Material M1 Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells M1 material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, M1 material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Composition and characteristics

Other elements in total should be no more than 0.1%. Impurities may contain the following elements, not more than (GOST 859-2001):

- iron – 0.005%;

- nickel – 0.002%;

- sulfur – 0.004%;

- arsenic – 0.002%;

- lead – 0.005%;

- zinc – 0.004%;

- oxygen – 0.05%;

- antimony – 0.002%;

- bismuth – 0.001%;

- tin – 0.002%.

Copper alloy M1 has excellent physical characteristics: high electrical conductivity and low (0.018 μΩ) electrical resistivity, which after heat treatment by annealing decreases by another 2.8%. The plastic properties of the alloy make it possible to use it for the manufacture of parts used in fixed joints with operating temperatures up to 250°C

Due to the very low impurity content, the cost of M1 copper is 20% higher than the other popular brand, M2. Various types of rolled copper made from M1 alloy are widely used in cryogenic industries. Due to its thermal stability, its viscosity, strength and plastic properties do not change under extreme temperatures.

Pure copper

Grade M0 contains 99.95% Cu and no more than 0.05% impurities. According to special technical conditions, several grades of vacuum copper and especially oxygen-free pure copper are produced, which is used in the electric vacuum industry. Strips, tapes, rods, and pipes are produced from oxygen-free copper of series A and B. Tapes and rods are made from vacuum pure copper. Rods are produced from pure copper, which is deoxidized with manganese. All these semi-finished products are used in the electrovacuum industry. Oxygen-free pure copper is characterized by a low (-100°C) recrystallization temperature.

Application of M1 copper

M1 copper is widely used for:

- production of current conductors, tin-free bronze rolled products;

- production of rods and wire for welding;

- creation of cryogenic equipment designs;

- production of electrodes suitable for welding copper and cast iron products.

Also, many products are made from M1 copper alloy. The production of each of them has its own characteristics. Copper sheets and tapes are checked for bending. The slabs are also subjected to certain tests. Pipes with a large cross-section are made by pressing. The properties of finished products are checked for compliance with GOST.

Fill out the information below and our managers will contact you as soon as possible and also advise you on any questions you may have.

Source

Copper m1 m2 m3 difference - Metalist's Handbook

- 1 Copper M1 - prices in Moscow. Hard, soft, pressed, annealed copper

- 2 Copper sheet grades M1, M1R, M2, M2R, M3, M3R. GOST 495-92

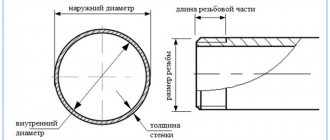

- 3 Copper pipe (tube)

- 4 Copper

- 5 Article about the types and differences of copper scrap, and the services of the Phoenix-C company

sells bushings, round bars, strips, wire rods, sheets, pipes, hexagons, foil, tires and wire from copper alloy M1 at the lowest prices in the assortment.

All types of products are manufactured in accordance with the relevant GOSTs. If necessary, we sell in pieces/blanks. We also provide related services for metalworking, packaging, storage and delivery of goods to various regions of Russia.

We will provide you with a comfortable full-cycle service. Flexible system of discounts. Your own fleet of vehicles - free delivery within Moscow within 1 day. Delivery to the regions in 2-3 days (free delivery to the transport company terminal).

Copper alloy M1 is produced in accordance with GOST 859-2001. This material contains 99.9% copper, as well as other substances: iron, arsenic, nickel, zinc, sulfur, lead, oxygen, bismuth, tin and antimony. This is a highly plastic material with good corrosion resistance. It is highly processed and is part of the manufacturing process for many other metals.

The key alloying elements here are nickel and phosphorus. Copper alloy M1 can be oxygen-free, cathodic, deoxidized with phosphorus or oxygen. At the same time, according to technical parameters, hard and soft copper are distinguished. This alloy is used primarily in the automotive and aircraft industries, as well as in instrument making.

| Copper pipe M1T | Check availability, sizes and prices in the catalogue. |

| Copper pipe M1M (MM) | Check availability, sizes and prices in the catalogue. |

| Copper busbar М1М (ШММ) | Check availability, sizes and prices in the catalogue. |

| Copper bus M1T (SHMT) | Check availability, sizes and prices in the catalogue. |

| Copper wire M1M | Check availability, sizes and prices in the catalogue. |

| Copper wire M1T (MT) | Check availability, sizes and prices in the catalogue. |

| Copper strip (bus) M1 | Check availability, sizes and prices in the catalogue. |

| Copper tape M1 | Check availability, sizes and prices in the catalogue. |

| Copper tape M1M | Check availability, sizes and prices in the catalogue. |

| Copper tape M1T | Check availability, sizes and prices in the catalogue. |

You can get more information on the current range of M1 copper products we offer from our managers.

Moscow, sh. Enthusiastov, 56, building 44

This material has a number of analogues abroad:

- American alloy C11000;

- English composition C106;

- Italian copper Cu-DHP;

- European copper Cu-ETP;

- German alloy 2.0090.

They have similar technical characteristics and can be used for the same tasks as the M1 brand.

Areas of application

M1 alloy is used for the manufacture of conductive parts and various rolled semi-finished products. The alloy is also used for the production of tin-free bronze compounds. It is popular in the production of cryogenic equipment, and the wire is often used to make rods intended for welding.

This composition is often used in the automotive and aircraft manufacturing sectors for the production of certain equipment components. It can also be used for the production of devices for various purposes - this is facilitated by the flexibility and ductility of the material.

Buy rolled copper M1 at a profit

We offer to buy rolled copper alloy M1 on favorable terms:

- Large selection of assortments and standard sizes.

- Possibility of additional metal processing - cutting, bending, galvanizing, perforation

- Sale in pieces and blanks

- Sales of products, both wholesale and retail.

- Prices without intermediary commissions.

- Various payment methods and terms.

- Flexible system of discounts for wholesale and regular partners.

- Free professional consultations.

- Possibility of pre-packaging the order in the warehouse.

- Fast delivery times. Shipment of paid goods within 24 hours in Moscow.

- Delivery to Russian regions in 2-3 days. If necessary, we will independently calculate and order the services of a transport company. Delivery to the transport company terminal is free.

- Packaging of goods in accordance with customer requirements. It is possible to use several types of packaging: PET polyester tape and PVC polyethylene film.

- Possibility of storing goods in our warehouse until shipment.

- Return of goods in accordance with the legislation of the Russian Federation.

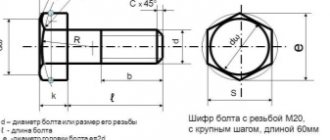

Copper rods. Conventions. GOST 1535-2006.

The symbols of copper rods used in documentation and certificates are standardized according to GOST 1535-2006, “Copper rods”.

Recording a symbol

| Bar | X | XX | X | X | … | … | … | … | GOST 1535-2006 |

| Product type | |||||||||

| Preparation method | |||||||||

| Section shape | |||||||||

| Precision manufacturing | |||||||||

| State | |||||||||

| Section dimensions | |||||||||

| Length | |||||||||

| Copper grade | |||||||||

| Special conditions | |||||||||

| Standard | |||||||||

The following abbreviations are used:

- KR - round

- KV - square

- SHG - hexagonal

- N - normal

- P - increased

- B - high

- M - soft

- P - semi-solid

- T - hard

- A - permissible diameter deviations with symmetrical tolerances

- AB - for processing on automatic machines

- L - soft state of increased plasticity

- F - semi-solid state of increased plasticity

- Y - solid state of increased plasticity

- OK - with cut ends

- C - increased accuracy in curvature

- P - regulated requirements for tensile testing

- HB - regulated requirements for Brinell hardness testing

- HV - regulated requirements for Vickers hardness measurement

- BT - rod in free-winding coils

- BU - rod in coils of layer-by-layer ordered winding

An “X” is placed in place of missing data, except for the length designation and special conditions.

If special conditions are not specified by the consumer in the order, then the rods are manufactured with performance conditions at the discretion of the manufacturer.

Examples of bar symbols

Drawn rod, round, high-precision manufacturing, hard, 10 mm in diameter, of unmeasured length, made of M1 grade copper, intended for processing on automatic machines:

- Rod DKRVT 10 ND M1 AB GOST 1535-2006

Drawn rod, hexagonal, high-precision manufacturing, soft, diameter 19mm, length 3000mm, made of copper grade M2:

- Rod DShGPM 19 x 3000 M2 GOST 1535-2006

Drawn rod, square, of normal manufacturing precision, semi-solid, with a diameter of 10 mm, a multiple of the measured length of 1500 mm, from copper grade MZ:

- Rod DKRNP 10 x 1500 KD MZ GOST 1535-2006

Drawn rod, round, high precision manufacturing, semi-solid, diameter 10mm. of unmeasured length, made of copper grade M1, increased ductility, with regulated tensile test requirements, intended for processing on automatic machines:

Pressed rod, round, diameter 35mm, unmeasured length, made of MZ copper:

- Rod GKRHH 35 ND MZ GOST 1535-2006

Copper grades for electrical engineering and in general

Copper grades consist of the letter “M”, which means copper. This is followed by a number from 0 to 4. Sometimes one of the letters is then found that characterize the method of producing the metal: k - cathode, p - deoxidized with low residual phosphorus, f - deoxidized with high residual phosphorus, b - oxygen-free. Oxygen-free is M0, and deoxidized is M1. There are many grades of copper, let's look at some:

A special grade of copper is M1E. This is electrical copper, which is produced in the form of tires, rods of various diameters and sections. It can be extra hard, hard, semi-hard and soft. The conductivity of soft copper is a couple of percent higher.

Available in the form of tires, rods, circles. The rods, in turn, have a diameter from 5 to 40 mm and a cross-sectional shape - circle, square, hexagon. This type of copper has a limited shelf life - up to a year for soft copper and six months for hard copper.

Copper m1 m2 m3 difference

Due to their properties, various grades of copper are very popular in the industrial environment. This metal is good because it is flexible and, regardless of the operating environment, with the exception of exposure to sulfur dioxide and ammonia, it is resistant to corrosion.

The external distinctive feature of copper is its pink-red color. Depending on the purity, copper is divided into types with the technical designations M1, M2, M3. This metal comes into production in the form of wire, sheets, pipes, and rods.

This is due to different application situations.

Based on its composition, copper is divided into oxygen-free and deoxidized; the symbol is M0 and M1, respectively. Oxygen-free is used in the manufacture of parts for electrical, electronic, and electrovacuum industrial products. O2 in oxygen-free brands is no more than 0.001%, and in deoxidized ones - 0.01%.

The breakdown of copper grades is presented in the table:

Variety of copper alloys

The most common alloy in industry is brass. It is a compound of zinc and copper. When a third, fourth, fifth, etc. appears in this composition. element, brass becomes complex, or special. In this case, it receives an aluminum, iron-manganese, manganese-tin-lead prefix.

This alloy is well suited for work involving casting, pressing, and cutting, since, unlike the usual composition of copper, it is characterized by increased resistance to fracture, elasticity and endurance. These qualities facilitate the processing of parts.

Brass rods are made in compliance with GOST 2060-90. Manufacturing accuracy is increased, normal and high. Plasticity – hard, medium, and soft.

Brass wire is produced taking into account GOST 1066-90, brass grades L68, L80, L63, LS59-1 are used. The chemical composition is regulated by GOST 15527.

The tape is produced in accordance with GOST 2208-91. Brass L85, L90, L80, L68, L63, LS59-1, LMts58-2 is used, the chemical composition is determined by GOST 15527. Condition: semi-solid, soft, hard, spring-hard and extra-hard. Normal production accuracy is acceptable - in width and thickness, in thickness and increased accuracy in width, increased accuracy in thickness and normal accuracy in width.

Special grades are also produced - for stamping, anti-magnetic, with increased crescent accuracy, with a normalized extrusion depth that can withstand bending testing.

You can see all this in the photo.

Brass pipes are produced in accordance with the GOST 494-90 standard. Cold-rolled and drawn pipes are grades L63 and L68, and pressed pipes are grades L63, L60, LS59-1, LZhMts59-1-1, chemical. composition GOST 15527. Length – 1-6 m.

Special products – pipes of increased precision, special curvature, anti-magnetic.

Copper Applications

Copper processing goes deep into history. Initially, people used copper sheets to make jewelry and household utensils. And only then a method for producing bronze was discovered by combining an alloy of tin and copper. Thus began the Bronze Age.

The time you live in and the Bronze Age are separated by millennia, but copper is still widely used today. If we look inside old televisions, receivers, transformers, and other wonders of technological progress of the last century, we will find whole spools of copper wire there.

In modern industry, copper and alloys have an importance that is difficult to overestimate, so the price of copper is quite high. But, nevertheless, almost all equipment is made using this metal.

Copper-aluminum wire is also used as electrical wiring. It is a good conductor and does not undergo destruction or corrosion over time.

In addition, copper is an excellent thermal conductor. Therefore, it is the number one metal used in the production of air conditioners. And the strength and impermeability of copper pipes allows them to be used for transporting certain types of caustic liquids and gases.

Copper is widely used in various industries, and the list is so large that it is impossible to list everything now.

Without touching on the topic of industry, wire from this valuable metal is used to create works of art. For example, trees made of beads. Small beads are strung on it, and thanks to the flexibility of this material, the finished product takes the shape required for the composition.

Source

Features of production and application

Copper of a chemical composition similar to the domestic M1 grade is produced in many countries with a developed metallurgical industry:

- Japan (JIS standard), USA – C1100, C1220.

- European Union (EN standard) – Cu-ETP.

- England (BS standard) – C106.

- France (AFNOR standard) – Cu-B.

- Italy (UNI standard) – Cu-DHP.

The undoubted leader in the production of various oxygen-free copper alloys - analogues of the domestic M1 grade is the German metallurgical industry. In accordance with DIN and WNR standards, non-ferrous metallurgy plants produce three types of alloys - Ecu57, ECu58, SF-Cu.

The coefficient of friction of metal with lubricant is 0.011, without lubricant - 0.043. There are two categories of alloys according to GOST 1173-2006 in terms of Brinell hardness:

| solid | HB 10 -1 95MPa |

| soft | HB 10 -1 55MPa |

During the casting process, it must be remembered that the linear shrinkage of M1 is 2.1%. Copper melts at a temperature of 1083°C, casting is carried out in the temperature range of 1150-1250°C.

M1 is produced in the form of cast (horizontal casting ingots, GOST 193-79) or deformed (wire rod, TU 1844-01003292517-2004; strip, GOST 1173-2006; annealed and pressed rod, GOST 1535-2006; pipe, GOST R 52318- 2005) semi-finished products. Rolled sheets must be subjected to bending tests. According to the standard, tape up to 5 mm thick must withstand bending until the sides touch. Thicker sheets (6-12 mm) are checked until the sides are parallel.

Semi-finished products produced by cold rolling are tested for bending at temperatures up to 90°C. Cold-deformed copper pipes (soft, semi-hard, hard) are produced using technology that does not affect further performance. They do not defrost and are resistant to rupture when liquid media freeze. Large cross-section pipes are manufactured using pressing technology.

Alloy M1 is used in cryogenic production. It is used to make current conductors, wire, rods and electrodes for automatic welding and gas welding of non-critical joints of cast iron and copper parts. M1 is the main alloy for the production of high quality bronze.

Source

Description

M1 copper is used : for the production of current conductors; rental; high-quality tin-free bronzes; cryogenic equipment products; round drawn thin-walled pipes; cold-rolled foil and strip, cold-rolled and hot-rolled sheets and plates for general purposes; wires for the manufacture of metal shielding braids of the PML type, intended for shielding wires and cables; hot-rolled and cold-rolled anodes used for galvanic coating of products; cold-deformed rectangular tape with a thickness of 0.16−0.30 mm, intended for coaxial trunk cables; radiator tapes intended for the manufacture of cooling tubes and radiator plates; drawn pipes of rectangular and square cross-section, intended for the manufacture of conductors for stator windings of liquid-cooled electrical machines; profiles for the manufacture of rotors of submersible electric motors; round welding wire and round welding rods drawn and pressed with a diameter from 1.2 to 8.0 mm, intended for automatic welding in an inert gas environment, submerged arc and gas welding of non-critical structures made of copper, as well as the manufacture of electrodes for welding copper and cast iron.

Note

M1 copper is obtained by melting cathodes. Copper grade M1 in chemical composition corresponds to copper grade Cu-ETP according to Euronorm EN 1652:1998.