Purpose and areas of application of pipeline bends

Steel bends are used in the installation of various technological and main pipelines. They smoothly change the direction of flow and are widely used in various fields:

- in the oil and gas sector;

- water supply, heating and fire extinguishing systems;

- energy industry;

- in metallurgical production;

- Housing and communal services, etc.

Most often, bends are used in industrial main and domestic pipelines, at pumping stations. The outlet material is selected based on operating conditions and the aggressiveness of the working environment. Another important parameter is the geometry of the connected pipes.

For pipelines operating with an aggressive environment at high pressure, seamless, steeply curved or welded products made of alloy or stainless steel, and galvanized bends are used. Welded bends are used when laying various communications with a medium pressure of up to 2.5 MPa and a pipe cross-section of up to 1 thousand mm.

Household communication systems are equipped with bent or steeply curved bends made of high-carbon steel with a diameter of up to 2 thousand mm.

Bends for corrugated pipes Korsis

Korsis corrugated pipes are products made using the latest technologies; the design features a two-layer structure with smooth internal walls and a black outer corrugation that protects the surface from ultraviolet radiation. Thanks to this structure, the pipes have high ring rigidity, allowing them to be used at great depths. The material of the pipe inner walls is polypropylene - this allows the products to be used at temperatures of flowing liquids of about 65 C.

Rice. 8 Korsis pipes, socket with O-ring - design and appearance

Advantages of steel bends

Bends play an important role in the pipeline system, allowing it to be changed in direction and increasing its strength. The main advantages and purpose of steel bends:

- Ensures smooth rotation of the pipeline.

- Possibility of operation in various conditions - they have high strength characteristics.

- Resistant to temperature changes.

- Long service life.

The production of bends is regulated by various standards. Products are manufactured in accordance with OST 34-10-752 (sectoral bends for power systems), OST 36-21 (welded sectional bends), GOST 30753 (seamless bends), GOST 17375 (steeply curved bends), etc.

Dimensions of sewer fittings and recommendations for installation of sewer lines

The dimensions of sewer outlets correspond to the pipes to which they are connected and are regulated by GOST. It should be taken into account that for external sewerage, special orange-colored pipes are used, which are thicker than internal pipes (2 mm wall thickness of internal pipes and 3.1 - 3.4 mm of external pipes).

Rice. 9 Plastic sewer outlet - dimensional parameters

When laying an external sewer line, the following recommendations must be observed:

- The trench is dug in such a way as to prevent pipes from freezing in winter, while taking into account the slope, which is for a line with a diameter of 110 mm. is 20 mm. per 1 linear meter.

- If the depth is too large, the pipes are thermally insulated (you can use a built-in or external heating electric cable) and raised higher.

- A layer of sand 100-150 mm thick is usually placed at the bottom of the trench; for thermal insulation and reducing the load on the pipe walls, the pit is filled with expanded clay and then leveled to the ground with soil.

Materials and production methods

Steel bends are made from alloy, stainless, corrosion-resistant or carbon steel. Chrome-plated, nickel-plated and galvanized products with increased resistance to corrosion processes are produced. The material of manufacture influences the scope of application of the bends.

Household communications that do not have contact with aggressive environments are made of carbon steel . If the system contains chemically active substances, then bends made of stainless or alloy steel are used.

Alloyed bends are used at temperatures from −60 to +40 °C with pressures up to 7.4 MPa, which allows them to be installed on pipelines in cold climatic zones. Stainless steel products are intended for pipeline systems transporting hot, acidic, and alkaline media. They are resistant to corrosion.

Galvanized elbows are a common type of product made from galvanized steel. They are able to withstand high pressure and transport aggressive media.

Bends vary in manufacturing method. Highlight:

- Steeply curved.

- Stamp-welded.

- Bent.

- Welded sector/sectional.

- Chiseled.

Peculiarities

Low-density polyethylene is another material from which pipes and bends for them can be made. They have the following positive qualities:

• Such pipes do not rust or oxidize. • They are lightweight. • They are not afraid of aggressive environmental influences. • They are elastic. • Bends made of HDPE have high strength characteristics. • They are able to provide stable pressure in the pipeline.

The polyethylene bends in question allow you to save considerable amounts of money on transportation. This is not surprising if we remember that they are several times lighter than their metal prototypes.

Advantages

Another undoubted advantage of such parts is their ease of installation. In order to assemble a pipeline from this material, there is no need to use welding, and this saves on electricity or gas, depending on what type of welding would be used if the pipes were made of metal.

Bends for PPU pipes

A material with similar positive qualities from which pipes and bends can be made is PVC. Below is a list of these benefits.

We recommend: Adapter coupling box for cable and pipes: reinforced, ip67, dkc

1. Relatively small specific gravity. 2. Durability with proper use. 3. Ease of installation. 4. Reasonable price.

PVC pipes are not afraid of almost any environmental factors. These factors include temperature changes, rusting, moisture, chemically active substances, and ultraviolet radiation. The sections will not become overgrown and the pipe walls will not become thinner.

Types of pipeline branches

Stamp-welded

Stamp-welded bends are made from stamped sheet steel of a given thickness using the welding method. This allows us to obtain products with high strength characteristics and cross-sections up to 1420 mm.

Such bends are used on main pipelines of the oil and gas industry. They are produced from stainless, structural and alloy steel according to TU 102-988-95 or other standards.

Welded sectional

This type of bends is produced from separate sections/sections of pipes that are welded together to obtain a finished product with a given angle of rotation. Sectional bends are used in systems with pressures up to 2.5 MPa and temperatures up to 425 °C. They are inferior in strength to other types, but are the most budget-friendly option for bends.

Material of manufacture: carbon or low-alloy steel. Diameter - 108–1620 mm, rotation angle - 30, 45, 60 or 90°.

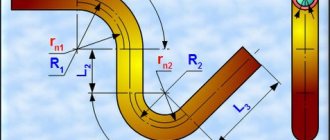

Bent

Bent elbows are made on special pipe bending machines by bending a steel pipe (in a hot or cold state) to the desired angle from 2 to 90°. The release is regulated by GOST 24950 and other GOST and TU standards.

Such products are used in places where it is not possible to install a steeply curved outlet option. The pressure of the medium in the system is up to 100 MPa, the temperature is from −50 to +510 °C.

Steeply curved

Steeply curved bends are produced by pulling a pipe through a special mold with a specified angle of rotation on pipe bending equipment. This allows you to obtain a high-quality part with precise geometric characteristics. The production of products is regulated by GOST 17235.

The material used is carbon and stainless steel. The angle of rotation of the outlet can be 30, 45, 60 or 90°. The diameter of the products is from 18 to 426 mm, the working pressure is up to 16 MPa. It is possible to manufacture from other alloys or at a different angle of rotation according to individual drawings.

Spot

Turned elbows are made from cast steel billets. This method is the least common due to the high cost of manufacturing products. However, it allows you to obtain products with any thickness and high pressure resistance up to 100 MPa.

Types of parts

Variety of sewer outlets

Bends for creating sewage systems are classified according to many characteristics:

- material;

- size;

- configurations;

- connection method.

Turns and 90-degree corner connections are called bends; parts that provide a connection angle of 30 or 45 degrees are considered half-bends.

To assemble a single system from parts of different diameters, special adapters are used to eliminate leaks at the joints. They are sold on the market under the name “socket restorer”.

Material of manufacture

In the manufacture of plumbing outlets, various materials are used, which have advantages and disadvantages. Products made of plastic: polypropylene, polyvinyl chloride have become widespread. Old-built houses are equipped with cast iron sewerage.

Products made from these materials do not require the use of any electrical devices during installation. It’s easy to assemble a single structure with your own hands; for connection, one end is made in the form of a socket, and the other in the form of a smooth pipe with a taper.

Installation of polyethylene parts will require the use of special soldering stations. A heating wire is mounted in the wall of the fitting. After joining the parts, voltage is applied to the spiral, it heats up and fuses the components. Such sewer systems are done “once and for all.” The configuration of communications can only be changed by dismantling and subsequent soldering of new connections.

Size of fittings

For internal sewerage of residential buildings, the most popular sizes of pipes and, therefore, branches for them are considered to be products with internal diameters from 40 to 110 or 150 mm.

Plastic bends (polypropylene and polyvinyl chloride) are unified and supplied to the retail network mainly with diameters of 40, 50, 110, 150 mm. For drainage from a washing machine, you can purchase pipes and fittings for them with a cross-section size of 25 mm; the bathtub and dishwasher can be connected to drains with an internal passage of 40 mm. For risers, pipes 110 or larger are used, equipped with bends of 110 and 50 mm.

Cast iron sewer outlets have a nominal internal passage of 65 mm, while the pipe itself is produced with an outer diameter of 81 mm. For risers, a pipe with an internal diameter of 100 mm and an external diameter of 118 or 125 and 144, respectively, is used.

Configuration of fittings

Types of sewer outlets can be seen in the catalogs of any company that produces plumbing systems. The list of products includes:

- one- and two-plane crosspieces;

- tees;

- bends and half-bends;

- audits;

- bends with reduction, where a smaller one is connected to the main pipe of a larger diameter;

- bottles - transitions from a smaller diameter to a larger one.

Bends for turns have angles of 15, 30, 45, 67 and 90 degrees. By combining parts, you can make angles sufficient to assemble a sewerage system of any shape.

Installation rules

Installation of bends on pipelines is carried out using the welding method. This is a labor-intensive process that requires certain skills from the welder. When welding, it is necessary to constantly monitor the alignment of the internal surfaces and edges of the parts being welded. To do this, alignment is performed using a special vice (for small diameter pipelines) or rotators. The latter are used for welding large-diameter pipes and guarantee strong adhesion of the elements to each other during the welding process.

When welding bends and pipelines, you must follow the installation rules:

- Before installation, you need to check the availability of accompanying and regulatory documentation and study the instructions.

- Welding work is carried out only by trained specialists who have the appropriate permits and regulations.

- Work is carried out only in special protective clothing with a mask.

- No foreign objects are allowed in the workplace. There must be a fire extinguishing agent and ventilation.

- Welded edges of parts must be prepared. Products are not allowed to have defects or irregularities, chips, cracks, delaminations, etc.

- During the welding process, it is necessary to control the specified mode, selected based on the characteristics of the materials being welded.

Manual electric arc welding is carried out at direct current in two stages.

Pipe rotator

In production, welding of bends to pipes is carried out using special equipment. Typically, these special equipment are rotators. The parts to be welded are clamped in the device and rotate around their axis, which makes it possible to perform high-quality welding of the outlet.

Let's consider the main advantages of using a rotator when welding a rotary product with a pipe:

- allow you to weld pipes with large diameters;

- the use of an autonomous drive in the rotator design allows you to regulate the rotation speed of the part;

- ensure precise alignment of pipes;

- can work not only with straight parts, but also with more complex, from a structural point of view, elements (for example, tees).

Today, there are many types of bends that allow you to solve any problem when installing pipelines. At the same time, a wide range of these products obliges specialists to study a large amount of information in order to know and comply with the features and rules for using all such products.

Prices for steeply curved steel bends according to GOST 17375-2001 welded

| Name | Price with VAT |

| 1 performance | |

| 15(21,3×2,0) | 17.38 rub. |

| 15(21,3×3,2) | 17r. |

| 20(26,9×2,0) | 21.16 rub. |

| 20(26,9×3,2) | 38.6 rub. |

| 25(33,7×2,3) | 29.81 rub. |

| 32(42,4×2,6) | 48.88 rub. |

| 32×2,0 | 37.68 rub. |

| 38×3,0 | 37.04 rub. |

| 40(48,3×2,6) | 60.41 rub. |

| 40(48,3×3,6) | 86.56 rub. |

| 45×2,5 | 50.5 rub. |

| 45×3,0 | 56.5 rub. |

| 50(60,3×2,9) | 74.62 rub. |

| 57×3,0 | 51.27 rub. |

| 76×3,5 | 92.68 rub. |

| 89× 3,5 | 138.25 rub. |

| 89×8,0 | 487 rub. |

| 108×3,5 | 190.74 rub. |

| 114×3,5 | RUB 219.92 |

| 133×3,5 | 338.32 rub. |

| 159×4,5 | 568.64 rub. |

| 219×5,0 | RUB 1,428 |

| 219×6,0 | RUB 1,602.44 |

| Seamless | |

| 57×3,0 | 76.58 rub. |

| 57×3,5 | 81.29 rub. |

| 57×5,0 | 130 rub. |

| 57×6,0 | 154.6 rub. |

| 76×3,5 | 149.1 rub. |

| 76×5,0 | 156 rub. |

| 76×6,0 | 233.96 rub. |

| 89×3,5 | 202.52 rub. |

| 89×6,0 | RUB 316.96 |

| 108×4,0 | 325.01 rub. |

| 108×6,0 | 451.18 rub. |

| 114×4,0 | RUB 309.88 |

| 133×4,0 | 468.81 rub. |

| 133×6,0 | 761.5 rub. |

| 159×4,5 | 721 rub. |

| 159×6,0 | 976.08 rub. |

| 219×6,0 | RUB 1,749 |

| 219×8,0 | RUB 2,601.82 |

| 219×10,0 | RUR 3,571 |

| 273×7,0 | RUB 3,536.19 |

| 325×8,0 | 4,771 rub. |

| 325×10,0 | RUB 6,771 |

| 377×8,0 | 6,601 rub. |

| 377×9,0 | RUR 7,451 |

| 426×8,0 | 8,651 rub. |

| 530×10,0 | RUB 16,981 |

| 720×10,0 | RUB 36,901 |