremely undesirable, despite the fact that modern products can withstand temperatures up to 110°C. It is important to note that the service life in this mode is sharply reduced. Steel bend 90°, manufactured in accordance with GOST 17375-2001, is effective for working environments with temperatures up to 450°C.

- Increased service life in aggressive environments. Plastic analogues lose their qualities in difficult conditions.

- Increased resistance to mechanical damage. The metal outlet is several times stronger and more reliable than its other analogues.

As a result, it should be noted that steel products, despite the cost, are economically beneficial, as they are distinguished by their durability. Experts recommend not wasting time on introducing plastic outlets, but using classic models in the required quantities.

Justification for the reduced cost in contrast to the factory price

The 90° steel elbow manufactured by our company has an attractive price compared to its competitors. Moreover, the cost may be lower than that of many manufacturers. This is due to several factors:

- Many years of experience. We supply our products in large volumes, so the cost of a 90° bend is lower than that of most competitors.

- Reduced cost levels. We have developed an efficient infrastructure, which plays a significant role in reducing trading costs. We have two huge warehouses for finished products, focusing not on quantity, but on quality. This is due to highly qualified personnel and other fundamental factors.

- Full production cycle. Our group of companies is a wide network of various enterprises, thanks to which it is possible to create closed and most efficient processes for creating bends, offering low prices for finished products.

These and other factors allow our company to set competitive prices for 90° steel bends, while maintaining the high quality of the products sold. We develop attractive price offers for customers for the purchase of bends, therefore we are very popular and well-known in our field.

GOST standards and their features for 90° bends

Our company offers high-quality products in accordance with GOST 17375-2001. These bends are manufactured using the hot drawing method and belong to the category of 3D products, that is, they have a radius of 1.5 DN. 90° bends according to GOST are intended for technological connection of pipelines with the same cross-section and located at right angles relative to each other. They are recommended for use with liquids such as gas, water, oil and steam. Installation is carried out to pipelines by welding at the ends of the branches. The products are made from the following steel grades: 09G2S, 10, 10G2, 20. The 90° bend works effectively in the temperature range of -70 - +450°C.

Similar technical conditions apply to GOST 17380-2001. If it is necessary to increase the performance of products operating in an environment of sudden temperature changes, regular water hammer, increased external loads, or with specific chemical properties of the environment, it is possible to produce bends with thick walls in accordance with the technical specifications and technological documentation for this type of product.

Our bends fully meet modern requirements and standards set by GOST 17375-2001, and are an example of high quality, strength, durability and reliability. By ordering bends in accordance with GOST 17375-2001 from our company, you can verify this yourself.

Strict compliance with regulatory requirements

Our company manufactures 90° bends in accordance with all standards required for technology and the production process by state authorities supervising the installation of specific types of pipelines. Due to their technical parameters, the products are suitable for use in pipelines of national importance or public utilities. They are officially recognized as products with high performance indicators that satisfy the requirements of regulatory organizations regarding the quality of backbone networks.

produces 90° bends on an industrial scale. This opportunity has the following advantages:

- production on high-precision, highly specialized equipment;

- highly qualified employees, careful quality control;

- certificates and other documents confirming compliance with state standards;

- the presence of two spacious warehouse buildings, with a sufficient amount of own-produced products.

Main customers of 90° steel bends

Today there are a huge number of enterprises in need of supplies of steel bends with an angle of 90°. Among them it is worth highlighting:

- construction companies engaged in the construction of houses and industrial structures, including life support facilities;

- repair and construction companies, including city utilities, government organizations specializing in pipeline installation;

- companies whose activities relate to the chemical, oil and gas industries that need to lay pipes for transporting working fluids.

Benefits of cooperation with

has been successfully producing large-diameter steel fittings for many years. During this time, state structures at the microeconomic level, international corporations, and medium and small businesses in need of bends for pipelines have become the company's partners.

Benefits for clients when contacting our company

- High quality of manufactured products. Steel bends with an angle of 90°, as well as other products, are created on the basis of high-quality steel grades using modern European equipment. Thus, the manufacturing process is characterized by maximum precision, resistance to any load, reliability and durability. Control at each stage is carried out not only by the relevant technological equipment systems, but also by professional specialists.

- Affordable price. "Uralteplomontazh" today is a large manufacturer that strives to minimize production costs by optimizing costs and reducing production costs without compromising the quality of products.

- Large warehouses. We always have stocks of finished products with bends, adapters, and tees in stock. That is why your order is processed promptly and delivered in the shortest possible time. If you need a huge batch of fittings, the company is ready to ensure their uninterrupted supply.

- Consultations with specialists. The staff of Uralteplomontazh is always happy to help its clients with any questions that arise. Managers will help you make the right choice, solve problems with documentation and delivery of goods to the site.

Key Features

The products are characterized by high performance characteristics. Among their advantages is resistance to the effects of almost all unfavorable external factors of any origin: biological, atmospheric, chemical, man-made. In addition, the list of product advantages includes:

- the ability to smoothly rotate the pipeline axis;

- being integrated into the main line using electric welding, they provide maximum connection reliability;

- are immune to temperature fluctuations, since steel has a low coefficient of thermal expansion;

- can be used in harsh operating conditions;

- have high mechanical strength;

- absolutely gas-tight.

Steel bends successfully withstand high operating pressures and are capable of operating in conditions of critically high and low temperatures. They are resistant to excess ambient moisture, reliable, and operate for a long time.

GOST and assortment

Standard bends comply with the standards prescribed in GOSTs.

Seamless welded elbows are made in accordance with the standards specified in GOST 30753-2001. The bending of these steel products can be different: 35 degrees, 60, 90 or 180. The wall thickness must be at least 4 mm, but not more than 36 mm. The diameter indicated by the norm is from 57 to 820 mm.

GOST 17375-2001 describes the parameters of welded bends made of steel, with a diameter from 32 mm to 320. Steel can be of different types. The wall thickness can vary from 2 to 32 mm.

Standard round bends

Bent fittings are made in accordance with GOST 22793-83.

GOST 17380-2001 sets standards for the production of seamless steel bends that are welded. The permissible temperature range is between – 70 and + 450 degrees Celsius.

Photos will help you better understand the types of bends. The main thing is to know that you need to choose a fitting so that it matches the pipeline and is suitable for the conditions in which it will be used.

Classification

The above division - hot-deformed, hot-stamped, bent, welded, stamp-welded - is the main classification of products. Sometimes, when describing products, they operate with other parameters of the fittings: sector options (obtained by electric welding) and smooth (all others). Steeply curved bends are also distinguished - these are those that have a small diameter. They are made mainly by stamping and bending. If the pipeline is not required to be compact, the outlet fittings for it will most often be stamped or welded; they are large in size.

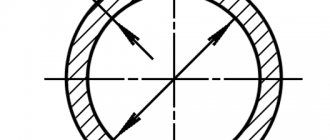

There is another classification of the product: 2D and 3D. This parameter characterizes the ratio of the bend radius to the internal diameter of the product. In 2D these two values are approximately the same; in 3D the turning radius is one and a half times larger than the diameter. This designation can also look like: R-1.5D (this is a 3D type) or R-1D (a 2D option).

Marking

The main parameter characterizing steel bends is DN (DN in some documentation). This is their nominal diameter, or nominal diameter, the main criterion for choosing the exact model of the product when installing it in a pipeline and matching it with adjacent sections of the pipeline. DU must be indicated in the product designation.

Another important value is the wall thickness, since the elbow must fit perfectly into the pipeline line. The diameters of steel bends and wall thickness are standardized and correspond to the size range of pipes used today in everyday life and in production.

According to the angle of rotation of the knees, they are divided into models designed for an angle of 15, 30, 45, 60, 90 degrees. This value is also indicated in the designation.

An example of a short marking is 45° 38x2 09G2S, where:

- 45° — rotation angle;

- 38 – internal diameter, mm;

- 2 – thickness of its wall, mm;

- 09G2S – steel used.

Full marking of the product may also include length, GOST or other regulatory document according to which production was carried out, brand or identification number of the manufacturer, batch number.

The designation is applied to the product by embossing, paint or a sticker/label.